13X-type molecular sieve and preparation method thereof

A technology of molecular sieve and gel, which is applied in the chemical industry, can solve the problems of not finding a way to use it, and achieve the effect of reducing synthesis cost and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

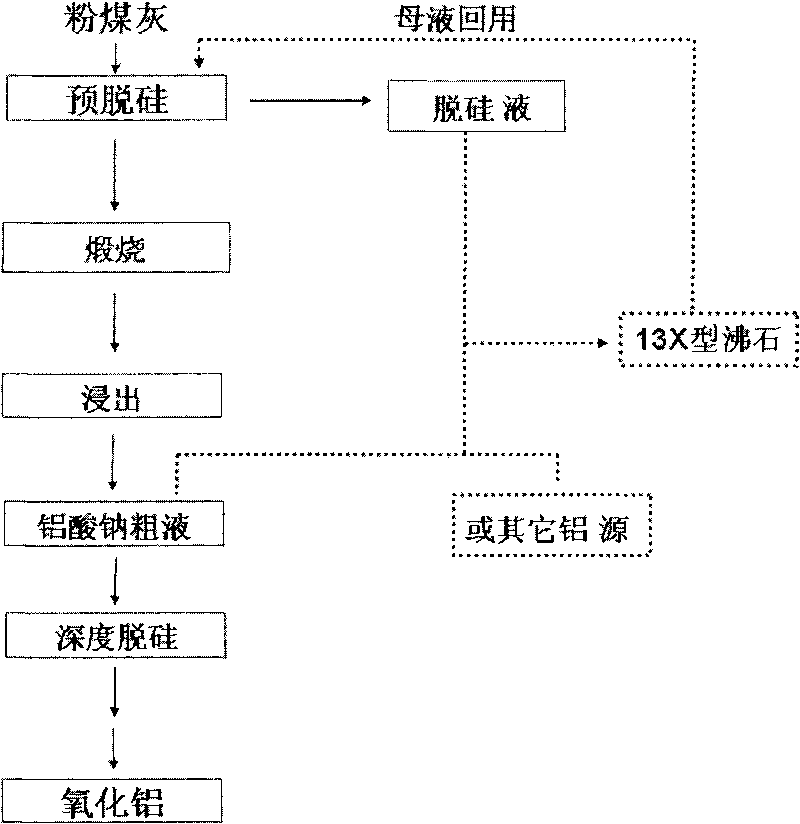

Method used

Image

Examples

Embodiment 1

[0060] High alumina fly ash (with Al 2 o 3 In terms of weight percentage, the aluminum content is 50%) finely ground to 500 mesh, weighed 20 grams, put it into a high-pressure reactor with stirring, and added 40 grams of 25% ash / alkali mass ratio of 1:0.5 NaOH solution (calculated as NaOH, mass concentration), heat desiliconization at 130°C for 2 hours, after the reaction time is up, take out the mixed material and filter, wash the filter cake until the pH of the lotion is 9, and the lotion is the result of the first filtration. In the filtrate, the filtrate is desiliconized liquid.

