Coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction method and system

A technology of oxygen-enriched combustion and fluidized bed, which is applied in the field of boiler combustion, can solve the problems that power plants are difficult to bear economical decline, achieve the effects of reduced power, reduced recirculated flue gas volume, and improved economical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

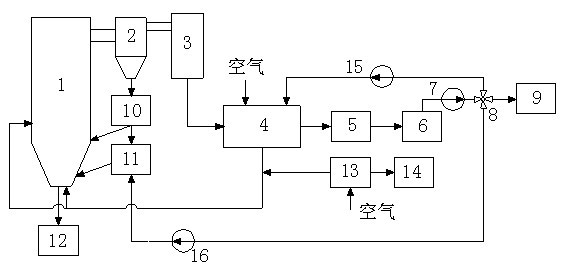

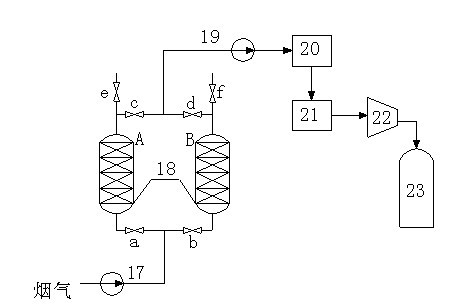

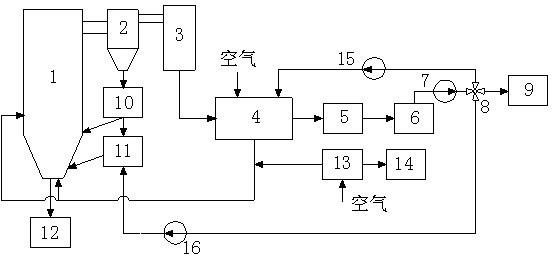

[0027] The method of the present invention combines micro-oxygen-enriched combustion in a coal-fired fluidized bed with physical adsorption to jointly form an industrialized coal-fired boiler CO 2 emission reduction technology. The micro-oxygen-enriched combustion of the coal-fired fluidized bed uses a mixture of air, oxygen and recirculated flue gas as a combustion aid. The oxygen content in the mixed gas is about 25%, and the recirculated flue gas content is 30%-40% %, the balance is air. In the micro-oxygen-enriched combustion mode, the CO in the flue gas is generated 2 The gas concentration is 30% to 40%, the CO in the flue gas 2 Physical adsorption technology is used for removal.

[0028] The coal-fired fluidized bed micro-oxygen-enriched combustion system of the present invention includes an air separation oxygen generator, an air supply device, a circulating fluidized bed device, a dust removal device and a CO 2 Recovery device, the above-mentioned device is describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com