Dust-free environment-friendly coal firing power generation method

An environmentally friendly, coal-burning technology, applied in fuel supply, combustion equipment, machines/engines, etc., to achieve full energy utilization, avoid corrosion, and increase combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

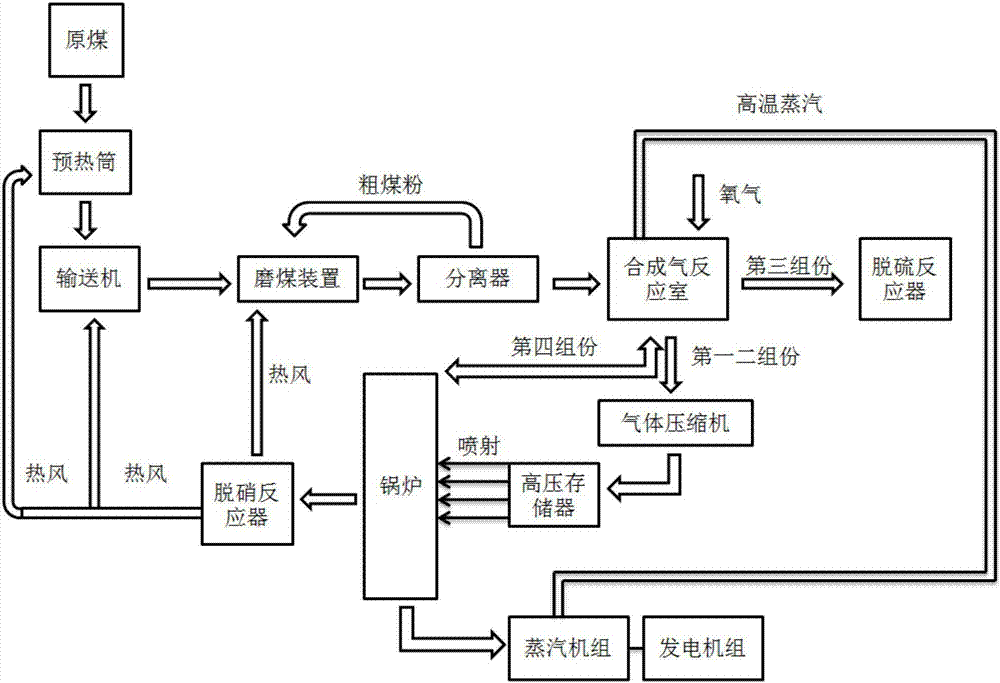

Image

Examples

Embodiment 1

[0052] The flue gas temperature in the preheating cylinder and at the bottom of the conveyor is 170°C, and the raw coal is dried to 20wt% for the first time and 14wt% for the second time, so as to complete the drying and dehydration of the raw coal, and the fine coal flowing out from the separator The powder reacts with high-temperature steam at 220°C, containing hydrocarbon synthesis catalysts and hydrogen cracking catalysts and oxygen in the synthesis gas reaction chamber to form combustible synthesis gas, wherein the hydrocarbon synthesis catalysts include iron-copper catalysts, and the hydrocarbon synthesis catalysts contain 68% The total iron metal, the balance is copper metal and unnecessary impurities, the volume ratio of hydrocarbon synthesis catalyst to hydrogenation catalyst is 7.5, combustible synthesis gas can include H2, CO and NH3, and the ratio of H2, CO and NH3 is 1.5 :2:1, the H2S gas in the third component is passed into a desulfurization reactor containing a ...

Embodiment 2

[0054] The flue gas temperature in the preheating cylinder and at the bottom of the conveyor is 190°C, and the raw coal is dried to 19wt% for the first time and 13wt% for the second time, so as to complete the drying and dehydration of the raw coal, and the fine coal flowing out from the separator The powder reacts with high-temperature steam at 250°C, containing hydrocarbon synthesis catalyst and hydrogen cracking catalyst and oxygen in the synthesis gas reaction chamber to form combustible synthesis gas, wherein the hydrocarbon synthesis catalyst includes iron-copper catalyst, and the hydrocarbon synthesis catalyst contains 70% The total iron metal, the balance is copper metal and unnecessary impurities, the volume ratio of hydrocarbon synthesis catalyst to hydrogenation catalyst is 6, combustible synthesis gas can include H2, CO and NH3, and the ratio of H2, CO and NH3 is 5 :2:1, the H2S gas in the third component is passed into a desulfurization reactor containing a catalys...

Embodiment 3

[0056] The flue gas temperature in the preheating cylinder and at the bottom of the conveyor is 210°C, and the raw coal is dried to 17wt% for the first time and 11wt% for the second time, so as to complete the drying and dehydration of the raw coal, and the fine coal flowing out from the separator The powder reacts with 320°C high-temperature steam in the synthesis gas reaction chamber, contains hydrocarbon synthesis catalysts, hydrogen cracking catalysts and oxygen to form combustible synthesis gas, wherein the hydrocarbon synthesis catalysts include iron-copper catalysts, and the hydrocarbon synthesis catalysts contain 72% The total iron metal, the balance is copper metal and unnecessary impurities, the volume ratio of hydrocarbon synthesis catalyst to hydrogenation catalyst is 4.5, combustible synthesis gas can include H2, CO and NH3, and the ratio of H2, CO and NH3 is 18 :2:1, the H2S gas in the third component is passed into a desulfurization reactor containing a catalyst ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com