Method of manufacturing a powered electric excavator device

An electric excavator and manufacturing method technology, applied in the direction of earth moving machine/shovel, electrical components, construction, etc., can solve the problems of fuel consumption products not green, high excavator use cost, air pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

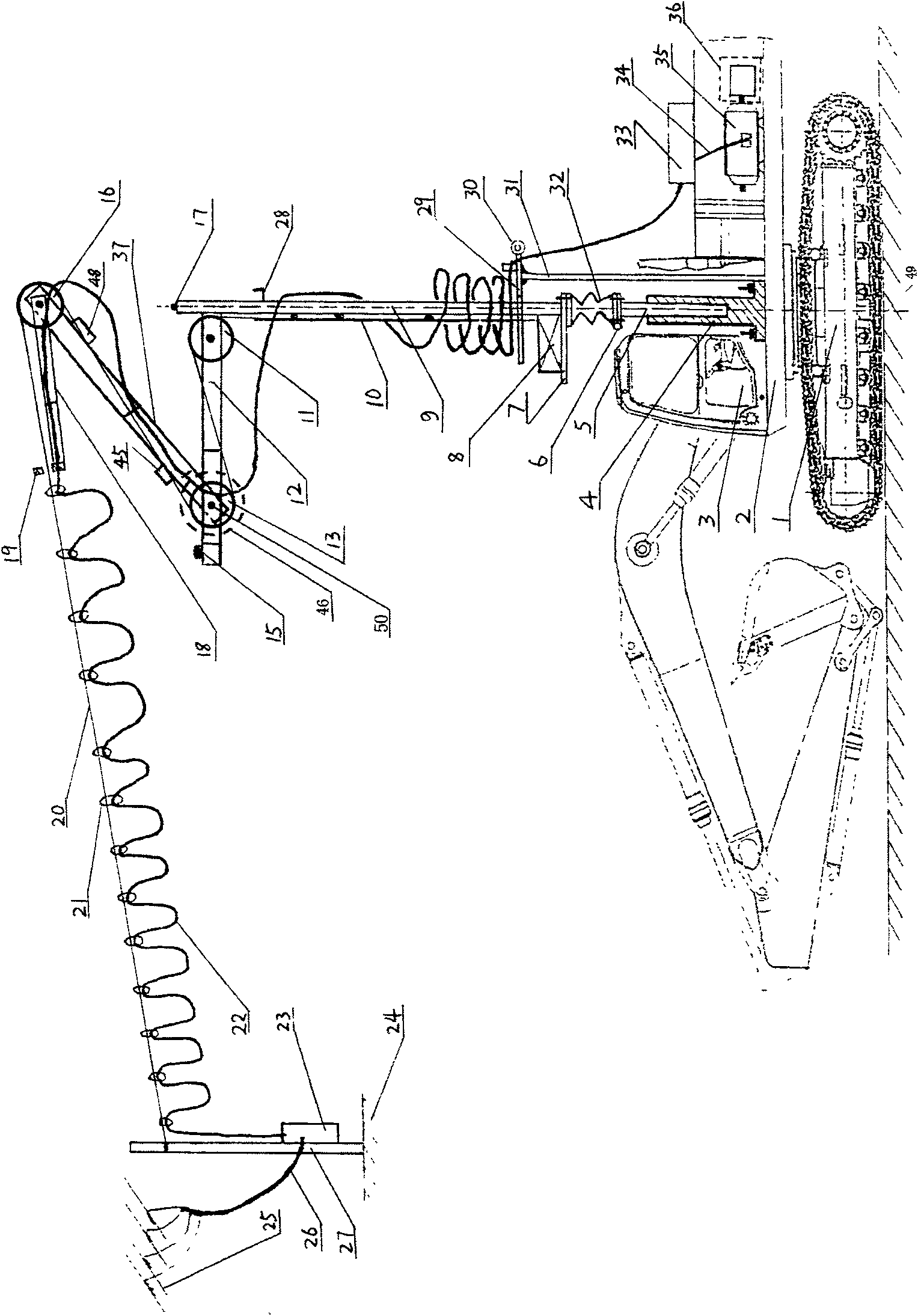

[0028] Example 1: Combining Attachment figure 1 , is a schematic diagram of the structure of the present invention. The manufacturing method of the power supply type electric excavator device of the present invention is composed of a basic vehicle body unit, a vehicle-mounted utility pole unit, a vehicle-mounted motor unit, a stationary vehicle body moving unit and a power supply unit.