Embodiment 2

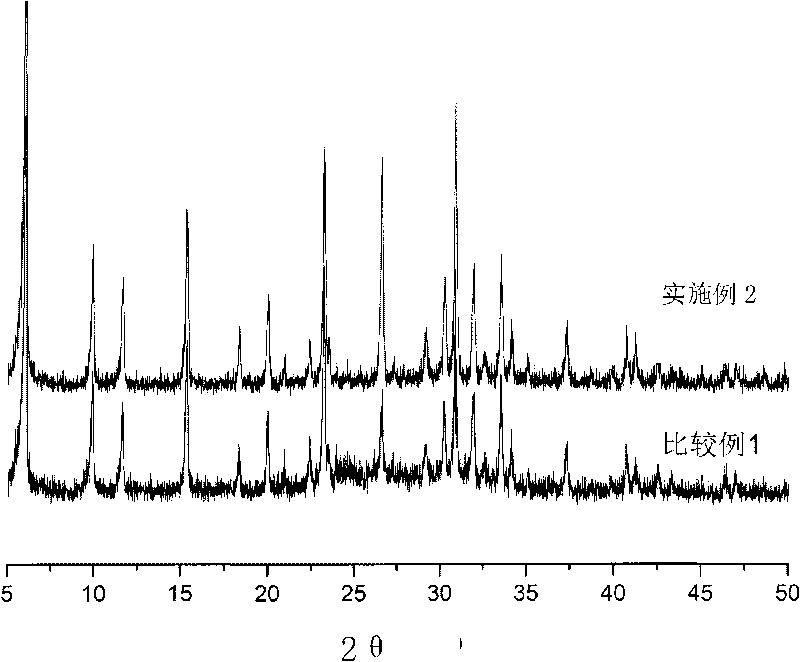

[0062] Get the desiliconization solution of A batch (desiliconization solution A) and carry out inductively coupled plasma (ICP) emission spectrum analysis, its composition is as shown in Table 1, by molar ratio, Na in the desiliconization solution 2 O / SiO 2 = 1.3, SiO 2 / Al 2 o 3 =756.5,H 2 O / Na 2 O=60. Take 100mL of the desiliconization solution and put it into a polytetrafluoroethylene beaker, and place it in a constant temperature water bath at 40°C. Then add 4.9 g of AlCl to the Teflon beaker 3 , the molar composition of the resulting mixture is: 5Na 2 O:Al 2 o 3 : 4SiO 2 : 300H 2 O, the mixture was stirred for 3 hours to form a gel, and the stirring was stopped. Transfer the gel to a closed crystallization tank and age at 70°C for 5 hours, then raise the temperature to 90°C for 5 hours to crystallize, after cooling, filter the product, wash with water until the pH is 10, and dry the filter cake at 90°C to obtain product. XRF and XRD tests show that SiO 2 / ...

Embodiment 3

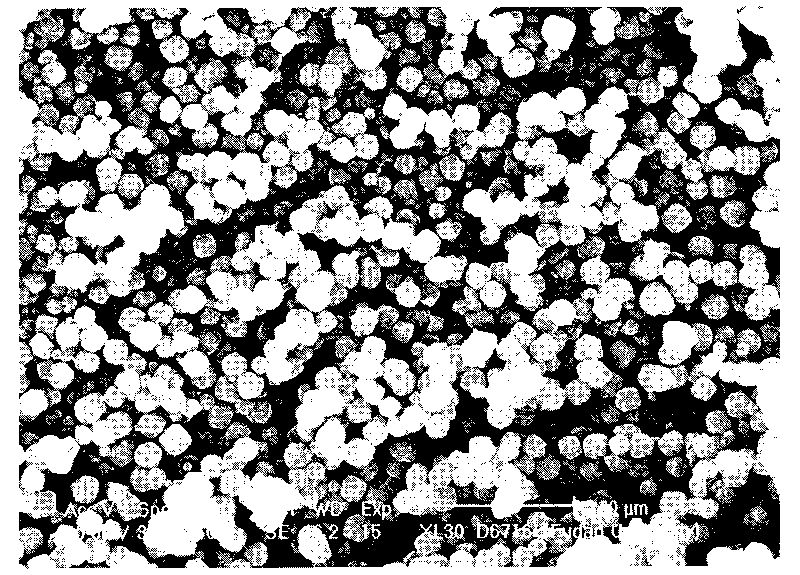

[0066] Take 100 mL of the desiliconization solution A in Example 2, put it into a polytetrafluoroethylene beaker, and place it in a constant temperature water bath at 30°C. Then add 3.8 grams of NaAlO to the tetrafluoroethylene beaker 2 , the resulting mixture has a molar composition of 4.9Na 2 O:Al 2 o 3 : 3.2SiO2 2 : 247H 2 O, the mixture was stirred for 3 hours to form a gel, and the stirring was stopped. Transfer the gel to a closed crystallization tank and age at 60°C for 6 hours, then raise the temperature to 80°C for 5 hours to crystallize, after cooling, filter the product, wash with water until the pH is 10, and dry the filter cake at 100°C to obtain product. XRF and XRD tests show that SiO 2 / Al 2 o 3 The molar ratio is 2.8, and its crystal phase structure is X-type molecular sieve, and SEM shows that its crystal grain is about 1 micron ( image 3 Shown), the relative crystallinity is 142%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com