Patents

Literature

89results about How to "Zero pollution discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

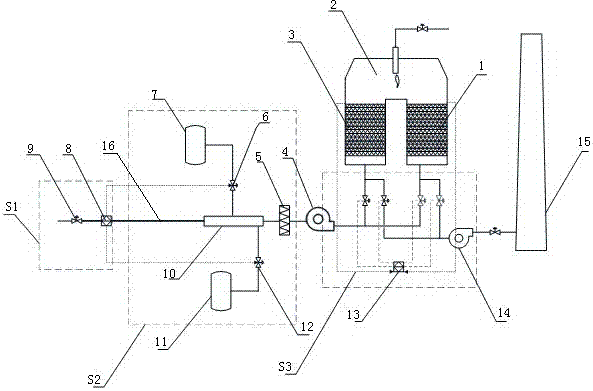

Coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction method and system

InactiveCN102425789ALow costZero pollution dischargeSolidificationFluidized bed combustionProcess engineeringPollution

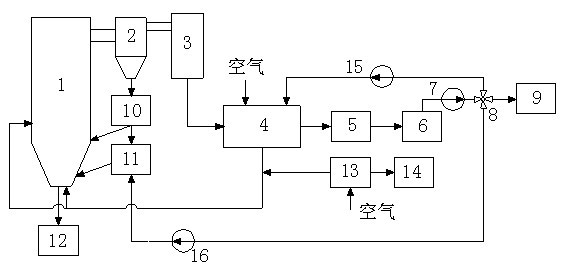

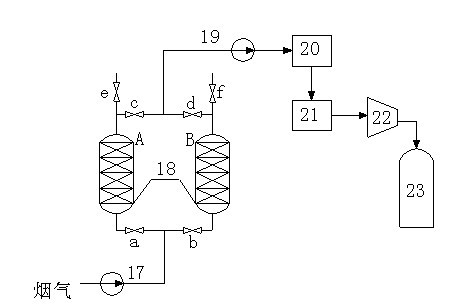

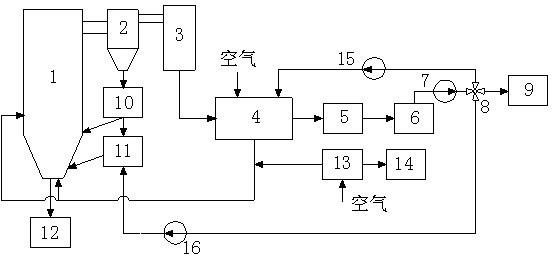

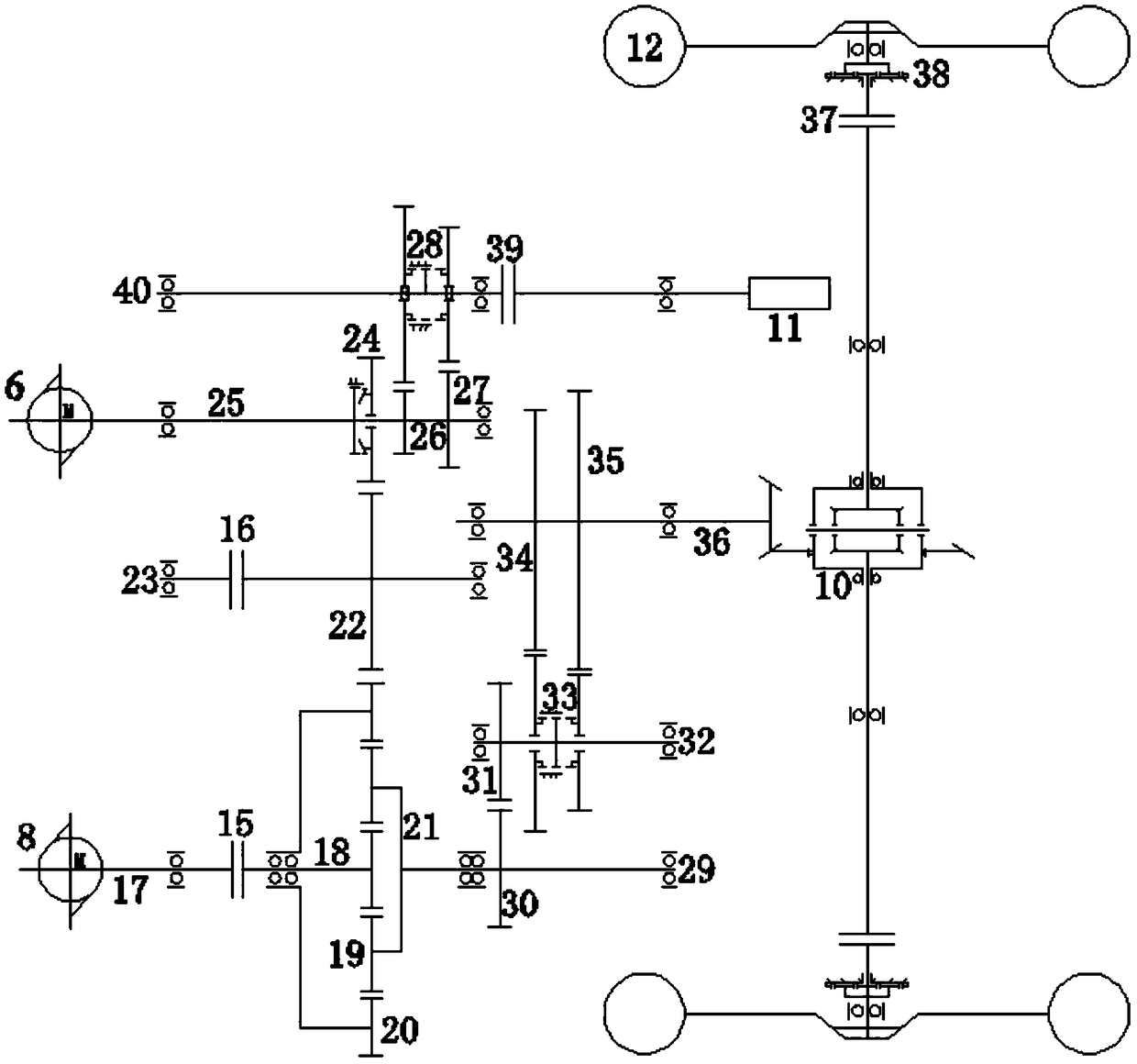

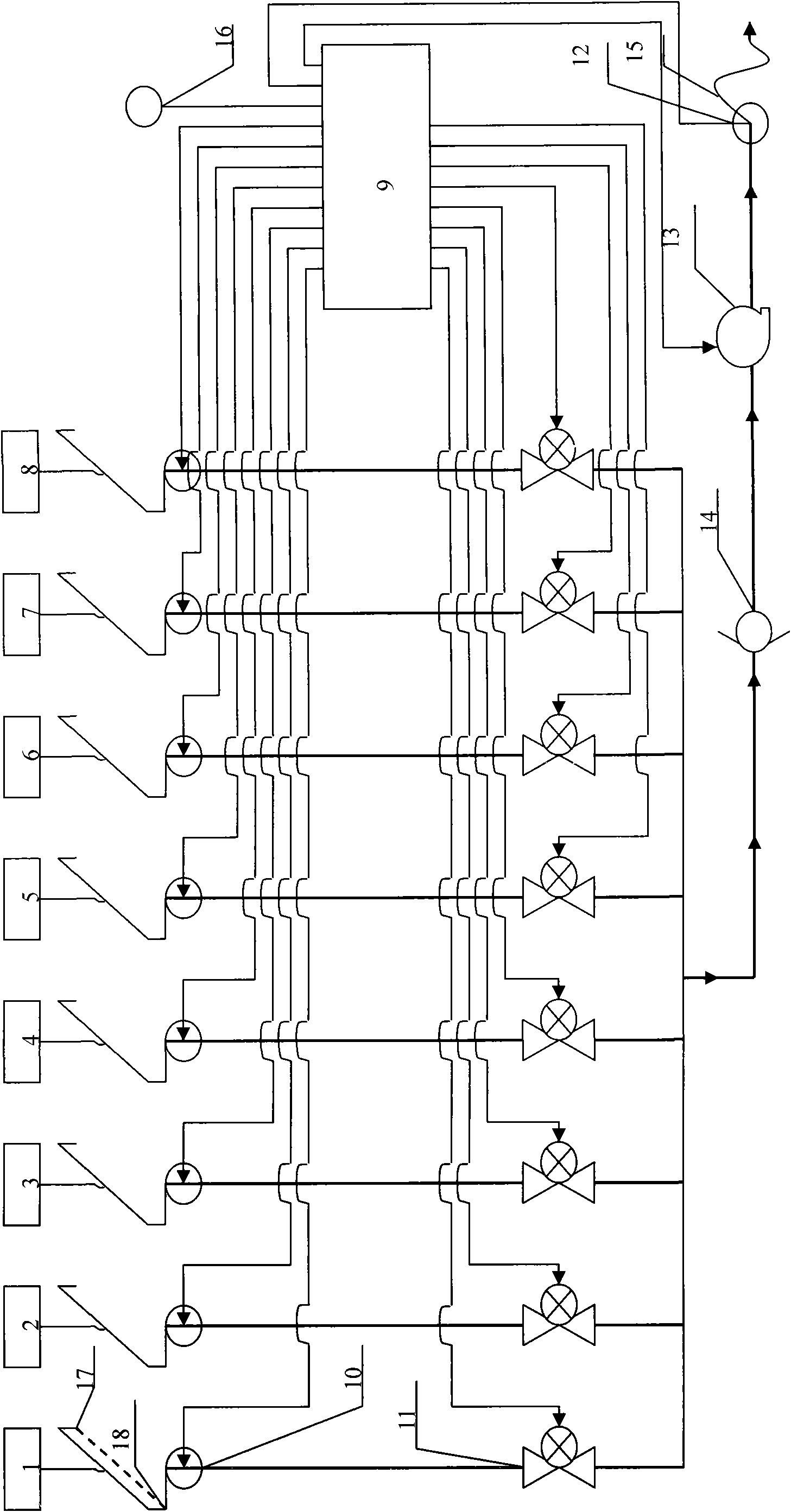

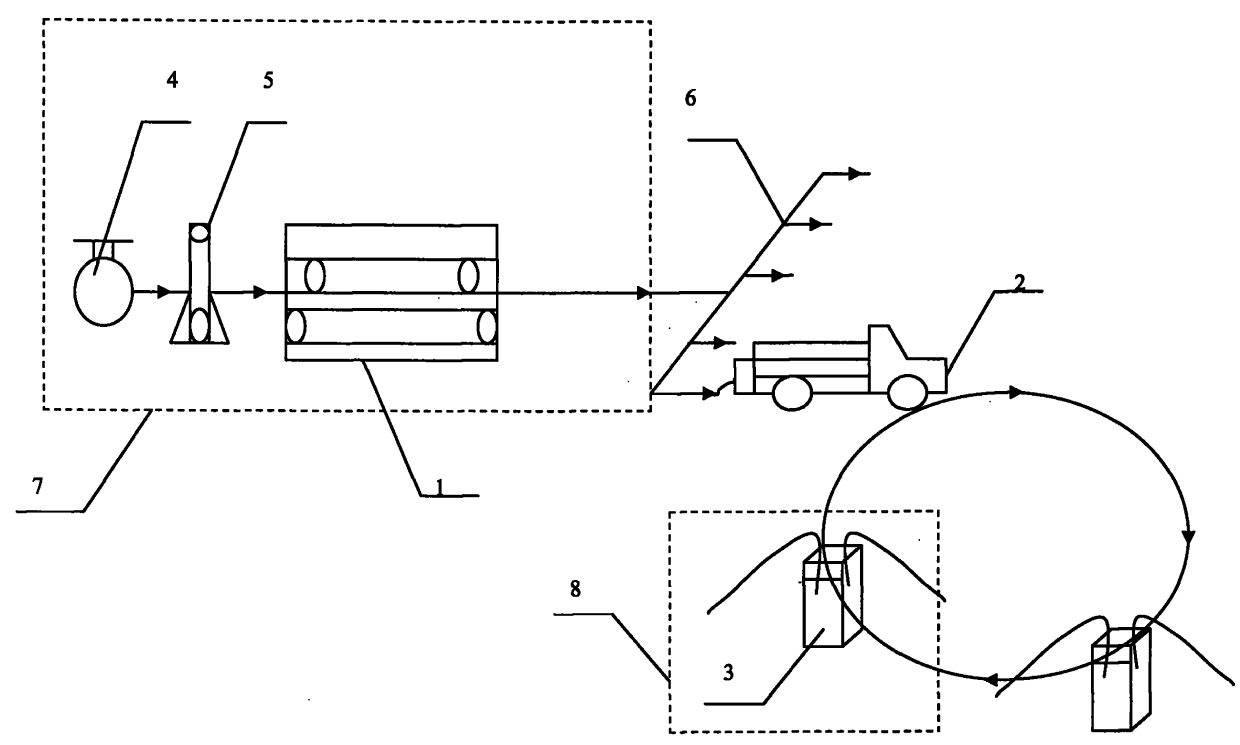

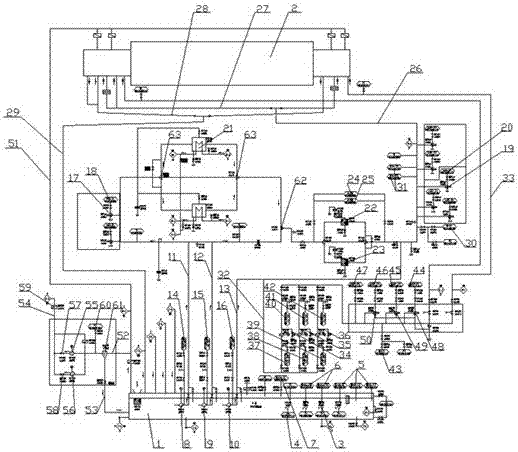

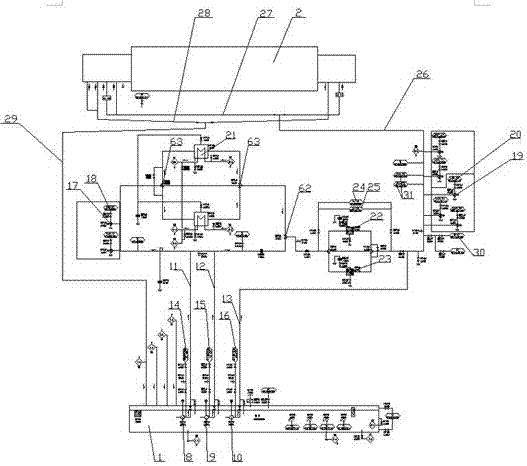

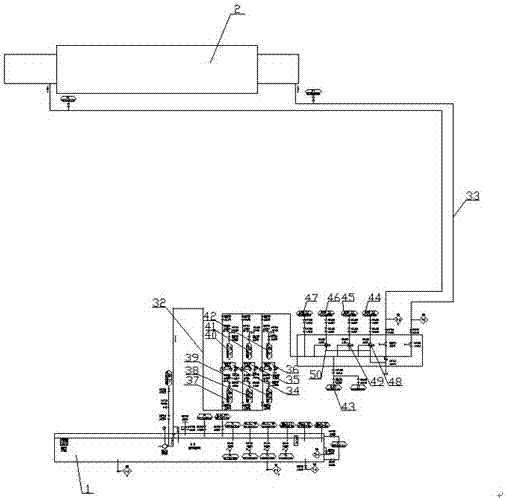

The invention discloses a coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction method and a coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction system for solving the problem of low-cost CO2 emission reduction of an industrialized coal-fired boiler. A micro oxygen rich combustion mode using mixed gas of air, oxygen and recycled smoke as a combustion aid is adopted, wherein the mixed gas contains about 25 percent of oxygen, 30 to 40 percent of recycled smoke and the balance of air; and in the micro oxygen rich combustion mode, the concentration of the CO2 gas in the generated smoke is 30 to 40 percent, and the CO2 in the smoke is removed by adopting a physical adsorption technology. The invention also provides a system device for implementing the method. By considering oxygen making cost, energy consumption and optimal comprehensive effect of separating CO2 by physical adsorption and combining the micro oxygen rich concept and the circulating fluidized bed combustion technology, desulfuration, denitration, decarburization and zero pollution emission at lower cost can be realized. The invention has the advantages of good economic efficiency, simple process, low energy consumption, high automation degree in operation process and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