[0029] The basic vehicle body unit is composed of a lower vehicle body part (1), a slewing platform (2), and an upper vehicle body part (3), and the connection mode of the original excavator is maintained among them. The upper body part (3) is the remaining parts after the upper body of the original excavator has been removed with all its fuel power and corresponding accessories, and the lower body part (1) and the slewing platform (2) are the original body parts. Accessories.

[0030] The vehicle-mounted utility pole unit is composed of a hollow base (4), a lower support rod (5), a spring a...

Embodiment 2

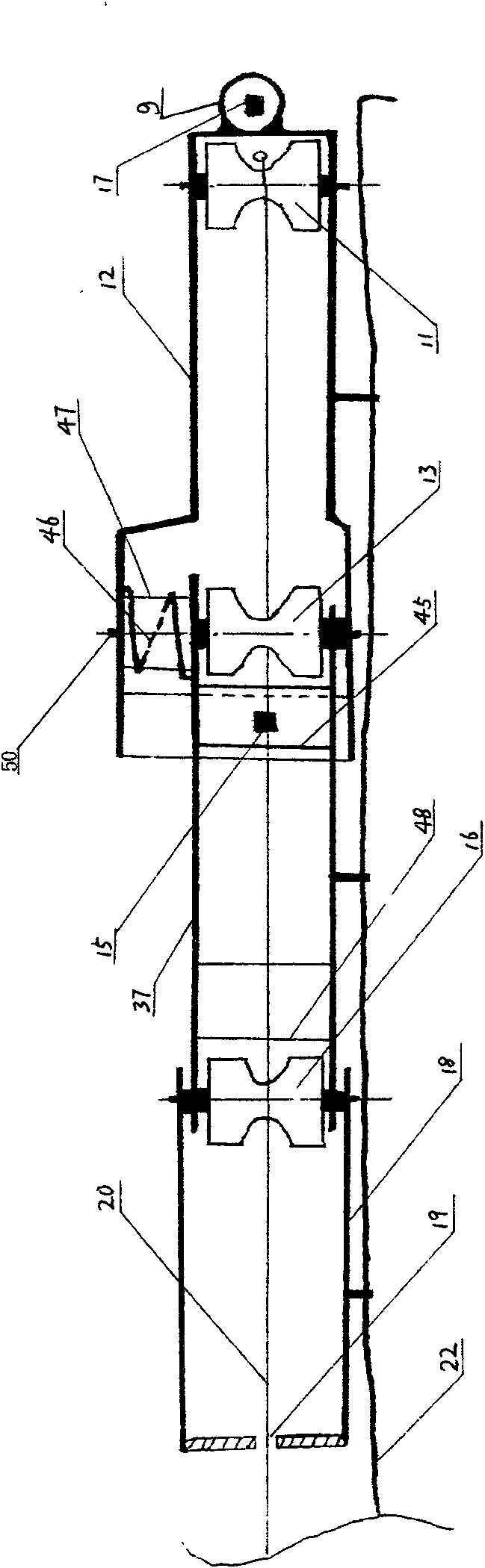

[0031] Example 2: Combining Attachment figure 2 , is the structural schematic diagram of the pulley assembly of the present invention. It consists of a fixed pulley (11), a central fixed pulley (13), a tensioning fixed pulley (16), a fixed fixed frame

