Cast-in-place concrete filling tire body

A technology of concrete and carcass, applied in building materials, building components, floors, etc., can solve the problem of igniting other objects, and achieve the effect of high support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

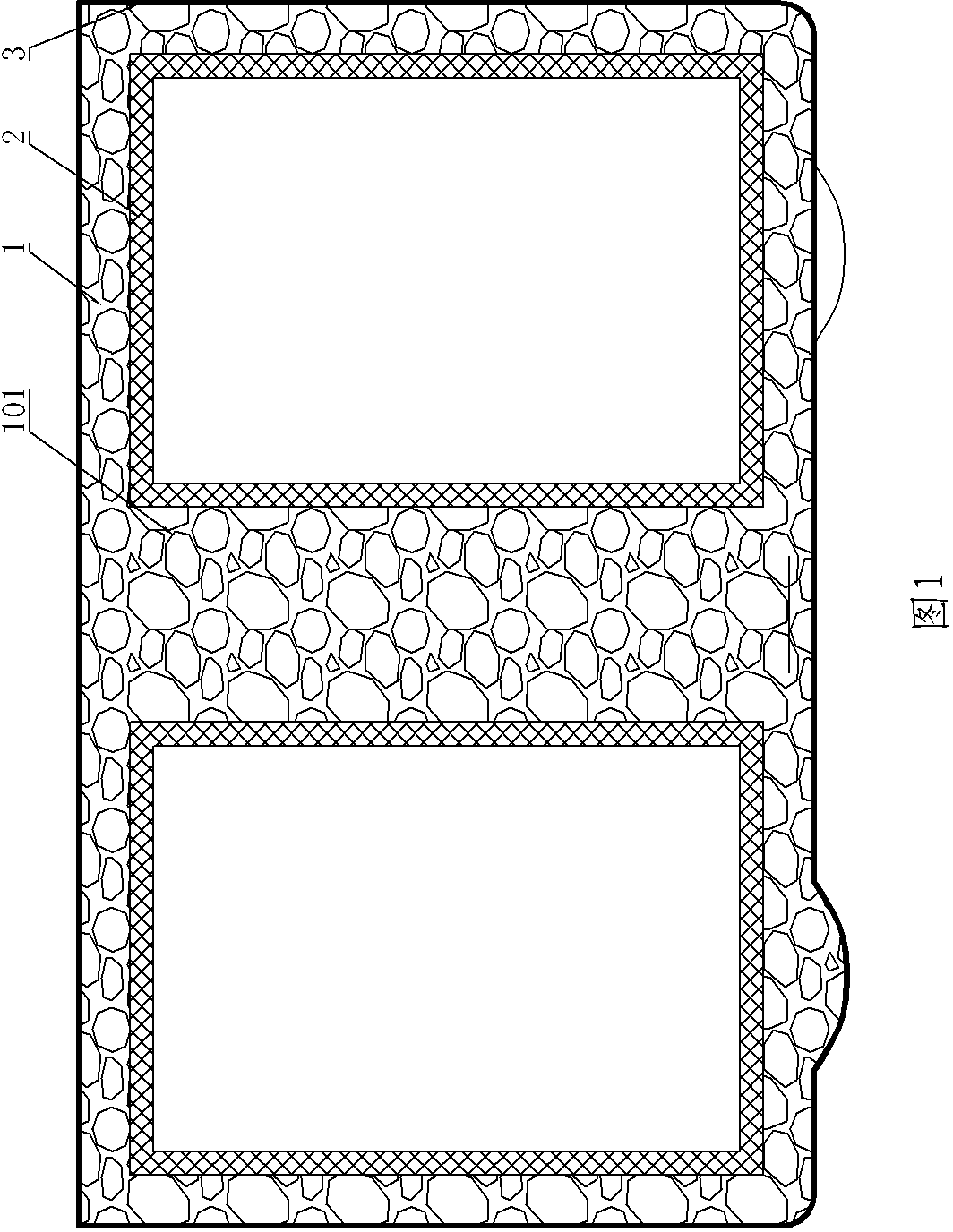

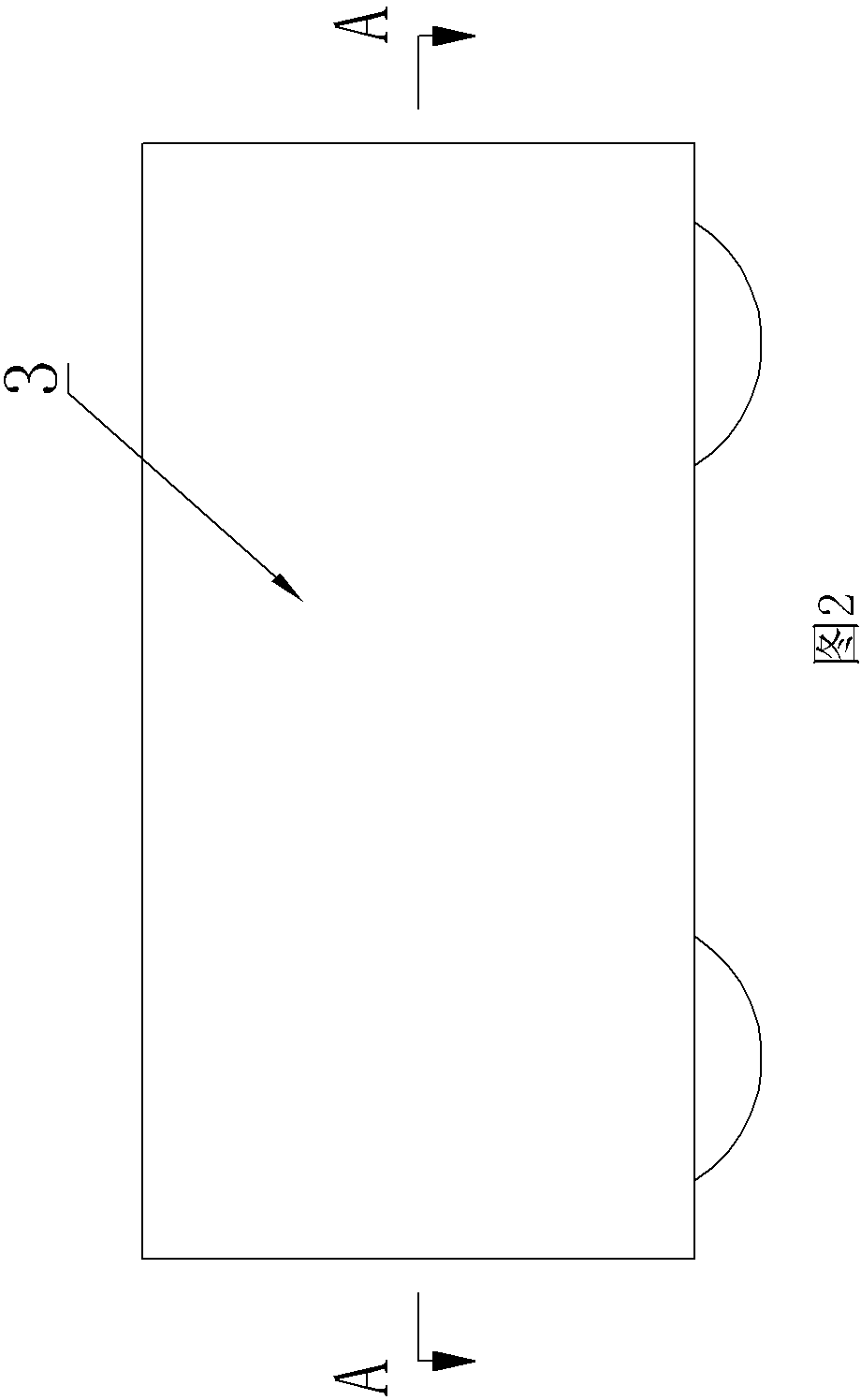

Method used

Image

Examples

Embodiment 2

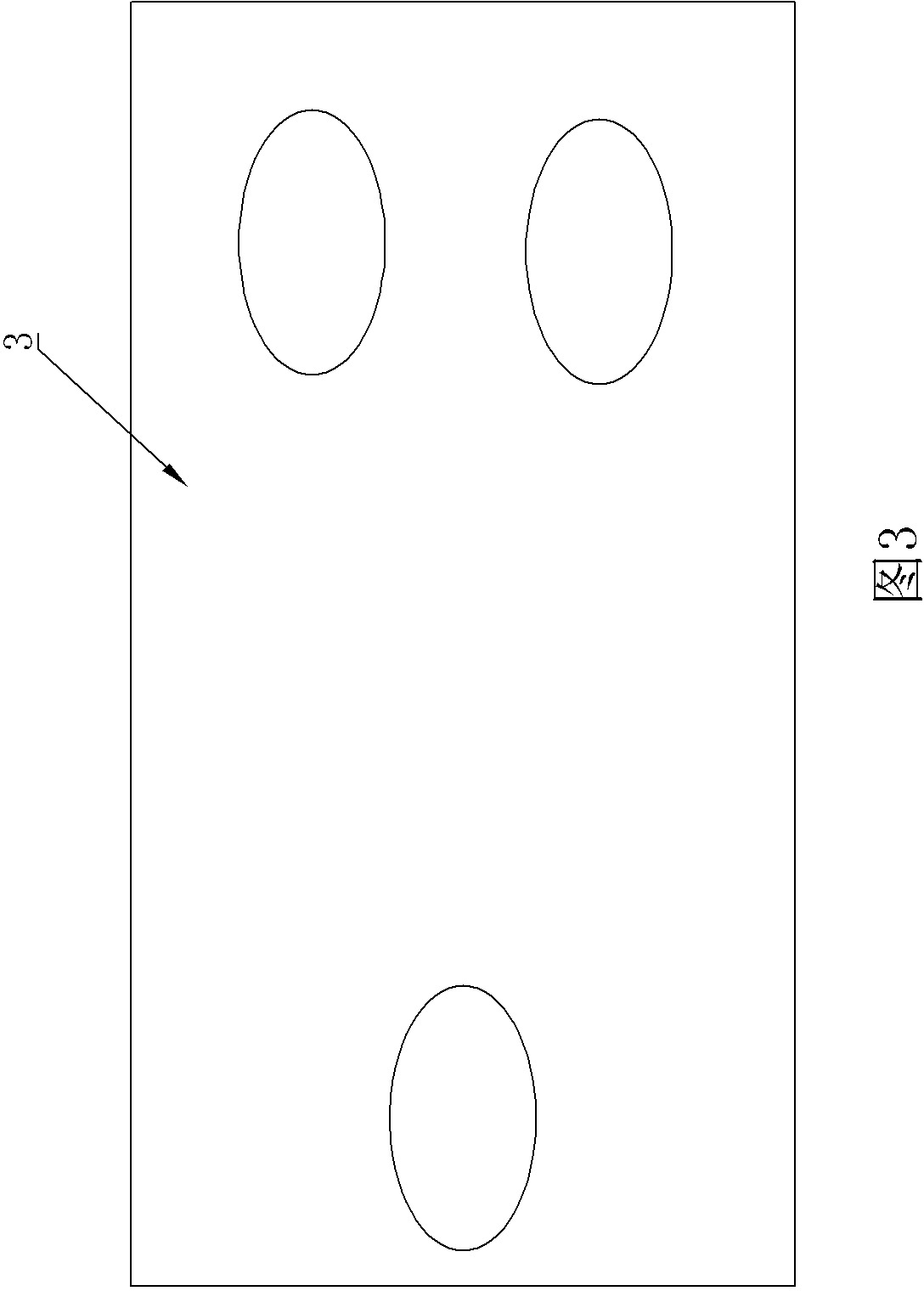

[0024] Embodiment 2 of the cast-in-place concrete filling matrix of the present invention: as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the inner cavity of the carcass matrix 21 is a spherical inner cavity, and the corresponding annular inflatable inner container 22 can be waste tires, or items similar in shape.

[0025] In the above embodiments, the box body of the carcass base is made of foamed concrete. In other embodiments, the box body of the carcass base can also be made of ordinary concrete.

[0026] In the above-mentioned embodiment, the waterproof coating that the waterproof layer of the outer surface of the carcass matrix adopts is a polymer cement-based waterproof coating. In other embodiments, the material of the waterproof coating of the waterproof layer can also be other types of waterproof coatings, such as Polyurethane waterproof coatings, nanotechnology waterproof coatings, acrylic waterproof coatings, etc.; or directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com