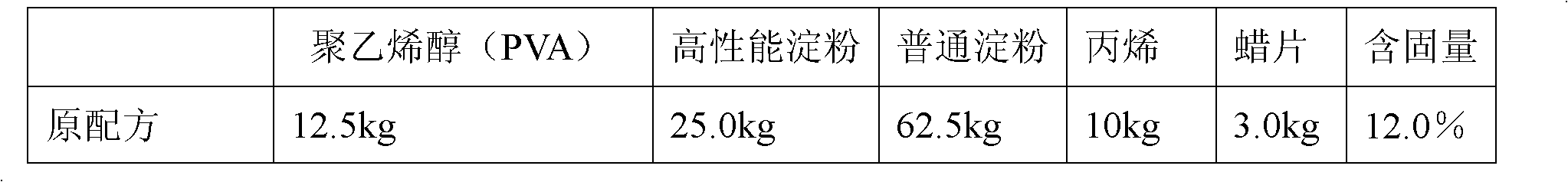

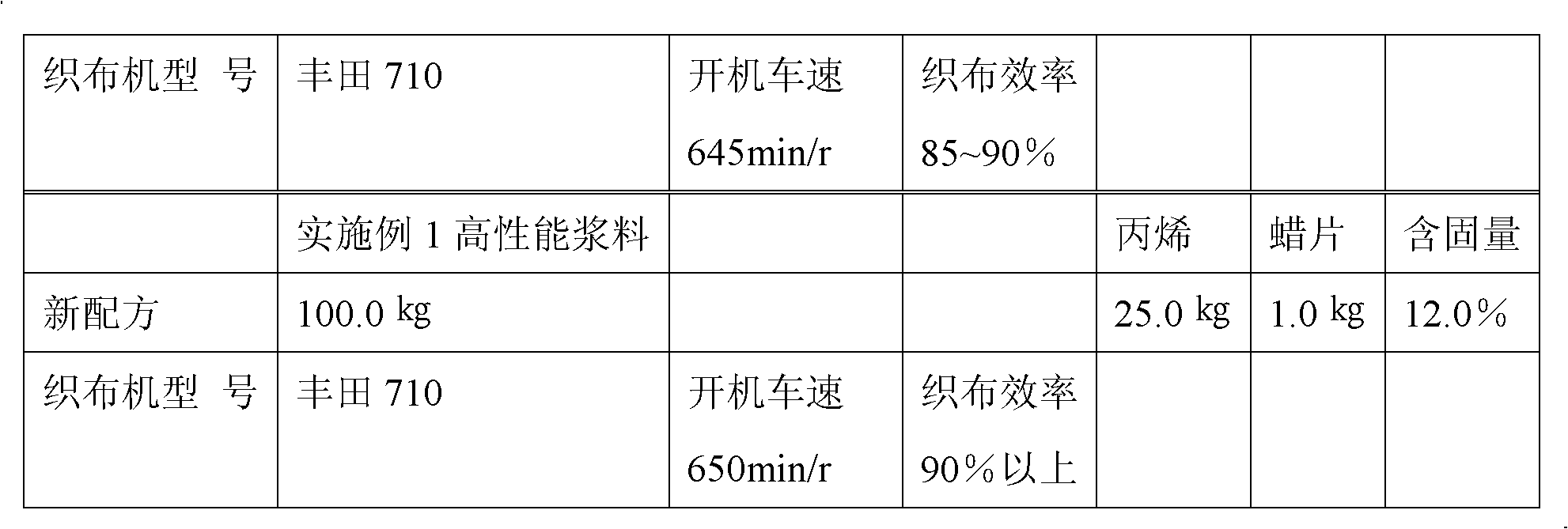

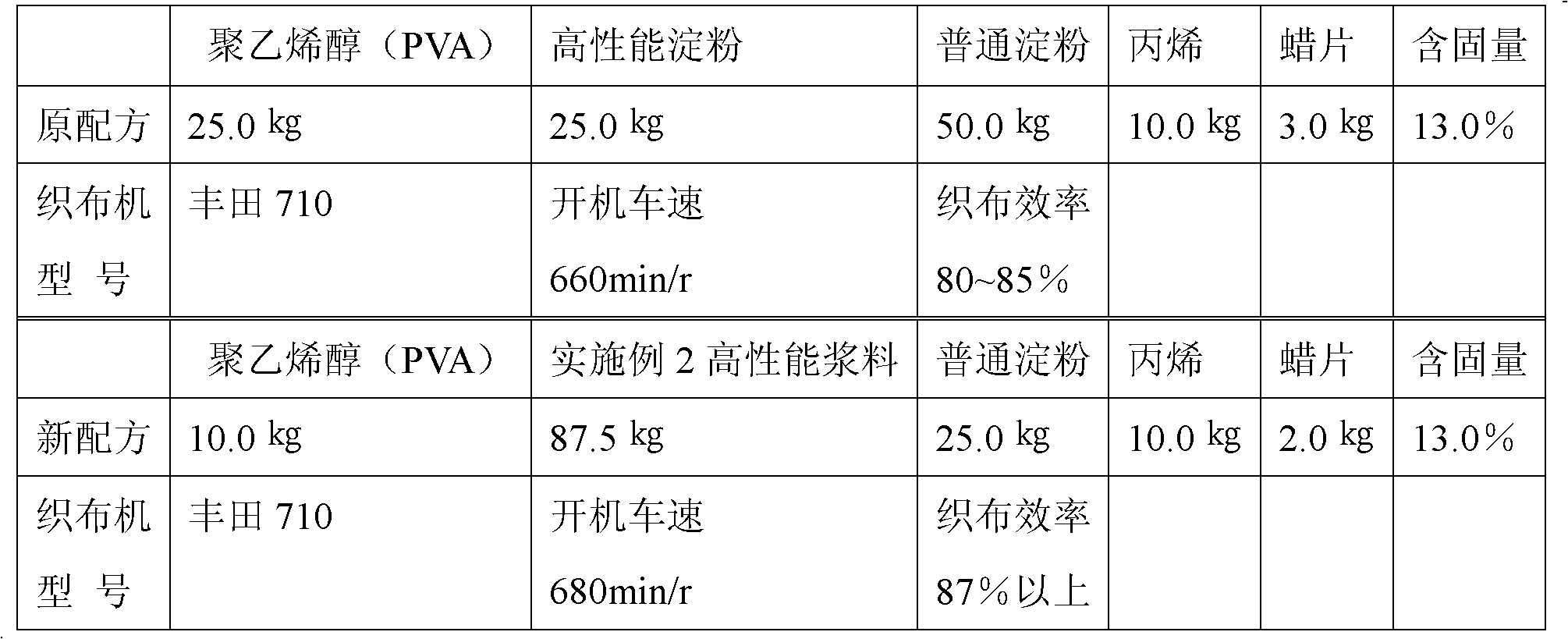

Multi-component high-performance sizing agent

The invention discloses a multi-component high-performance sizing agent. The sizing agent is prepared from various raw materials by a mixing reaction, wherein the raw materials comprise corn starch, phosphate, tween, persulfate, and at least one of phosphorus oxychloride and epoxy chloropropane. The sizing agent has the characteristics that the adhesion force is high, the film-forming ability is high, a serous film is coriaceous, the elasticity is high, the bending resistance (fatigue resistance) is improved by 3 to 4 times compared with a common modified starch sizing agent, and the abrasion resistance and the ageing resistance are high. The serous liquid is not frozen, caked or layered at normal temperature, and has high liquidity and stable viscosity. The sizing agent has no polyvinyl alcohol; when the sizing agent is sized on spinning cotton yarns; for the variety with general tightness, the polyvinyl alcohol does not need to be used for less than 50 yarns; or no or less polyvinyl alcohol is used for sizing on polyester cotton or over 50 cotton yarns; the yarns are easy to desize; the serous liquid waste water is easy to treat; the environment pollution is low; and the production process has zero pollution emissions.

Owner:YIXING JUNDA SLURRY TECH

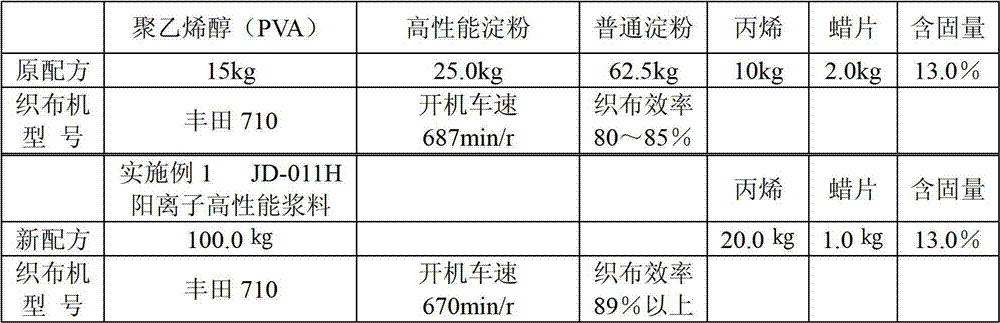

Cation high-performance size

The invention discloses cation high-performance size which is made from the following raw materials: corn starch, hydroxides, trimethylamine hydrochloride and persulfate through a hybrid reaction, wherein corn starch accounts for 80%-95% by weight, calcium hydroxide and / or magnesium hydroxide account(s) for 1%-10% by weight, trimethylamine hydrochloride accounts for 1%-15% by weight, and persulfate accounts for 0.1%-15% by weight. The cation high-performance size has the advantages of strong adhesive ability, good film forming property, tough size film, and excellent elasticity; the flexibility (fatigue endurance) is improved by 3-4 times in comparison with common modified starch size; the cation high-performance size is excellent in wear-resisting and anti-aging properties; and the size has good flowability under the condition of normal temperature, and is stable in viscosity. Polyvinyl alcohol is not used. When pure cotton yarns are sized during spinning, 60-count yarns of common tightness do not need polyvinyl alcohol, and when polyester or pure cotton yarns higher than 60-count are sized, no polyvinyl alcohol is needed or only a small amount of polyvinyl alcohol is needed, so that desizing is easy, the size waste is easy to process and causes small pollution to the environment; and zero pollution emission is realized in a production process.

Owner:YIXING JUNDA SLURRY TECH

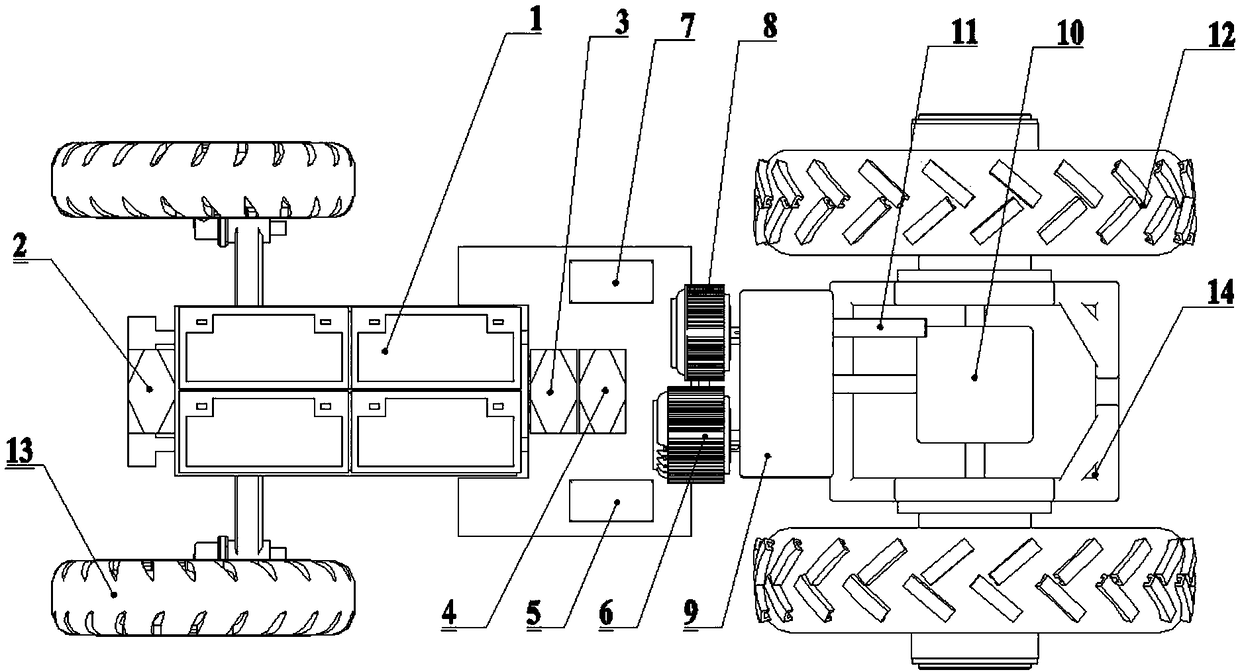

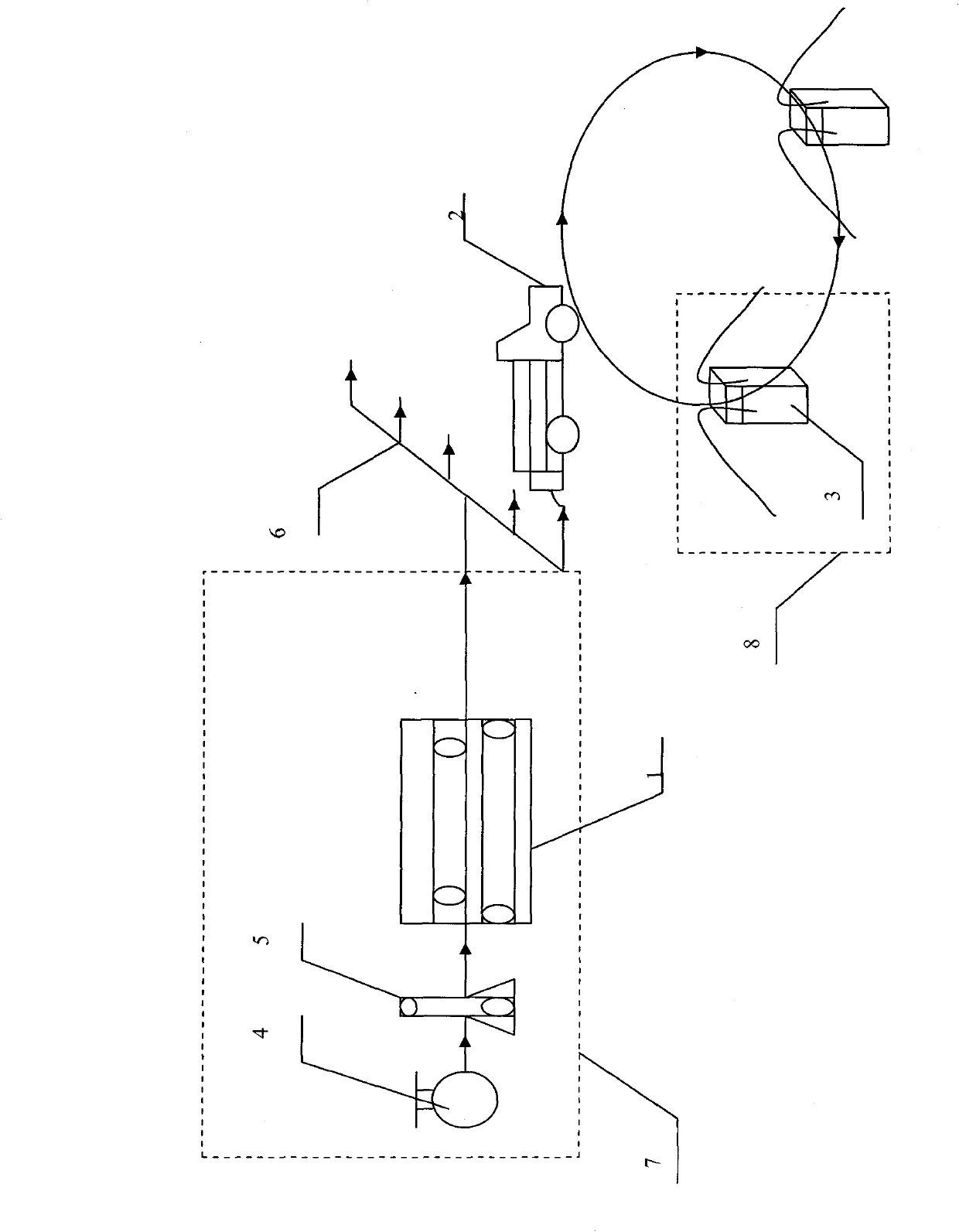

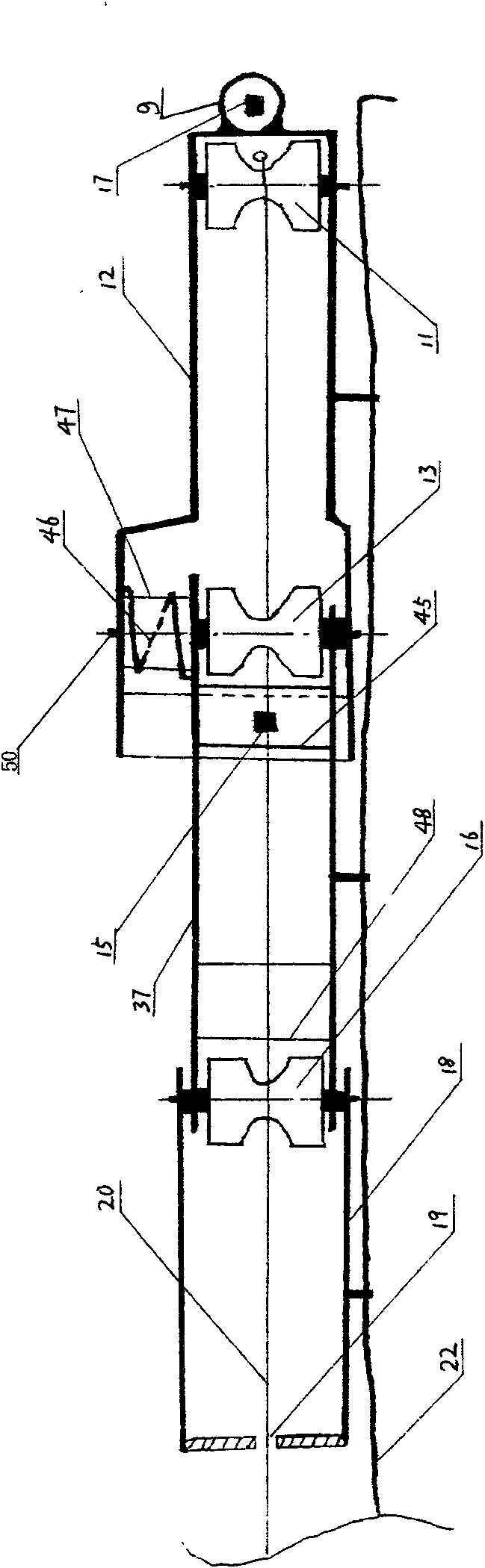

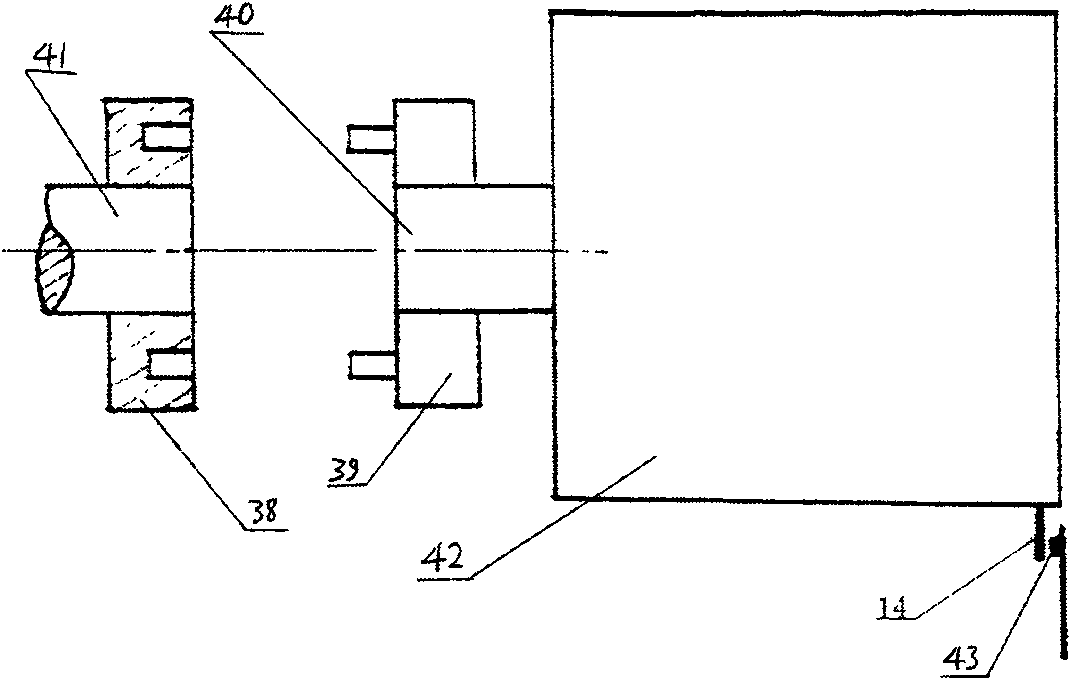

Double-motor coupling driving electric tractor and control method thereof

ActiveCN109466340AZero pollution dischargeMeet environmental requirementsSpeed controllerElectric devicesTractorDrive wheel

