Coal-quality machine-made charcoal preparation method

A technology of mechanism charcoal and coal quality, applied in special forms of dry distillation, solid fuels, biofuels, etc., can solve the problems of insufficient industrialization, low output, limited source of raw materials, etc. The effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

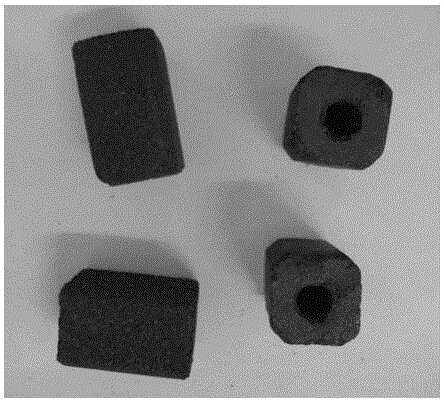

Image

Examples

Embodiment 1

[0017] The coal-based machine-made carbon preparation method includes the following specific steps:

[0018] (1) Broken lignite and biomass charcoal into lignite particles and biomass charcoal particles of 0.1-0.5 mm;

[0019] (2) Carbonize the 0.1-0.5mm lignite particles in step (1) at 700°C for 6 hours in isolation from the air, and cool to room temperature to obtain carbonized products;

[0020] (3) Mix the carbonized product obtained in step (2), the biochar particles obtained in step (1) and the binder according to the mass ratio of 80:18:2, and then add water and stir evenly to obtain a mixed material, which contains water The control is 10% of the mass of the mixed material; the biochar is pine nut shell charcoal; the binder is composed of 40wt% sodium humate, 45wt% industrial starch, 5wt% water glass (concentration: 400g / L) and 10wt% bentonite. Made

[0021] (4) The mixed material obtained in step (3) is pressed into shape under a pressure of 0.5 MPa, and dried at 15...

Embodiment 2

[0024] The coal-based machine-made carbon preparation method includes the following specific steps:

[0025] (1) Broken lignite and biochar into lignite particles and biochar particles of 0.5-1mm respectively;

[0026] (2) Carbonize the 0.5-1mm lignite particles in step (1) at 800°C for 4 hours in isolation from the air, and cool to room temperature to obtain carbonized products;

[0027] (3) Mix the carbonized product obtained in step (2), the biochar particles obtained in step (1) and the binder according to the mass ratio of 95:0:5, and then add water and stir evenly to obtain a mixed material, which contains water The control is 15% of the mass of the mixed material; the biomass charcoal is straw charcoal; the binder is composed of 40wt% sodium humate, 45wt% industrial starch, 5wt% water glass (concentration: 600g / L) and 10wt% bentonite. become

[0028] (4) Compress the mixed material obtained in step (3) under a pressure of 1 MPa, and dry it at 100°C to obtain coal-base...

Embodiment 3

[0031] The coal-based machine-made carbon preparation method includes the following specific steps:

[0032] (1) Broken lignite and biochar into 1-2mm lignite particles and biochar particles;

[0033] (2) Carbonize the 1-2mm lignite particles in step (1) at 600°C for 8 hours in isolation from the air, and cool to room temperature to obtain carbonized products;

[0034] (3) Mix the carbonized product obtained in step (2), the biochar particles obtained in step (1) and the binder according to the mass ratio of 60:35:5, and then add water and stir evenly to obtain a mixed material, which contains water The control is 10% of the mass of the mixed material; the biochar is bagasse charcoal; the binder is composed of 40wt% sodium humate, 45wt% industrial starch, 5wt% water glass (concentration: 700g / L) and 10wt% bentonite. Made

[0035] (4) The mixed material obtained in step (3) is pressed into shape at a pressure of 0.5 MPa, and dried at 200°C to obtain coal-based machine-made ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com