Son-mother gas filling station

A gas cylinder and luck technology, applied in the direction of gas/liquid distribution and storage, special distribution devices, equipment loaded into pressure vessels, etc., can solve problems such as no discovery, achieve fast expansion speed, increase gas filling capacity, and simplify the process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

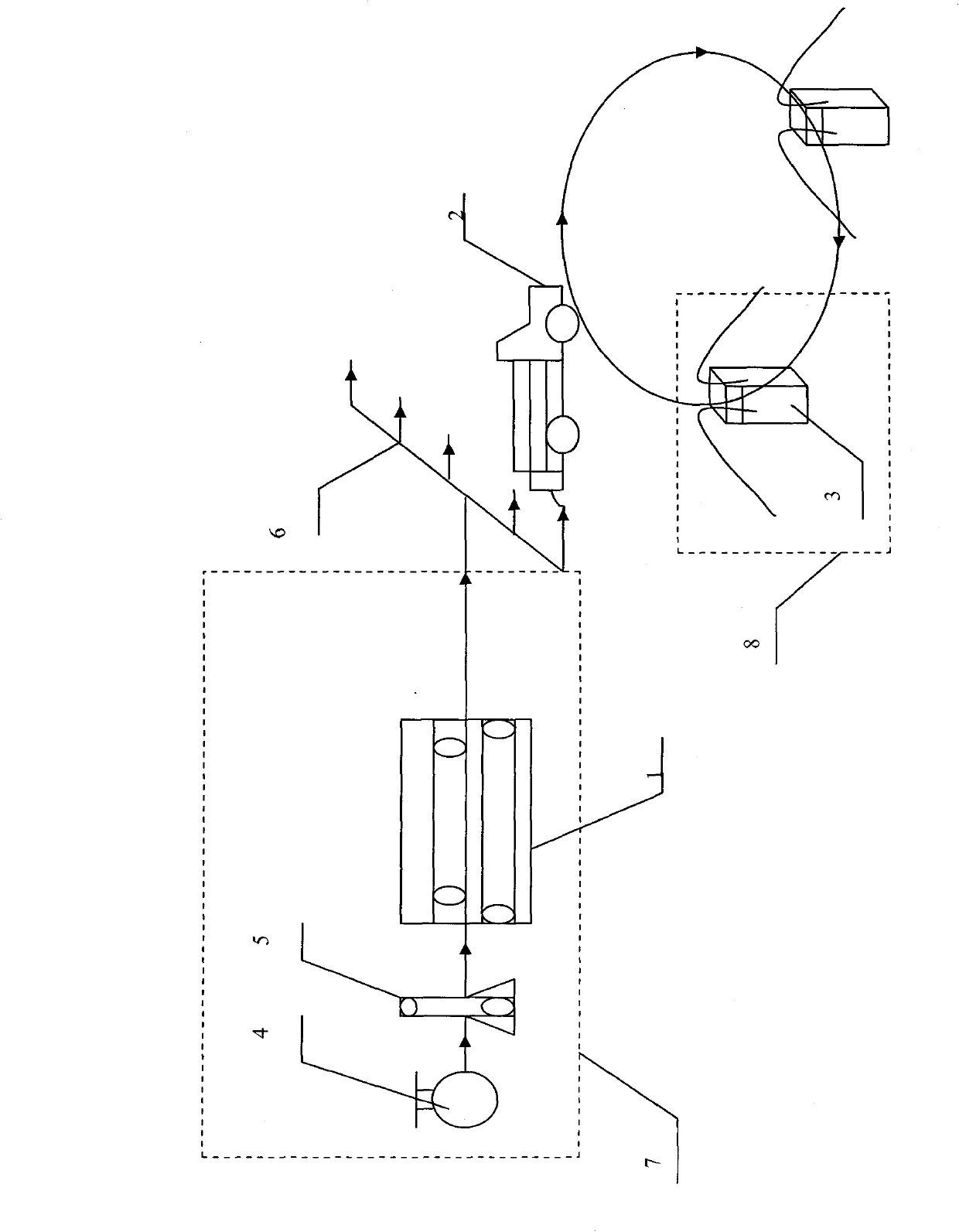

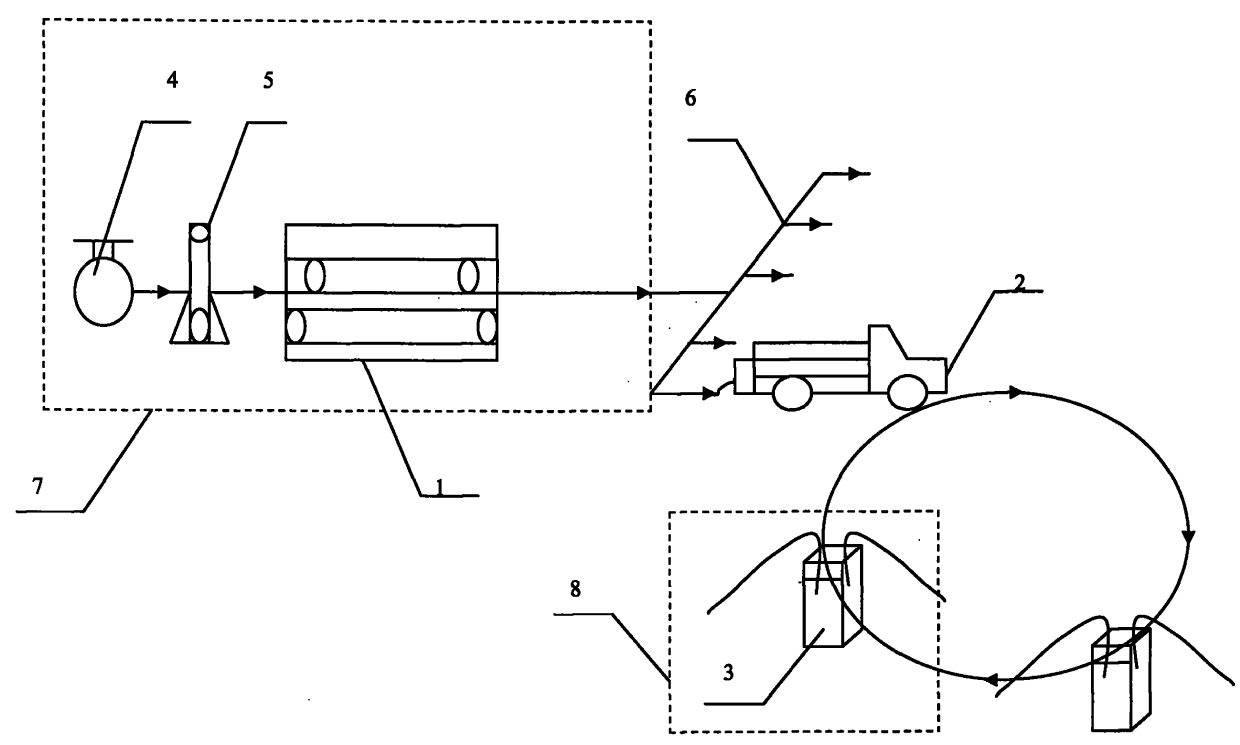

[0049] figure 1 It is the flow chart of the parent-child filling station with pipeline natural gas as the parent station; 1 indicates the compressor; 2 indicates the gas cylinder of the luck trailer; 3 indicates the filling machine; 4 indicates the natural gas pipeline; 5 indicates the dehydration, filtering and drying device; 6 indicates Inflatable busbar; 7, the dotted line box indicates the mother station area; 8, the dotted line box indicates the substation area or gas filling terminal.

[0050] Process implementation process:

[0051] In the 7 mother station, the natural gas is pumped from the 4 natural gas pipeline and then pressurized to 25-30MPa by the 5 dehydration, filtration and drying device to the 1 compressor, and the gas cylinder of the luck trailer is filled with gas through the 6 inflatable bus bar, and the trailer gas cylinder is filled with gas The pressure is 25MPa, and it is transported to each corresponding sub-station to be connected with the filling ma...

