Method for comprehensively utilizing PTA (pure terephthalic acid) wastewater containing solid particles

A suspension in water, solid-phase extraction column technology, applied in chemical instruments and methods, natural water treatment, water/sewage multi-stage treatment, etc., can solve the problems of increased operating costs, large floor space, hidden safety hazards, etc., to achieve Zero pollution discharge, saving operating cost, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

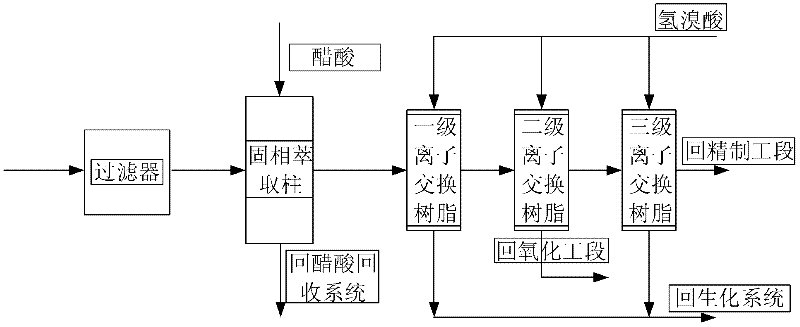

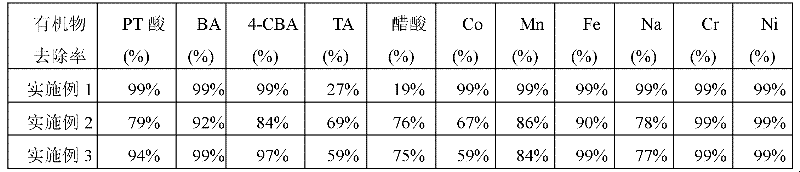

[0023] See the process flow figure 1 , first cool down the PTA solid water to 40°C, and then transport the cooled PTA solid water to the filter with a filter precision of 0.2 μm. A dense filter cake layer is formed, the clear liquid passes through the filter element, and the permeate enters the solid-phase extraction column. When the permeate passes through the solid-extraction agent styrene-based macroporous resin bed, the dissolved organic matter in the water is intercepted by the solid-extraction agent, and the metal ions Still retained in the water, after solid extraction, the effluent flows into the three-stage ion exchange resin. When the wastewater passes through the ion exchange resin bed, the metal ions in the water are graded and exchanged. The primary ion exchange resin, styrene-based cation exchange resin, is used to remove Fe, Ni, Cr and other trace metal ions, secondary ion exchange resin acrylic cation exchange resin is used to recover valuable metal ions such a...

Embodiment 2

[0025] Cool down the PTA solid water to 45°C, and transport the cooled PTA solid water to the filter. The filter precision is 0.2 μm, and the filtering method is external filtration. The dense filter cake layer, the clear liquid passes through the filter element, and the permeate enters the solid phase extraction column. When the permeate passes through the solid extraction agent divinylbenzene macroporous resin bed, the dissolved organic matter in the water is intercepted by the solid extraction agent, and the metal ions It remains in the water, and after solid extraction, the effluent flows into the three-stage ion exchange resin. When the wastewater passes through the ion exchange resin bed, the metal ions in the water are graded and exchanged. The first-stage ion exchange resin acrylic cation exchange resin is used to remove Fe, Ni , Cr and other trace metal ions, the secondary ion exchange resin phenolic cation exchange resin is used to recover valuable metal ions such as ...

Embodiment 3

[0028] Cool down the PTA solid water to 50°C, and transport the cooled PTA solid water to the filter through the pump. The filter precision is 0.2μm, and the filtering method is external filtration. The suspended particles in the water are filtered by the filter element in the external filter filter. Intercept to form a dense filter cake layer, the clear liquid passes through the filter element, and the permeate enters the solid phase extraction column. When the permeate passes through the polyacrylic macroporous resin bed of the solid extraction agent, the dissolved organic matter in the water is intercepted by the solid extraction agent. The metal ions still remain in the water. After solid extraction, the effluent flows into the three-stage ion exchange resin. When the wastewater passes through the ion exchange resin bed, the metal ions in the water are graded and exchanged. The primary ion exchange resin is a phenolic cation exchange resin used to remove Fe. , Ni, Cr and ot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com