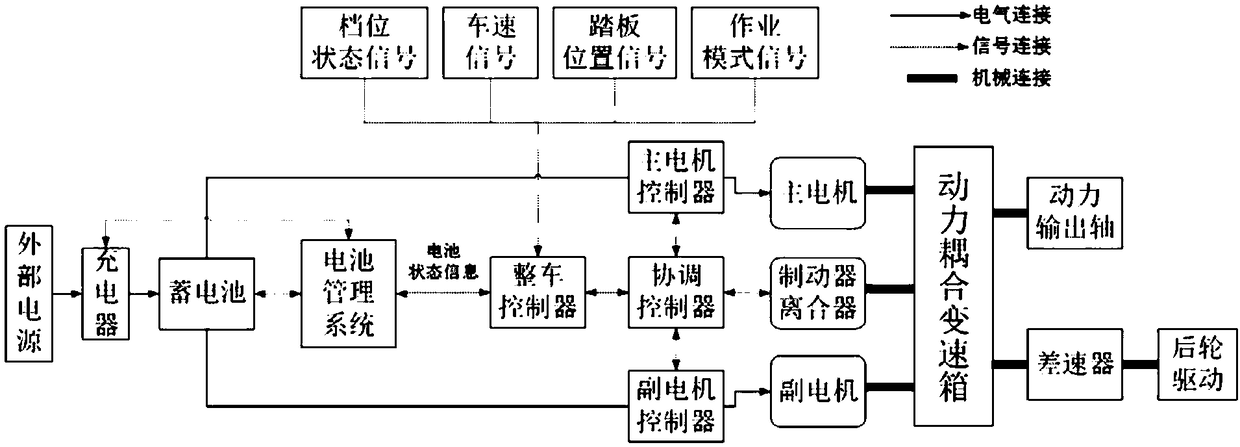

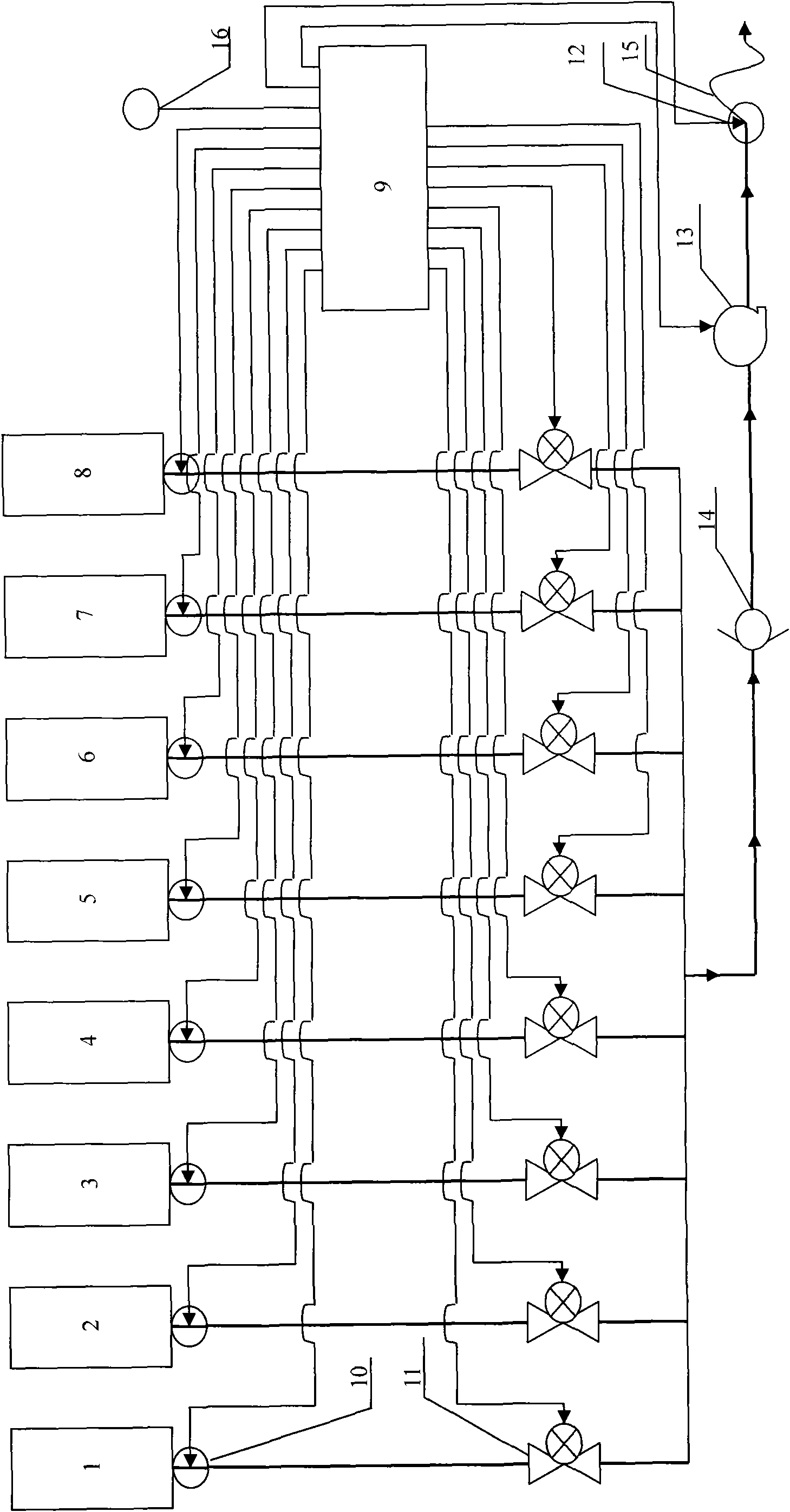

The invention discloses a double-motor coupling driving electric tractor and a control method thereof. The tractor comprises a storage battery pack 1, a battery management system 2, a whole vehicle controller 3, a coordinating controller 4, a main motor controller 5, a main motor 6, an auxiliary motor controller 7, an auxiliary motor 8, a power coupling gearbox 9, a differential mechanism 10, a power output shaft 11, driving wheels 12, a steering wheel 13 and a frame 14, wherein the main motor 6 and the auxiliary motor 8 are arranged at the input end of the power coupling gearbox 9, the outputend of the power coupling gearbox 9 has two paths of power output, and one path of power is output to the differential mechanism 10 and then transmitted to the two driving wheels 12 to drive the electric tractor to run; the other path of power is output to the power output shaft 11 to drive the electric tractor PTO to work. The electric tractor can achieve zero-pollution discharge and meet the power requirements of different operation loads under different working conditions, the working efficiency of a driving system is improved, and the cruising ability is enhanced.

Owner:洛阳勇鑫精工制造有限公司

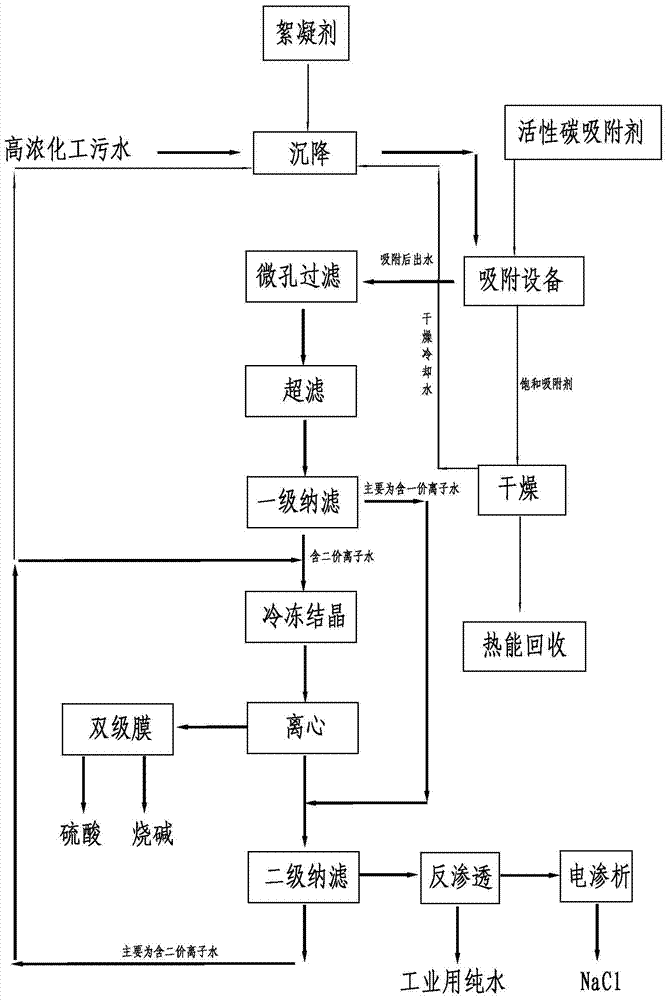

Comprehensive treatment process of waste water high in concentration and high in salinity

ActiveCN105016530AEasy to getEasy to operateMultistage water/sewage treatmentAlkali metal chloridesFiltrationReverse osmosis

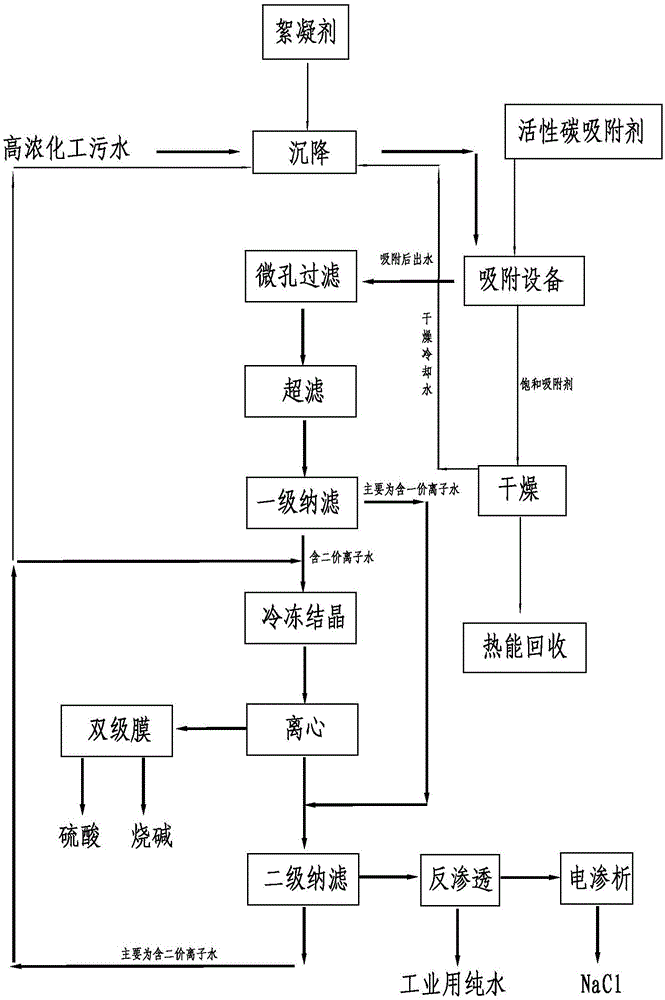

The invention relates to a comprehensive treatment process of waste water high in concentration and high in salinity. The process comprises the steps of centralizing the waste water, adding organic flocculant, and sedimentating large particle impurities and a large proportion of suspended matters and floating objects; adding activated carbon absorbent for absorbing organic matters; conducting filtration, removing granular impurities, colloidal substances and suspended matters in water, and then separating monovalent ions and divalent ions in the waste water through first-grade nanofiltration; making water containing the monovalent ions to be subjected to reverse osmosis, and obtaining pure water which can be used as industrial water; making concentrated water to be subjected to electrodialysis for concentrating monovalent salt, and obtaining NaCl accessory substances; making water containing the divalent ions to be subjected to freezing crystallization, conducting the centrifugation, making crystal body sections to be subjected to two-stage membrane electrodialysis, obtaining acid-alkali products, and making a water layer to be subjected to nanofiltration treatment; making the saturated absorbent which absorbs the organic matters to be subjected to dewatering and drying, and conducting the recycling. According to the comprehensive treatment process of the waste water high in concentration and high in salinity, the cost is low, the organic matters and inorganic salt in the waste water can be removed simultaneously and then utilized, energy is saved, and the environment is protected.

Owner:沧州绿源水处理有限公司

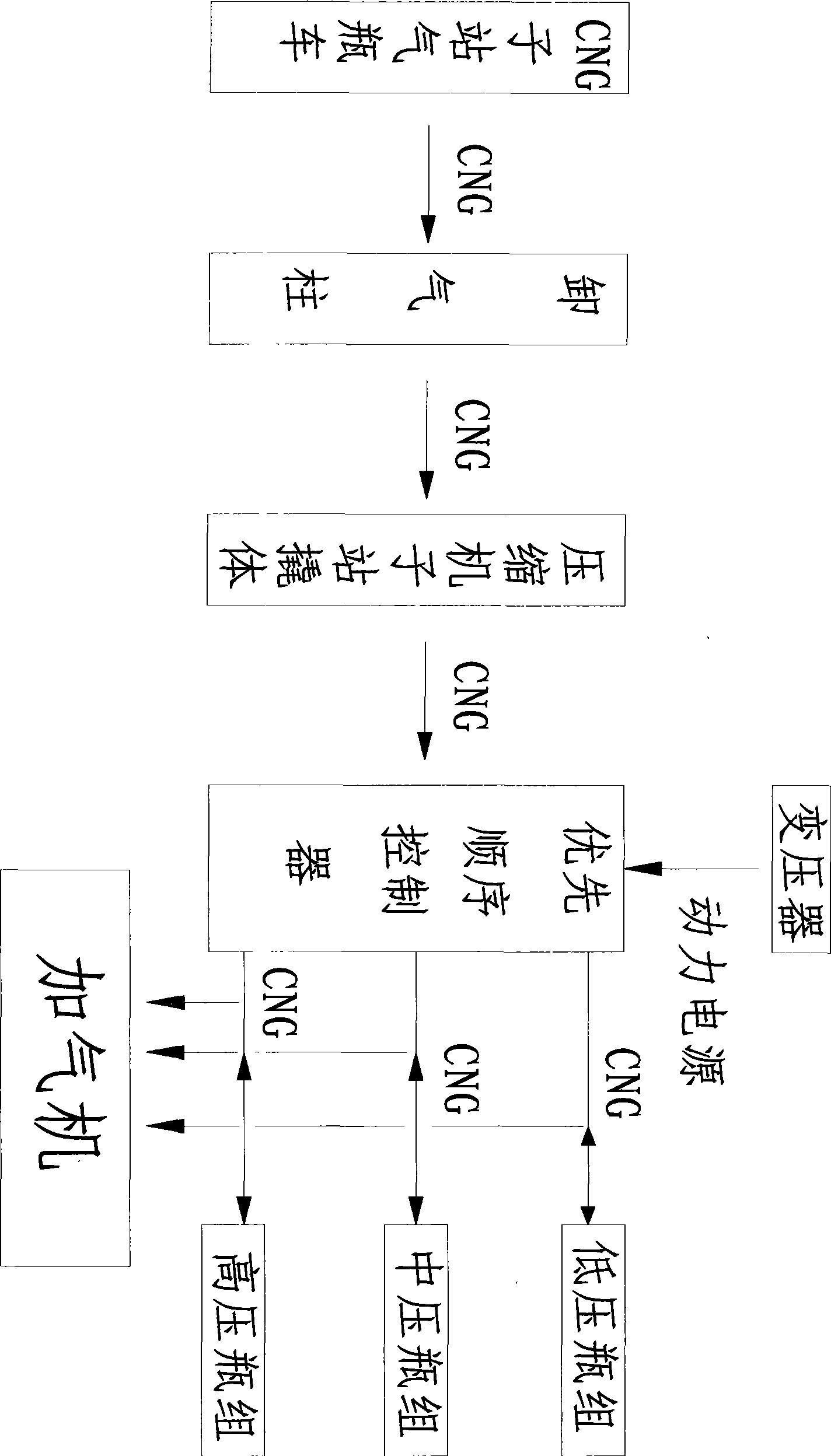

Gas dispenser and gas station composed of the same

ActiveCN101566277ASimple structureVersatileVessel mounting detailsFluid transferredGas cylinderMechanical wear

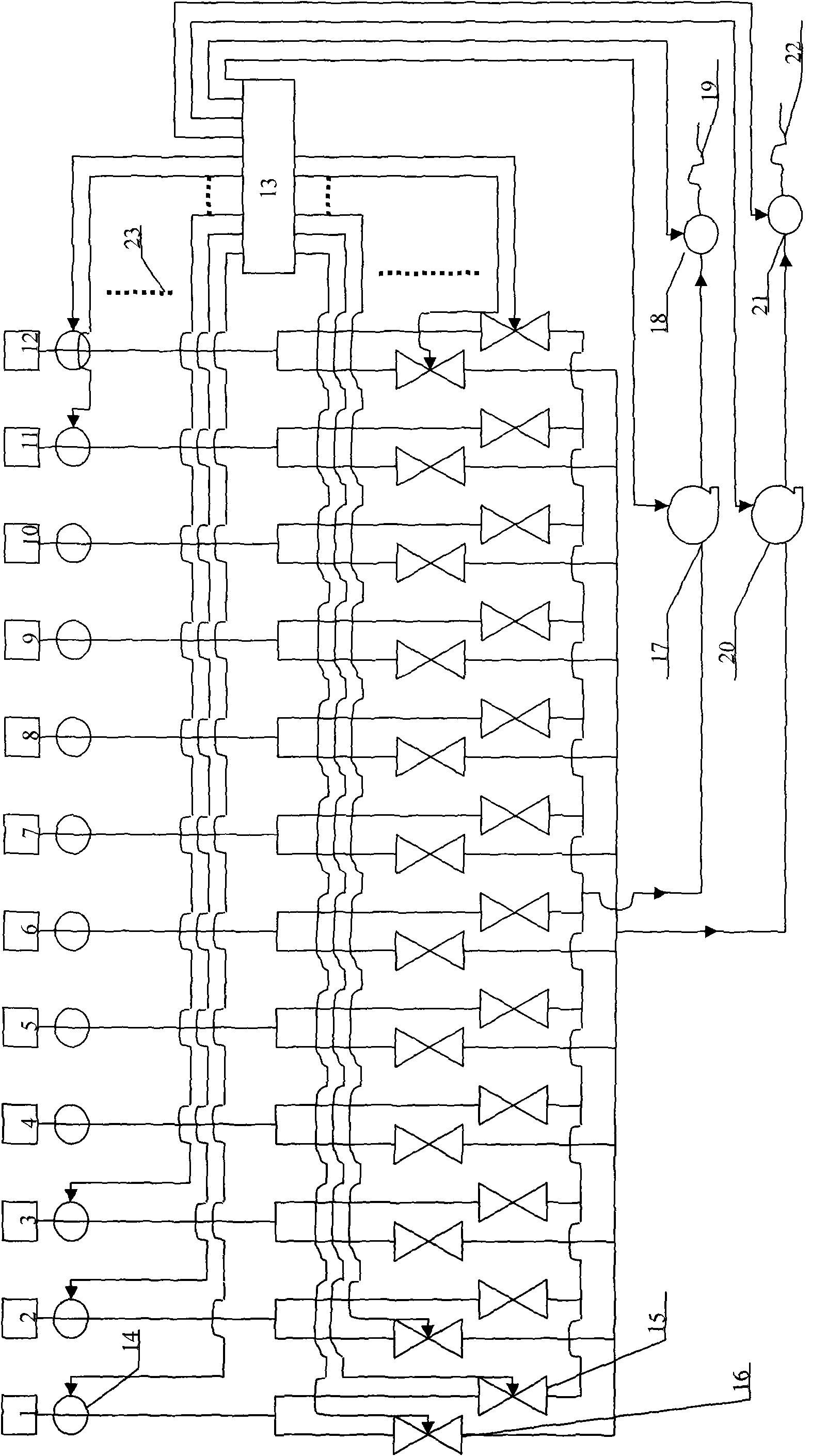

A gas dispenser is technically characterized in that a PLC firstly collects the pressure value of a pressure sensor in a gas dispersion gun, namely the pressure value in a vehicular gas cylinder. Then the pressure value is added with a preset value, wherein 0<the preset value <20. The summation is compared with the pressure value of each pressure sensor under a plurality of gas cylinder openings. The valve corresponding with the pressure value which is most approximative to and larger than the summation is opened for dispensing the gas through pressure difference. The steps are adopted again before balancing or after balancing. The steps are repeated until the value of the pressure sensor in the gas dispersion gun is the rated pressure value of the vehicular gas cylinder, wherein the rated pressure value is smaller than or equal to 20MPa. Then the valve is closed and the gas dispensation is finished. The gas station of the invention is composed of a plurality of gas cylinders and gas dispensers. The gas station is technically characterized in that the plurality of gas cylinders are used circularly for providing the high-pressure gas for satisfying the using amount of continuous gas dispensation of a single gun or a plurality of guns to the vehicular gas cylinder. The invention changes the technical route of prior gas substation. The matching of large-scale power devices of compressor and hydraulic pump is not required. The gas dispenser has no mechanical wear and extraordinarily low current consumption. The gas dispenser of the invention is the developing direction of the future.

