Boiler with back-burning coal spreader

A coal thrower and boiler technology, applied in the field of boilers, can solve the problems of Ringelmann blackness value, waste and high coal consumption that fail to meet environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

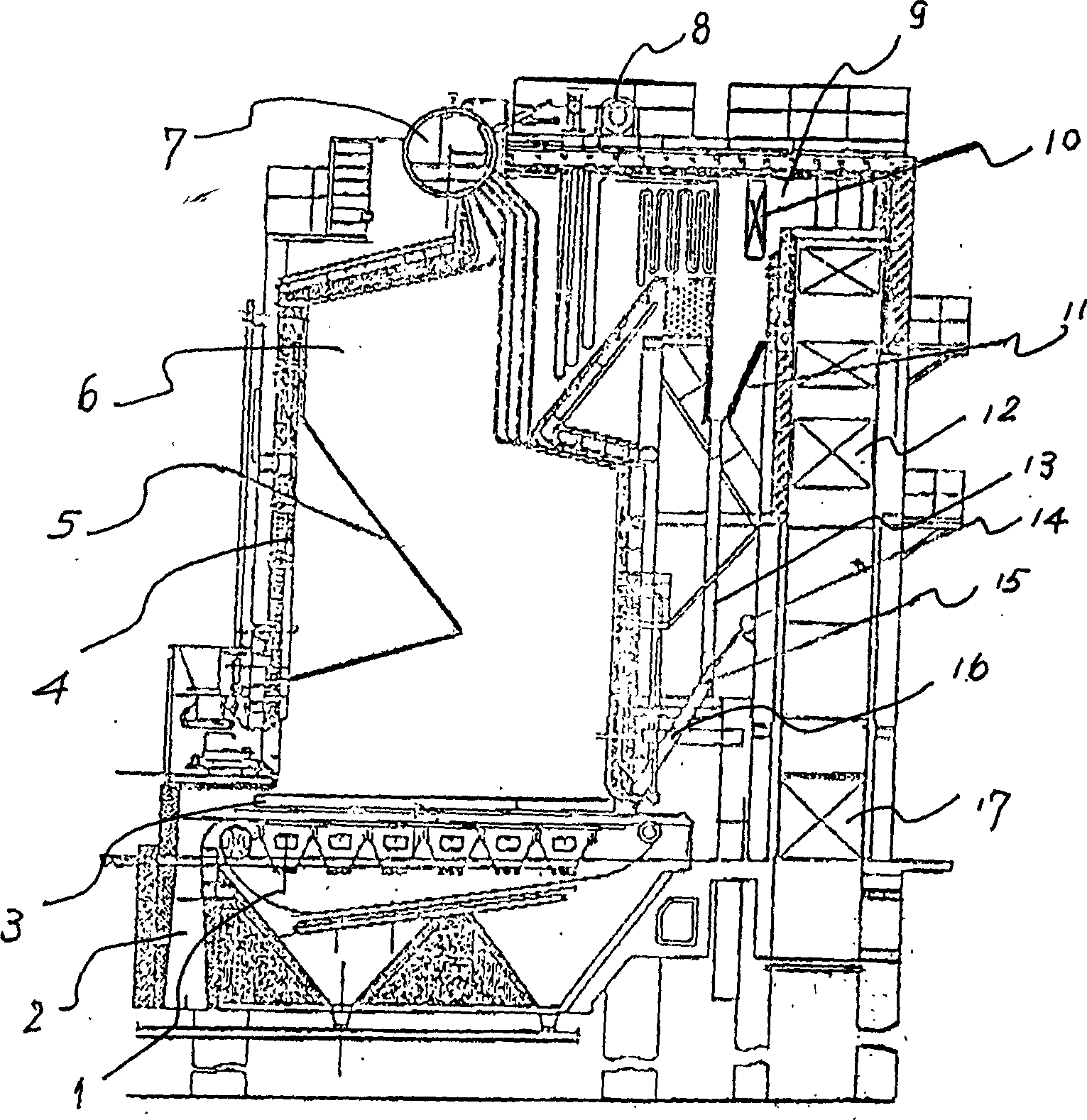

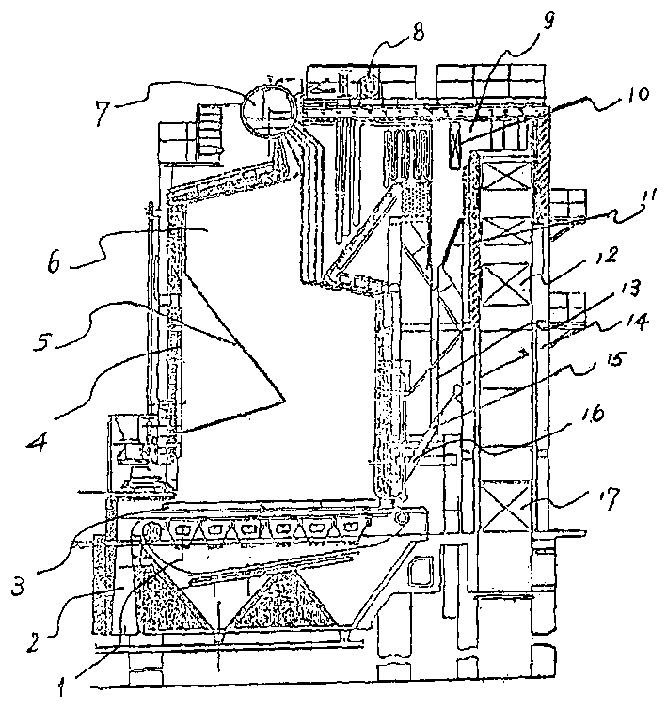

[0007] Embodiments of the present invention will be further described in conjunction with the accompanying drawings. Depend on figure 1 As shown, it includes air chamber 1, slag outlet 2, grate 3, front wall 4, furnace 6, bubble 7, superheater 8, steering chamber 9, economizer 12, air preheater 17, its characteristics Yes, there is a furnace arch 5 built in the furnace 6, a separator 10 is built in the steering chamber 9, and a recycling device is installed at the bottom of the separator 10. The built-in furnace arch in the furnace can be a front arch, a rear arch or a front and rear arch. What is set in this embodiment is a front arch 5, which is installed on the front wall 4 of the furnace 6 of the main body of the coal thrower. The front wall of the common coal thrower boiler furnace is generally equipped with a water-cooled wall. The front wall of the present embodiment The arch replaces the water-cooled wall and is installed at the original water-cooled wall. The end po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com