Automatic spheroidization device for producing spherical graphite

A technology of spherical graphite and automatic feeding, which is applied in the field of automatic spheroidizing devices for producing spherical graphite, can solve the problems of high production cost, difficulty in screening, waste, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

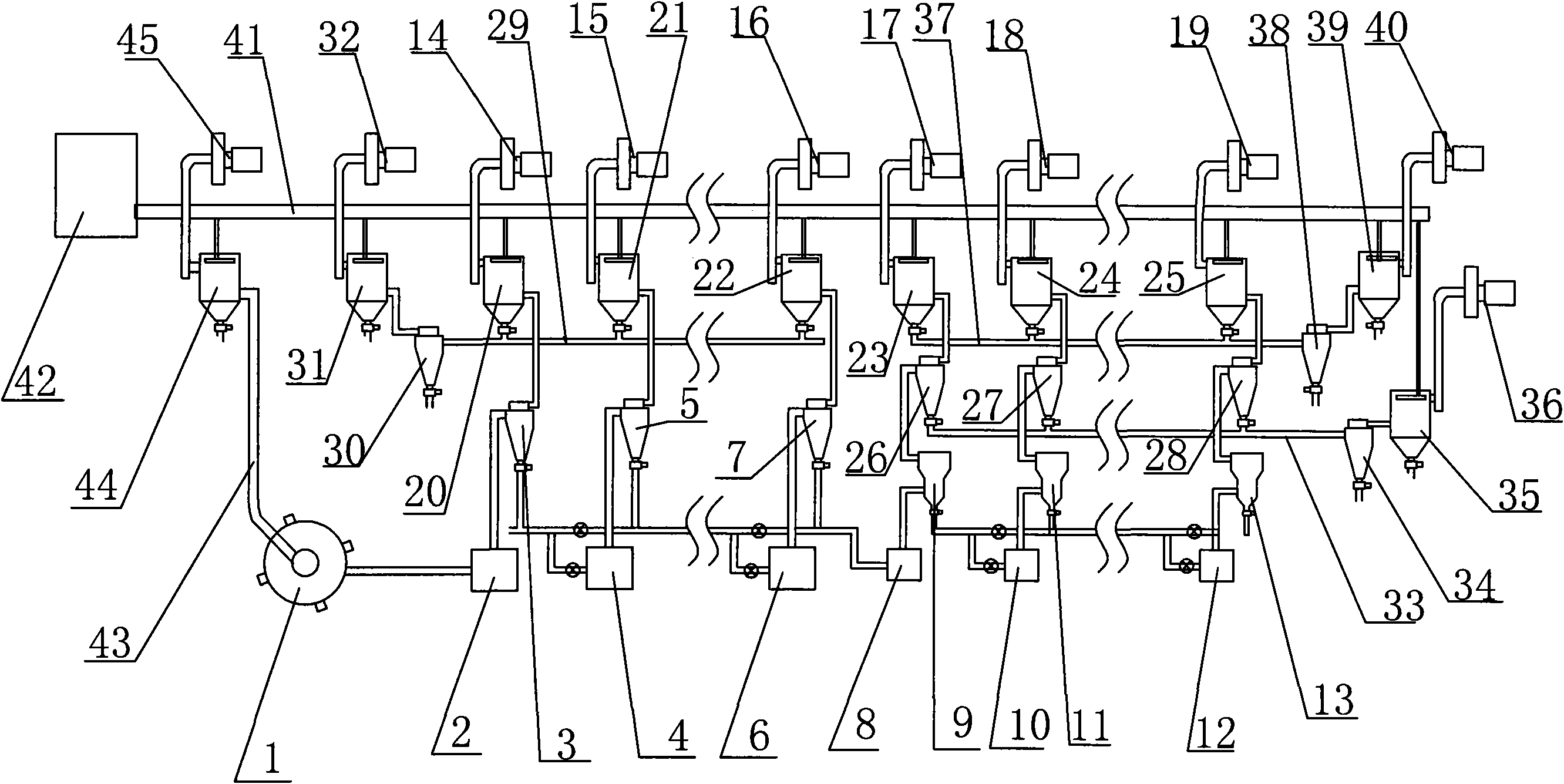

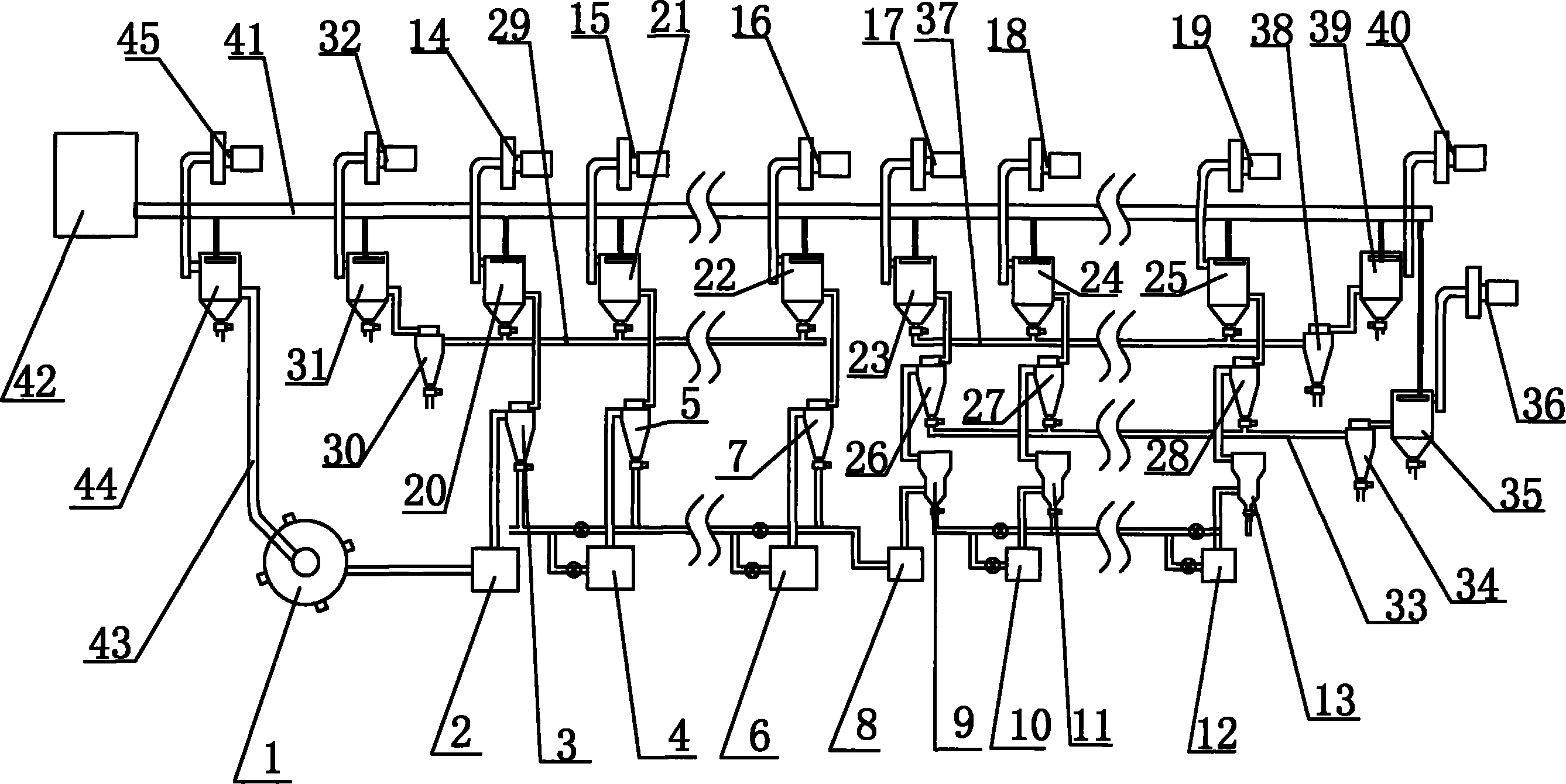

[0041] Graphite powder raw material is connected by the outlet of the material bin in the automatic feeding device 1 through the pipeline to the air vortex powder refiner I2 of the first-stage powder refinement unit working group of the powder system, and the air vortex powder is finely The chemical machine Ⅰ2 is connected with the cyclone separator Ⅰ3 in this working group. The upper end of the cyclone separator Ⅰ3 is equipped with a fine particle material outlet to connect with the pulse dust recovery device Ⅰ20 in this working group. The lower end of the cyclone separator Ⅰ3 is provided with a main material outlet to pass through The powder conveying pipe is connected with the air vortex powder refining machine II4 of the lower working group, and connected in sequence. Five groups of powder refining unit working groups are set in the powder system, and the last group of cyclone separator III7 The outlet of the main material is connected to the air-flow vortex spheroidizer I8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com