Vacuum evaporation system capable of controlling evaporating airflow distribution and components

A technology of vacuum evaporation and air flow, which is applied in the direction of vacuum evaporation plating, ion implantation plating, metal material coating technology, etc., can solve the problems of complex structure control factors, waste of evaporation material process cost, long debugging process, etc. To achieve the uniformity of evaporation, shorten the distance of evaporation, and reduce the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

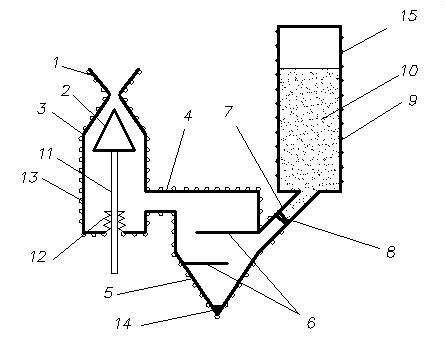

[0027] Example 1: see figure 1, the vacuum evaporation system that can control the distribution and composition of the evaporation airflow is composed of an evaporation gun (3), a high-temperature pipeline (4), a high-temperature evaporation crucible (5), a feeding valve (8) and a storage tank (9). The evaporation gun (3) has a spout (1) with upper and lower conical surfaces, and a movable airflow guide plug (2) is placed inside the spout (1), and is placed in front of the spout (1) to be evaporated. The substrate (16), the evaporation gun (3) is connected with the high-temperature evaporation crucible (5) with a cross baffle (6) through the heating pipe (4) or buffer bottle, and the other side of the crucible (5) passes The pipeline (7) equipped with the feeding valve (8) is connected to the storage tank (9). There are heating coils (13) on the outer wall of the evaporation gun (3), the heating pipeline (4), the high-temperature evaporation crucible (5) and the pipeline (7)...

Embodiment 2

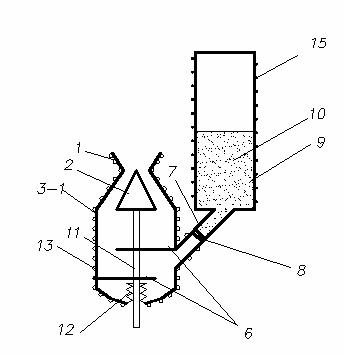

[0028] Example 2: see figure 2 , the vacuum evaporation system that can control the distribution and composition of the evaporation airflow is a simplified structure of embodiment 1. In this embodiment, the whole system is simplified as consisting of a high-temperature vacuum evaporation gun (3), a feeding valve (8) and a storage tank (9 )composition. The high-temperature vacuum evaporation gun (3) here combines the functions of the high-temperature vacuum evaporation gun (3), the high-temperature pipeline (4), and the high-temperature evaporation crucible (5) in Example 1. The vacuum evaporation gun here is used both as an evaporation gun and as an evaporation crucible. The high temperature vacuum evaporation gun is made of high temperature resistant materials such as molybdenum, tantalum, stainless steel and other materials. The up and down of the spout is all tapered such a spout itself has the function of divergence, and there is also a gas guide plug (12) below the spo...

Embodiment 3

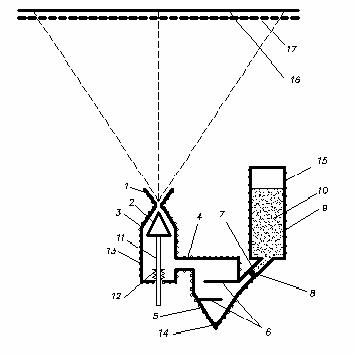

[0029] Embodiment 3: see image 3 , the vacuum evaporation system that can control the distribution and composition of the evaporating air flow is basically the same as that of Embodiment 1. The difference between this embodiment and Embodiment 1 is that there is a through-hole on the top of the high-temperature vacuum evaporation gun (3) in the entire system. A mask plate (17) and a substrate (16). It shows that due to the use of the high-temperature vacuum evaporation gun (3) of Example 1, a uniform vacuum evaporation gas flow can be obtained for the substrate directed upward by the high-temperature vacuum evaporation gun. Molecules of the evaporated gas basically move in a straight line, so even if the mask plate is not in close contact with the substrate, a better upward mask projection effect can still be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com