Embodiment 2

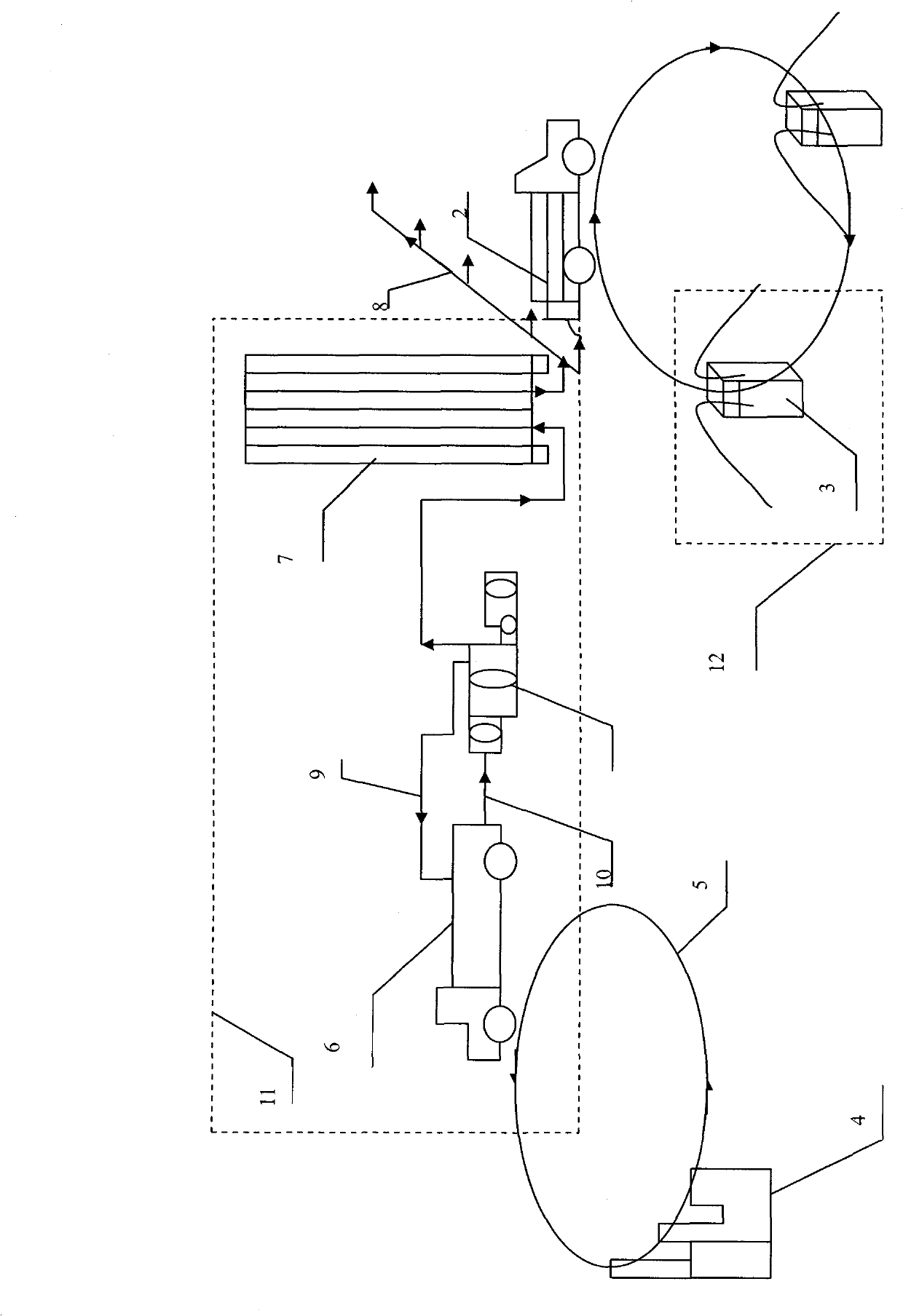

[0053] figure 2 It is the flow chart of the mother-to-child refueling station with the LNG gasification station as the parent station; 1 represents the compressor; 2 represents the gas cylinder of the luck trailer; 3 represents the gas dispenser; 4 represents the LNG factory or receiving station; 5 represents the LNG tanker Circular transportation between the factory and the gasification station; 6 indicates the LNG liquid tank car; 7 indicates the vaporizer; 8 indicates the gas-filled bus; 9 indicates the gas phase unloading; 10 indicates the LNG liquid phase channel; Boxes indicate substation areas or refueling terminals.

[0054] Process implementation process:

[0055] LNG liquid tank car 6 is transported circularly between the 5th factory and the gasification station. In the 11 mother station, the 6LNG liquid tank car is connected to the cryopump, and the LNG liquid in the 6 tank car flows into the cryogenic pump through 10 through 9 gas phase unloading. The cryogenic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com