Peanut vine separating device for peanut harvesting

A separation device and peanut harvesting technology, which is applied to digging harvesters, harvesters, threshing equipment, etc., can solve the problems of uneven growth of peanut seedlings, high labor intensity, and low efficiency, and achieve ingenious ideas, novel structures, The effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

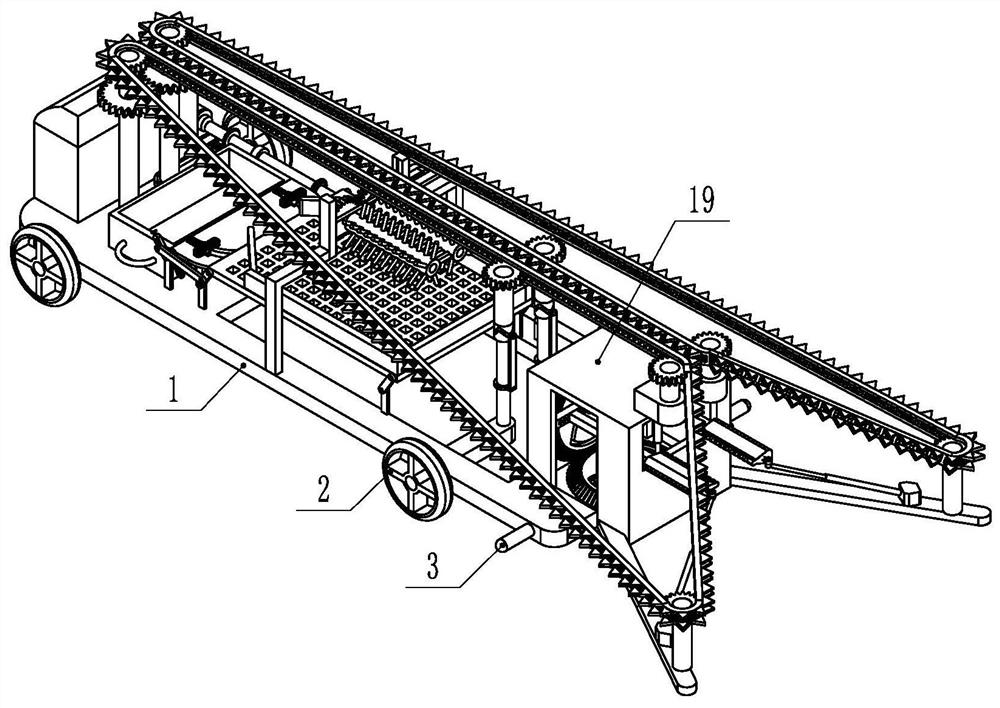

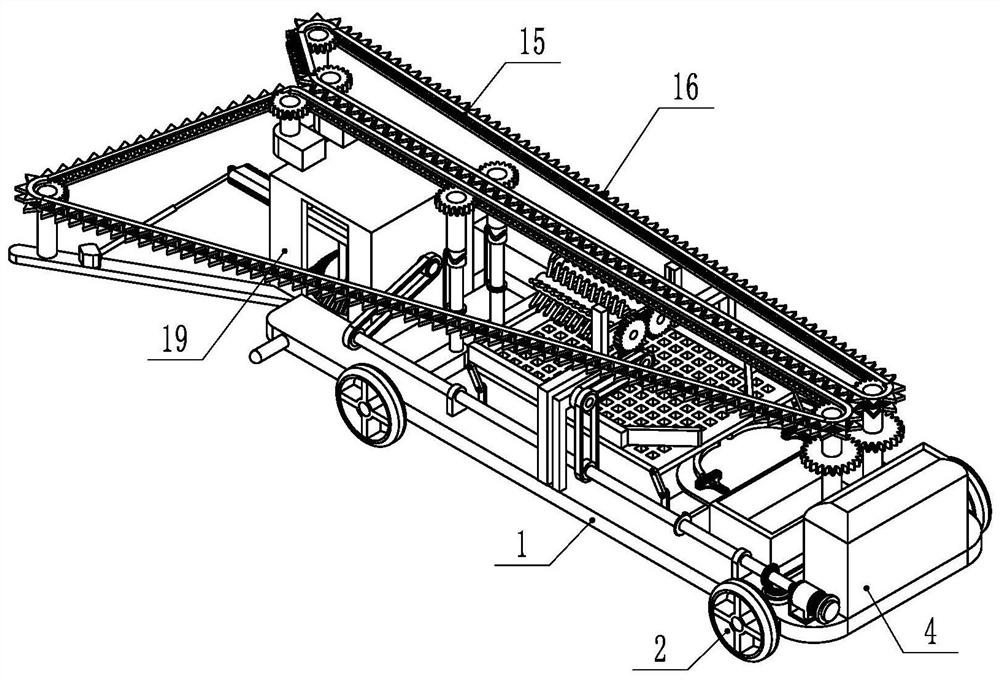

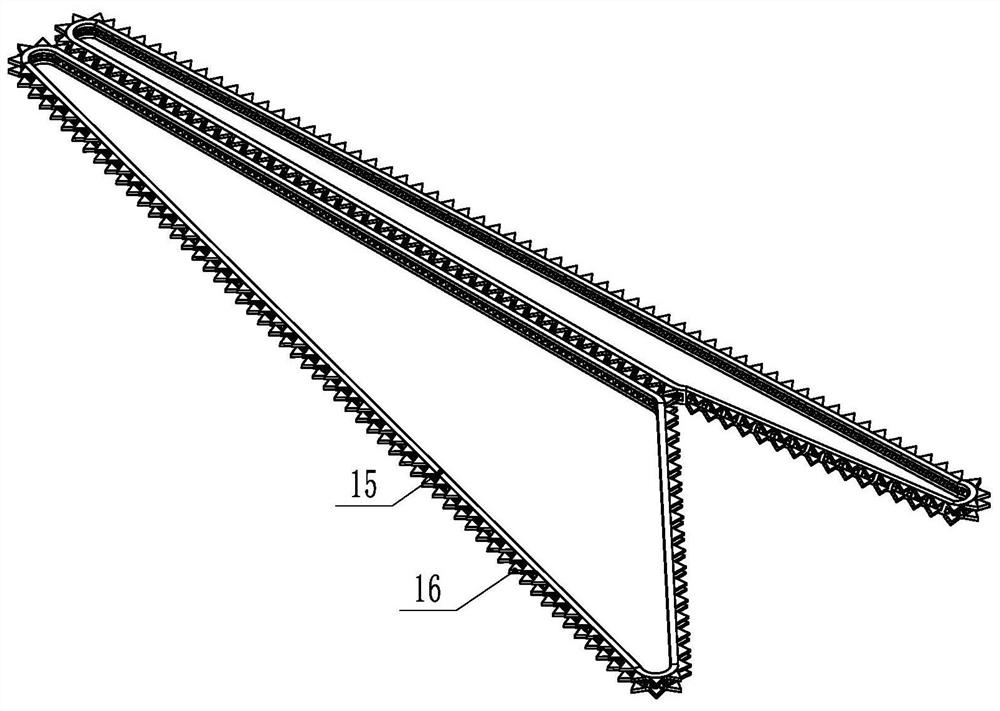

[0041] Such as Figure 1-21 As shown, the present invention provides a peanut seedling separation device for harvesting peanuts, including a bottom plate 1, the left and right sides of the upper end of the bottom plate 1 are respectively equipped with chains 15 inclined to the outer lower end of the front end, and the left and right sides of the upper end of the bottom plate 1. The ends are respectively equipped with tooth-shaped splints 29 that can move to the inside and then move upwards at the same time; The fruit-picking shaft 42 that is matched with the chain 15 and can move up and down while rotating. The middle part of the upper surface of the bottom plate 1 is equipped with a leaking plate 58 that matches the fruit-picki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com