Owner:沈军

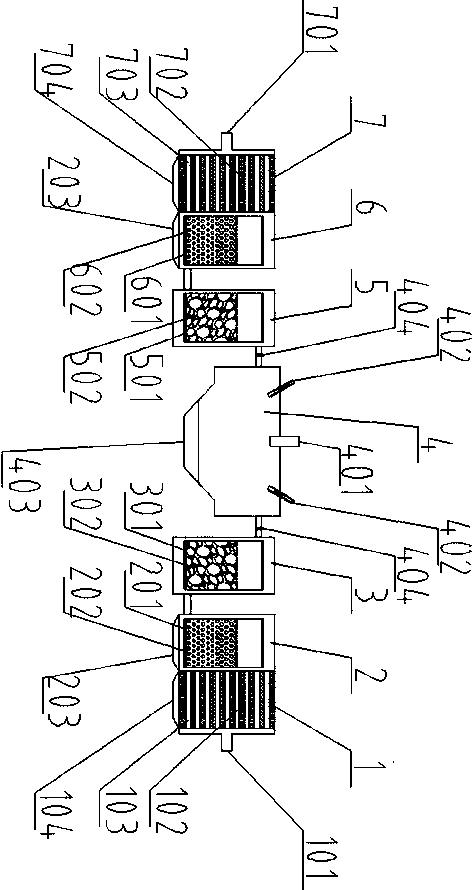

Automatic spheroidization device for producing spherical graphite

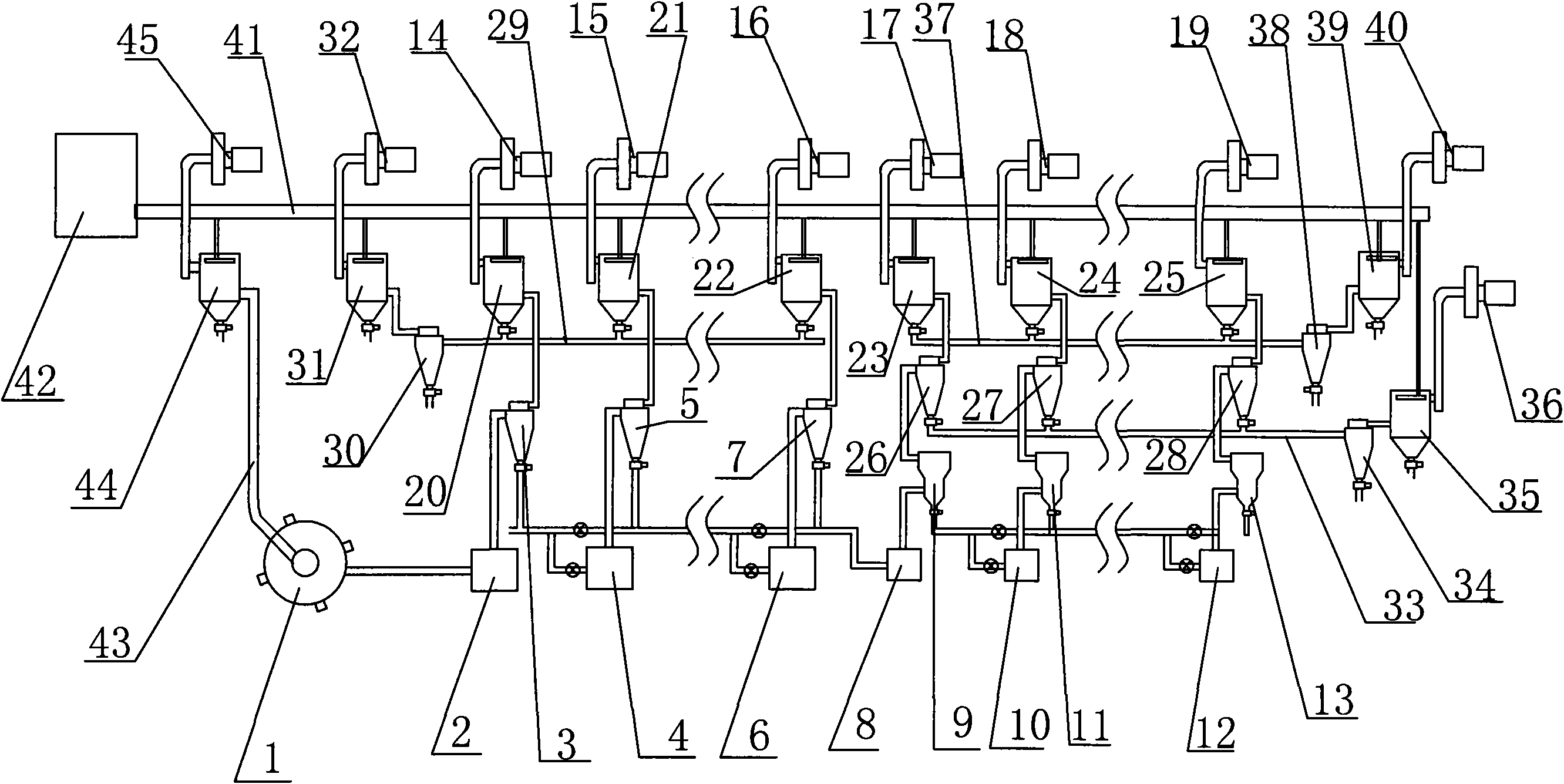

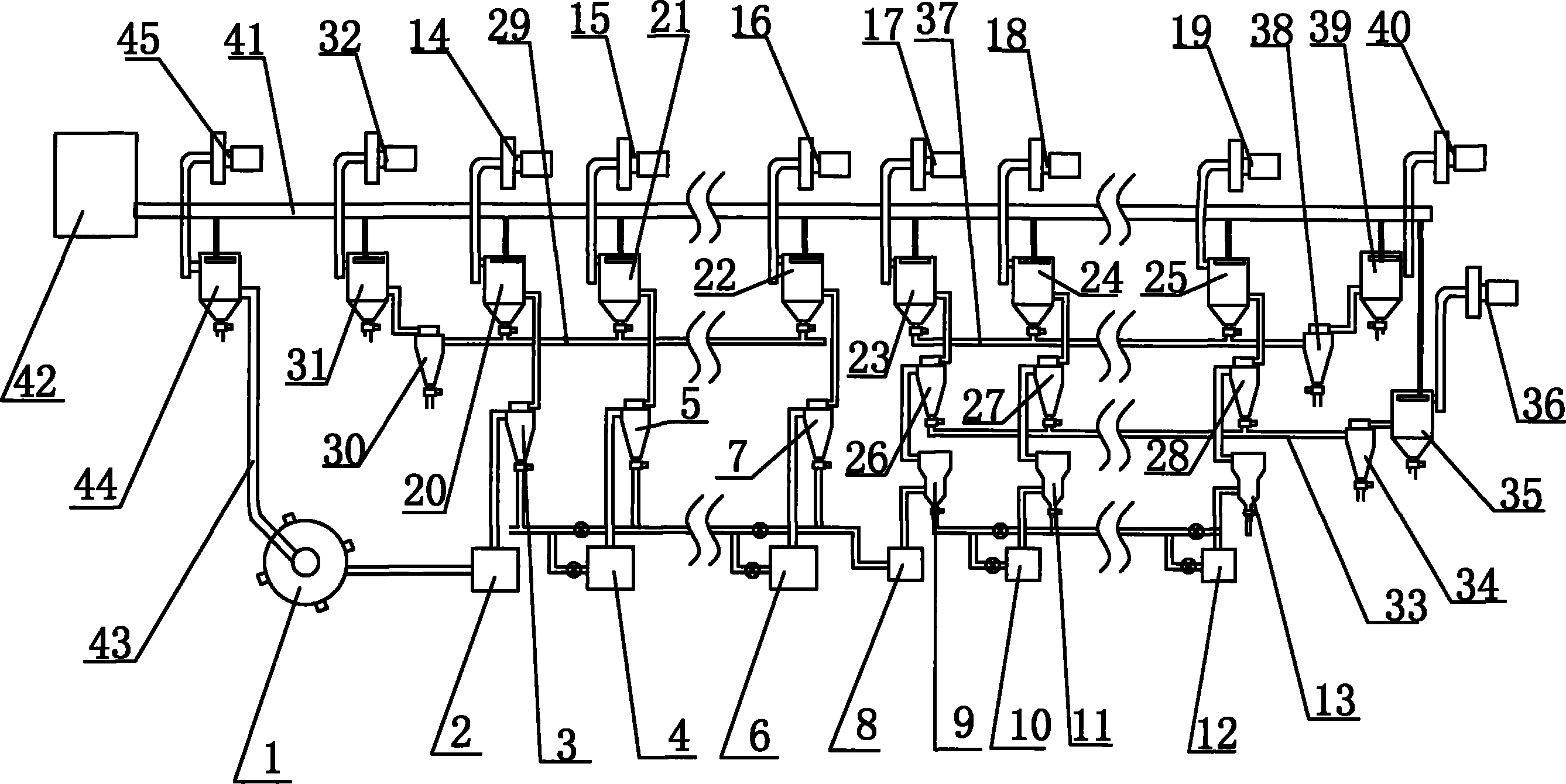

The invention discloses an automatic spheroidization device for producing spherical graphite, which mainly comprises an automatic material supply device, a powder system, a spheroidization system, a dust recovery system and a material collection system, wherein materials enter the powder system from the automatic material supply device and after being processed, and enter the spheroidization system and the material collection system in turn; the whole process is carried out in a sealed pipe in sequence; a vacuum exhaust fan is used for providing power; and in a production process, the efficiency is high and no pollution is generated. The device can realize the fully-automatic control in a whole process from material supply to powder making to spheroidization to separation to product recovery to dust recovery; the prepared graphite powder is spherical material; the surface of the graphite powder has openings; the values, which are preset before production, of the tap density, specific surface area and size distribution can be achieved; the product quality is stable; the yield can be improved by more than three times; over 40 percent of energy can be saved; over 60 percent of cost can be saved; and dust leakage and high noise are prevented.

Owner:LUOYANG GUANQI INDAL & TRADE

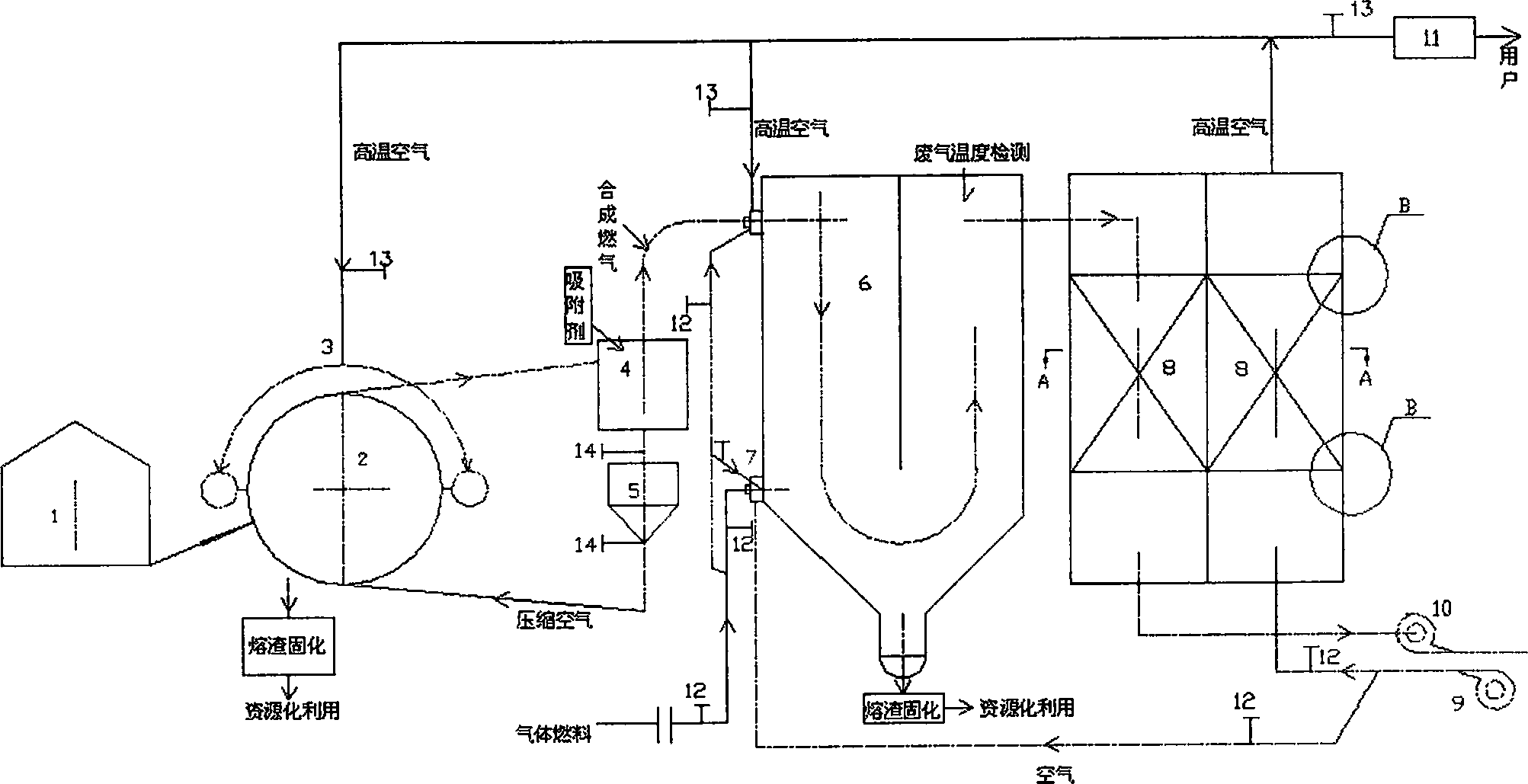

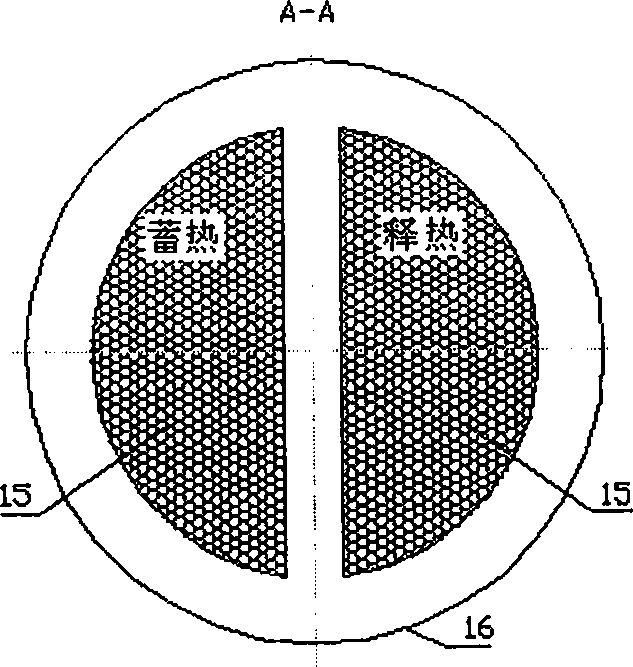

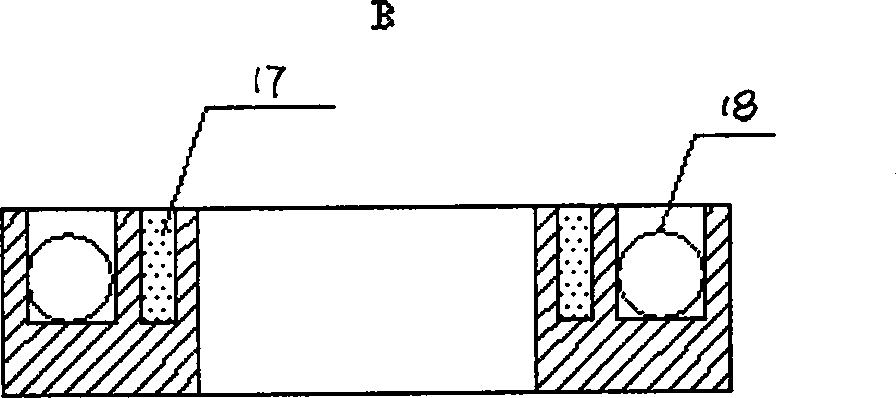

Incineration treating method and system for gasifying and melting domestic waste from city

The present invention provides an urban house refuse gasification melting incineration treatment method and its equipment. It is characterized by that the high-temperature air obtained from waste heat of smoke produced by recovering, gasifying, melting and incinerating refuse can be introduced into gasifying furnace and incinerator furnace, and can be used as air required for refuse gasification and combustion-supporting air required for melting and incinerating refuse, so that it can ensure refuse stable gasification and complete combustion, and can completely solve dioxine and secondary pollution of heavy metals and others. Said treatment equipment system is formed from storage bin, gasifying furnace, dust-collecting device, incinerator furnace and high-effective heat storage chamber, etc.

Owner:CHONGQING UNIV +1

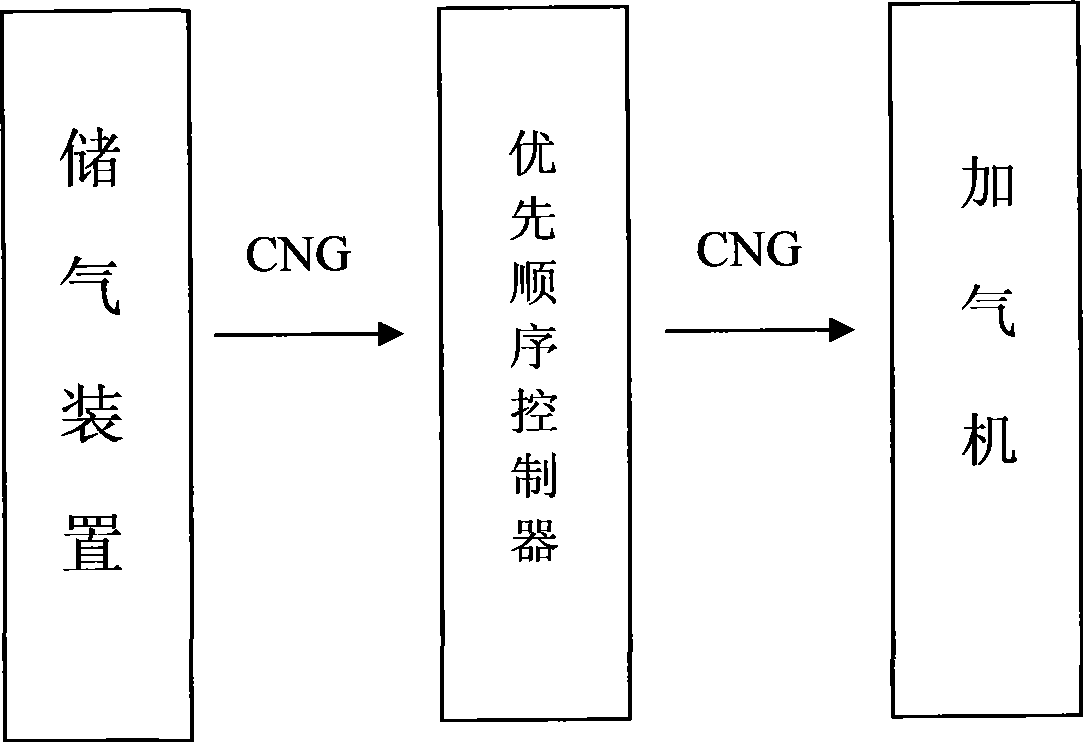

Secondary gas filling station

InactiveCN101509599ASimple structureSave peopleVessel mounting detailsFluid transferredCompressed natural gasGas cylinder

The invention relates to a brand-new branch gas station, only consisting of a gas adding machine, a priority sequence controller and a plurality of gas storage devices. The branch gas station has the technical characteristics that each gas storage device is composed of a plurality of gas tanks which are filled with high pressure compressed natural gas (CNG) of 25 MPa, the gas storage devices alternatively and cyclically provide high pressure CNG to form alternate recycle high pressure technology, solving the problem that the gas storage devices need a compressor or a hydraulic pump sell the remaining gas by pressurization, saving the massive equipment investment such as compressor, hydraulic pump, intra-station gas tank group and the like and easily standardizing the three major components: the gas adding machine, the priority sequence controller and the gas storage devices, being free from daily consumption such as power supply, mechanical wear and the like; in addition, the branch gas station is matched with a major gas station and pursues the technical road featuring L-CNG and is easily and rapidly replicated in cities throughout the country, thus enjoying the possibility of changing the backward situation at home where for the past dozens of years, CNG stations are hard to be integrated into a complete sales network.

