Coke oven heating method capable of lowering concentration of nitrogen oxides in waste gas

A technology of nitrogen oxides and heating methods, which is applied in the heating of coke ovens, combustible gas heating coke ovens, coke ovens, etc. It can solve the problems of not meeting the emission standards of nitrogen oxides, huge investment in treatment equipment, and restrictions on popularization and application. , to achieve the effects of small footprint, low investment and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

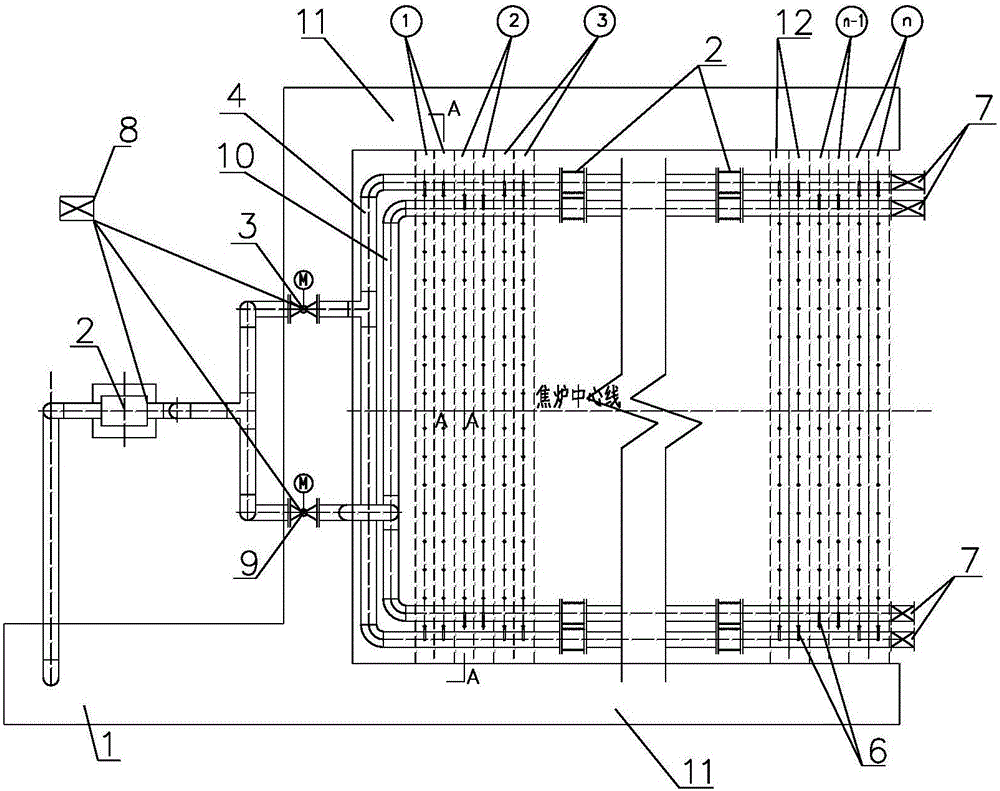

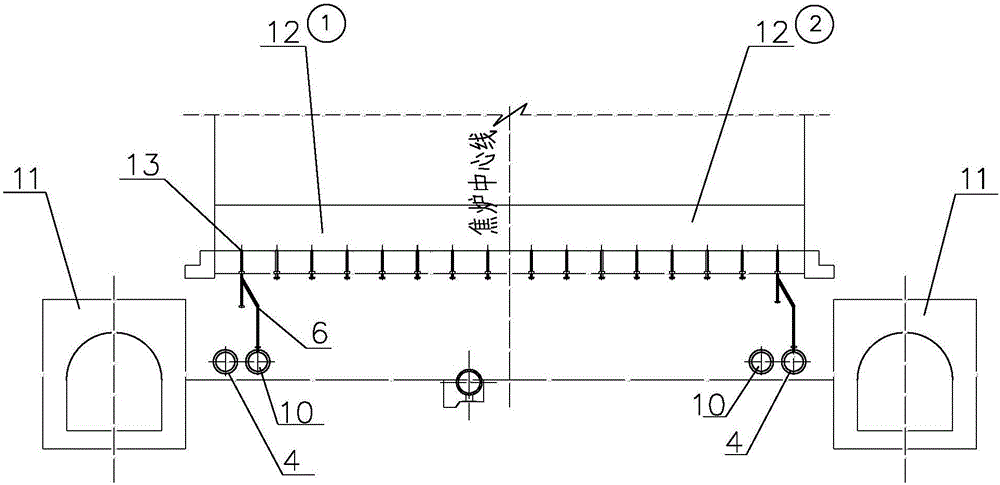

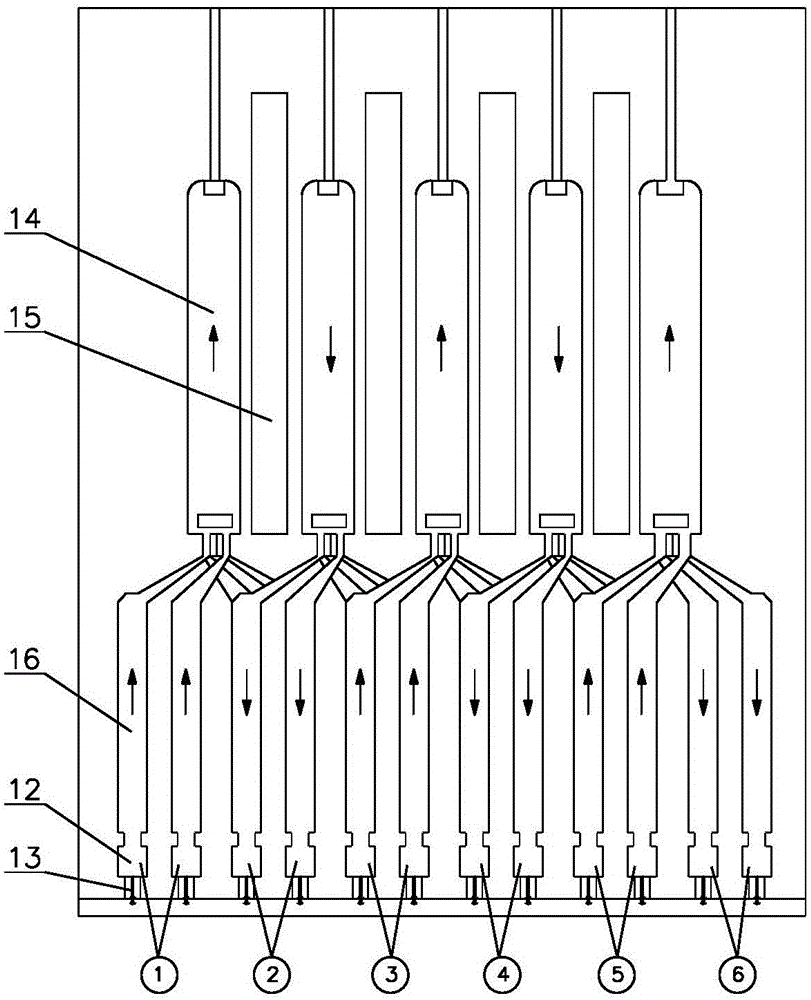

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0023] like Figure 1-Figure 2 As shown, a coke oven heating method for reducing the concentration of nitrogen oxides in exhaust gas according to the present invention includes the following steps:

[0024] 1) The exhaust gas main pipe A 4 and the exhaust gas main pipe B 10 are buried side by side at the bottom of both sides of the coke oven small flue 12 respectively. The coke oven main flue 1 leads out the exhaust gas main pipe near the confluence point of the coke oven sub-flue 11, and the exhaust gas main pipe passes through the exhaust gas. The connecting pipe A is connected to the exhaust gas main pipe A 4, and the exhaust gas main pipe B is connected to the exhaust gas main pipe B 10; B 9, the high temperature blower 2, the electric regulating valve A 3 and the electric regulating valve B 9 are respectively connected with the coke ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com