[0032] (12), a swing type fixing frame (37), a free type fixing frame (18), a torsion spring (46), and a torsion spring inner sleeve (47) are composed. One end of the fixed fixing frame (12) is connected to the fixed pulley (11), and this end is vertically fixed to the upper end of the upper support rod (9), and the other end is connected to the central fixed pulley (13), the torsion spring through the movable shaft (50) (46), an inner sleeve of the torsion spring (47) and one end of the swing-type fixing frame (37). The other end of the swing type fixing frame (37) is connected with one end of the tensioning fixed pulley (16) and one end of the free type fixing frame (18) through a rod shaft. The other end of the free-type...

Embodiment 3

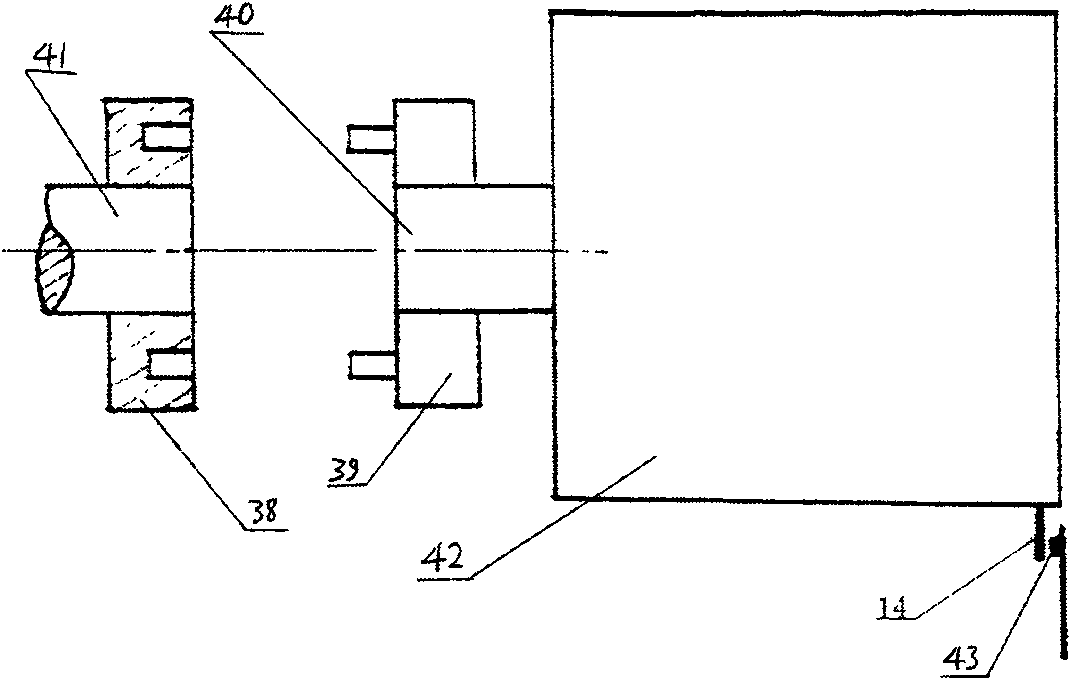

[0036] Example 3, in conjunction with the attached image 3, is a schematic diagram of the structure of the stationary vehicle body moving unit of the present invention. The stationary body moving unit (36) is composed of a concave connecting plate (38), a convex connecting plate (39), a turbo reducer (42) with a small motor, a circuit switch (43) and a small baffle plate (14). The female connecting plate (38) is fixed on the right end of the power shaft (41) of the electric motor (35), that is, the non-output end, and the male connecting plate (39) is fixed on the output shaft (40) of the turbo reducer (42). The output shaft (40) of (42) is concentric with the power shaft (41) of the electric motor (35). When the vehicle body needs to move temporarily, lock the turbo reducer (42) in a position where the male connection disk (39) and the female connection disk (38) can be completely butted together, otherwise it is locked in a completely separated position, that is, the turbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com