Method for promoting stable burning of biomass fuel and used for burning of fluidized bed

A biomass fuel and fluidized bed technology, which is applied to fluidized bed combustion equipment, combustion methods, and fuels burned in a molten state, can solve problems such as clogging and coking at the boiler tail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

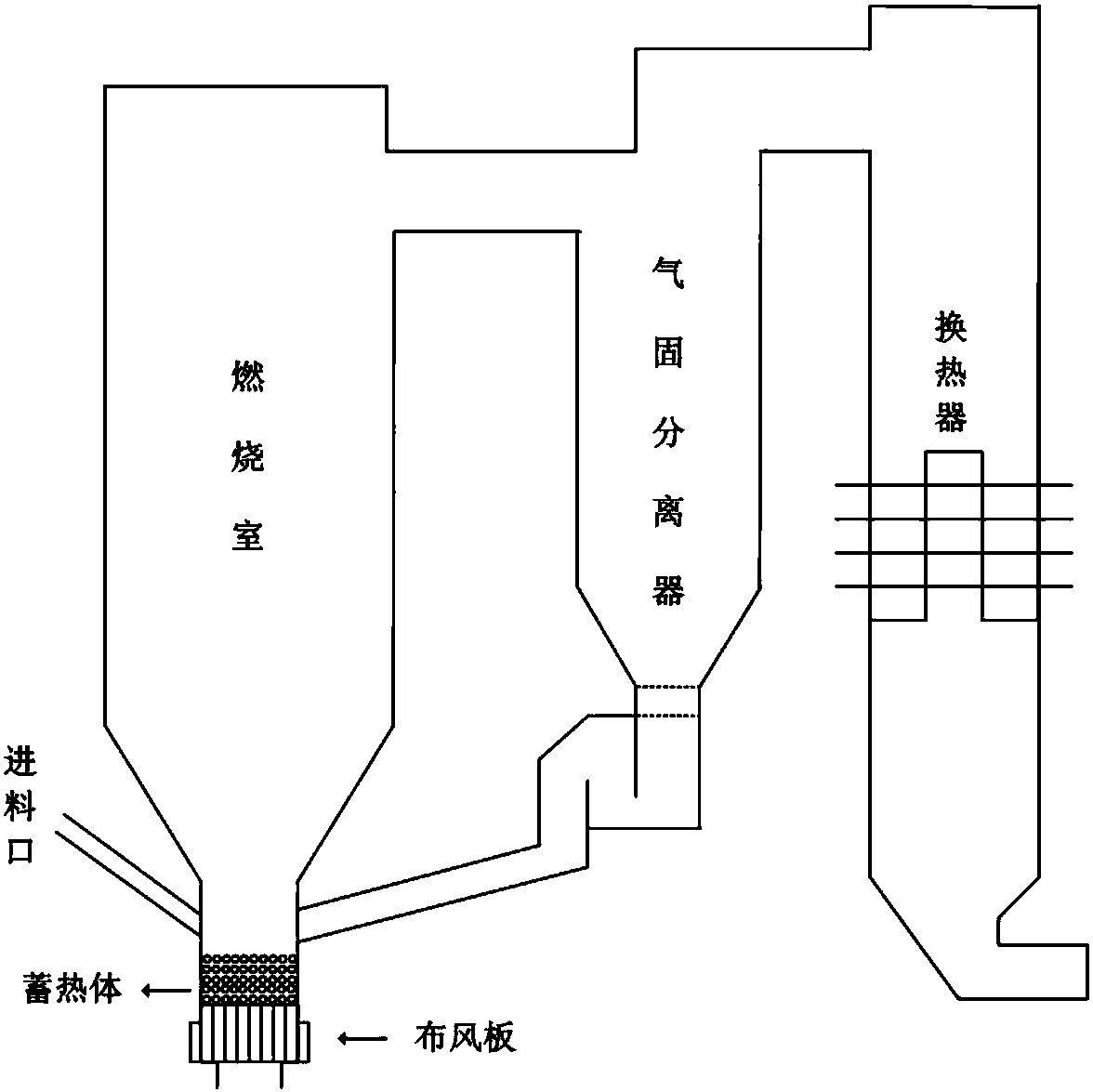

Embodiment 1

[0026] A rated 75t / h steam boiler, rated steam pressure 3.82Mpa, rated steam temperature 450°C, feed water temperature 150°C, primary air preheating temperature 150°C, biomass fuel 50% wheat straw + 50 rice straw, water content 15 %, without granulation, the fuel length is not greater than 10mm. Use ceramsite as heat storage body. After the ceramsite is broken, select particles with a particle size of 0-1.5mm and spread them on the air distribution board in the furnace with a thickness of 500mm. Ignite, control the temperature of the bed material, prevent local overheating, and control the temperature of the air chamber within 800 °C. Start the screw feeder to feed, put in fuel, and feed with the rated load fuel amount of 17t / h. The boiler runs smoothly, the combustion in the dense phase area is stable, the mixed combustion effect of fuel and heat storage body is good, and the thermal efficiency of the boiler is 91%.

Embodiment 2

[0028] One rated 75t / h steam boiler, rated steam pressure 3.82Mpa, rated steam temperature 450°C, feed water temperature 150°C, primary air preheating temperature 150°C, biomass fuel 50% wheat straw + 50 rice straw, water content 10 %, the fuel length is not greater than 10mm. Use ceramsite as heat storage body. The average particle size of ceramsite is 15mm, and the bulk density is 600Kg / m 3 , The regenerator is laid flat on the air distribution plate in the furnace, with a thickness of 600mm. Ignite, control the temperature of the bed material, prevent local overheating, and control the temperature of the air chamber within 800 °C. Start the screw feeder to feed, put in fuel, and feed with the rated load fuel amount of 17t / h. The boiler operates stably, the dense phase zone burns stably, the mixed combustion effect of fuel and heat storage body is good, and the thermal efficiency of the boiler is over 90%.

Embodiment 3

[0030] A rated 75t / h steam boiler, rated steam pressure 3.82Mpa, rated steam temperature 450°C, feed water temperature 150°C, primary air preheating temperature 150°C, biomass fuel is 50% wheat straw + 50 rice straw, granulated, Diameter 6~12mm, length 20~40mm, bulk density 850kg / m 3 . Use ceramsite as heat storage body. The average particle size of ceramsite is not more than 20mm, and the bulk density is the same as that of fuel, which is 850Kg / m 3 , The regenerator is laid flat on the air distribution plate in the furnace, with a thickness of 700mm. Ignite, control the temperature of the bed material, prevent local overheating, and control the temperature of the air chamber within 800 °C. Start the screw feeder to feed, put in fuel, and feed with the rated load fuel amount of 17t / h. The boiler runs smoothly, the combustion in the dense phase zone is stable, the mixed combustion effect of the fuel and the heat storage body is good, and the thermal efficiency of the boiler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com