Environment-friendly cable

A cable and environmental protection technology, applied in the field of wire and cable, can solve the problems of cable pollution, fire accidents, etc., and achieve the effect of excellent fire resistance and reasonable design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

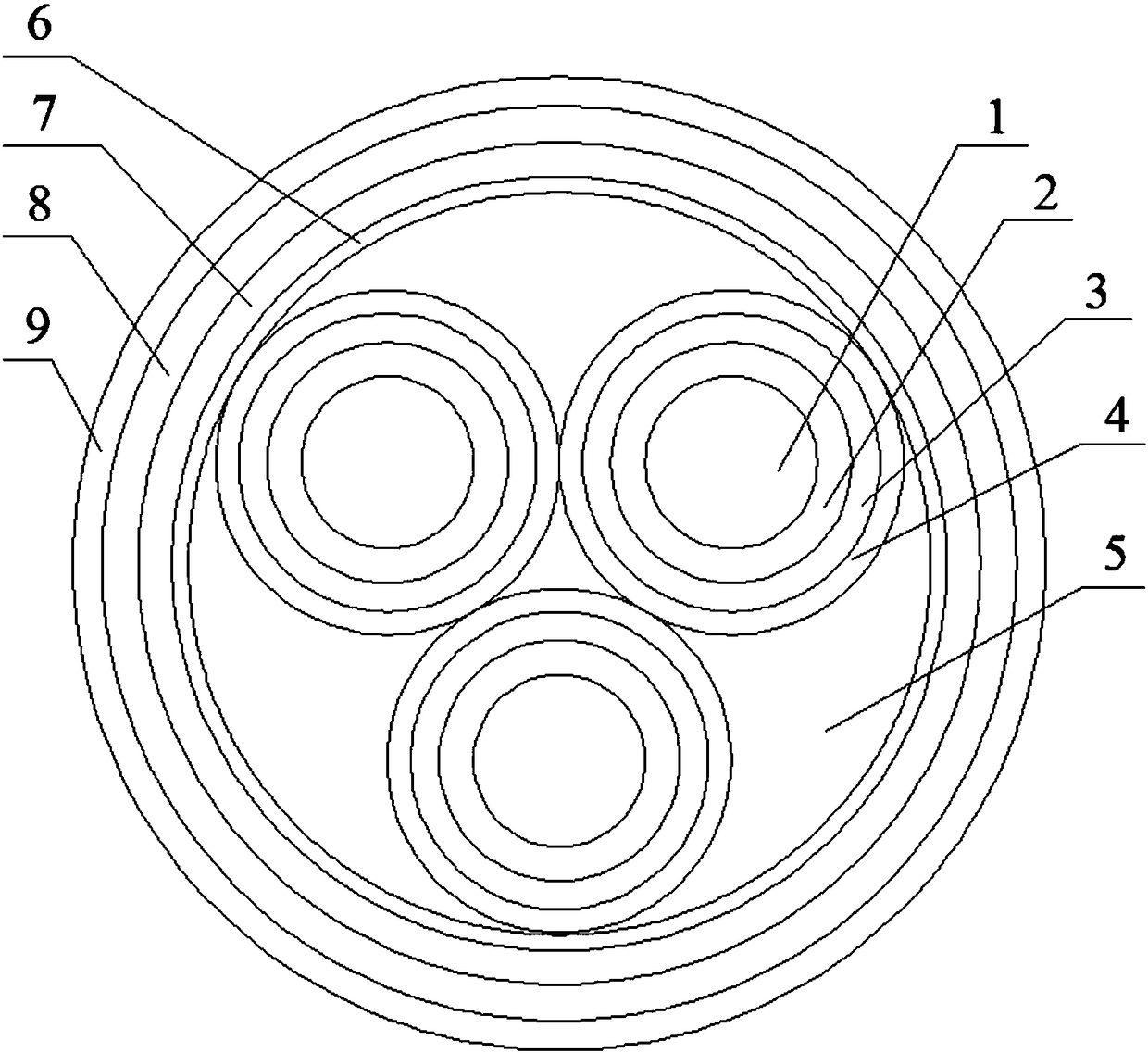

[0019] Such as figure 1 As shown, it is a schematic diagram of an environmentally friendly cable provided by the present invention, including a wire core and a cable core, the wire core includes a conductor 1 and a fire-resistant layer 2, and the wire core is covered with an inner fireproof insulating layer 3 and an outer fireproof insulating layer 4. A plurality of said wire cores are stranded to form a cable core, and said cable core is coated with a heat insulation layer 6, a fireproof layer 7, an armor layer 8 and an outer sheath 9 in sequence, and the gap between said cable cores is a filling layer 5 , the filling layer 5 is filled with non-alkali glass ropes.

[0020] Wherein, the conductor 1 is made of a circular pressed copper conductor, and the refractory layer 2 is a graphite synthetic mica tape made of graphene, thereby replacing the traditional artificially synthesized mica tape. The graphite synthetic mica tape does not contain fluorine elements, and its The gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com