Owner:沈军

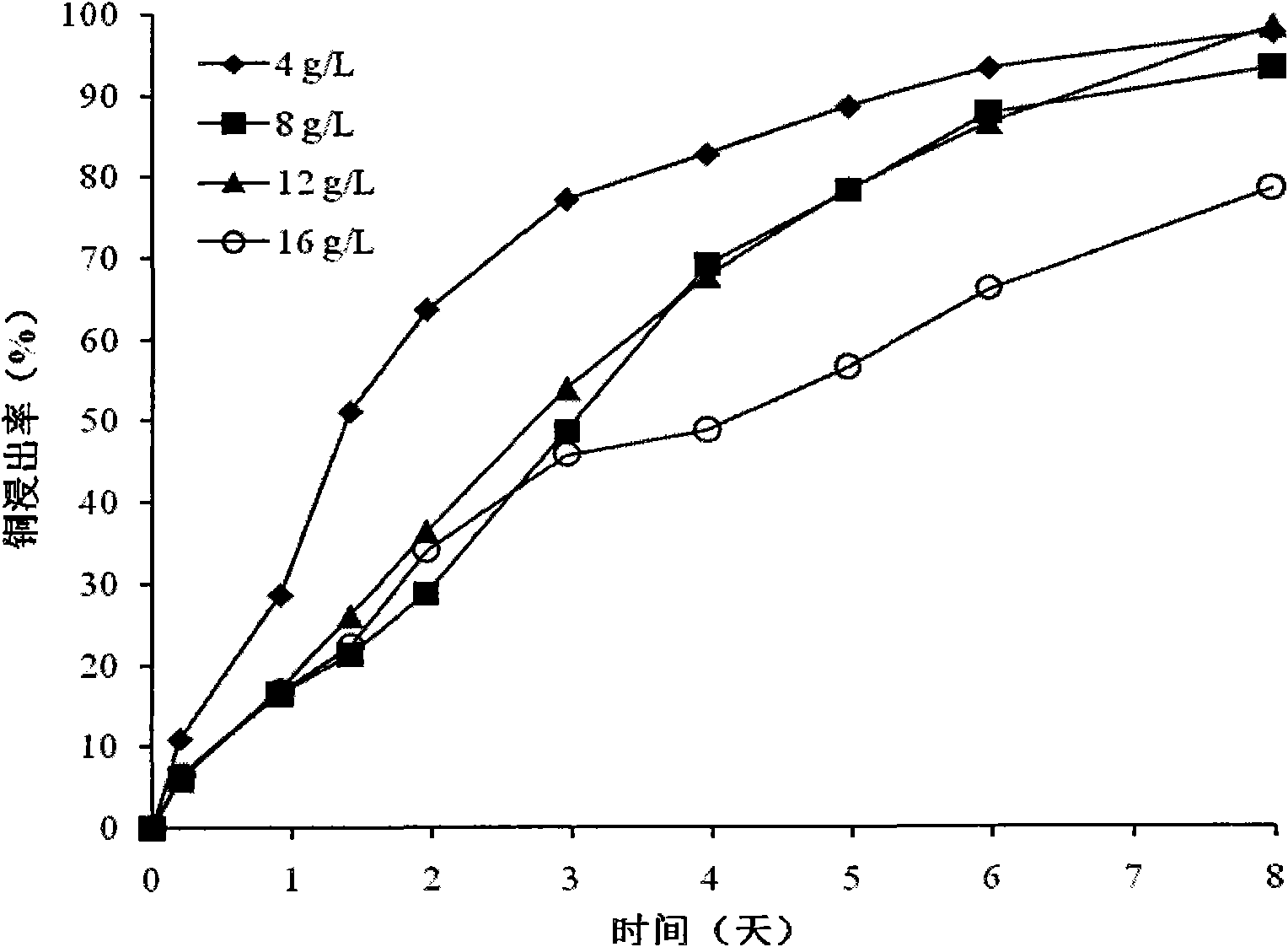

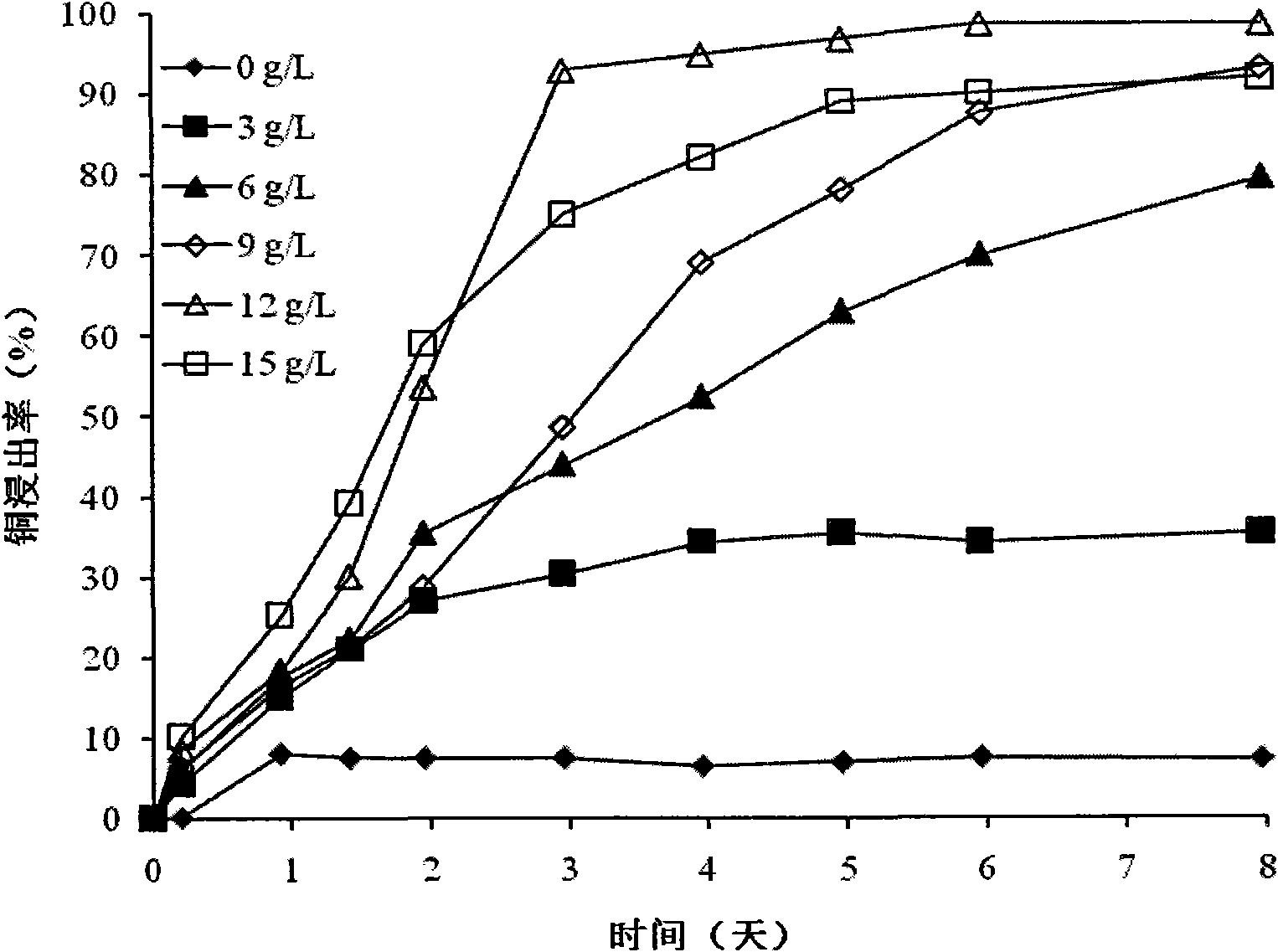

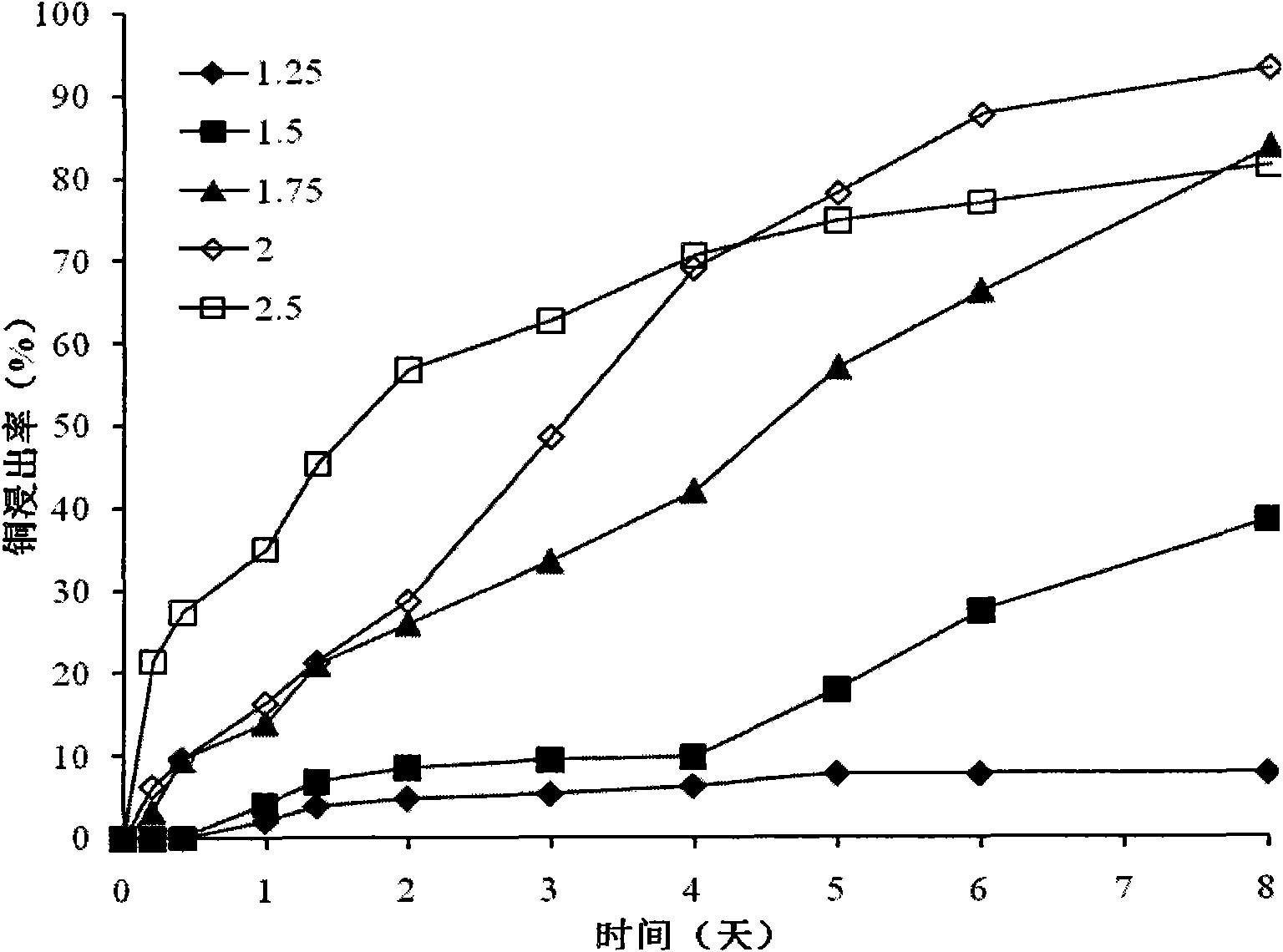

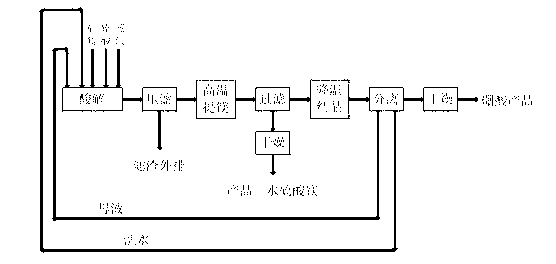

Method for leaching valuable metals in waste circuit board by acidophilic bacteria mixed culture

InactiveCN101962712AEliminate Growth Inhibitory FactorsHigh recovery rateProcess efficiency improvementPregnant leach solutionMixed culture

The invention discloses a method for leaching valuable metals in a waste circuit board by acidophilic bacteria mixed culture, comprising steps of: (1) preparing metal concentrate powders from the waste circuit board; (2) preparing the acidophilic bacteria mixed culture: collecting acid mine drainage from a sulfide ore mine, inoculating the pit water to 9K culture medium according to the inoculation amount of 5-40% by volume, culturing the culture medium in shaking conditions until a large number of reddish-brown precipitates are produced, filtering the solution and obtaining the acidophilic bacteria mixed culture; (3) leaching metals in the metal concentrate powders by the acidophilic bacteria mixed culture. The method of the invention has the advantages of high target metal recovery, low energy consumption, improves the leaching yield of copper by 98% or more during 2 days and the leaching yield of zinc and aluminum by 90% or more during 4 days, simplifies the treatment process and reduces the cost without separating and purifying microbial strains, can recycle the leach liquor repeatedly and substantially realizes zero-pollution emission.

Owner:SOUTH CHINA UNIV OF TECH

Bovine feces three-stage treatment process

InactiveCN101456763AImprove breathabilityFast heatingBio-organic fraction processingWaste based fuelLiquid storage tankSlurry

The invention relates to three-section treatment technology for cow manure, which comprises: adding straw powder which accounts for 0.5 to 2 times of the total volume of the cow manure into the cow manure, performing aerobic fermentation and temperature rise treatment on mixed raw materials of the cow manure and straws, and sending the mixed raw materials into an anaerobic reactor through a loading machine; uniformly spraying biogas slurry to the fermented raw materials in the anaerobic reactor for a few times, adjusting the water content of the fermented raw materials to be between 75 and 80 percent, and performing anaerobic fermentation treatment for a period; making biogas slurry generated by anaerobic fermentation flow to a liquid storage tank, using the biogas slurry for recycled spraying, and making biogas generated by the reactor pass through a biogas cooling and purification system and enter a gas storage device; performing aerobic fermentation treatment on fermented residue after anaerobic fermentation is over, stopping aerobic fermentation when the water content of the fermented residue is reduced to be between 30 and 40 percent, and drying the fermented residue to make the water content of the fermented residue reduced to be between 25 and 10 percent; and sending the fermented residue into a crusher, crushing the fermented residue into particles to prepare an organic fertilizer, and packaging the organic fertilizer for standby. The technology has reasonable design and low cost.

Owner:HEILONGJIANG LONGNENG WEIYE ENVIRONMENT TECH CO LTD

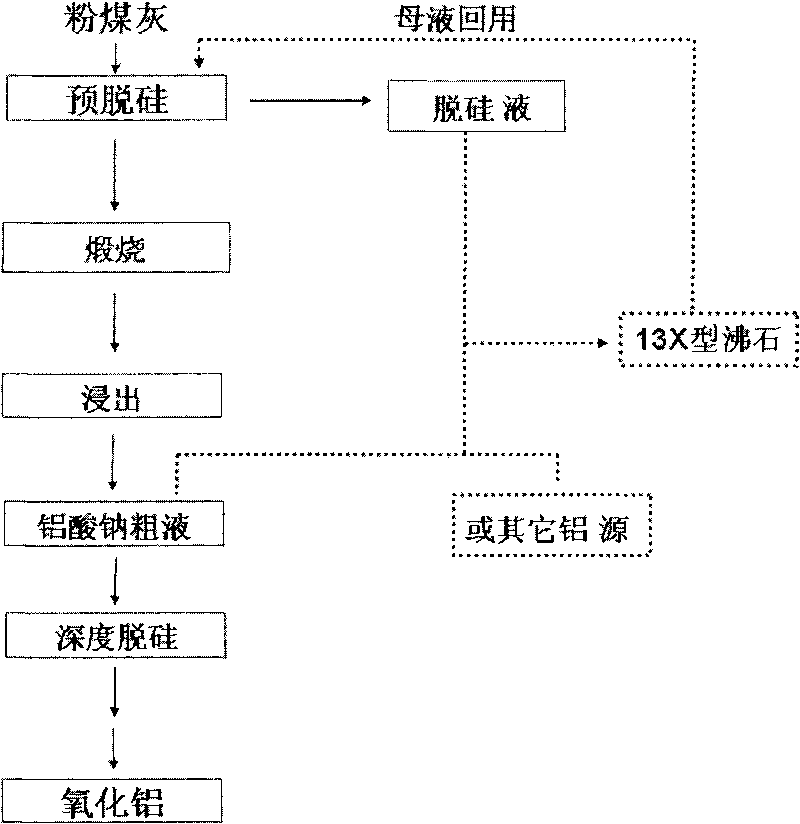

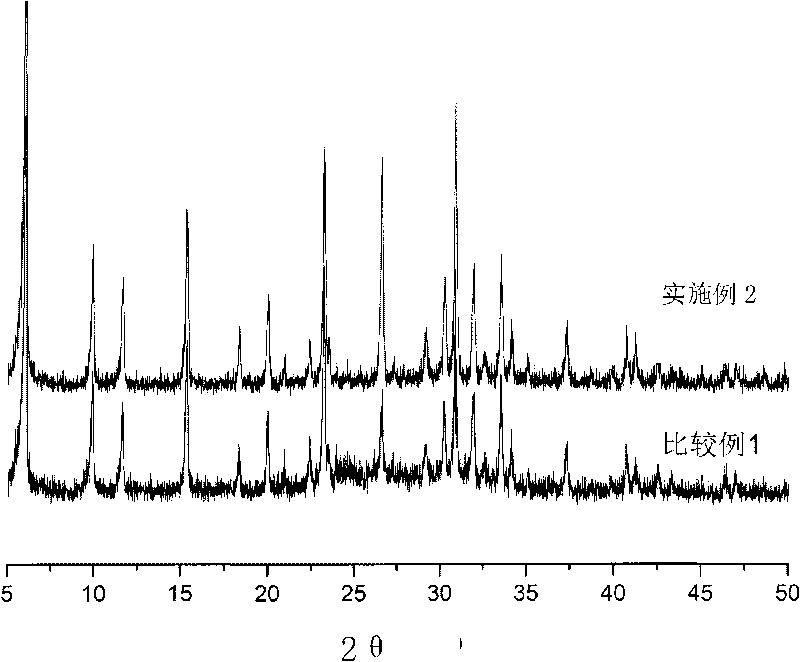

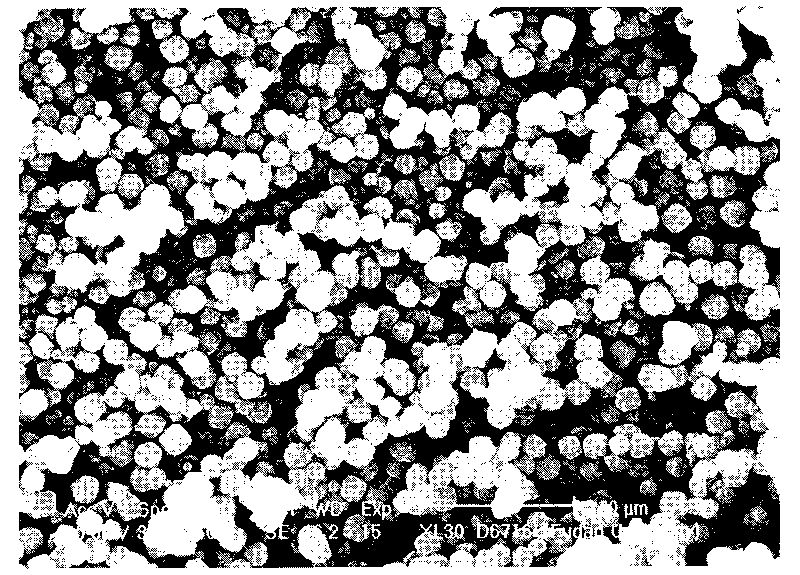

13X-type molecular sieve and preparation method thereof

InactiveCN101734683AEfficient use ofReduce pollutionOther chemical processesCrystalline aluminosilicate zeolitesMolecular sieveSynthesis methods

The invention provides a method for preparing a 13X-type molecular sieve. The method is characterized by desilicating high-aluminum fly ash to obtain a desilicated liquid as a silicon source and an aluminum source to prepare the 13X-type molecular sieve. The invention further provides the 13X-type molecular sieve prepared by the method of the invention. By adopting the synthesis method of the 13X-type molecular sieve provided in the invention, not only the synthesis cost is reduced, but also the fly ash, in particular the fly ash with high aluminum content, is more effectively used for extracting the desilicated liquid and sodium aluminate crude liquid, wherein the desilicated liquid is generated in the desilication process of alumina.

