Circular production of hexamethylolmelamine

A hexamethylol melamine and production process technology, applied in the field of hexamethylol melamine, can solve the problems of easy clogging of filter cloth, inability to effectively recycle or process, inconvenient cleaning, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

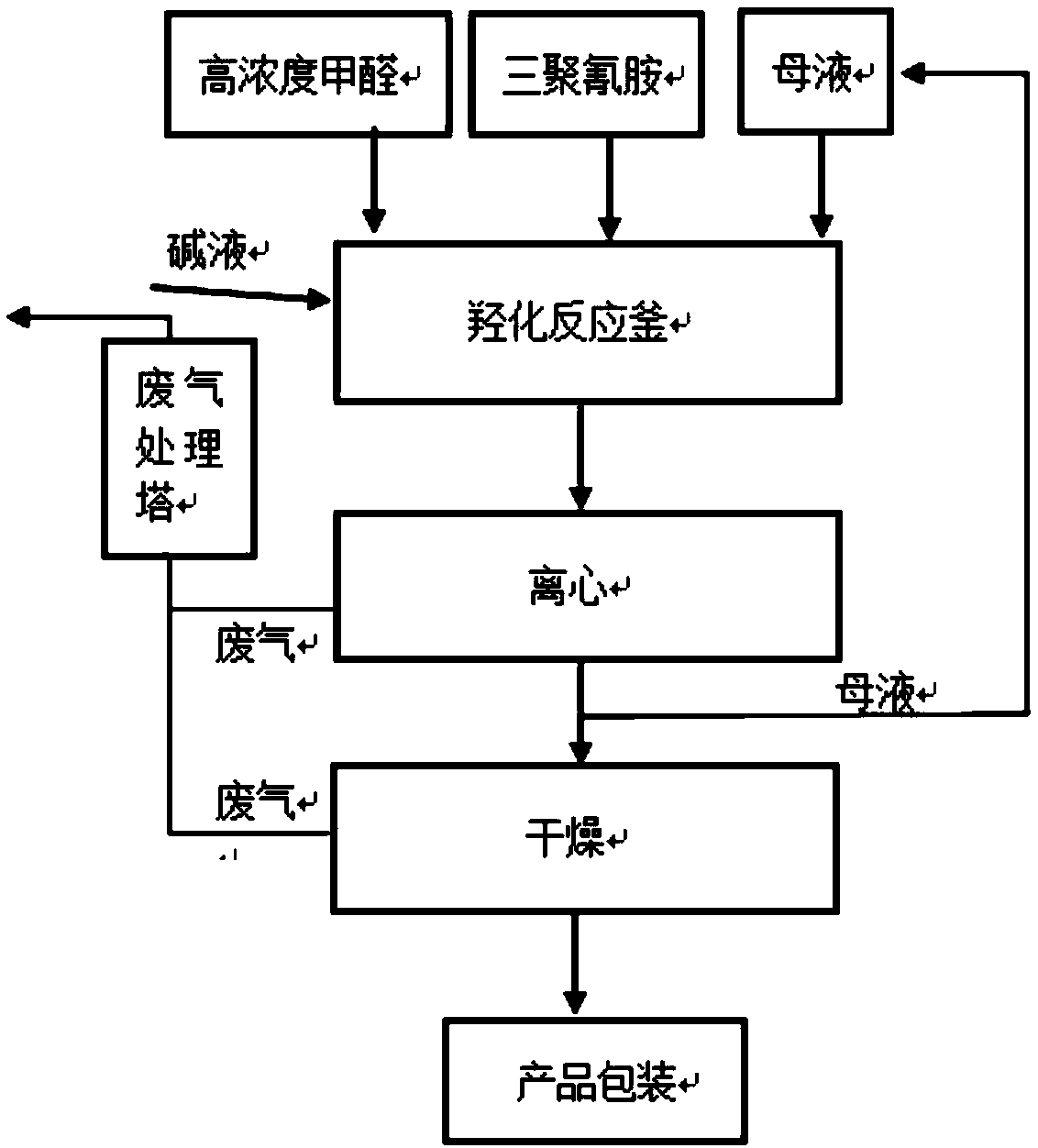

[0039] Such as figure 1 As shown, the production process of hexamethylolmelamine of the present invention generally includes adding formaldehyde, melamine, and alkali in a hydroxylation reactor to react, centrifuging and drying to obtain the product and packaging it. The exhaust gas generated during the centrifugation and drying process is passed to the exhaust gas treatment tower for subsequent treatment. The mother liquor separated by centrifugation is recycled as raw material for production in the whole process. The specific circulation production process is as follows:

[0040] 1) Add water or (recycle) mother liquor in the hydroxylation reactor;

[0041] 2) adding formaldehyde aqueous solution to the reaction kettle, and keeping the formaldehyde content at 10% to 25%, preferably 15% to 20%;

[0042] 3) Stir and heat the solution in the kettle to 40-80°C, pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com