Self-stabilizing staged combustion pulverized coal burner

A pulverized coal burner, a technology of staged combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

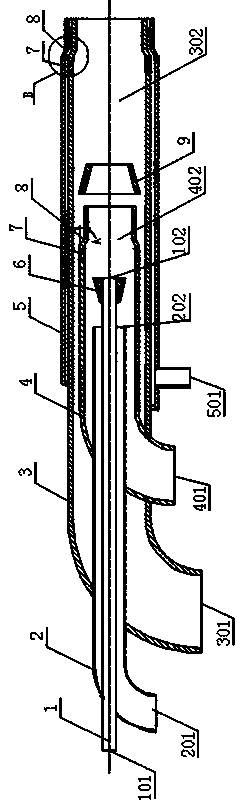

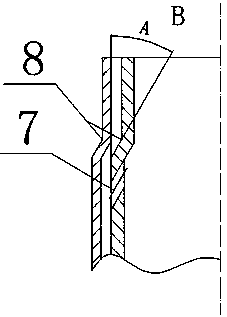

[0022] like figure 1 and figure 2 As shown, a self-stabilized combustion pulverized coal burner with staged combustion includes an ignition gun 1 from inside to outside, a primary pulverized coal air duct 2, a burnout air distribution air duct 4, a secondary pulverized coal air duct 3 and a perimeter air duct 5. The ignition gun 1 and the primary pulverized coal air duct 2 are slidingly socketed, and the nozzle 102 of the ignition gun is provided with an ignition oil nozzle and a choke plug 6 for adjusting the air resistance of the air outlet of the primary pulverized coal air duct , the choke plug 6 is a conical structure with a small front and a large rear made of wear-resistant and high-temperature-resistant ceramic material, which has good fire resistance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com