Novel water-coal-slurry fired organic heat carrier boiler

A heat carrier furnace and water-burning technology, which is applied in the transportation of non-flammable liquid/gas, combustion method, combustion equipment, etc., to achieve the effects of not easy coking, improved burnout rate, and long process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

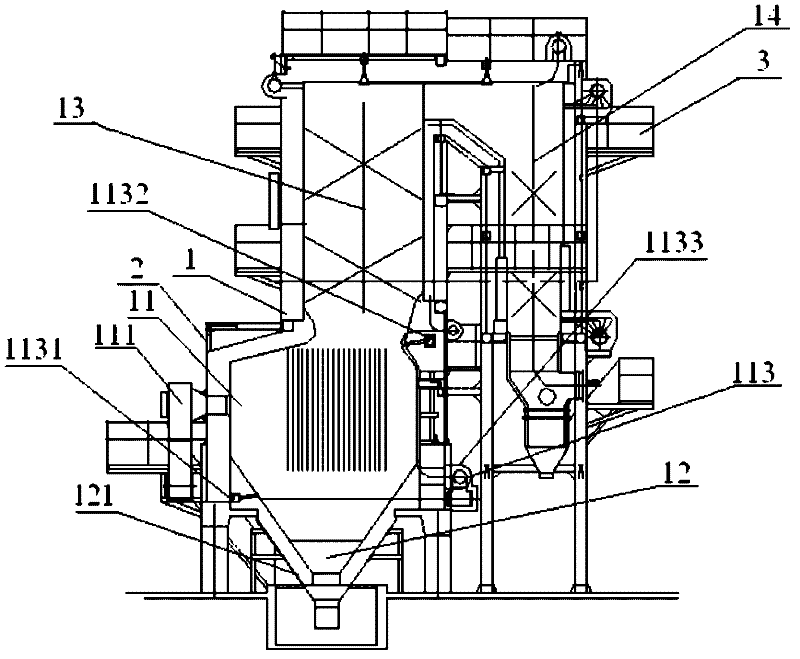

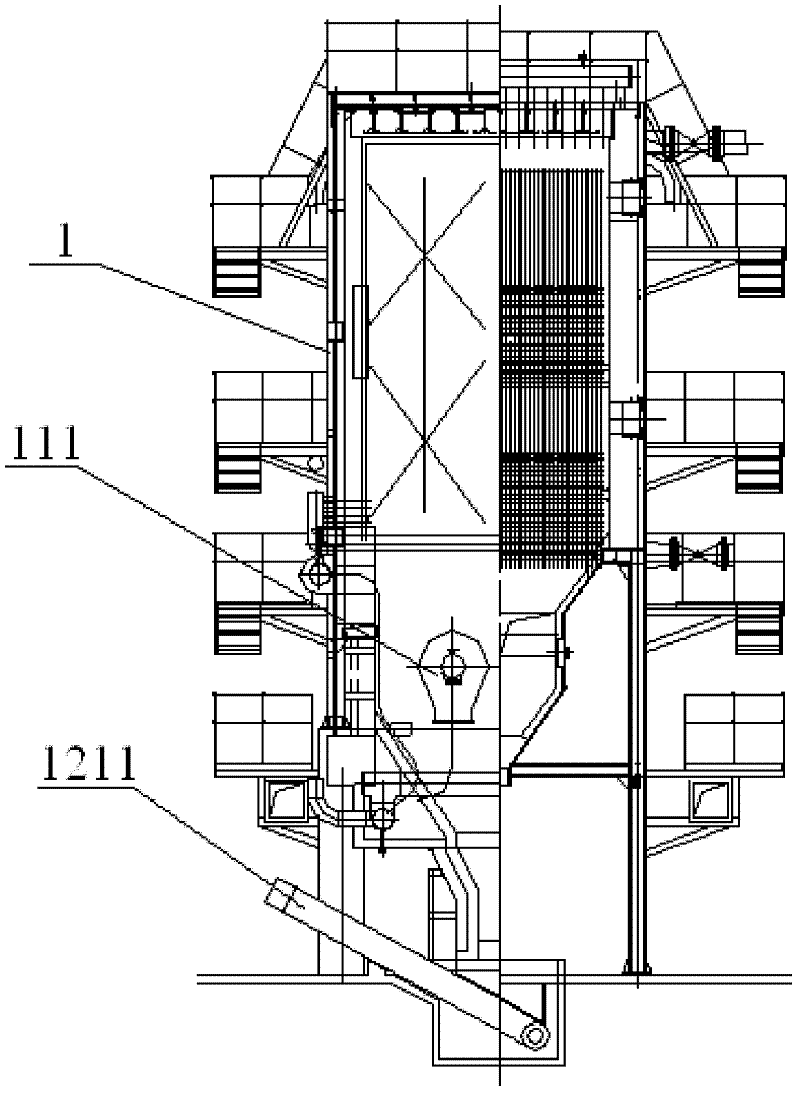

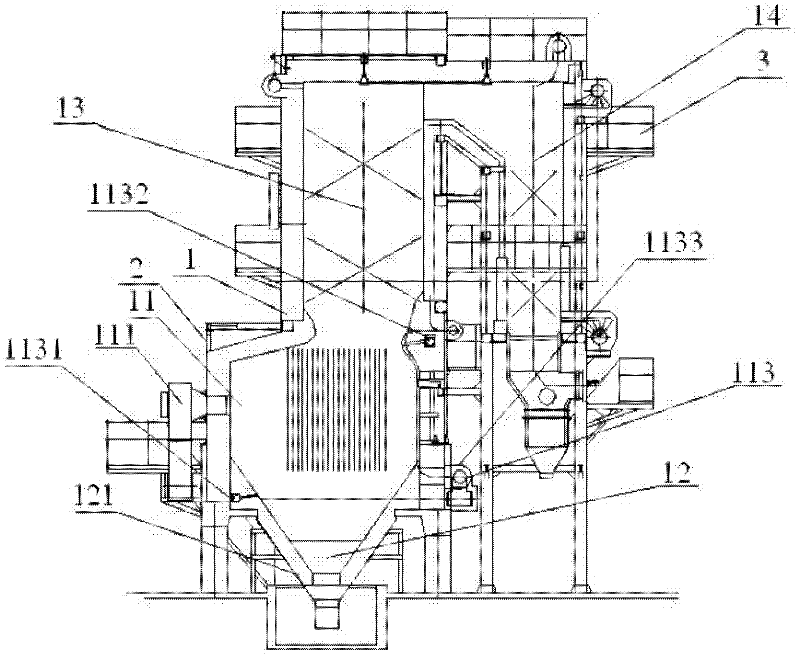

[0020] Further illustrate the present invention below in conjunction with accompanying drawing

[0021] Referring to the attached picture:

[0022] The novel coal-water-slurry organic heat carrier furnace of the present invention comprises a boiler foundation, a furnace wall, a furnace body 1, an outer guard plate, a steel frame 2, and a platform escalator 3, and the furnace body 1 includes a furnace chamber 11, a cold ash Bucket ash discharge system 12, oil cooling system 13, convection tube bundle 14, flue gas duct, air preheater, the furnace 11 is surrounded by the front wall, the left wall, the right wall and the rear wall, the furnace 11 A swirl burner 111 is arranged on the front wall, and the distance between the swirl burner 111 and the upper edge of the furnace 11 and the cold ash hopper 121 is greater than the flame flow width of the swirl burner 111, and the The distribution of the swirling burners 111 matches the shape of the furnace 11; the furnace 11 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com