Circulating structure and method for exhaust gas of coke oven

A technology of exhaust gas circulation and coke oven, which is applied in the direction of coke oven, coke oven heating, combustible gas heating coke oven, etc. Control and reduce waste gas and other problems to achieve the effect of improving work efficiency and safety, shortening construction period and reducing investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

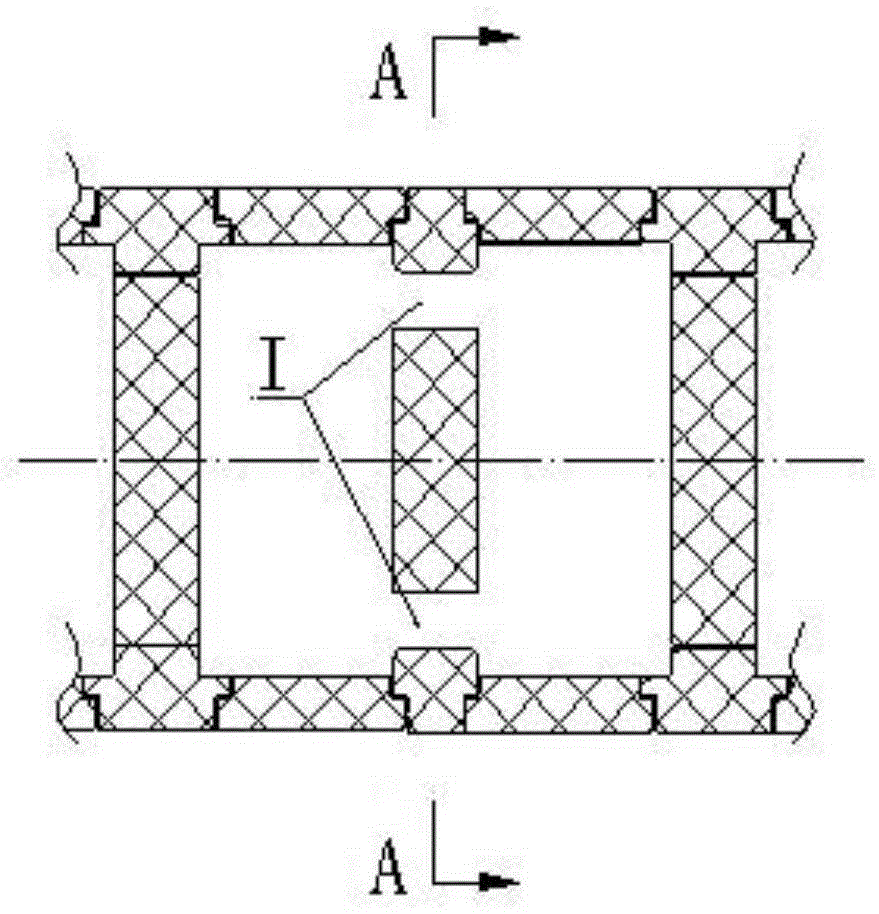

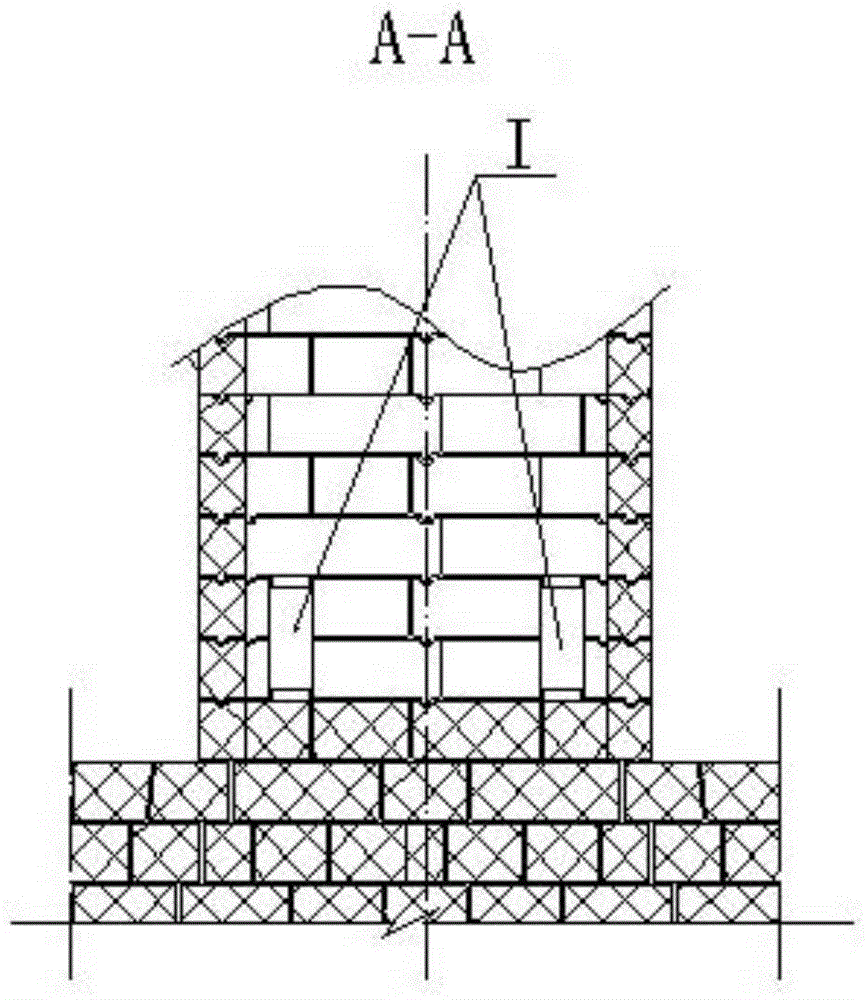

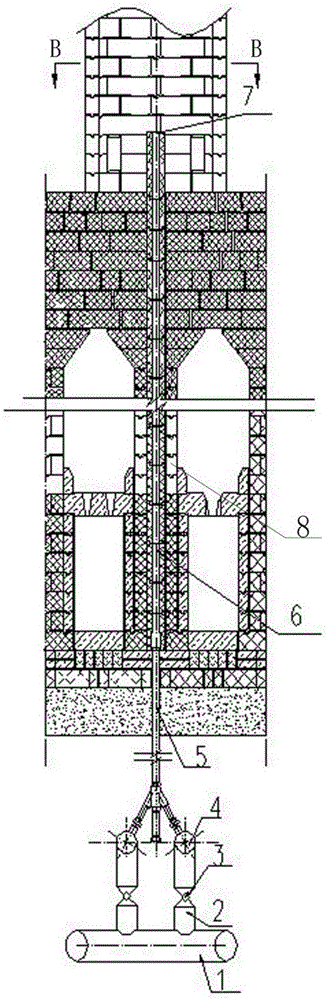

[0028] See Figure 3-Figure 4 , is a structural schematic diagram of the coke oven exhaust gas circulation structure of the present invention. A coke oven waste gas circulation structure according to the present invention includes a waste gas main pipe 1, a connecting pipe 2, an automatic flow controller 3, a basement horizontal pipe 4, a lower nozzle pipe 5 and a brick waste gas channel 6 connected in sequence, and the waste gas main pipe 1. Connect the waste gas source through an external frequency conversion fan. The basement horizontal pipe 4 is arranged horizontally along the coke oven. The brick exhaust flue outlet 7 on the top is located in the vertical fire path 9 of the combustion chamber.

[0029] The outlet 7 of the brick waste gas channel is round or square in shape, and the opening form is full opening or half opening.

[0030] A w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com