Heat storage ash melting device

A melting device and regenerative technology, applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve the problem that the melting device cannot meet the requirements, shorten the start-up time, increase the residence time, and ensure that the melting temperature is consistent with the requirements. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further described in conjunction with the accompanying drawings and specific embodiments.

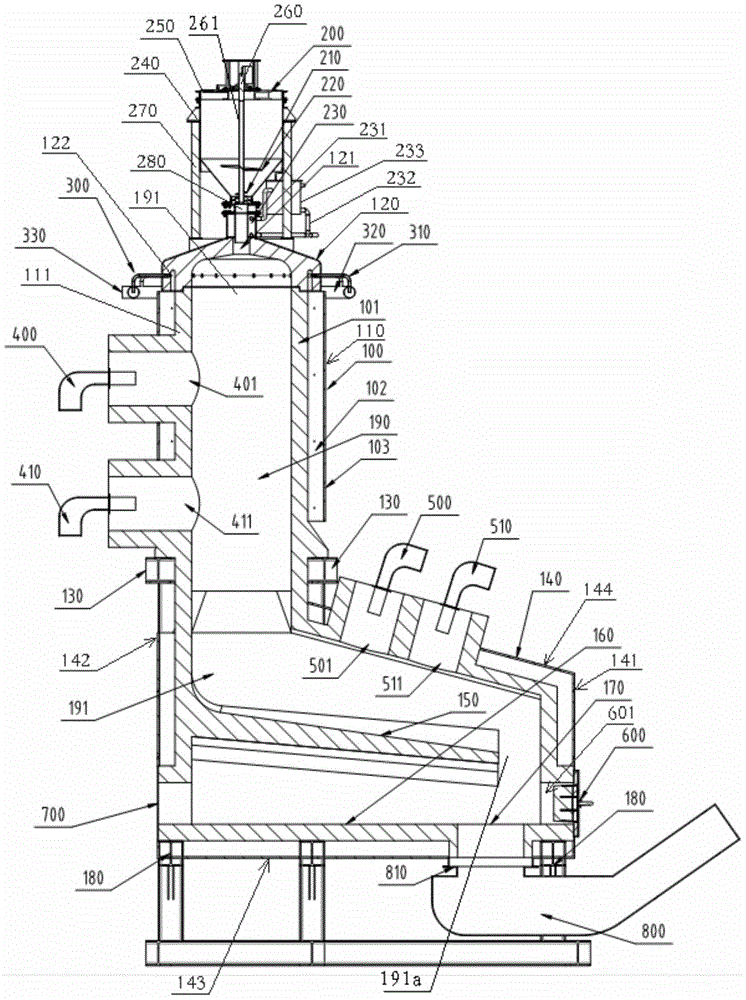

[0035] Referring to the regenerative bed type ash melting device drawn in the figure, it includes a body of furnace 100, which body of furnace 100 includes a vertical furnace body 110 at the top of the body of furnace 100 and a box type furnace body 140 at the bottom of the body of furnace 100, The vertical furnace body 110 is supported above the box furnace body 140 through an annular horizontal bracket 130 , and the box type furnace body 140 is supported on the foundation through a horizontal bracket 180 .

[0036] The vertical furnace body 110 is a cylindrical vertical furnace body, which is equipped with a cylindrical vertical furnace hearth 190, and the top of the cylindrical vertical furnace hearth 190 is provided with a feeding port 191, on the rear wall 111 of the vertical furnace body 110 Two flame passages 401, 411 are configured, and the two fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com