Steam boiler capable of achieving partial gasification combustion of coal

A technology for steam boilers and boiler bodies, which is applied to steam boilers, solid fuel combustion, combustion chambers, etc., can solve the problems of poor boiler fuel adaptability, high requirements on the shape of the furnace arch, and high carbon content in ash and slag. Adaptability, avoid black smoke, reduce the effect of carbon content in ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

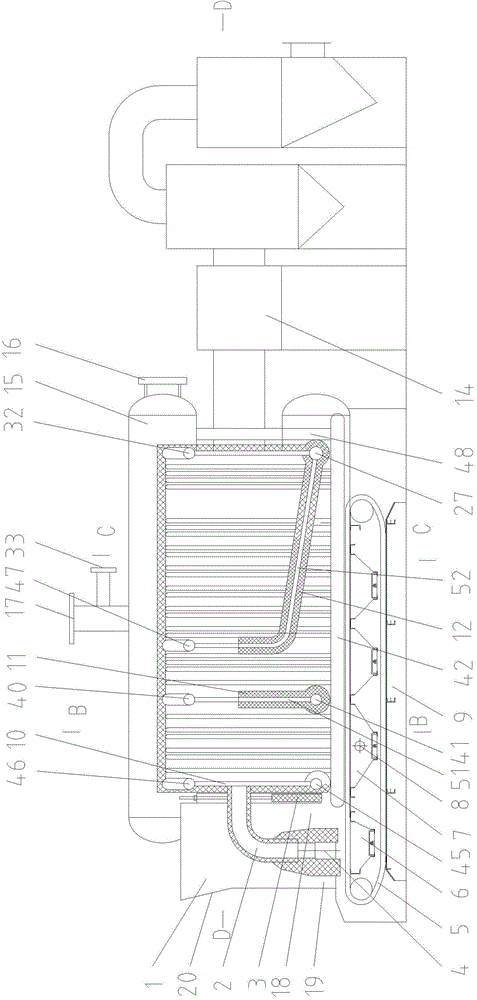

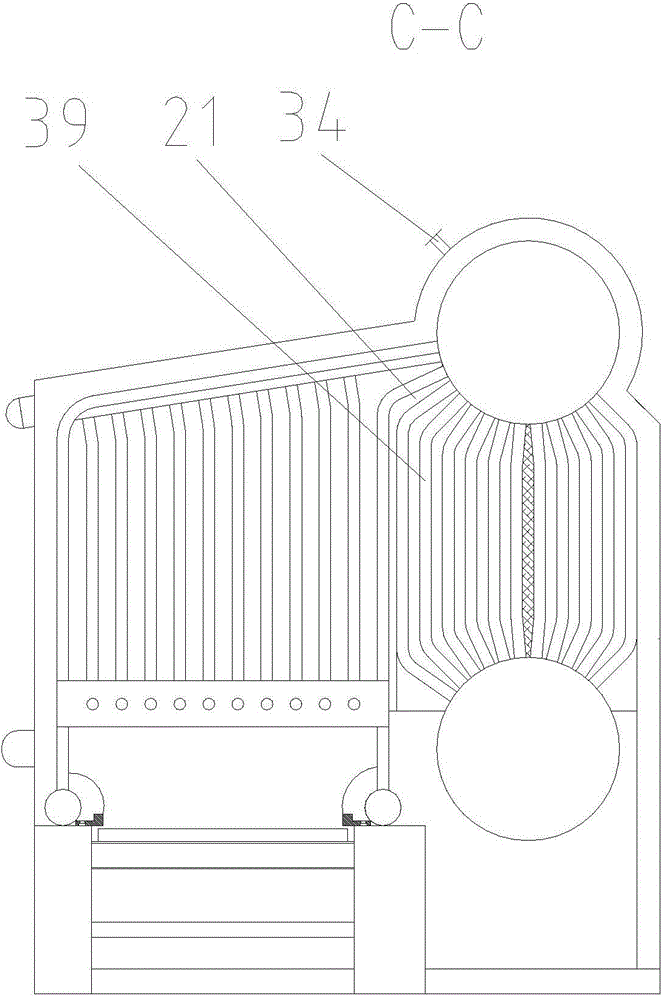

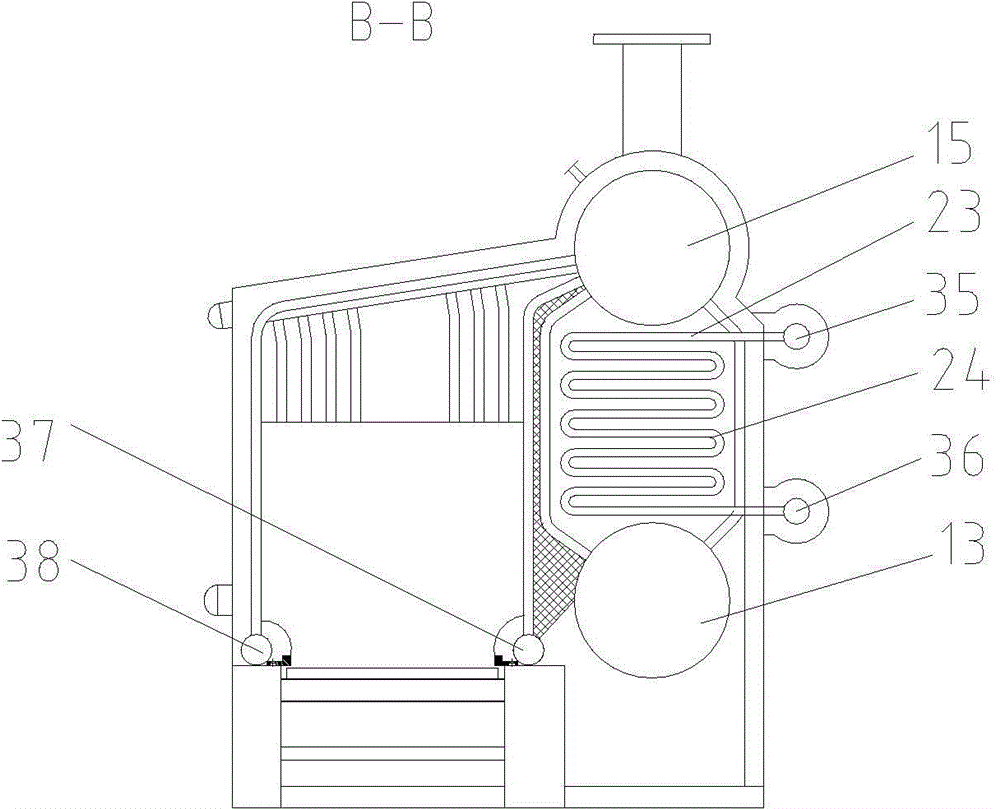

[0028] see Figure 1-Figure 4 In this embodiment, the steam boiler that can realize the partial gasification and combustion of coal includes a combustion device 9, a boiler body 42, a coal economizer 14, and an air preheater 29. Between the economizer 14 and the air preheater 29, a Dust collector 28.

[0029] The combustion equipment 9 includes a coal scuttle 1, a pre-combustion chamber 4, a pre-combustion chamber flue 2, a coal drop channel 19 in front of the coal scuttle, a coal drop channel 18 behind the coal scuttle, a coal gate 3, a chain grate 5, a pre-combustion Chamber air chamber 6, air chamber 7, steam nozzle 8. Wherein, a pre-combustion chamber 4 is arranged inside the coal hopper 1, and the pre-combustion chamber 4 is located above the chain grate 5. Below the chain grate 5 below the pre-chamber 4, a pre-chamber air chamber 6 is arranged to provide air for combustion of fuel on the chain grate 5 in the section where the pre-chamber 4 is located. A pre-combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com