Combustion-supporting adhesive for fire coal

A binder and coal-burning technology, which is applied in the field of organic or inorganic synthesis, can solve the problems of difficult thermal strength and thermal efficiency, and achieve the effect of accelerating combustion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

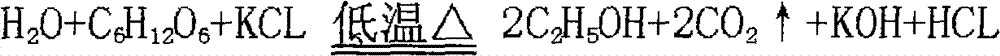

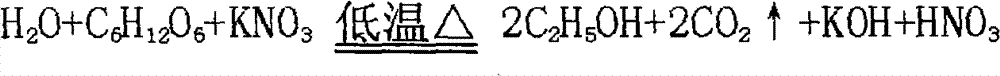

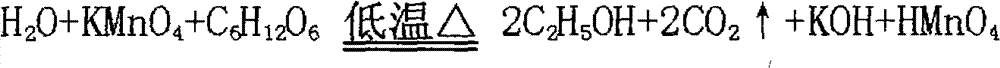

Method used

Image

Examples

Embodiment (2

[0020] Embodiment (2): cellulose 3%, potassium chloride 5%, sodium nitrite 3%, bentonite 79% sulfuric acid slag 10%. The above materials are mixed and ground for at least 24 hours. Fine to no particles. White coal is mixed with binder 100:3-5% for later use. After burning for 1 hour, rake out and observe, and it will be found that the coal mixed with the binder is completely burned. Embodiment (3): Maltodextrin 5%, Potassium Chloride 15%, Potassium Permanganate 3%, Ammonium Nitrate 3%, Sodium Nitrite 1%, Bentonite 73%, the above several kinds of materials are mixed and finely ground without any particles , at least stacked for more than 24 hours. White coal is mixed with binder 100:5% for use, and the effect of bituminous coal is better. Put it into the furnace and burn it for 1 hour and then rake it out for observation. It will be found that the white coal mixed with bonding is completely burned.

Embodiment

[0021] Embodiment (4): Cellulose 5%, Potassium Permanganate 10%, Repone K 5%, Ammonium Nitrate 3%, Sodium Nitrite 3%, Bentonite 74%, above several kinds of materials are mixed and ground to disappear particle, Stack for at least 24 hours. White coal is mixed with binder 100:5% for use, and bituminous coal is more effective. Put it into the furnace and burn it for 1 hour and then rake it out for observation. It is found that the white coal mixed with binder burns more completely.

[0022] Embodiment (5): maltodextrin 5%, potassium permanganate 3%, potassium chloride 3%, potassium nitrate 10%, ammonium nitrate 3%, sodium nitrite 3%, sulfuric acid slag 73%, the above several materials After mixing, grind until there are no particles, and stack it for at least 24 hours. White coal is mixed with 100:5% of the binder for later use. If it is bituminous coal, the effect is better. Put it in the furnace and burn it for 1 hour and then rake it out for observation. It is found that afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com