Owner:DATANG INT CHEM TECH RESINST

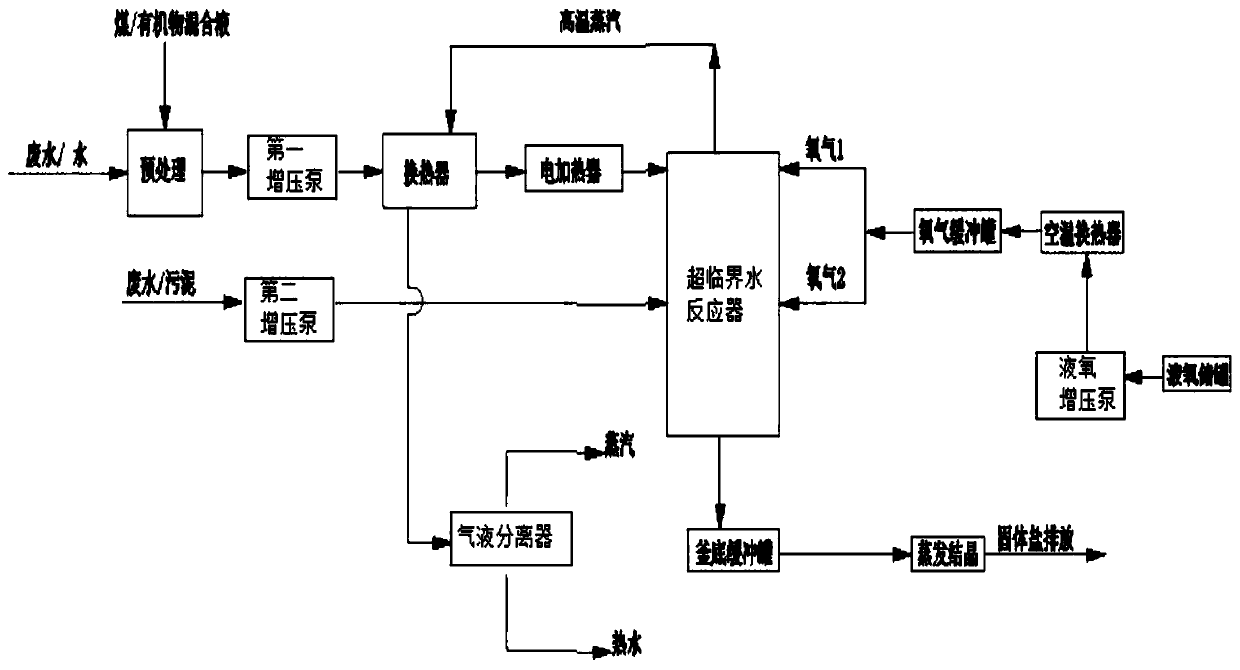

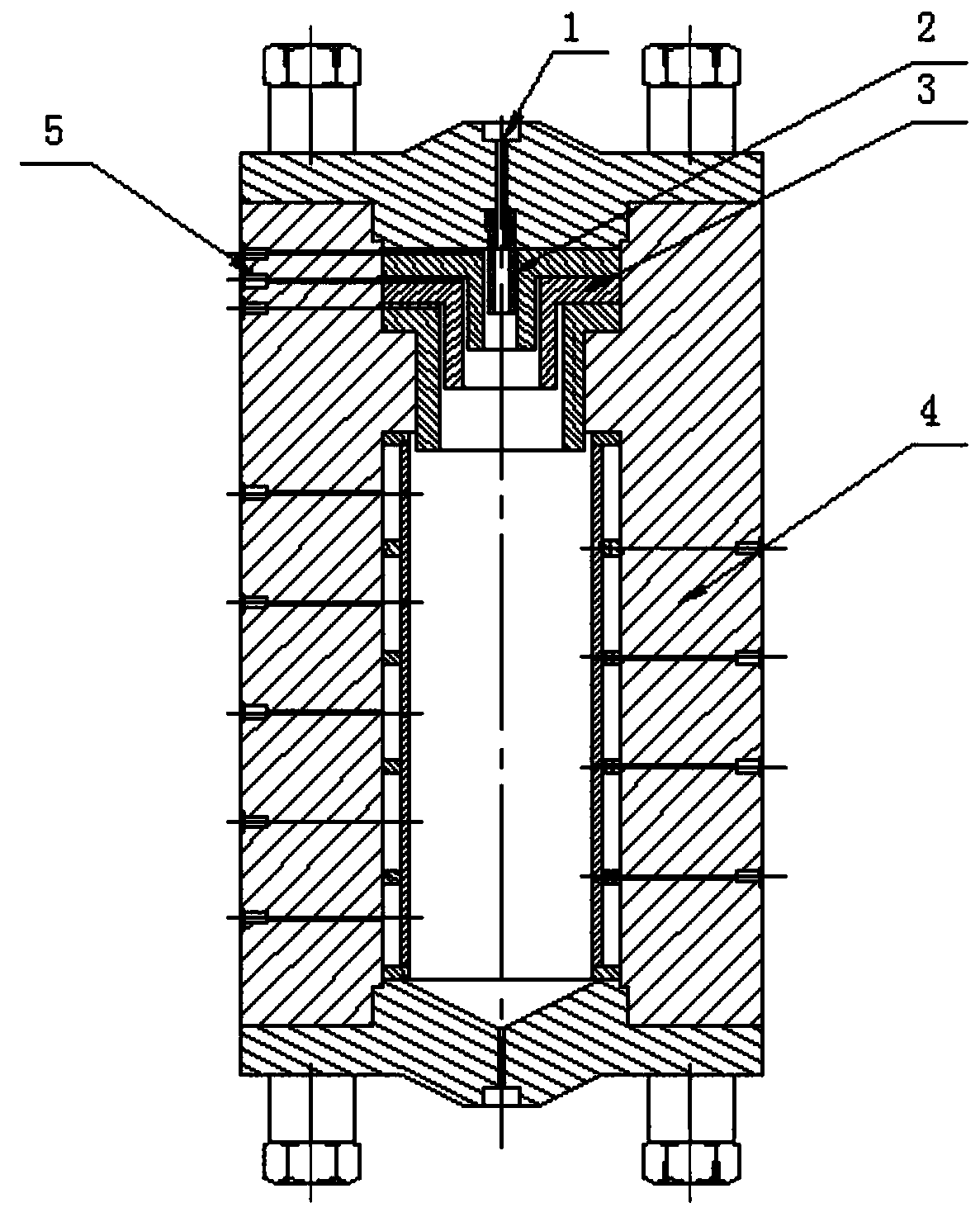

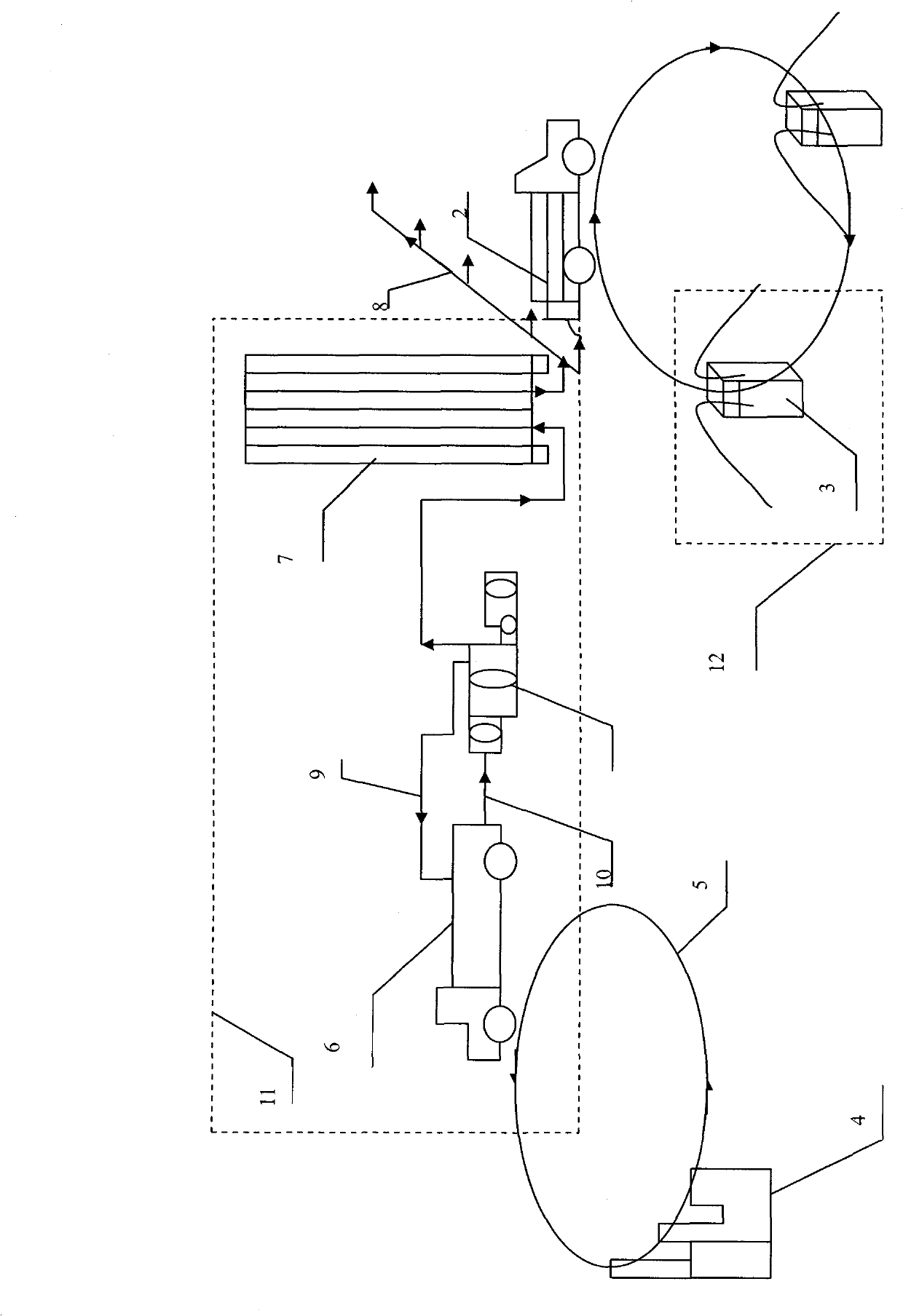

Wastewater and sludge treatment system and method using coal and organic matter as raw materials

PendingCN110510726ARealize clean utilizationNo secondary pollutionSludge treatment by oxidationSpecific water treatment objectivesHigh concentrationIndustrial waste water

The invention relates to a wastewater and sludge treatment system taking coal and organic matters as raw materials, the wastewater and sludge treatment system comprises a coal and organic matter mixedmaterial pretreatment unit; a liquid pressurizing unit; an oxygen supply unit; a supercritical water oxidation reaction unit; an evaporation crystallization unit; a heat recycling unit; a gas-liquidseparation unit and a waste heat utilization unit. The supercritical water oxidation reaction unit comprises a supercritical water oxidation reactor, wherein a liquid inlet of the supercritical wateroxidation reactor is connected with a coal and organic matter mixed liquid outlet of the coal and organic matter mixed material pretreatment unit, a first oxygen inlet is communicated into the supercritical water oxidation reactor after being merged with the liquid inlet, and a second oxygen inlet is communicated into the supercritical water oxidation reactor after being merged with a wastewater / sludge inlet. The waste water and sludge treatment system and process using coal and organic matters as raw materials have wide application range, high efficiency and zero pollution discharge, can realize energy and resource recovery at the same time, and are particularly suitable for industrial waste water, sludge, high-concentration organic waste water and hazardous waste treatment.

Owner:碧流天能(北京)科技股份有限公司

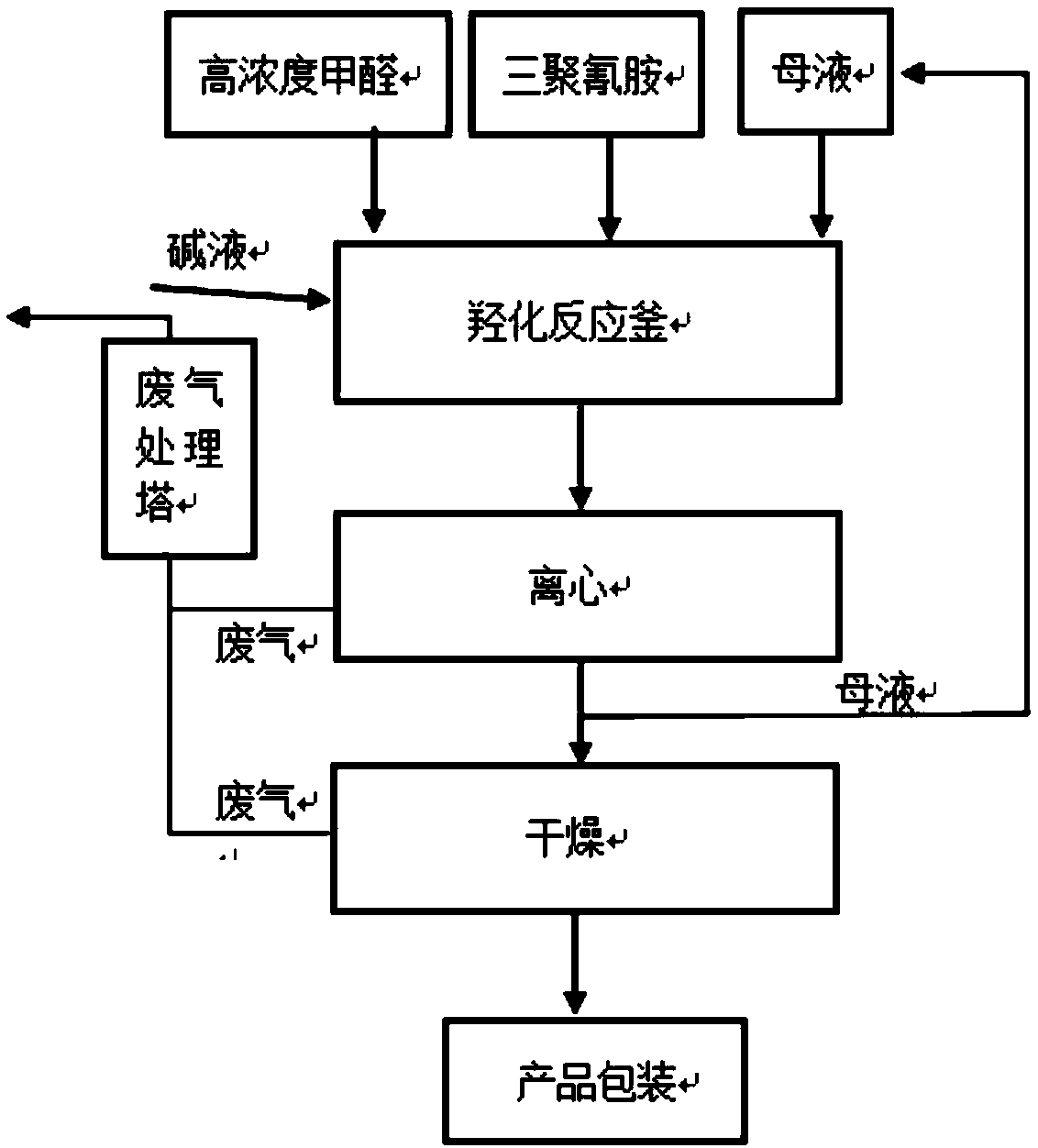

Pentahydroxy-methylmelamine and hexahydroxy-methylmelamine joint-production method

ActiveCN107245057AReduce manufacturing costImprove production conversion rateOrganic chemistryMelamine formaldehydePulp and paper industry

A pentahydroxy-methylmelamine and hexahydroxy-methylmelamine joint-production method comprises the steps that melamine, formaldehyde and water are put in a penta-hydroxylation reaction kettle according to stoichiometric ratio; a reactant is centrifugally separated, wastewater is removed, and a finished product pentahydroxy-methylmelamine is obtained after drying; part of wastewater is returned to the penta-hydroxylation reaction kettle for repeated production, and the rest is introduced into a hexa-hydroxylation reaction kettle to serve as part of mother liquor for producing hexahydroxy-methylmelamine. According to the joint-production process, pentahydroxy wastewater and hexahydroxy wastewater can be used for cyclic and joint production, accordingly the production costs of a pentahydroxy product and a hexahydroxy product are remarkably reduced, especially the production cost of the pentahydroxy product, and meanwhile zero-pollution discharge is achieved.

Owner:CHONGQING JIANFENG HAOKANG CHEM

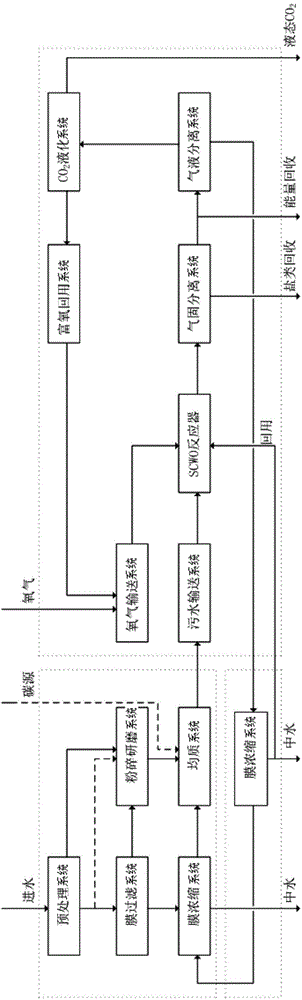

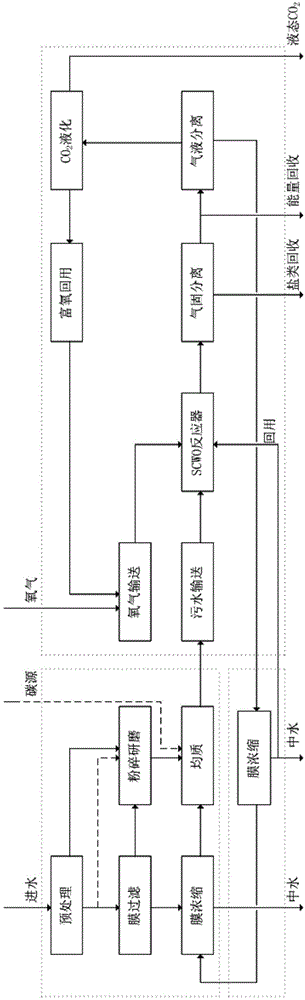

Novel comprehensive treatment system and method for sewage with zero-pollution discharge

The invention relates to a novel comprehensive treatment system for sewage with zero-pollution discharge. The system comprises the following units: a sewage condensation unit, which comprises a pretreatment system, a membrane filtration system, a membrane condensation system, a crushing and grinding system, and a homogenization system; a supercritical water oxidation unit, which comprises an oxygen conveying system, a sewage conveying system, a supercritical water oxidation (SCWO) reactor, a gas-solid separation system, a gas-liquid separation system, a CO2 liquefaction system, and an oxygen-enriched air reuse system; and an effluent membrane condensation unit, which comprises a membrane condensation system. The invention also comprises a novel comprehensive treatment method for sewage with zero-pollution discharge. The system and the method are suitable for sewage treatment, and is used for treatment of sludge, straw and other solid wastes at the same time; after treatment, the products comprises carbon dioxide, water and inorganic salt, and secondary pollution is not generated; heat generated in the process satisfies heat used for the system, and excess heat is used for heating, cooling and generating electricity; recovery of carbon dioxide and reuse of oxygen-enriched air can further save cost and enlarge profit.

