Ejector device having auxiliary-ejection force

A technology of a pushing device and a pushing plate, which is applied to home appliances, other home appliances, and household components, and can solve problems such as time-consuming and ineffective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

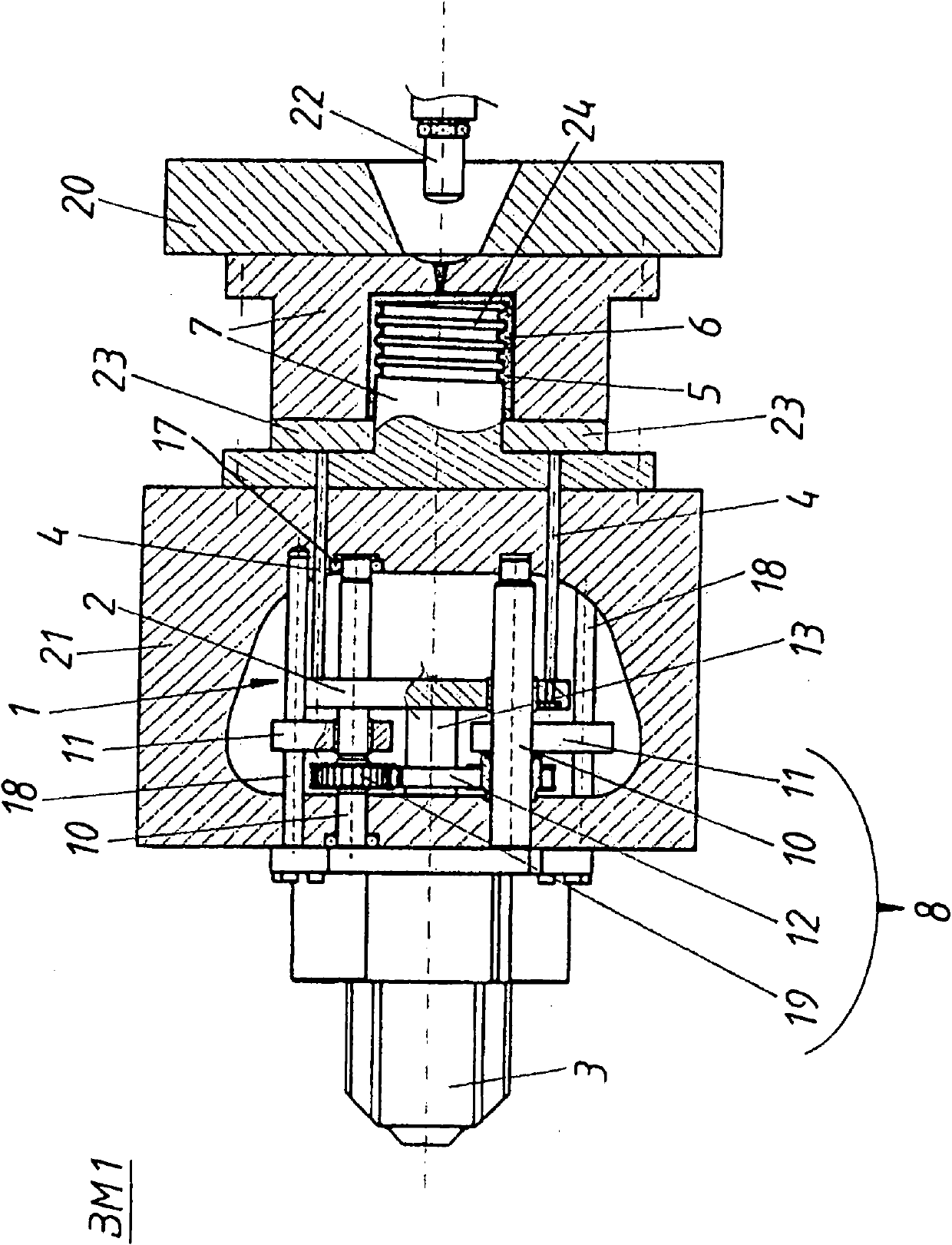

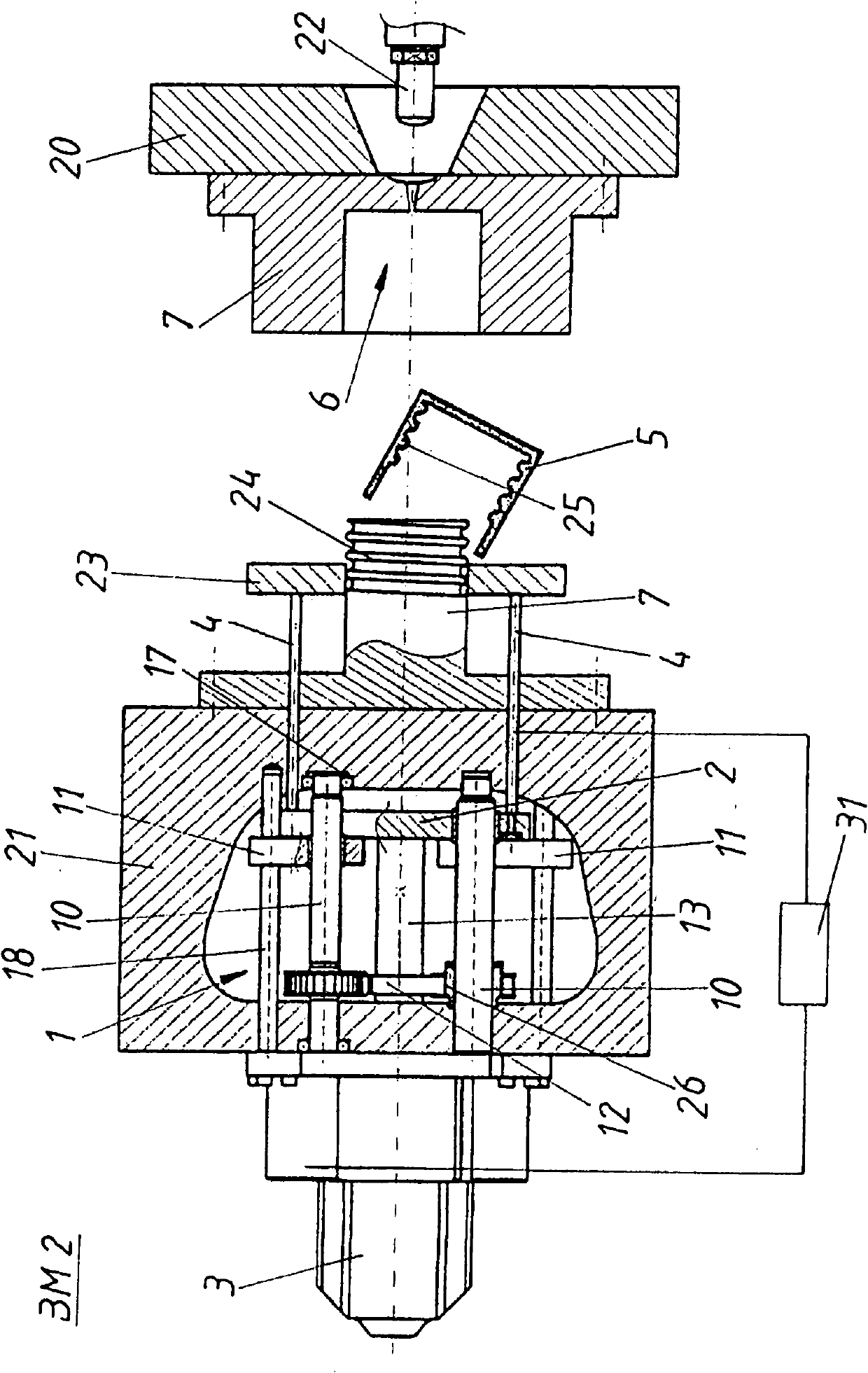

[0021] figure 1 The closed side of an injection molding machine including the ejector device 1 in the first operating mode BM1 is shown. Typically, the closing side of the injection molding machine has a fixed mold clamping plate 20 and a movable mold clamping plate 21 with the two-part injection molding tool 7 arranged between them. Simultaneously formed between the two halves of the injection molding tool 7 is a cavity 6 which, in this view, is filled with the melt which forms the molded part 5 , injected through the injection nozzle 22 .

