Novel heat accumulating type flat flame burner

A flat-flame burner and regenerative technology, which is applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of combustion-supporting air temperature increase, flame combustion temperature increase, and inconspicuousness, and reduce the peak combustion temperature of the flame , Reduce the formation of NOx, reduce the effect of flame combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

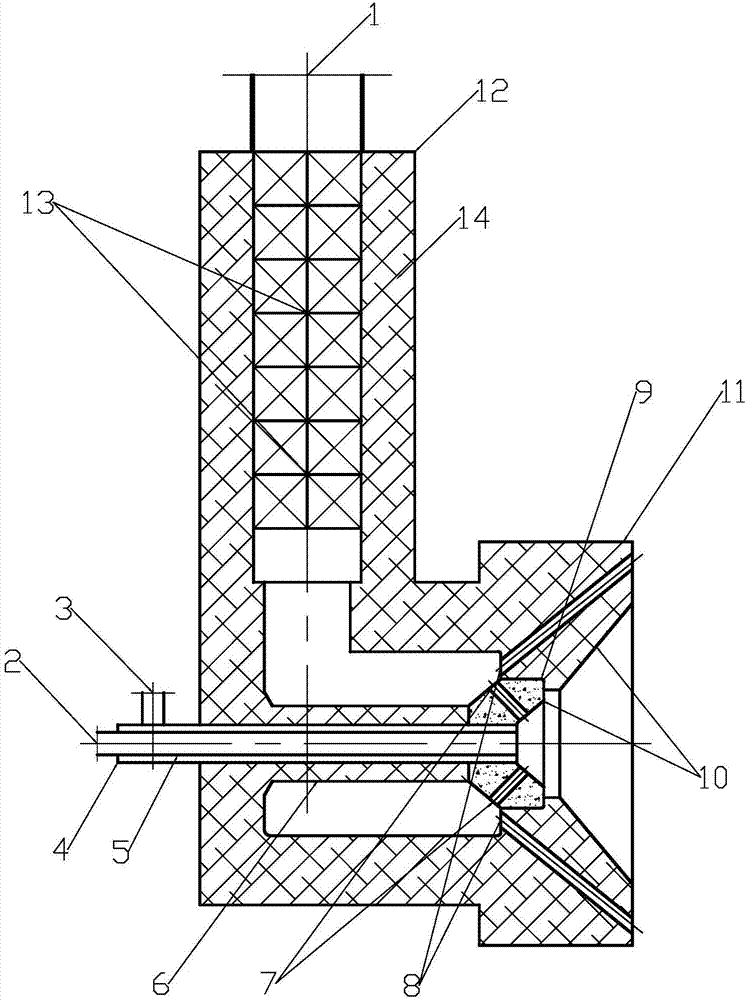

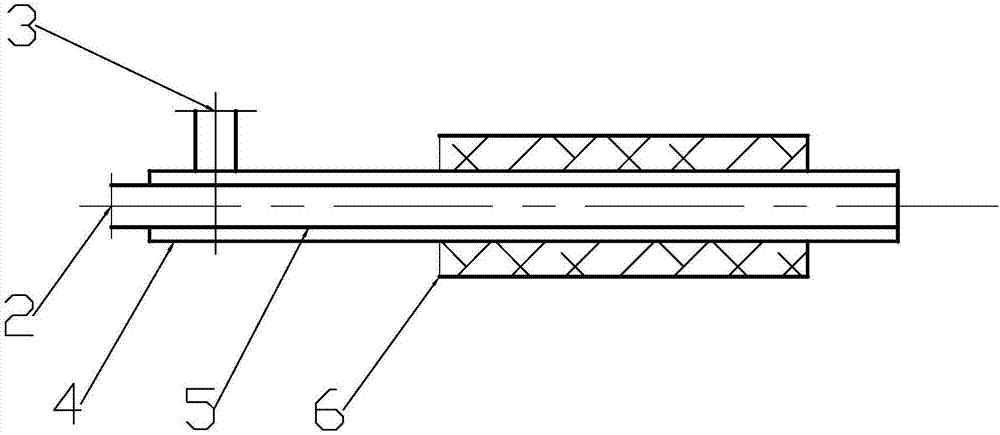

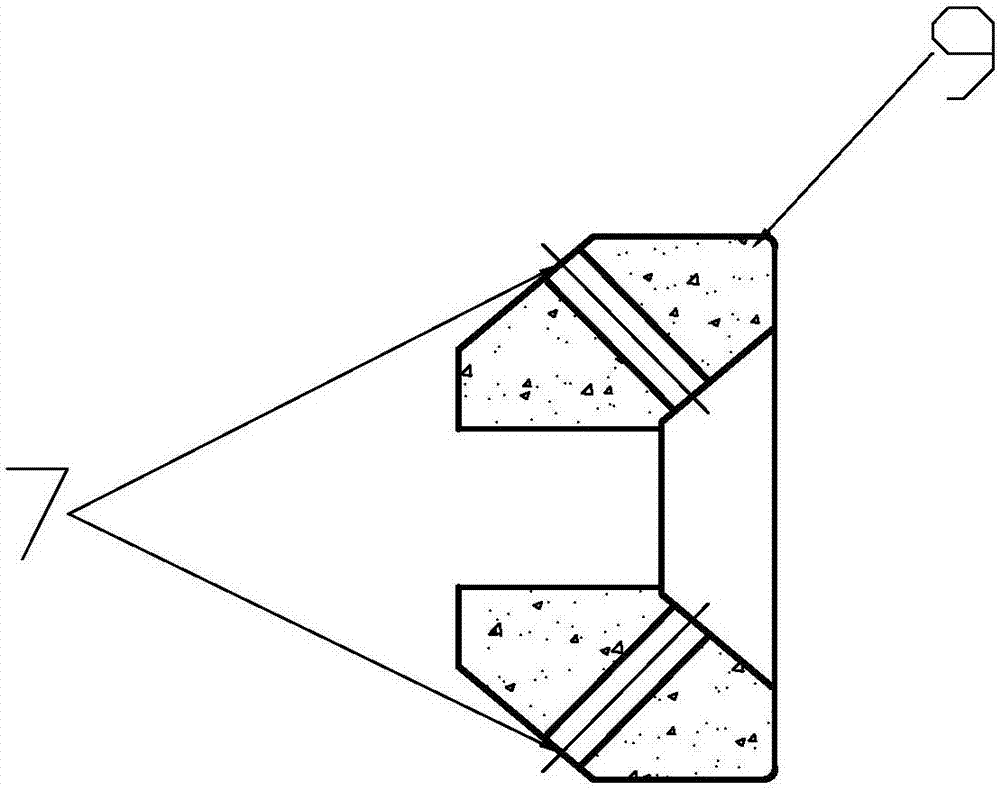

[0025] see Figure 1-6 As shown, the present invention relates to a novel regenerative flat flame burner, which includes a hollow burner shell 12 with a regenerator 13 inside, a flat flame burner brick 11, an air inlet 1, an ignition burner 16, a burner Nozzle core and air-fuel mixing head 9, the flat-flame burner brick 11 is fixedly arranged on the burner housing 12, the air-fuel mixing head 9 is fixedly arranged on the flat-flame burner brick 11, the air inlet 1 Installed on the top of the regenerator 13, one end of the flat flame burner brick 11 is provided with a flat flame combustion chamber 10 with a trumpet-shaped gradually widening structure, and the ignition end of the ignition burner 16 is arranged in the flat flame combustion chamber 10, The burner core includes a gas pipe 5 and a gas inlet 2 arranged at one end of the gas pipe 5. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com