Owner:王冰

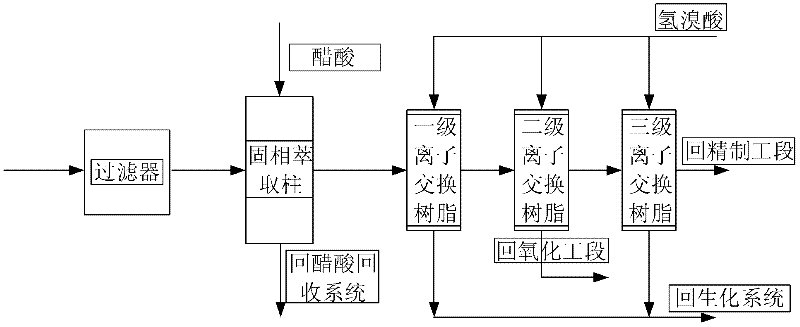

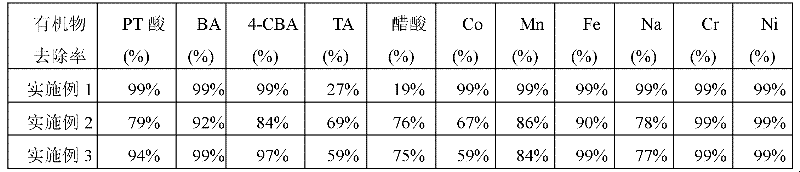

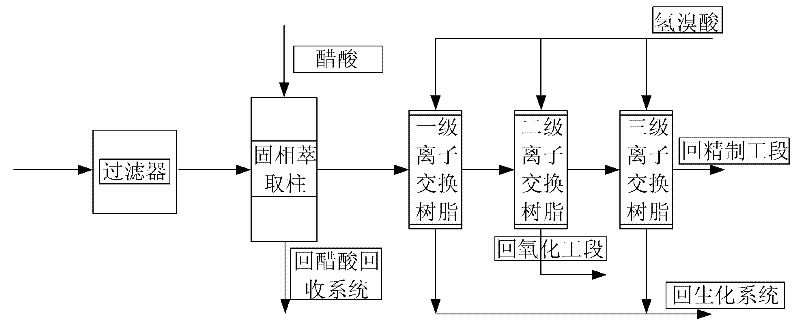

Method for comprehensively utilizing PTA (pure terephthalic acid) wastewater containing solid particles

InactiveCN102249454AHigh economic valueLow running costMultistage water/sewage treatmentNature of treatment waterSuspended particlesIon exchange

The invention belongs to the technical field of environmental engineering and industrial wastewater reuse, disclosing a method for comprehensively utilizing PTA (pure terephthalic acid) wastewater containing solid particles. The method comprises the following steps: cooling the PTA wastewater containing solid particles to 40-50DEG C; transmitting the wastewater containing solid particles into a filter; trapping suspended particles in water by the filter to form a compact filter cake layer; causing a clear liquid to pass through the filter core to form a penetrating fluid; then entering a solid-phase extraction column; and causing the effluent to flow through ion exchange resins to achieve the water quality for PTA production-purpose water. The method disclosed by the invention is simple to operate, has the advantages of small land occupation and low operation cost and has an important realistic meaning for comprehensive treatment for PTA production enterprise sewage.

Owner:李大伟

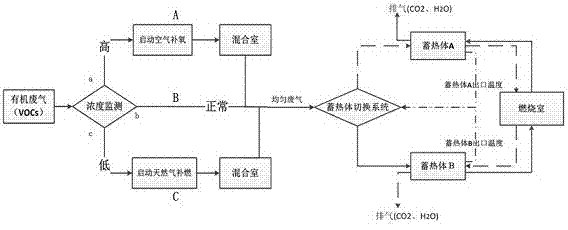

Low-NOx afterburning and VOC efficient removing method and system based on RTO

PendingCN107152691AEliminate high emissionsZero pollution dischargeIncinerator apparatusCombustion chamberCombustor

The invention discloses a low-NOx afterburning and VOC efficient removing method and a system based on RTO, and is applied to a double-chamber RTO waste gas treatment system in the field of organic waste gas treatment. The method monitors inlet waste gas online; corresponding equipment outer passage is switched according to the concentration of the water gas; and meanwhile, a heat storage body temperature field is combined to reversely switch the flowing direction of the waste gas in equipment, so that the thermal oxidation efficiency of the organic waste gas is improved; on the one hand, the method can realize low-NOx combustion on the basis of not greatly changing the equipment structure, reduces the performance requirements on a combustor, discards a low-NOx combustor with high use cost, and reduces the investment cost; and on the other hand, high-level VOC removing efficiency can be realized, fuels are sprayed into the organic waste gas for full mixing to greatly improve the combustion efficiency, and the combustion temperature in the combustion chamber is distributed more uniformly to generate the effect of flameless combustion, so that the fuels can be saved by above 20% compared with a combustor combustion method, and meanwhile, zero emission of NOx is realized.

Owner:南京艾尔普特环保科技有限公司

Process for treating landfill leachate by high-temperature incineration

ActiveCN110397940AImprove heat utilizationLow running costIncinerator apparatusThermal energyEvaporation

The invention discloses a process for treating landfill leachate by high-temperature incineration. The process for treating the landfill leachate by the high-temperature incineration involves a preheating system, an evaporative crystallization system, a phase-change heat storage system, and an incineration system; and the implementation characteristic comprises a starting stage S1, a feeding stageS2 and a circulation stage S3. According to the process, phase change heat storage and sensible heat storage are combined and used, a large amount of latent heat and sensible heat in evaporated moisture discharged by evaporation are recycled, recycled heat continues back into a system for treating the leachate, the problem of heat loss in evaporated moisture in an existing high-temperature treatment process of the leachate is solved, so that the heat energy utilization rate of the high-temperature incineration treatment leachate system is further improved, and the process is a leachate treatment process which is high in heat energy utilization rate, free of pollution emission, low in operation cost, safe and reliable.

Owner:源创环境科技有限公司

Ecological dredging recycling method

ActiveCN106277669ANo secondary pollutionWon't breakSludge treatment by oxidationClimate change adaptationFecesMycoprotein

The invention relates to an ecological dredging recycling method. The method is realized in the following steps: sediment is pretreated, sediment organic liquid fertilizer is fermented, a bacterial sediment liquid is added to a lake, reservoir or river to be used as a microbial strain, a nutrient solution or a concentrated nutrient solution passes through an aeroponic cultivation system, a residual plant absorption liquid is obtained through absorption of nutrient substances by plants, bacterial sediment is flavored by a flavoring agent, mycoprotein feed is prepared, and an alga liquid is obtained through alga culture of the residual plant absorption liquid; an alga culture container is made of a high-transmittance high-polymer hard material; algae comprise green algae and diatom; the culture period lasts 48-72 h; the illumination intensity is 3,000-7,000 LX, and the illumination time lasts 48-72 h; the obtained mycoprotein and the alga liquid enter a high-efficiency bioreactor via a feed adding system and a pipeline, residual feed and excrement of all aquatic organisms in the high-efficiency bioreactor are collected and dewatered and then enter an organic fertilizer fermentation system for fermentation recycle, and aquiculture water is directly discharged into a water body after being disinfected by a biological purification system in the high-efficiency bioreactor.

Owner:林映津

Son-mother gas filling station

InactiveCN101780940ASimple processFast expansionLiquid transferring devicesContainer filling under pressureGas cylinderTransformer

The invention relates to a son-mother gas filling station, which consists of a compressor or a low-temperature pump, a trailer cylinder and a gas filling machine. The son-mother gas filling station is technically characterized in that the compressor or the low-temperature pump increases outlet pressure to fill gas into the trailer cylinder, so that the pressure in the trailer cylinder is higher than the pressure in a vehicle cylinder, and the gas filling for the vehicle cylinder is completed through connection with the gas filling machine. The technical scheme greatly simplifies the technological flow, and is simple, efficient, energy-saving and safer. The terminal gas filling part of the son-mother gas filling station requires no power-driven power supply or transformer, thereby saving the labor and the cost of power consumption, and the gas filling terminal (son station) part can be easily constructed; the area directly occupied by the equipment is small, and the son station expanding speed is high; the investment in large-scale equipment such as a compressor leveling body, a hydraulic leveling body and the like is saved; the zero pollution and zero emission are realized; and the gas filling capability can be easily enhanced, and the invention avoids the problems of power consumption of the son station, mechanical wear and the like in the prior art. The gas filling terminal part of the son-mother gas filling station can fill gas into the vehicle cylinder in any place in a movable or fixed way.

Owner:沈军

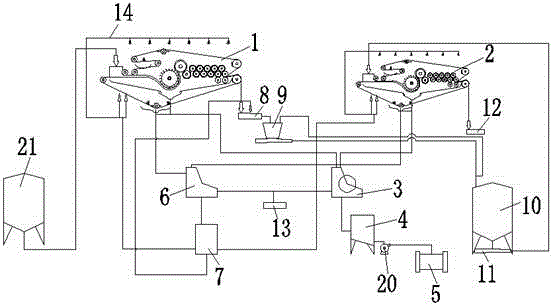

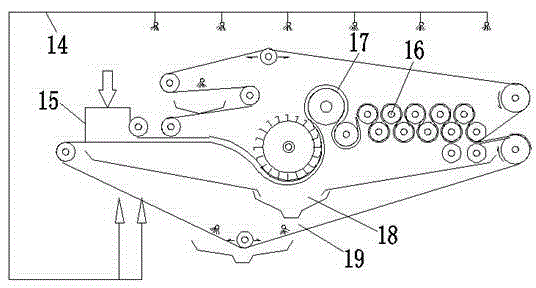

Waxberry juice extracting system in waxberry juice production

The invention relates to a waxberry juice extracting system in waxberry juice production. The waxberry juice extracting system comprises a band type juice extractor. A juice outlet of the band type juice extractor is connected with a spin vibration sieve, the spin vibration sieve is connected with a fruit juice buffer tank, the fruit juice buffer tank is connected with a duplex filter, a water outlet of the band type juice extractor is connected with a hydraulic sieve, the hydraulic sieve is connected with a cleaning water collecting tank, a residue outlet of a band type juice extractor I is connected with a deslagging device I, the deslagging device I is connected with a screw pump device, the screw pump device is connected with a secondary squeezing pulp tank, the secondary squeezing pulp tank is connected with an inlet of a band type juice extractor II through a screw pump, a residue outlet of a deslagging device II, and the band type juice extractor is provided with a CIP system. The waxberry juice extracting system is high in juicing pulp utilization rate and high in fruit juice quality, performs cleaning automatically, and runs stably.

Owner:YIXING HENGSHENG AGRI DEV CO LTD

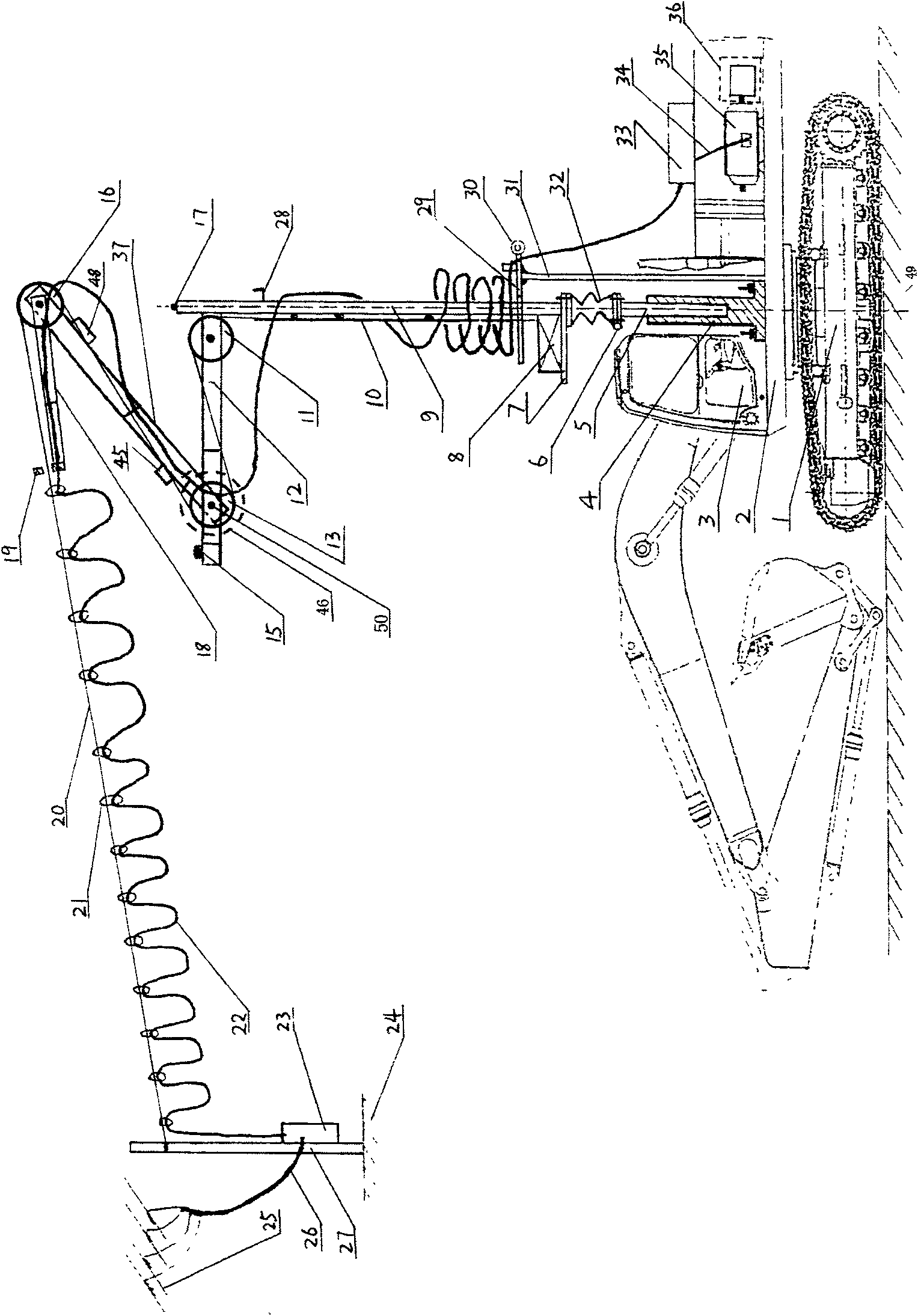

Method of manufacturing a powered electric excavator device

InactiveCN102277889AChange the form of power supplyZero pollution dischargeElectrical apparatusSoil-shifting machines/dredgersUtility poleAutomotive engineering

The invention is a manufacturing method of a power supply type electric excavator device, which relates to engineering machinery. It consists of five units: basic vehicle body, vehicle-mounted utility pole, vehicle-mounted motor, static vehicle body movement and power supply. The basic body unit is an excavator without a fuel engine system. The vehicle-mounted utility pole unit is arranged on the rotary platform and is composed of a hollow base, a spring assembly, a small winch, a pulley assembly, an upper pole and a lower pole. The vehicle-mounted motor unit includes a motor, a dedicated distribution box and cables. The mobile unit of the static car body includes a worm gear reducer with a small motor, a convex and a concave connecting plate. The power supply unit includes cement poles, shared distribution boxes, municipal power lines, steel wires, cable rings and power transmission cables. The present invention does not change the basic structure and usage of the existing excavator. The electric motor replaces the fuel engine to provide power for the car body, realizes barrier-free power supply through the vehicle-mounted utility pole unit and the power supply unit, and realizes zero emission by replacing oil with electricity.

