Large-inclination-angle belt conveyor

A technology of belt conveyor and large inclination angle, which is applied in the direction of conveyor, conveyor objects, transportation and packaging, etc. It can solve the problems of waste of coal resources, on-site ground and air pollution, residues, etc., and achieve less waste of coal resources and on-site pollution small, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

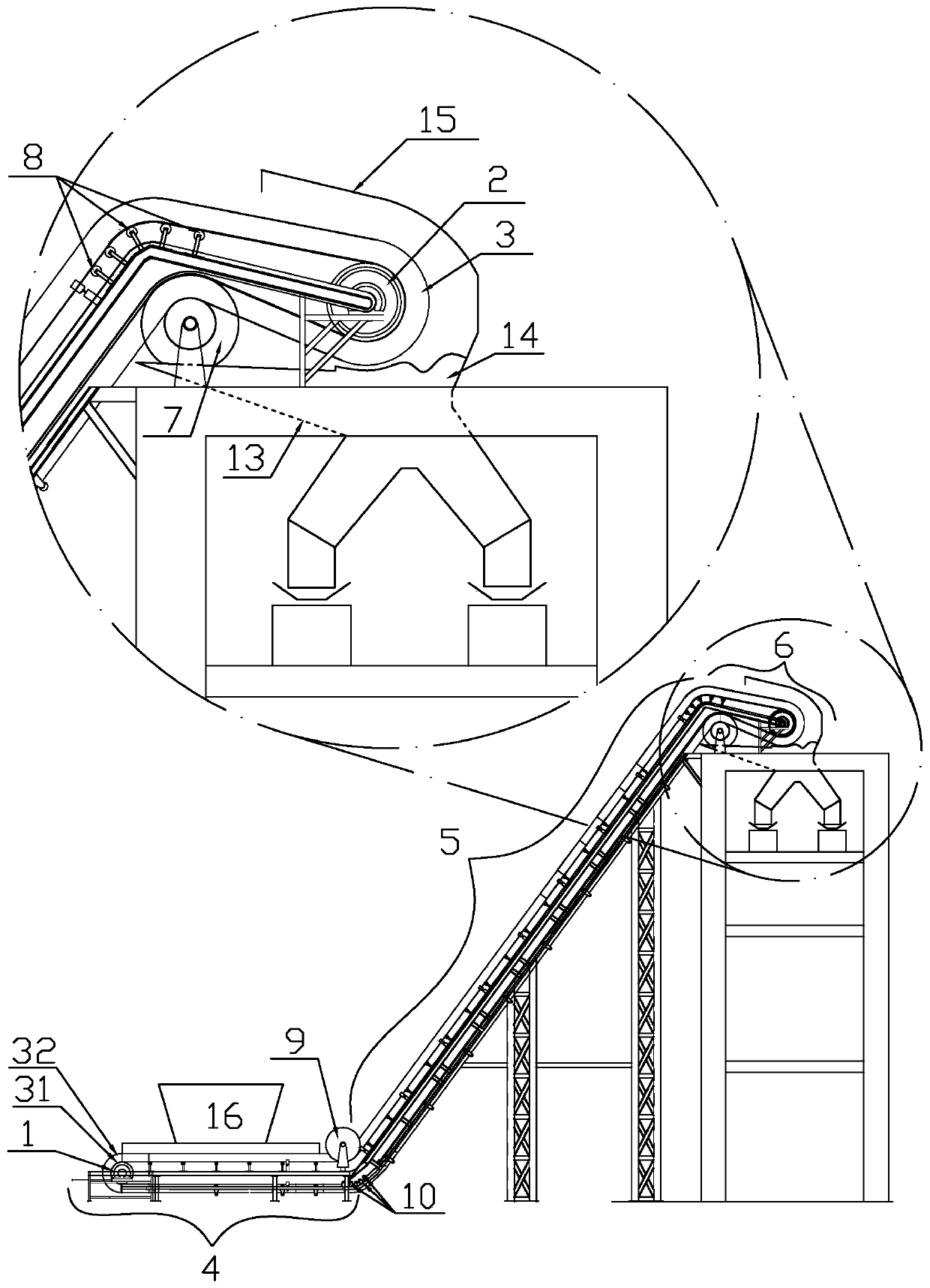

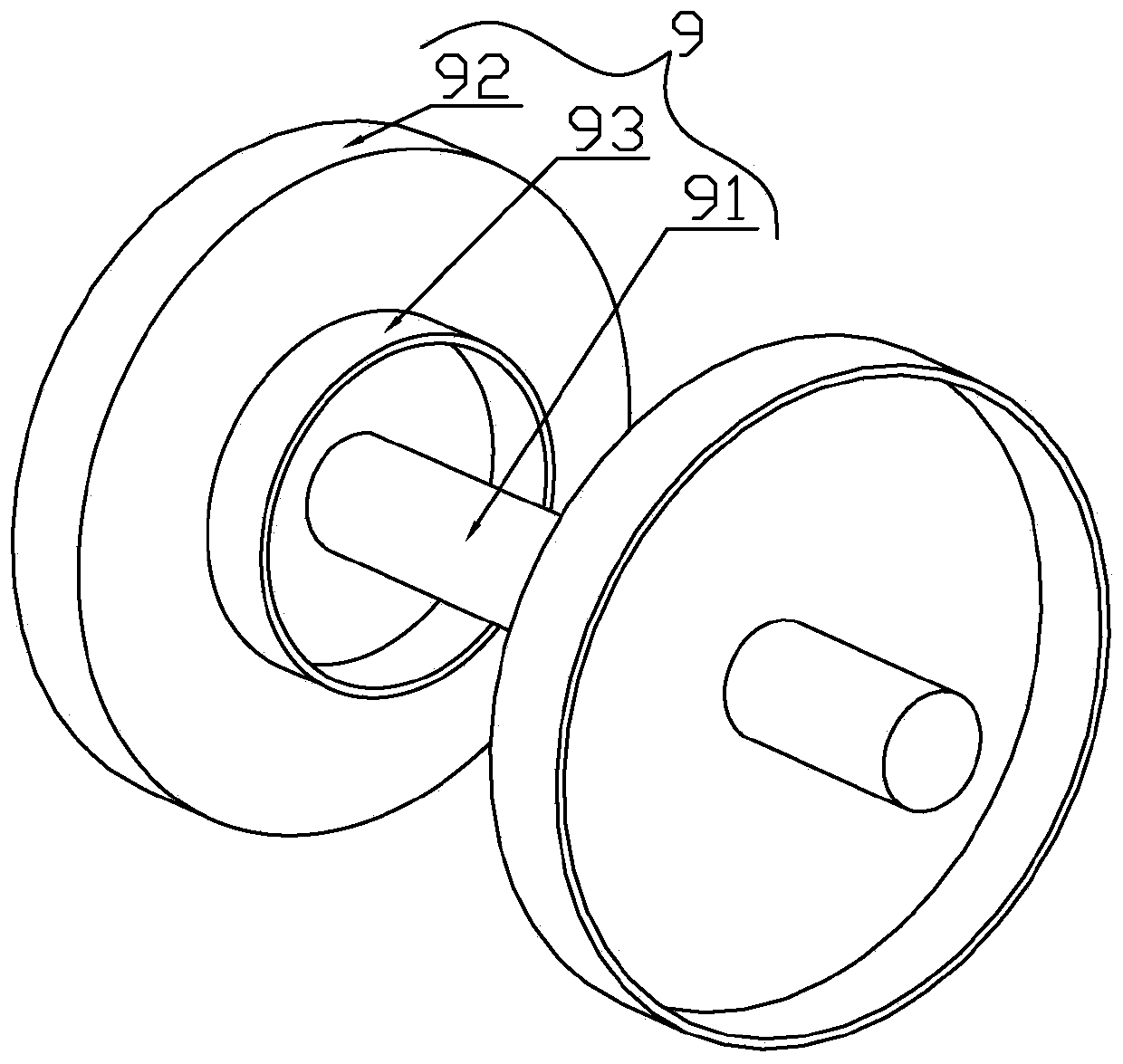

[0019] Implementation mode one: if Figure 1-2 As shown, the large-inclination belt conveyor includes a frame, a driving roller 1, a driven roller 2 and a skirt belt 3, and the frame includes a horizontal feed section 4, an intermediate inclined section 5 and a discharge section 6, and the discharge section The section 6 is higher than the horizontal feeding section 4, and the two ends of the middle inclined section 5 are respectively connected to the horizontal feeding section 4 and the discharging section 6, and the driving roller 1 shaft is mounted on the head end of the horizontal feeding section 4, and the driven roller 2 shafts are installed at the tail end of the discharge section 6, and the skirt belt 3 includes an annular base belt 31, and the outer surface of the annular base belt 31 is provided with two parallel pleated ring edges 32, and between the two parallel pleated ring edges 32 The annular base belt 31 is also provided with a plurality of vertical partitions ...

