Method and system for reducing nitric oxide in coke-oven exhaust gas

A technology for nitrogen oxides and waste gas, which is applied in the heating of coke ovens, coke ovens, and combustible gas heating coke ovens, etc., can solve the problems of inability to meet nitrogen oxide emission standards, huge investment in treatment equipment, and restrictions on popularization and application. To achieve the effect of simple structure, low investment and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

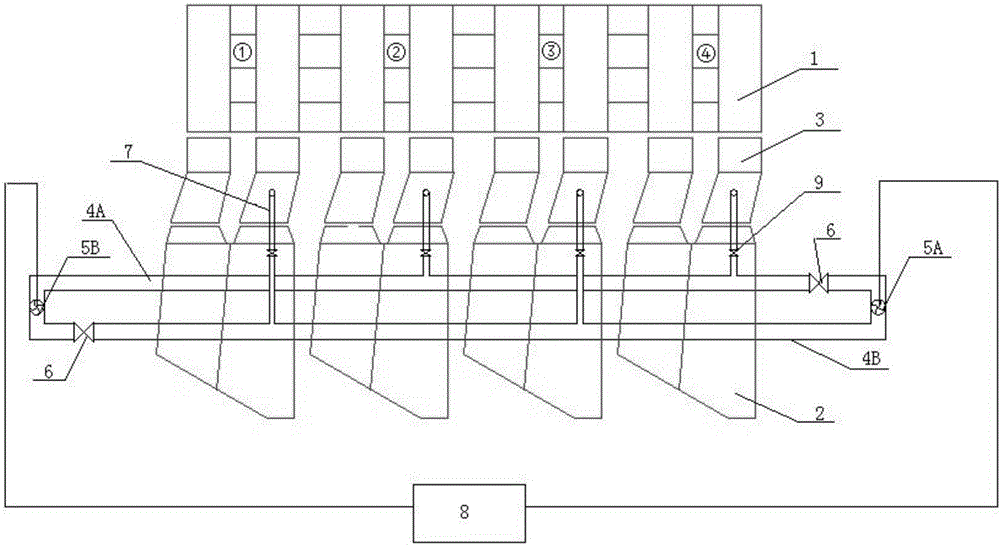

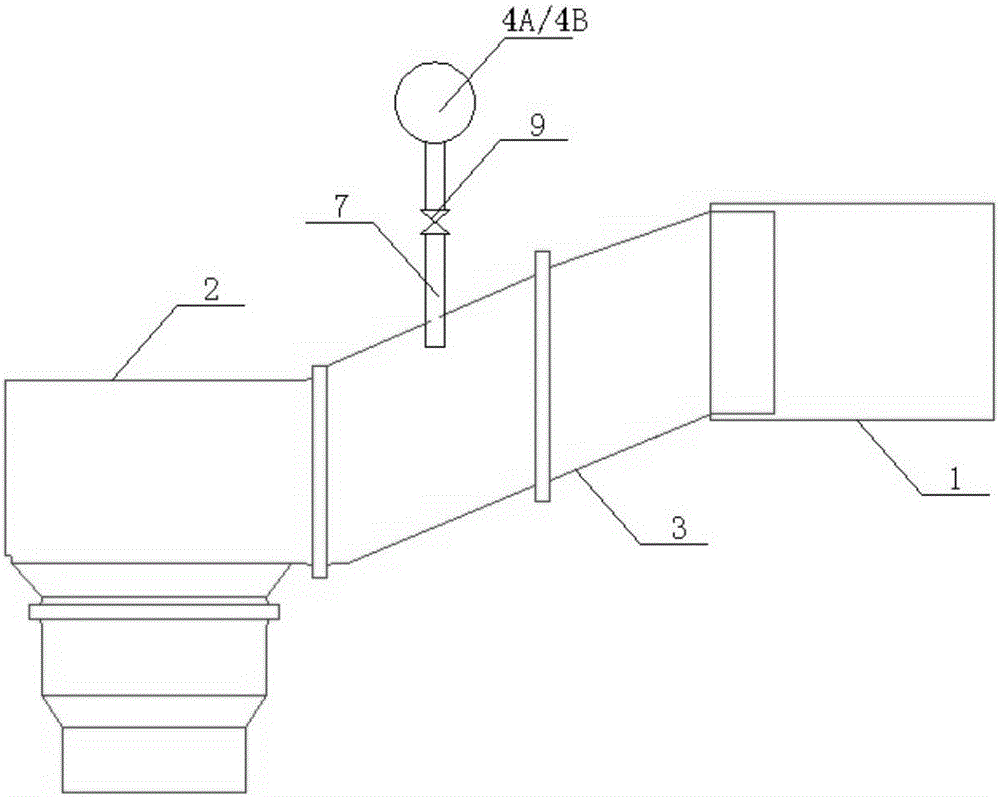

[0017] Such as figure 1 As shown, a method for reducing nitrogen oxides in coke oven exhaust gas according to the present invention, when the coke oven heating system performs a reversing operation, the exhaust gas is drawn out from the small flue 1 with a downward airflow through the exhaust gas branch pipe 7, and the exhaust gas descends After entering the exhaust gas main pipe 4A / 4B, it is introduced into the small flue 1 with updraft through the exhaust gas branch pipe 7; the exhaust gas outlet and inlet are both set at the exchange switch 2 / socket connected to the small flue 1 .

[0018] When the heating system of the coke oven is reversing, the adjacent small flues 1 have downdraft or updraft respectively; for example, during a reversing operation, the odd-numbered small flues in the same column of small flues 1 have downdrafts, while the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com