Low-NOx afterburning and VOC efficient removing method and system based on RTO

A supplementary combustion and high-efficiency technology, applied in combustion methods, combustion types, incinerators, etc., can solve the problems of high price of low-NOx burners, increased investment costs of enterprises, low VOC removal efficiency, etc., to improve VOC removal efficiency, reduce Investment cost, effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

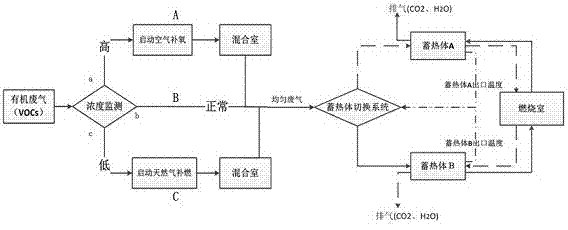

[0037] figure 1 It is a flow chart of the method disclosed in the present invention, and the arrows in the figure indicate the flow direction of RTO organic waste gas. Such as figure 1 The shown RTO-based low NOx supplementary combustion and VOC efficient removal method includes the following steps,

[0038] Step 1, concentration detection. After RTO organic waste gas (VOCs) is detected by the concentration detector, the concentration detector will send out three signals a, b, and c according to the detected exhaust gas concentration. Signal a indicates high exhaust gas concentration, and signal b Indicates normal exhaust gas concentration, signal c indicates low exhaust gas concentration;

[0039] Step 2: Exhaust gas stroke switching. In step 1, the concentration detector will send three signals a, b, and c according to the detected exhaust gas concentration to feed back to the exhaust gas stroke switching system. The exhaust gas stroke switching system includes three switc...

Embodiment 2

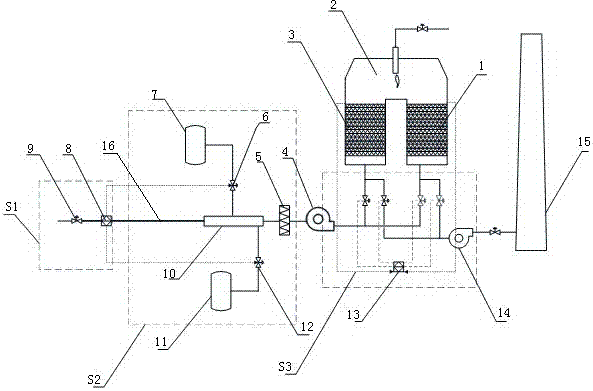

[0052] Such as figure 2 The shown RTO-based low NOx supplementary combustion and VOC high-efficiency removal system includes an exhaust gas concentration monitoring system S1, an exhaust gas stroke switching system S2, and a temperature-controlled heat storage body switching system S3 connected in series. The exhaust gas concentration detection system includes The waste gas conveying pipeline 16 is equipped with a concentration detector 8 on the waste gas conveying pipeline, and an exhaust gas inlet valve 9 is arranged on the waste gas conveying pipeline. The system includes a mixing chamber 10, the other end of the exhaust gas delivery pipeline is connected to the mixing chamber, one side of the mixing chamber is connected to the compressed air chamber 7 through a pipeline, and an air inlet valve 6 is arranged on the pipeline between the compressed air chamber and the mixing chamber, and the other side of the mixing chamber The natural gas chamber 11 is connected by a pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com