A comprehensive treatment process for high-concentration and high-salt wastewater

A high-salt wastewater and comprehensive treatment technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, alkali metal chloride, etc., can solve the problem that the equipment is expensive, cannot be used alone, and the electrode plate is easy to passivate and other issues, to achieve high environmental and social benefits, realize the resource utilization of inorganic matter, and achieve the effect of zero pollution discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

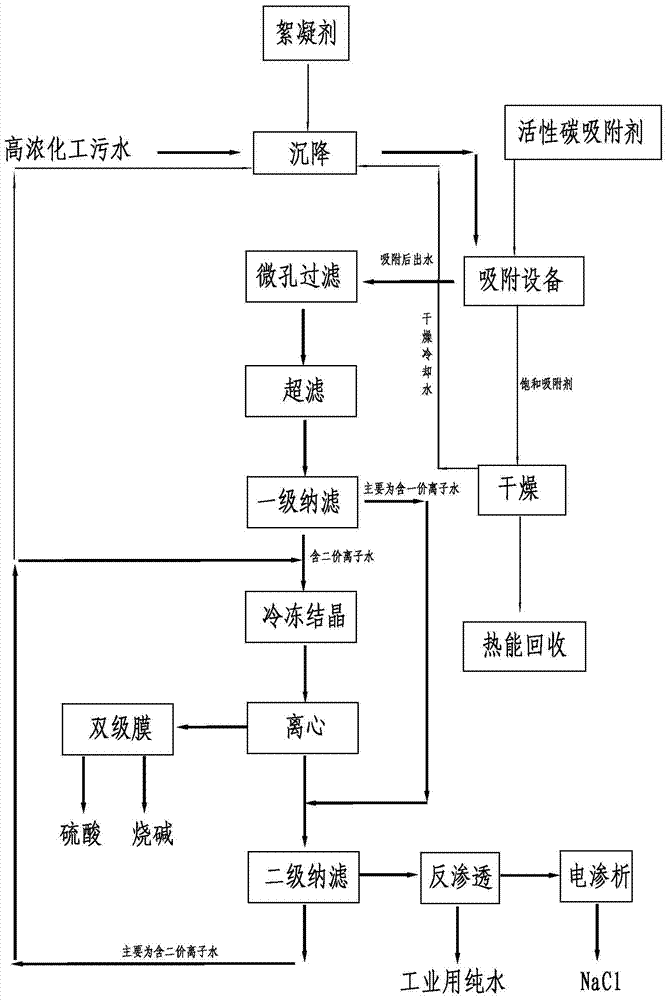

[0024] Such as figure 1 As shown, a kind of comprehensive treatment process of high-concentration and high-salt wastewater of the present invention comprises the steps:

[0025] Concentrate high-concentration and high-salt chemical wastewater, add an organic flocculant, and carry out sedimentation treatment to remove large particles of impurities and most of the suspended solids and floating solids in the wastewater; the organic flocculant can be: polyacrylamide or starch- Polyacrylamide; the settled wastewater is treated with composite coal-based adsorbent or coal-based activated carbon to remove most of the organic matter in the wastewater; then the wastewater is filtered through micropores to remove particulate impurities, colloidal substances and suspended solids in the water , and then further remove the residual small molecular suspended matter and organic matter in the water by ultrafiltration, and then separate the one and two valent ions in the water by one-stage nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com