Embodiment approach 2

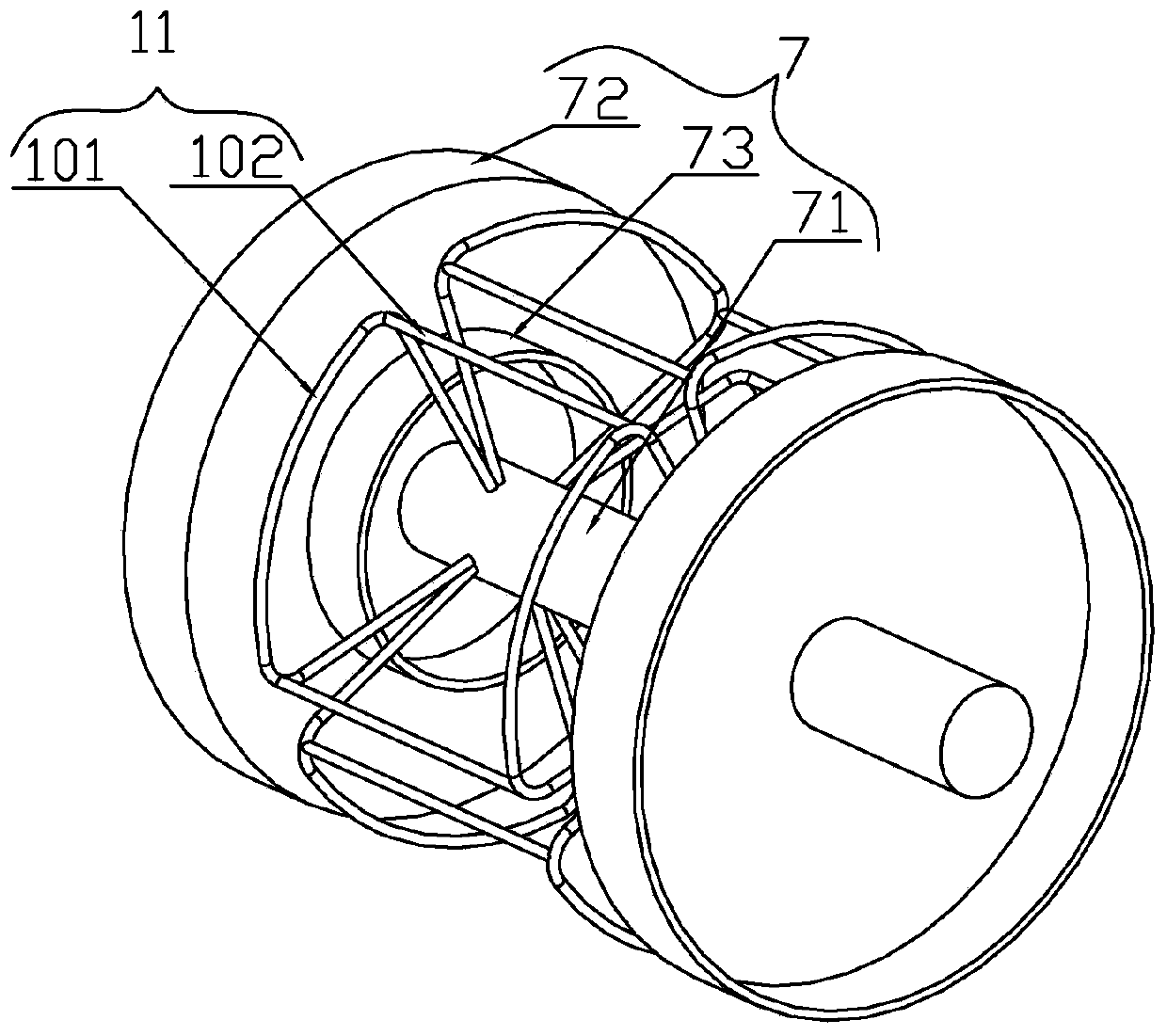

[0024] Implementation mode two: if image 3 , 4 As shown: the main shaft 71 between the two small pressure wheels of the upper corner pressure wheel 7 is provided with a plurality of protruding coal racks 11, and each coal rack 11 is composed of two fan-shaped racks 101 and two fan-shaped racks. Two connecting rods 102 between the racks 101 are formed. The above-mentioned coal racks 11 are evenly arranged around the main shaft 71. When the lower skirt belt 3 passes by, the above-mentioned coal racks 11 are pushed into each of the lower skirt belts 3 one by one. In the feeding grid 12 formed by the adjacent vertical partitions 33 and the endless base belt 31 .

[0025] A coal collecting hopper 13 is arranged below the upper corner pressure wheel 7, and the coal collecting hopper 13 communicates with the matching downstream coal hopper 14 of this large-inclination belt conveyor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com