An environmentally friendly flexible fireproof cable

A fireproof cable, environmental protection technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of inability to produce large-section and long-length cables, insulation layer shedding, etc., to enhance impact resistance, ensure smooth flow, and good bending. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

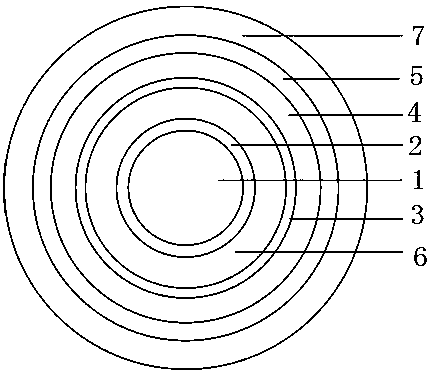

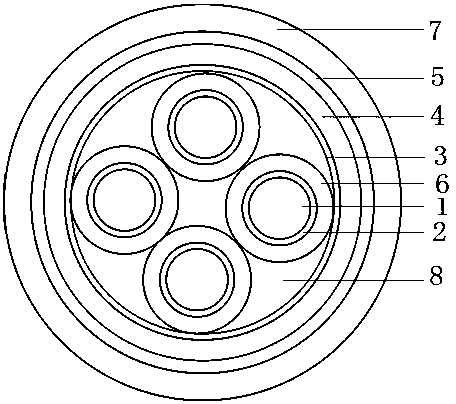

[0025] The round compact copper conductor is adopted, and the conductor structure is dense. Under the same cross-sectional area of the conductor, the outer diameter of the conductor after compaction is reduced by about 10%, thereby reducing the outer diameter of the product and facilitating installation and laying.

[0026] It adopts double fireproof insulation layer structure. The inside is overlapped with mineral insulation fireproof tape, and the thickness of the tape is 0.14mm. A new type of fireproof material, ceramic polyolefin insulating material, is extruded outside, and the thickness is 1.0 mm according to different specifications. In addition to the characteristics of ordinary polyolefin insulation materials, ceramicized polyolefin fireproof insulation materials also have excellent fireproof and fire-resistant characteristics. It can form a hard ceramic-like hard shell under the burning of the flame. The hard shell is in the fire environment ( (650°C-3000°C) does ...

Embodiment 2

[0030]The above-mentioned double fireproof insulating layer structure. The inside is overlapped with mineral insulation fireproof tape, and the thickness of the tape is 0.18mm. A new type of fireproof material, ceramic polyolefin insulating material, is extruded outside, and the thickness is 2.0 mm according to different specifications. In addition to the characteristics of ordinary polyolefin insulation materials, ceramicized polyolefin fireproof insulation materials also have excellent fireproof and fire-resistant characteristics. It can form a hard ceramic-like hard shell under the burning of the flame. The hard shell is in the fire environment ( (650°C-3000°C) does not melt or drip, and has a very good heat and fire insulation effect, which can ensure smooth power and communication in case of fire, and buy valuable time for personnel escape and fire rescue. An airtight cavity is provided between the inner and outer fireproof insulating layers. The cavity is composed of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com