High-efficiency micro-discharging fire coal hot water boiler

A hot water boiler and micro-emission technology, applied in the field of boilers, can solve the problems of increasing the economic pressure of coal-fired equipment enterprises, increasing operating costs, etc., and achieve the effect of solving environmental protection problems and clean combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

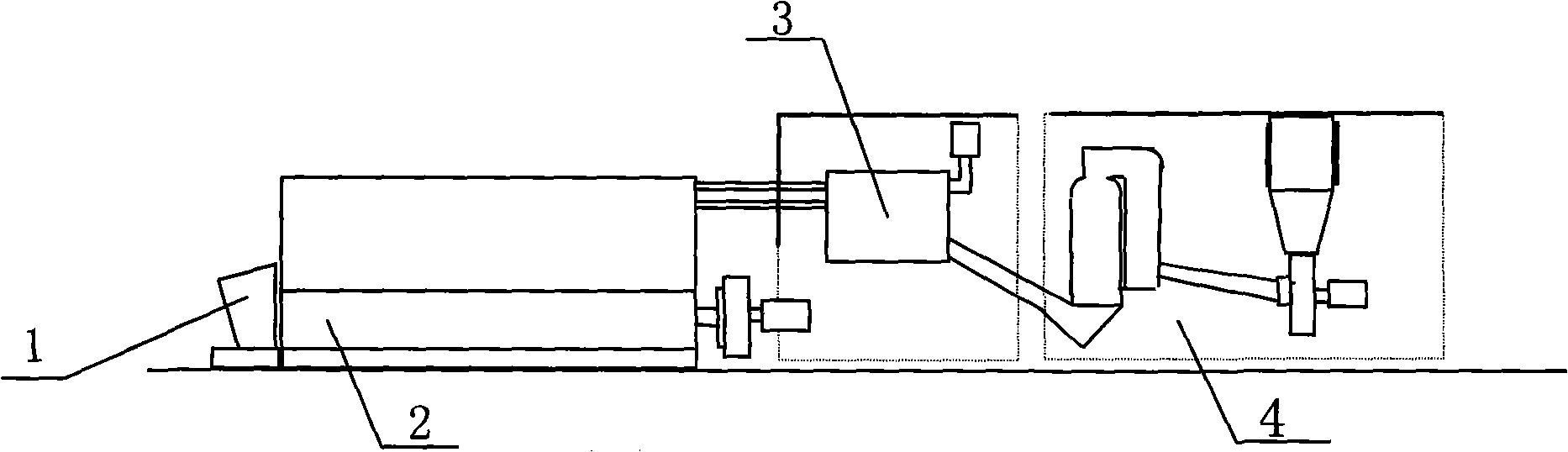

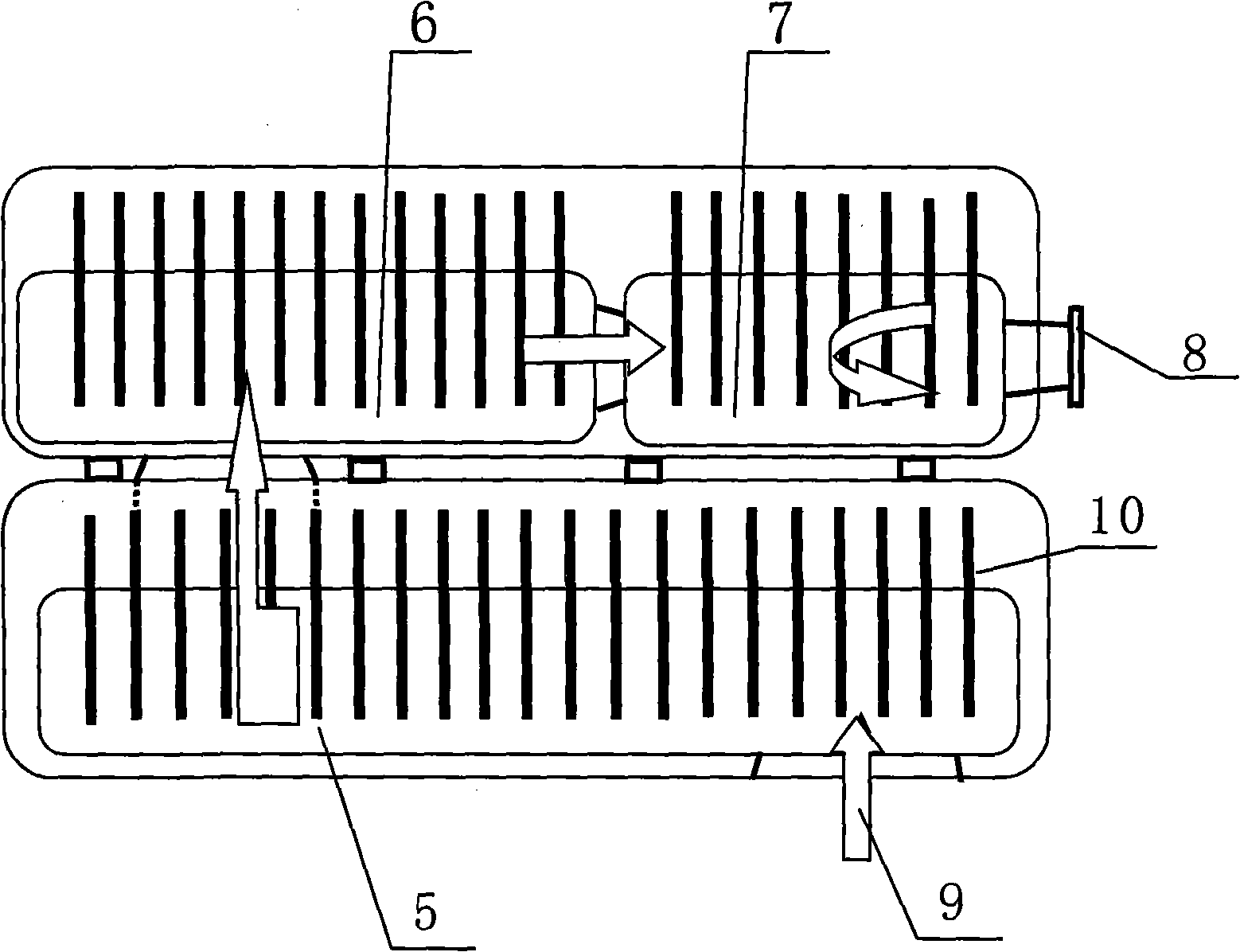

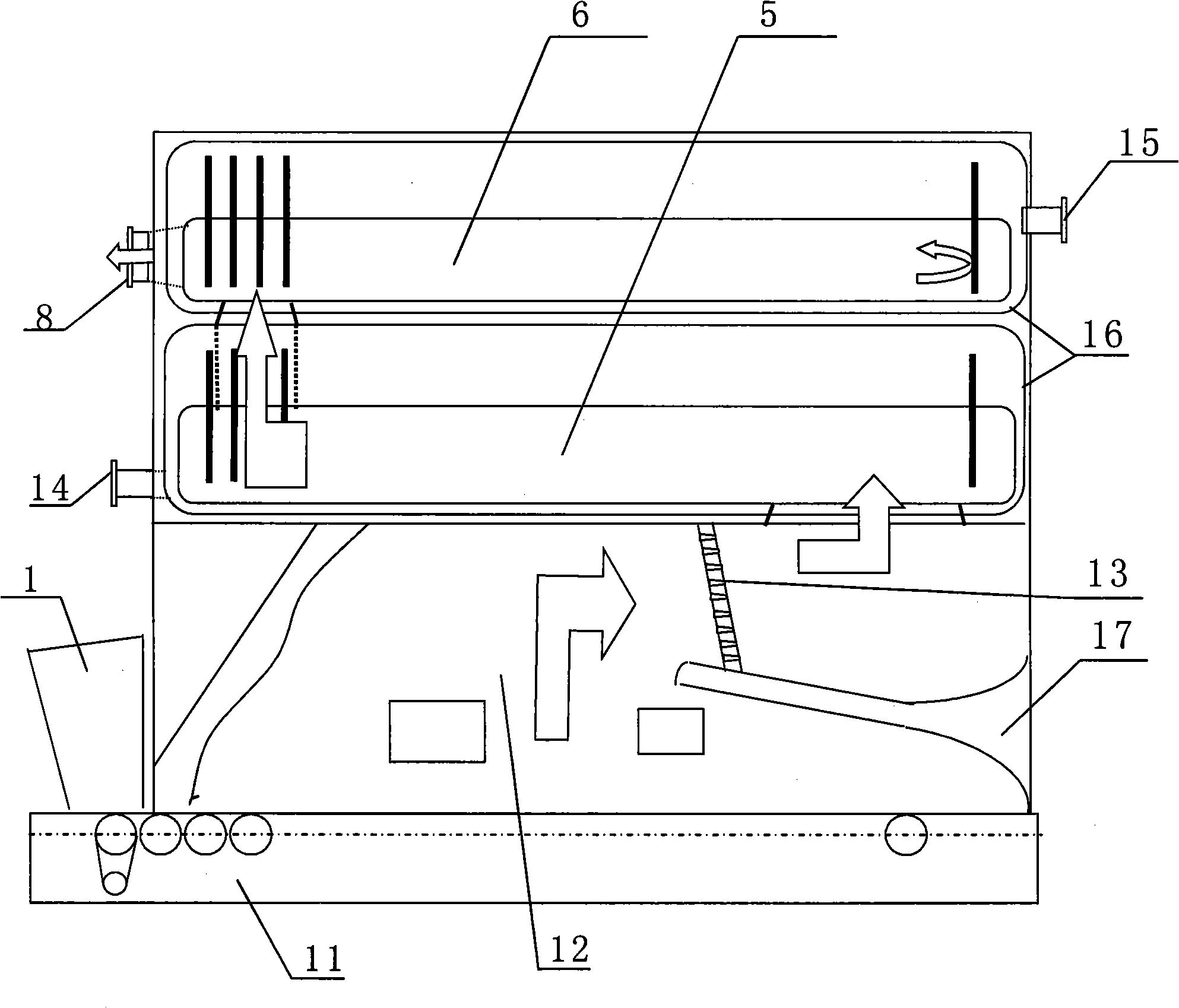

[0032] see figure 1 , including boiler body 2, one side of boiler body 2 is connected with coal feeder 1, the other side of boiler body 2 is connected with flue high temperature waste heat recovery system 3, and flue high temperature waste heat recovery system 3 is connected with desulfurization and dust removal system 4. see image 3 , the boiler body 2 includes a combustion chamber 12, a chain grate 11 is arranged below the combustion chamber 12, and a main galley and an auxiliary gallbladder as a furnace gall are sequentially arranged above the combustion chamber 12. The water inlet 14 is provided with a hot water outlet 15 and a smoke outlet 8 on the attached tank, and a fire equalizing plate 13 connected with the furnace arch 17 is provided in the combustion chamber 12 . see figure 2 , the main tank and the attached tank are provided with heat transfer steel pipes 10, the main tank is provided with a group of heat transfer steel pipes as the first 5 fire channels, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com