Process for treating landfill leachate by high-temperature incineration

A technology for landfill leachate and leachate, which is applied in incinerators, combustion methods, combustion types, etc., can solve the problems of evaporation moisture heat loss and other problems, and achieve the effects of reducing labor costs, improving economic benefits, and improving thermal energy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

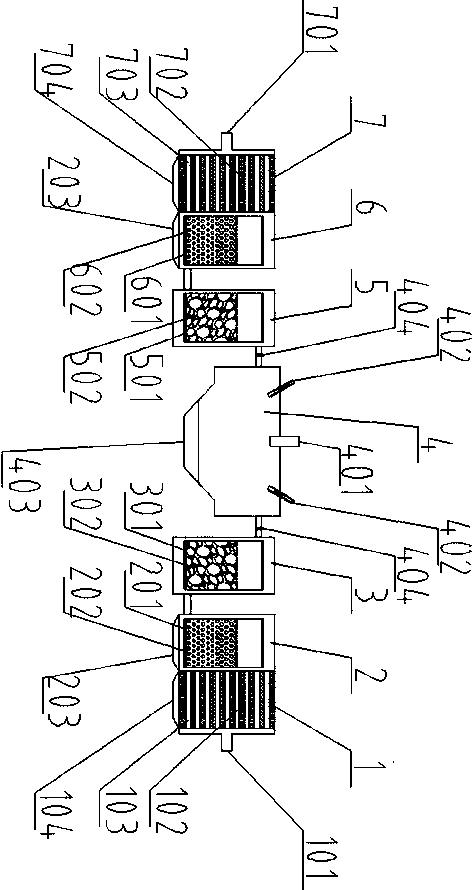

[0029] Attached below figure 1 Make a detailed description of the specific implementation steps of the invention.

[0030] Such as figure 1 A high-temperature incineration process for treating landfill leachate shown includes a start-up phase S1, a feed phase S2, and a circulation phase S3.

[0031] The feature of the start-up phase S1 is:

[0032] S1-1, close the flue gas valve 404 at one end of the incinerator 4, start the combustion burner 402 to increase the temperature inside the incinerator 4 to above 900°C, and spray atomized leachate into the leachate starting inlet 401. The atomized leachate is mixed with high-temperature flue gas in the incinerator 4 for heat exchange, and is quickly vaporized during the heat exchange process. During the high-temperature incineration process, the harmful organic components in the leachate are decomposed into CO, CO 2 、CH 4 Small molecular gases such as ammonia nitrogen and other inorganic components are decomposed into NO, NO 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com