Flexibly-adjustable high-activity metakaolin preparation system and method

A technology of metakaolin and preparation system, which is applied to the preparation system and preparation field of high-activity metakaolin, can solve the problems of difficult product quality control, small processing capacity, high energy consumption, avoid direct radiation contact with kaolin, reduce heat consumption, and improve finished products. Active Satisfaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

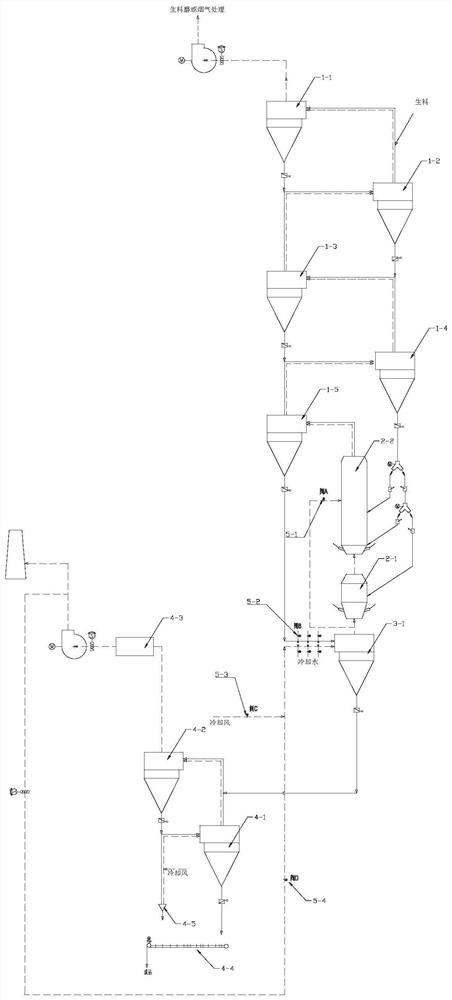

[0042] In this embodiment, the suspension preheating system includes the first, second, third, fourth and fifth cyclone preheaters, high-efficiency material spreading devices and connecting pipelines, etc.; the calciner system includes high-efficiency material spreading devices, hot air inlet pipelines, etc. , preheating furnace, the first burner arranged in the cone of the preheating furnace, the reforming furnace, the second burner arranged in the cone of the reforming furnace, the third burner in the middle of the reforming furnace and the flue gas outlet pipe, etc. ; The first cooling system includes the sixth cyclone cooler, high-efficiency spreading device and connecting pipelines, etc.; the second cooling system includes the seventh cyclone cooler, the eighth cyclone cooler, high-efficiency spreading device and connecting pipelines, etc.;

[0043] Such as figure 1 As shown, the kaolin raw ore enters the grinding system after the pretreatment process, and the raw meal po...

Embodiment 2

[0046] In this embodiment, the suspension preheating system includes the first, second, third, fourth and fifth cyclone preheaters, high-efficiency material spreading devices and connecting pipelines, etc.; the calciner system includes high-efficiency material spreading devices, hot air inlet pipelines, etc. , preheating furnace, the first burner arranged in the cone of the preheating furnace, the reforming furnace, the second burner arranged in the cone of the reforming furnace, the third burner in the middle of the reforming furnace and the flue gas outlet pipe, etc. ; The first cooling system includes the sixth cyclone cooler, high-efficiency spreading device and connecting pipelines, etc.; the second cooling system includes the seventh cyclone cooler, the eighth cyclone cooler, high-efficiency spreading device and connecting pipelines, etc.;

[0047] Such as figure 1 As shown, the kaolin raw ore enters the grinding system after the pretreatment process, and the raw meal po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com