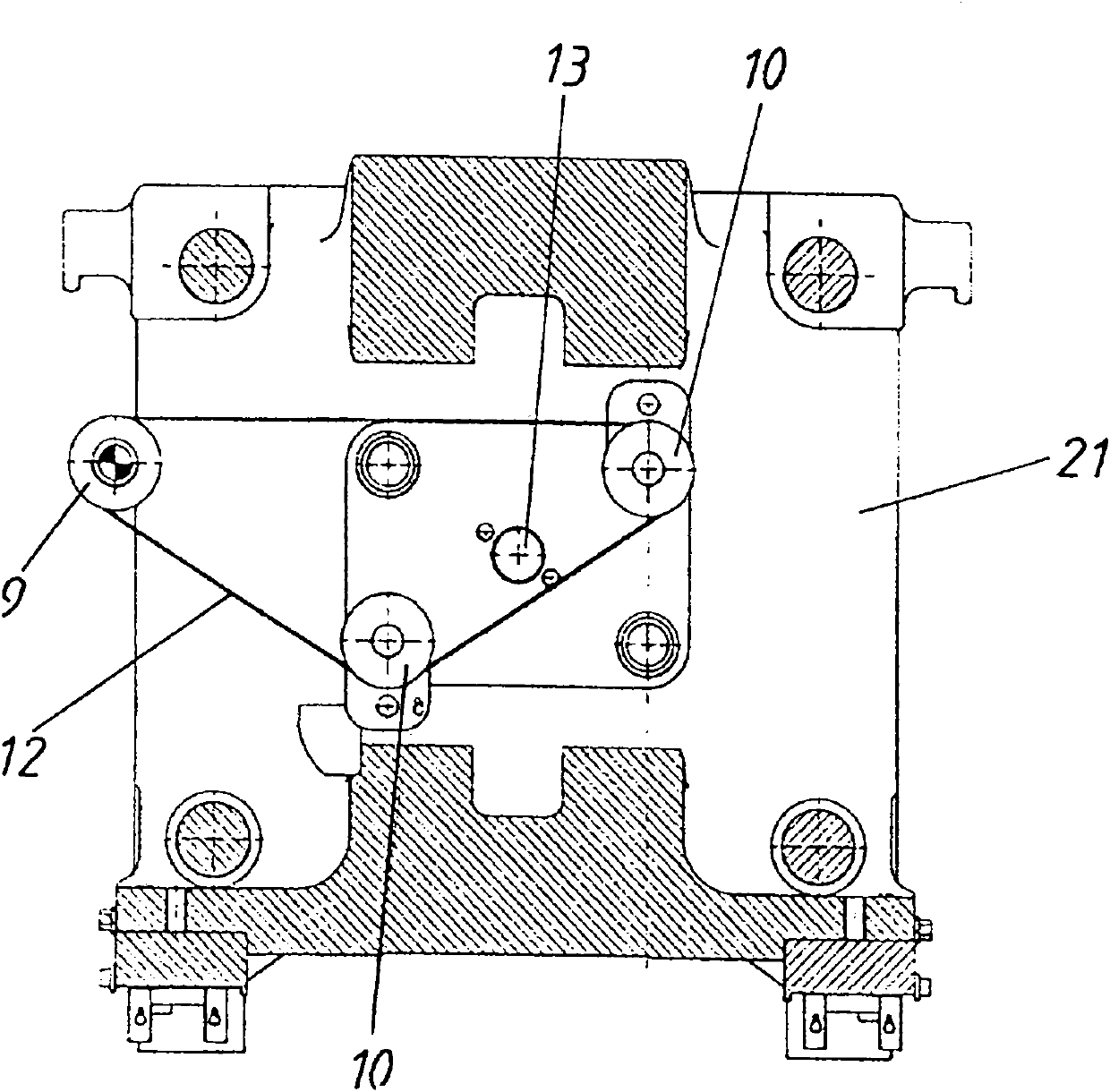

[0022] The pusher device 1 comprises a drive device 3 which drives the pusher plate 2 in translation via a spindle 13 . A plurality of ejector pins 4 are arranged on the ejector plate 2 through a movable mold clamping plate 21 . At their front end they have ejector pin projections 23 which act directly on the injection molded part 5 and which can be pulled off over the threaded core of the mold half 7 during a translational movement. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com