A kind of high temperature resistant rope and preparation method thereof

A technology of high temperature resistance and rope, applied in the direction of braid, flame retardant fiber, fiber treatment, etc., can solve the problem of high temperature resistance, and achieve the effect of improving safety and excellent high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

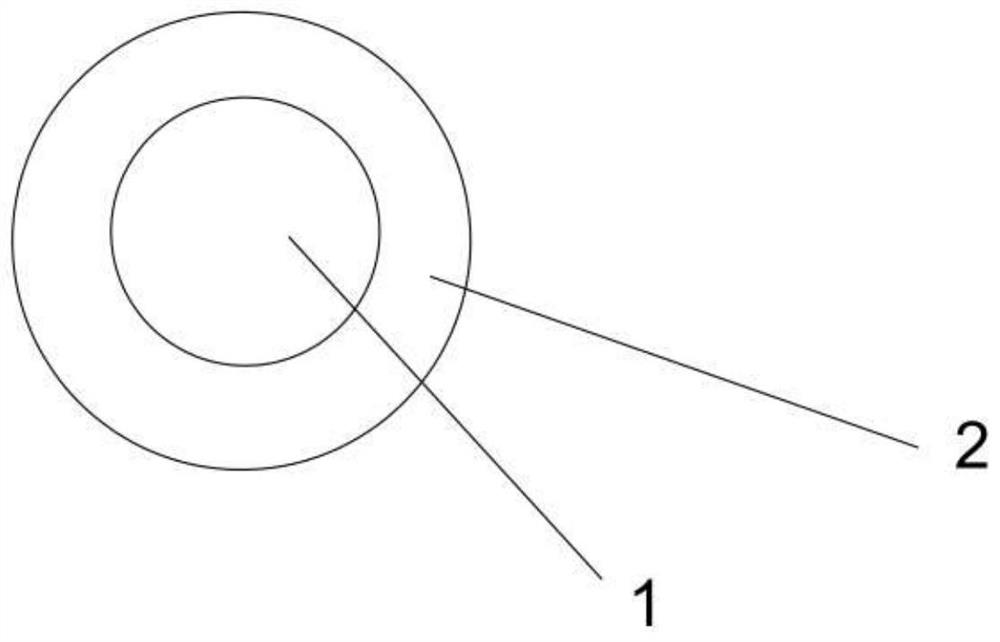

[0025] see figure 1 , this embodiment provides a high temperature resistant rope, the body includes a core rope 1 and an outer layer 2, the core rope 1 is a poly-p-phenylene benzobisoxazole fiber as the axis, 3 The root modified aramid fiber is wound axially around the polyparaphenylene benzobisoxazole fiber to form a single rope yarn, and then 12 single rope yarns are braided to form a basic rope strand, and finally 12x12 strands of basic rope The final core rope 1 is formed by strand braiding, and the outer layer 2 is formed by axially winding a modified aramid fiber with 3 polyparaphenylene benzobisoxazole fibers around the modified aramid fiber One strand of single rope yarn, then braided with 2 strands of single rope yarn to form a base strand, finally obtained by braiding with 2x12 strands of base strand, the outer layer 2 is braided directly on the core rope during the weaving process of 2x12 strands of base strand 1 and finally constitute the ontology.

[0026] Furth...

Embodiment 2

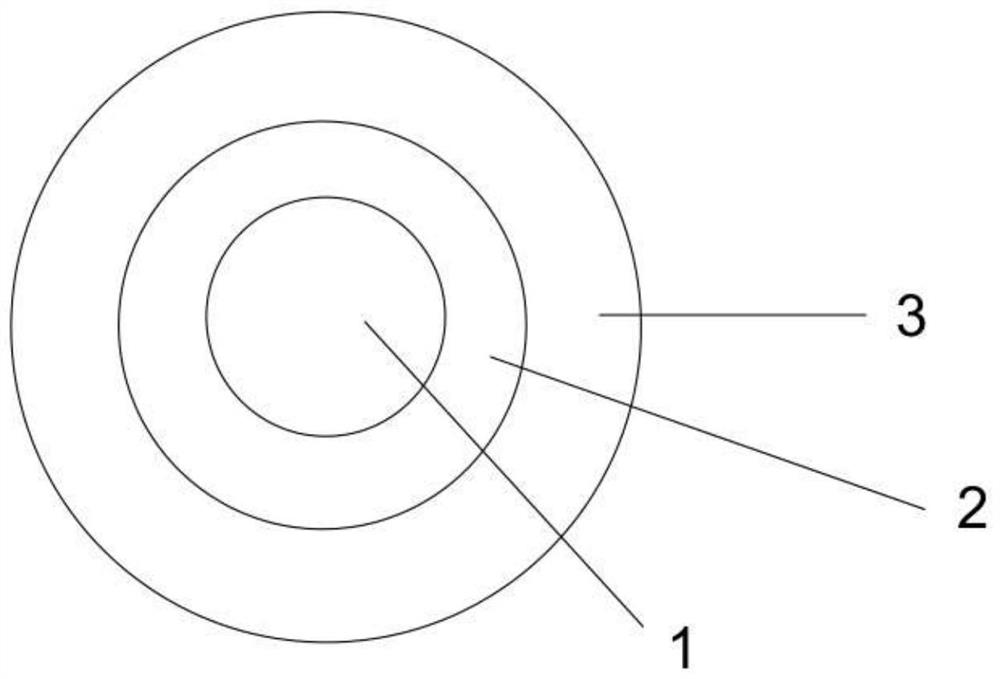

[0042] see figure 2 , this embodiment provides a high temperature resistant rope, the body includes a core rope 1 and an outer layer 2, the core rope 1 is a poly-p-phenylene benzobisoxazole fiber as the axis, 3 The root modified aramid fiber is wound axially around the polyparaphenylene benzobisoxazole fiber to form a single rope yarn, and then 12 single rope yarns are braided to form a basic rope strand, and finally 12x12 strands of basic rope The final core rope 1 is formed by strand braiding, and the outer layer 2 is formed by axially winding a modified aramid fiber with 3 polyparaphenylene benzobisoxazole fibers around the modified aramid fiber One strand of single rope yarn, then braided with 2 strands of single rope yarn to form a base strand, finally obtained by braiding with 2x12 strands of base strand, the outer layer 2 is braided directly on the core rope during the weaving process of 2x12 strands of base strand 1 and finally constitute the ontology.

[0043] Furt...

Embodiment 3

[0048] This embodiment provides a high temperature resistant rope, the body includes a core rope 1 and an outer layer 2, the core rope 1 is based on a poly-p-phenylene benzobisoxazole fiber, and three Modified aramid fibers are wound axially around polyparaphenylene benzobisoxazole fibers to form a single rope yarn, then 12 single rope yarns are braided to form a basic rope strand, and finally 12x12 basic rope strands Braiding constitutes the final core rope 1, the outer layer 2 takes one modified aramid fiber as the axis, and three polyparaphenylene benzobisoxazole fibers are axially wound around the modified aramid fiber to form a One strand of single rope yarn, and then weave 2 strands of single rope yarn to form a basic strand, and finally obtain it by weaving 2x12 strands of basic strand, and the outer layer 2 is braided directly on the core rope 1 during the weaving process of 2x12 strands of basic strand The exterior finally constitutes the ontology.

[0049] Further, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com