Preparation system and preparation method of high-activity metakaolin finished product with controllable color

A metakaolin preparation system technology, applied in chemical instruments and methods, lighting and heating equipment, preheating costs, etc., can solve the problems of difficult product quality, high energy consumption and small processing capacity of the metakaolin preparation system, and achieve reduction Operating costs, reducing difficulty, and avoiding the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

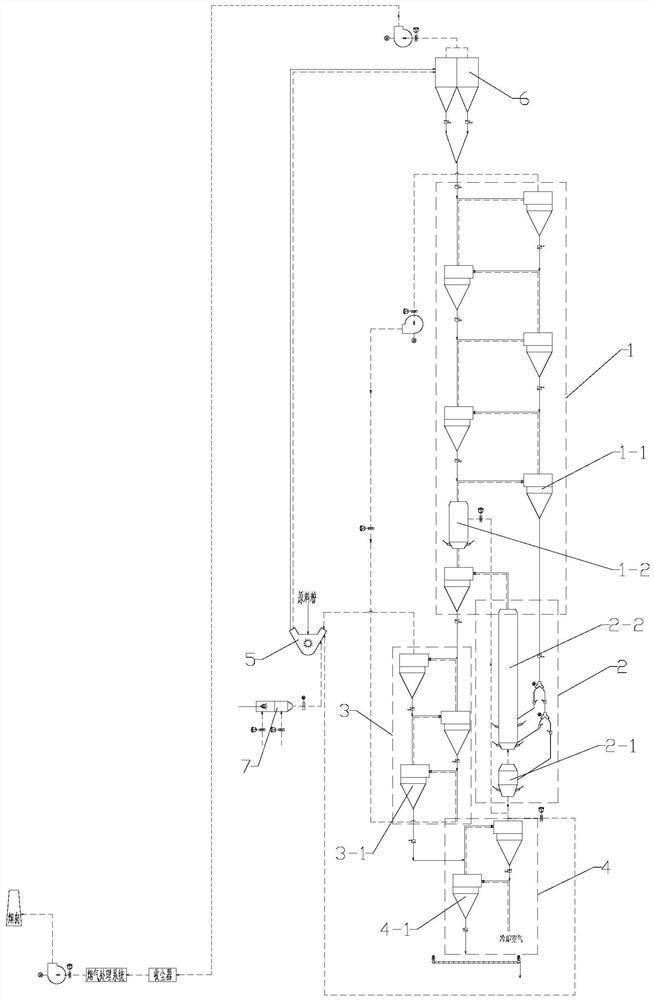

[0039] see figure 1 , this embodiment provides a highly active metakaolin preparation system with controllable finished color, including a drying and crushing system 5 for drying and crushing raw materials, a suspension preheating system 1, a calciner system 2, and a first cooling system 3 and a second cooling system 4 .

[0040] The material outlet of the drying and crushing system 5 is connected to the suspension preheating system 1 through the cyclone separator 6, and the separated flue gas enters the dust collector and the flue gas treatment system, and is discharged into the atmosphere after being processed. The heat source inlet of the drying and crushing system 5 is connected with the air outlet of the first cooling system 3 , and / or connected with the air outlet of the second cooling system 4 , and / or connected with the hot blast stove system 7 .

[0041] The suspension preheating system 1 includes a multi-stage cyclone preheater 1-1, a high-efficiency spreading devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com