Equipment for automatically piling up and magnetizing blocky magnetic materials

A technology of magnetic materials and magnetizing equipment, applied in the fields of magnetic objects, inductance/transformer/magnet manufacturing, electrical components, etc., which can solve the problems of difficult quality control, difficult management, and low manual work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

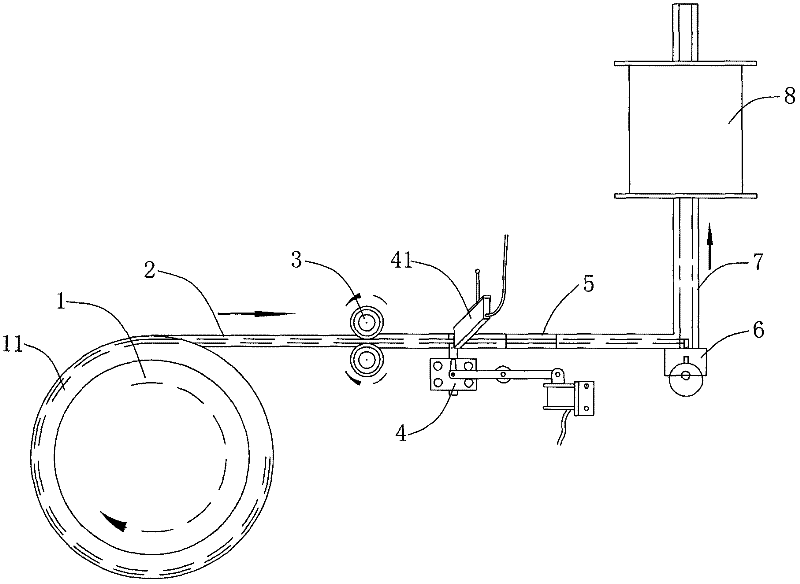

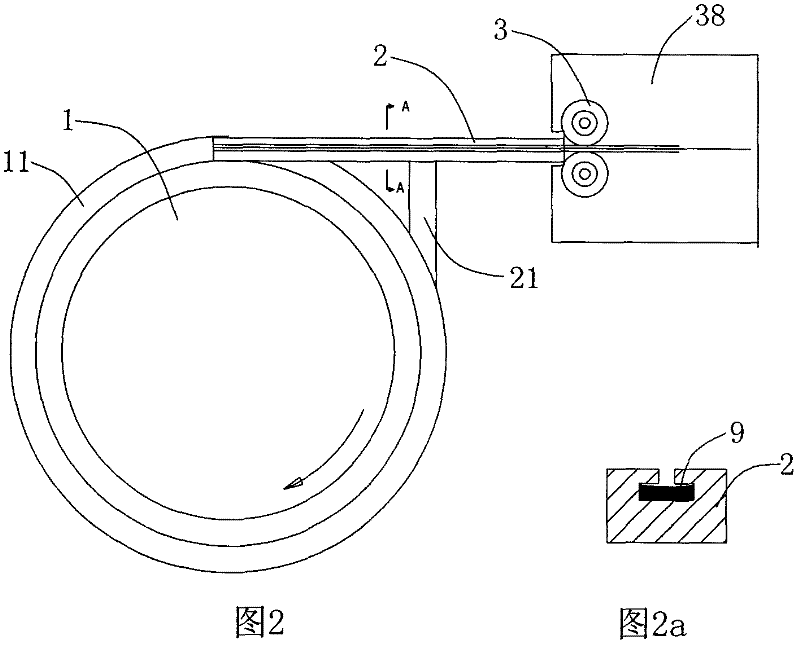

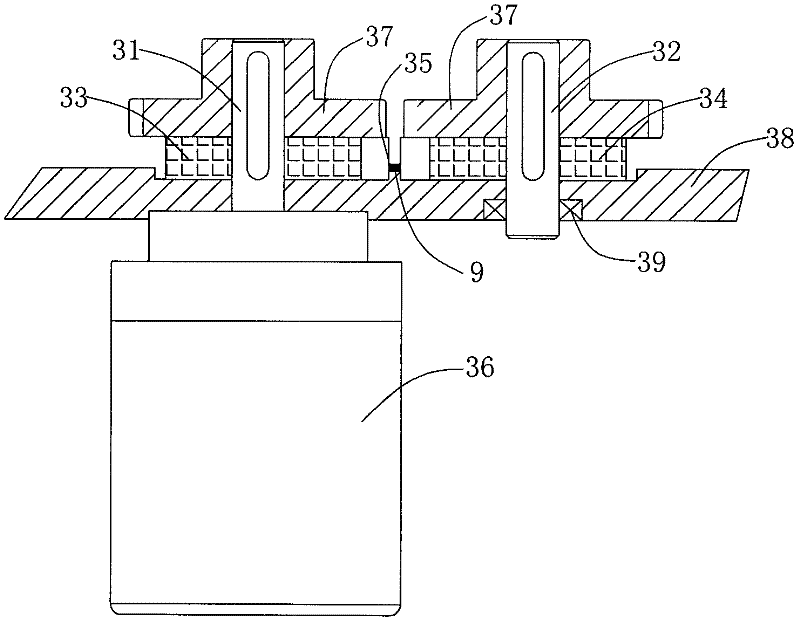

[0023] Figure 1 to Figure 7 Shown is the structural representation of the present invention.

[0024] The reference signs therein are: vibrating plate 1, spiral conveying channel 11, vibrating plate output track 2, ejector outlet 2a, support 21, workpiece pushing mechanism 3, first central axis 31, second central axis 32, first pushing Gear 33, second push gear 34, elastic gear teeth 35, first speed regulating motor 36, linkage gear 37, workbench 38, bearing 39, ejector mechanism 4, photoelectric detection sensor switch 41, ejector rod 42, ejector rod seat 43, extension spring 44, electromagnet 45, rocking arm 46, rotating shaft 46a, workpiece sideways device 5, workpiece input end 51, stand up track 52, inclined plane 52a, elastic ejection stacking mechanism 6, push rod 61, push rod seat 62, Stage clip 63, pulley 64, eccentric wheel 65, sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com