Method for treating hazardous waste by utilizing oxygen carrier to assist combustion in rotary kiln

A hazardous waste and rotary kiln technology, which is applied in the intersecting field of energy and environmental protection, can solve the problems of incomplete harmlessness, uneven distribution, and insufficient fuel combustion, etc., so as to improve combustion efficiency and oxygen utilization. Prospects are broad and the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

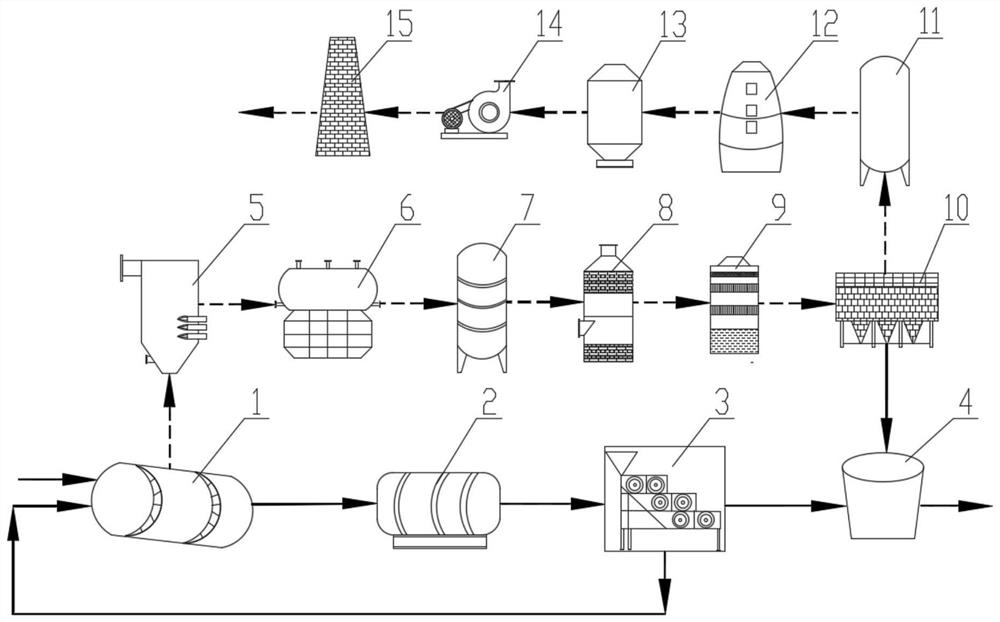

[0034] A device that utilizes an oxygen carrier to assist the rotary kiln 1 to burn hazardous waste. The schematic diagram of the system is shown in figure 1 As shown, the system mainly includes: rotary kiln 1, slag cooler 2, separation device 3, ash collection tank 4 and flue gas purification system;

[0035] The flue gas purification system includes a secondary combustion chamber 5, a waste heat boiler 6, a rapid cooling tower 7, a dry deacidification tower 8, an activated carbon adsorption tower 9, a bag filter 10, a wet deacidification tower 11, a mist removal tower 12, and flue gas heating Device 13, induced draft fan 14, chimney 15;

[0036] in,

[0037] The slag discharge outlet of the rotary kiln 1 is connected to the inlet of the slag cooler 2, the outlet of the slag cooler 2 is connected to the inlet of the separation device 3, and the ash discharge outlet of the separation device 3 is connected to the inlet of the ash collection tank 4;

[0038] The outlet of the ...

Embodiment 2

[0045] The present invention provides a method for using an oxygen carrier to assist the rotary kiln 1 to burn and treat hazardous waste. The schematic diagram of the system is as follows figure 1 shown, including the following steps:

[0046] Step 1. Add oxygen carrier and hazardous waste to the main combustion chamber of rotary kiln 1, and react at 850 °C for 90 minutes. Using the characteristics of oxygen carrier to absorb and release oxygen and the performance of the catalyst, the oxygen distribution in the main combustion chamber Uniformity, promotes the full mixing of hazardous waste and oxygen, realizes the complete combustion and burnout of hazardous waste, and reduces the emission of harmful pollutants;

[0047] The rotary kiln 1 is a counter-current rotary kiln 1, the hazardous waste is medical waste (mainly including bamboo sticks, plastics, fabrics, paper, glass, etc.), the oxygen carrier is calcium ferrite minerals, the main component: Fe 2 o 3 and CaO, containi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com