Owner:岳中珩

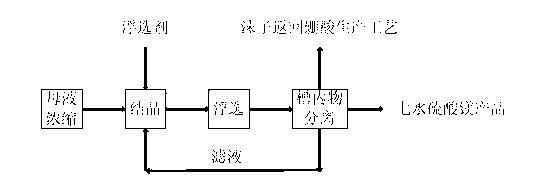

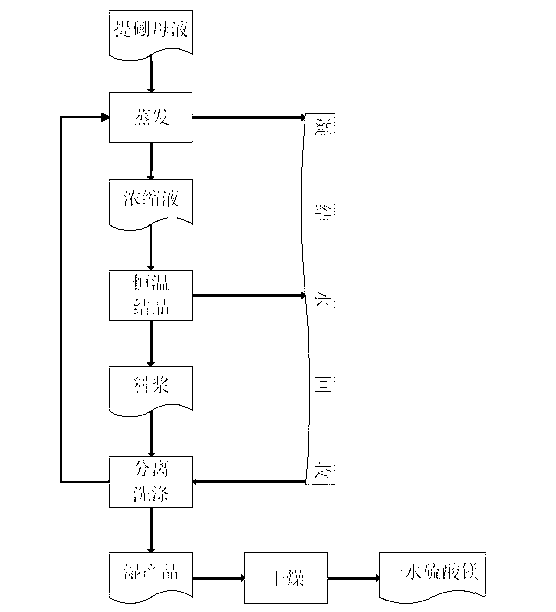

Process for recovering magnesium sulfate monohydrate from boron extraction mother liquor

InactiveCN103232048ATo achieve the purpose of recovering magnesium sulfate monohydrateIncrease added valueMagnesium sulfatesPhysical chemistryAnalytical chemistry

The invention relates to a process for recovering magnesium sulfate monohydrate from boron extraction mother liquor. The process comprises the following steps of: (1) pouring the boron extraction mother liquor with the initial composition of magnesium sulfate with the concentration of 18%-24% and boric acid with the concentration of 0%-4% into an evaporation reaction kettle under normal-pressure conditions, heating till boiling, and keeping the temperature unchanged; slowly increasing the temperature to 102-105 DEG C when the concentration of the boron extraction mother liquor achieves 1.397-1.410g / mL or 41-42 Be'; and continuously heating, and respectively obtaining a concentrated solution and condensed water A when the concentration of the boron extraction mother liquor achieves 1.468-1.483g / mL or 46-47 Be'; (2) transferring the concentrated solution into a crystallizer, and performing constant-temperature evaporation and crystallization to obtain slurry and condensed water B; (3) performing thermal separation on the slurry to obtain a magnesium sulfate monohydrate crude product; washing the magnesium sulfate monohydrate crude product with a mixed solution of the condensed water A and the condensed water B to respectively obtain a wet product and a washing solution; and returning the washing solution to the step (1) for recycling; and (4) drying the wet product till constant weight to obtain the magnesium sulfate monohydrate. The process disclosed by the invention has the characteristics of low energy consumption and low cost.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

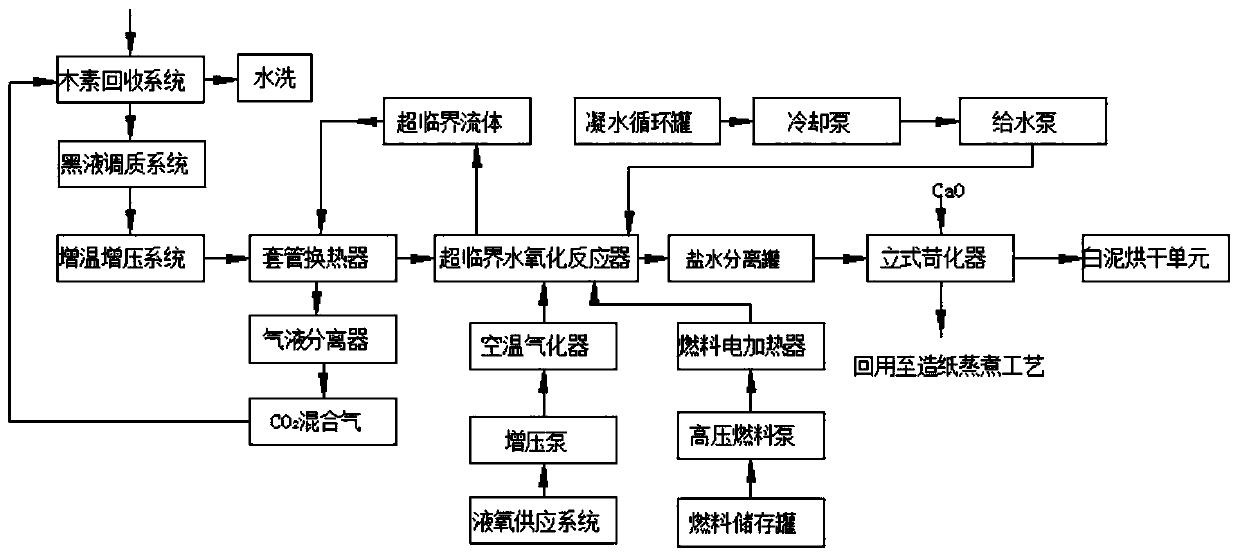

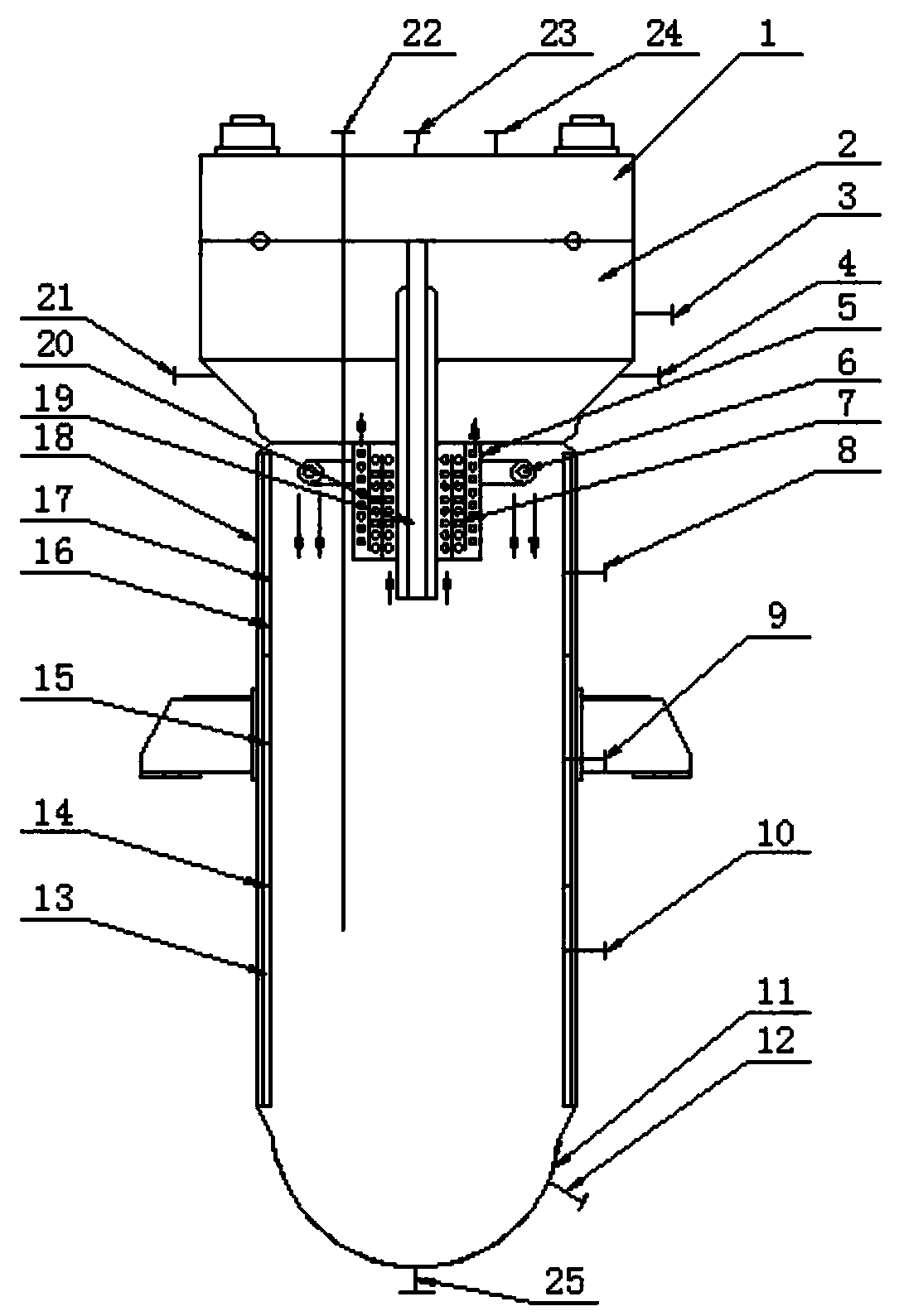

Supercritical water oxidation treatment and resource recovery system and method of alkaline paper-making wastewater

PendingCN109748376AImprove processing efficiencyZero pollution dischargeWater contaminantsWater/sewage treatment by heatingWater circulationTorch

The invention discloses a supercritical water oxidation treatment and resource recovery system of alkaline paper-making wastewater, which comprises a supercritical water oxidation unit, a black liquidpretreatment unit, an oxidant supply unit, an alkali recovery unit and a white mud utilization unit, wherein a supercritical water oxidation reactor is a multilayer torch firing and multilayer cooling supercritical reactor and is connected with a starting fuel system and a condensate water circulation system; the black liquid pretreatment unit comprises a lignin recovery system, a black liquid conditioning system and a warming and pressurizing system that are sequentially connected; the oxidant supply unit comprises a liquid oxygen booster pump and an air temperature vaporizer; the alkali recovery unit comprises a saline separation tank and a vertical causticizer; a salt discharge port is formed at the bottom of the supercritical water oxidation reactor; and the supercritical water oxidation reactor is sequentially connected with the saline separation tank and the vertical causticizer. The system is high in treatment efficiency, free of pollution discharge, simple to operate and lowerin treatment cost, can simultaneously achieve recycling of resources and energy sources, and saves investment.

Owner:新权诚工程建设项目咨询管理有限公司

Circular production of hexamethylolmelamine

ActiveCN107382889BReduce manufacturing costZero pollution dischargeOrganic chemistryHigh concentrationAqueous solution

Owner:李平

Tail gas treatment device of high-temperature sintering furnace for graphite production

InactiveCN107998810AMeets industry standardsAvoid recycling multiple timesUsing liquid separation agentMultistage water/sewage treatmentOil and greaseWater circulation

The invention discloses a tail gas treatment device of a high-temperature sintering furnace for graphite production. The tail gas treatment device comprises a spraying tower, a gas inlet pipe for fluegas to enter is arranged on the spraying tower, a blanking device is arranged at the bottom of the spraying device, a liquid outlet pipe for discharging cooling liquid and a liquid spraying pipe forconveying the cooling liquid are arranged on the side wall of the spraying tower, the liquid outlet pipe is positioned under the liquid spraying pipe, and a heating device for heating the inner side wall of the spraying tower is also arranged on the spraying tower. The tail gas treatment device disclosed by the invention has the benefits that the zero pollution discharge is realized, grease, floating oil and waste gas can be effectively treated, the energy consumption is low, and the efficiency is high; tail gas in the whole sintering furnace is treated by adopting a physical method, so that the use of chemical materials is reduced. Therefore, the treatment mode can be used for a long term, and the tail gas treatment cost is reduced; through a water circulation treatment device, the condensing effect of an aqueous solution is ensured, and water recycling is realized.

Owner:成都纽扣互动科技有限公司

Oil system of phase modifier

ActiveCN107202241AAvoid pollutionImprove recycling ratesEngine temperatureEngine pressureFuel tankFilter effect

The invention discloses an oil system of a phase modifier. The oil system comprises an oil tank, the phase modifier, a lubricating oil supply system, a lifting oil system and an oil smoke recycling system, wherein the lubricating oil supply system and the lifting oil system are arranged between the oil tank and the phase modifier, the inlet end of the oil smoke recycling system is connected with the outlet end of the phase modifier, the outlet end of the oil smoke recycling system is divided into two ways, one way is connected to the oil tank, and the other way is discharged into the air. According to the oil system, oil smoke containing lubricating oil passes through an oil smoke removing device, and filtered oil is transmitted to the oil tank, so that the recycling rate of the lubricating oil is increased; filtered clean gas is discharged into the air, so that the filtering effect is increased, air pollution is prevented, the recycling rate of the lubricating oil is high, and normal operation of the system can be guaranteed in the condition that main components of the system fail.

Owner:JIANGSU JIANGHAI LUBRICANTS HYDRAULIC EQUIP

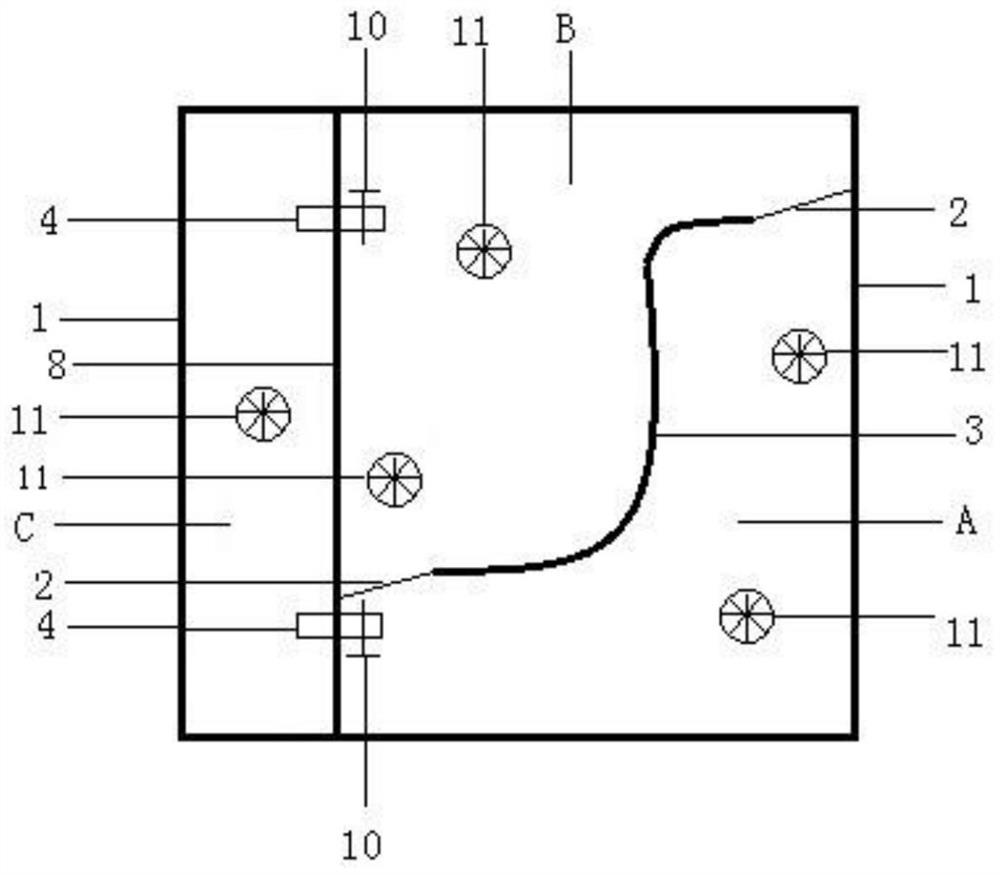

Zero-pollution discharge system for circulating aquaculture tail water in pond and construction method thereof

PendingCN112825811ARealize planting in stagesPrecise managementPisciculture and aquariaNutrientShrimp

The invention discloses a zero-pollution discharge system for circulating aquaculture tail water in a pond and a construction method thereof. A river crab escape prevention wall is built on the periphery of an aquaculture pond, the pond is divided into a purification area and an aquaculture area through a newly-built pond ridge, external water is firstly purified through the purification area, and a high-quality water source is provided for shrimp and crab aquaculture; secondly, circulating micro-flowing water is formed between the two areas, only new water is injected without changing water in the production process of the aquaculture pond, the water changing frequency in the production process of the aquaculture pond is reduced, and the effects of purifying water and saving water are achieved; and the aquaculture area is divided into different areas by an inner ridge of an S-shaped pond ridge, staging planting of aquatic plants and precise management of shrimp and crab aquaculture can be achieved, pond drying in different areas can be achieved in sequence when the pond is dried, aquaculture tail water rich in nutrient substances at the bottom layer is not discharged to the environment outside the pond, and zero-pollution discharge of the aquaculture tail water is achieved.

Owner:苏州市水产技术推广站

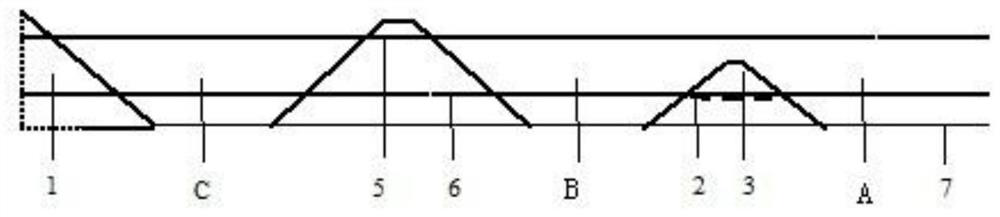

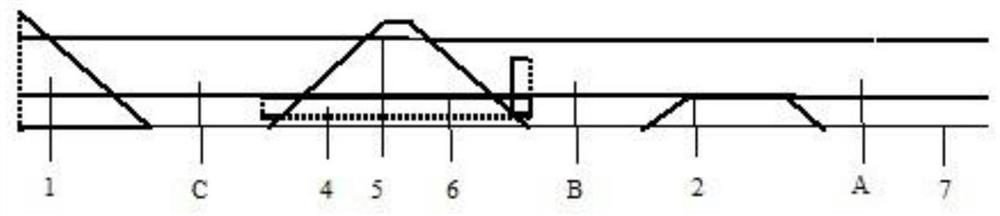

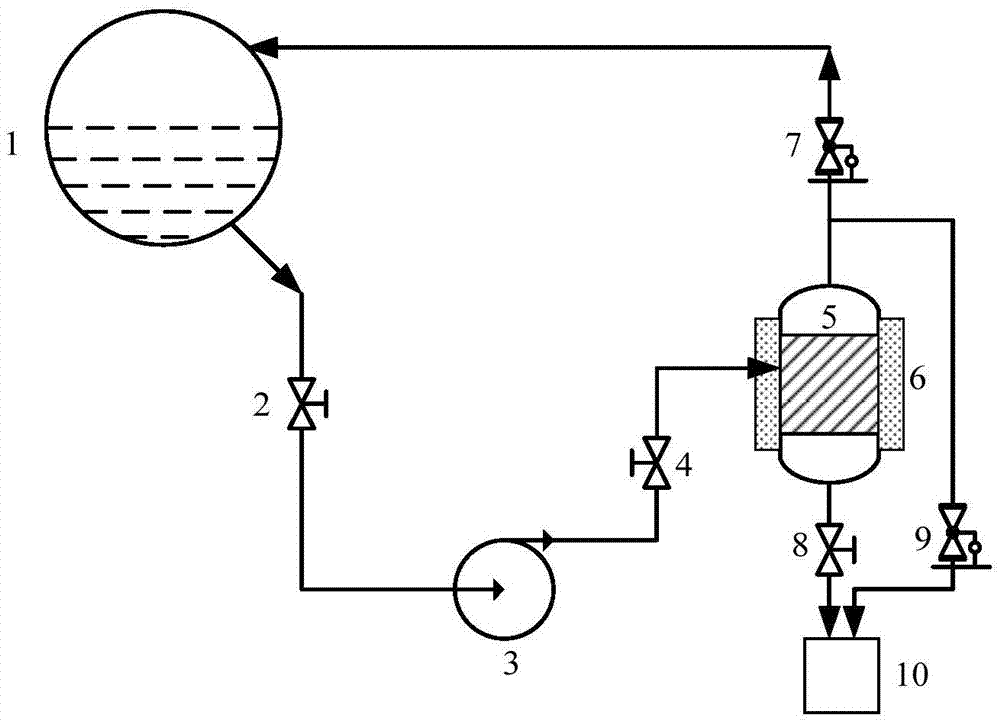

Concentration and crystallization treatment system and method of blow-down water of boiler drum

InactiveCN105439221AAvoid wastingImprove processing efficiencyWater/sewage treatment by heatingPower stationSewage

The invention belongs to the technical field of cyclic recycling and utilization of power station water treatment and resource energy sources and particularly relates to a concentration and crystallization treatment system and method of blow-down water of a boiler drum. The system is composed of a steam drum, a blow-down control valve, a booster pump, a reactor water inlet control valve, a supercritical water separation reactor, a heater, a decompression valve I, a salt discharging control valve, a decompression valve II and a salt collection device. With the adoption of the concentration and crystallization treatment system and method, under the condition that any catalyst is not added, the separation of salt and water is realized; and meanwhile, the cyclic recycling of the blow-down water and the recycling of the energy are realized, and a novel green, pollution-free and efficient method is provided for treating the continuous blow-down water of a steam boiler.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A comprehensive treatment process for high-concentration and high-salt wastewater

ActiveCN105016530BEasy to getEasy to operateMultistage water/sewage treatmentAlkali metal chloridesParticulatesHigh concentration

The invention relates to a wastewater treatment process, and provides a comprehensive treatment process for high-concentration and high-salt wastewater, comprising the following steps: concentrating the wastewater, adding an organic flocculant, and settling large particles of impurities and most of the suspended matter and floating matter; Add activated carbon adsorbent to adsorb organic matter; filter to remove particulate impurities, colloidal substances and suspended solids in water, and then separate monovalent ions in wastewater through primary nanofiltration; water containing monovalent ions undergoes reverse osmosis to obtain pure Water can be used as industrial water; Concentrated water undergoes electrodialysis to concentrate monovalent salts to obtain NaCl by-products; Water containing divalent ions undergoes freezing and crystallization, and after centrifugation, the crystal layer undergoes double-stage membrane electrodialysis to obtain acid-base products. The water layer is treated by nanofiltration; the saturated adsorbent that has absorbed organic matter is dehydrated and dried for recycling. The invention has low cost, can simultaneously remove organic matters and inorganic salts in waste water and utilize them, and is energy-saving and environment-friendly.

Owner:沧州绿源水处理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com