Fitting structure for built in type apparatus

A technology of appliance and structure, which is applied in the field of installation and structure of embedded appliances, can solve problems such as the inability to set the roof, damage to the ceiling lamp, etc., and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0072] 4( a ), ( b ) are enlarged side views showing other embodiments of the support portion 13 according to the present invention.

[0073] And, with figure 1 The components that are the same as those shown in FIG. 3 are given the same reference numerals, and their introductions are omitted. At this time, only the features of the various embodiments are introduced.

[0074] The supporting part 13 shown in Fig. 4(a) further extends downward the claw part 13d after extending the upper end of the guide inclined surface 13c to the outside to form a detachment preventing part 13d'.

[0075] If the detachment preventing portion 13d' is formed, the engaging portion 23b guided by the guide inclined surface 13c and engaged with the contact claw portion 13d is more reliably engaged and can be prevented from being detached.

[0076] In the support portion 13 shown in FIG. 4( b ), the claw portion 13d formed on the support portion 13 is formed as a long hole with the same inclination a...

Embodiment 3

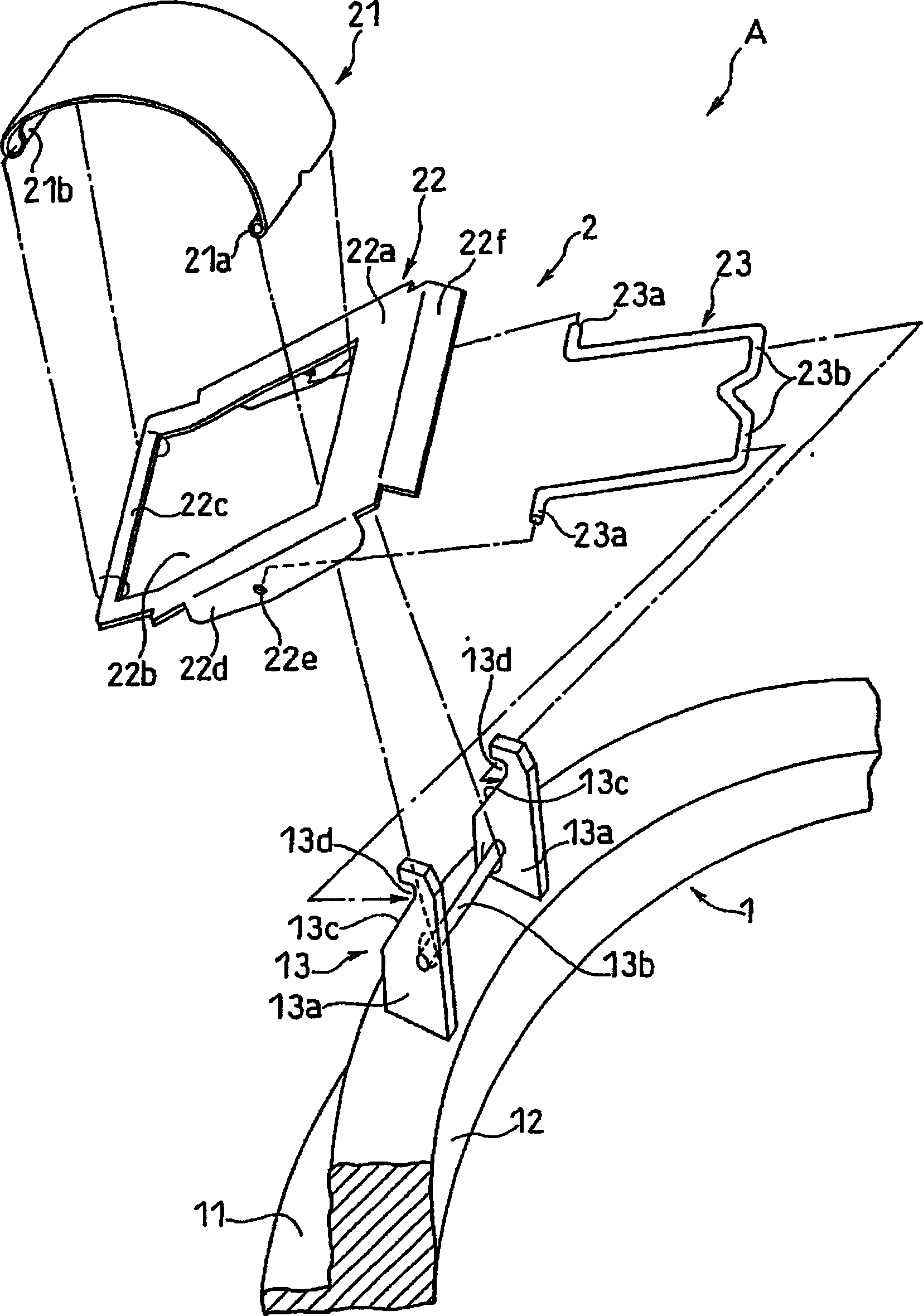

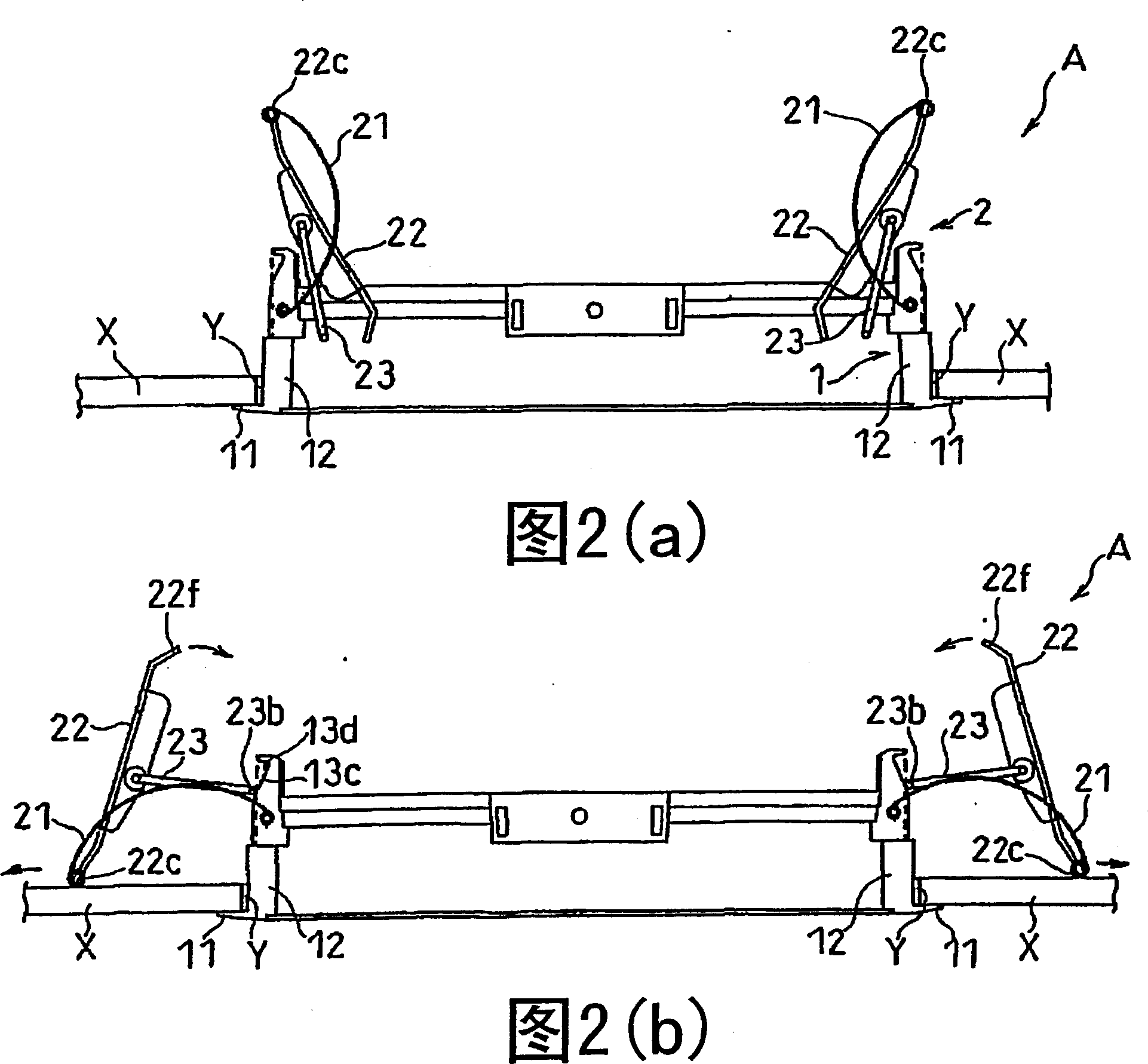

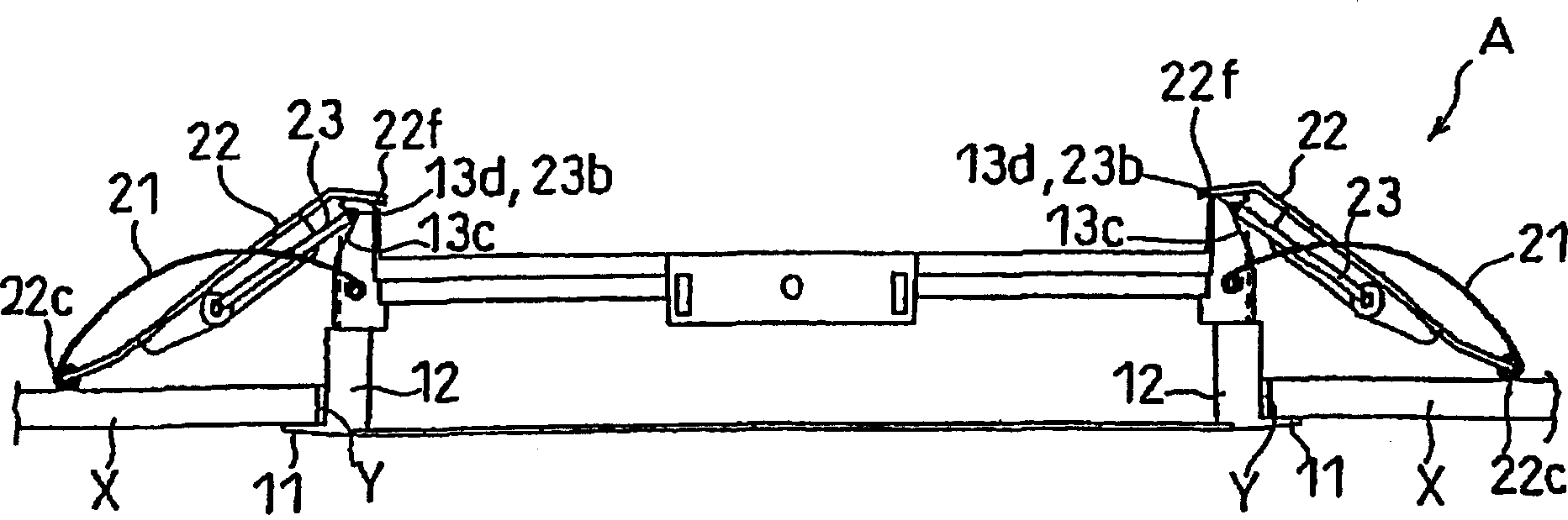

[0079] Figure 5 It is a perspective view showing the key parts of yet another embodiment of the installation structure A of the embedded appliance of the present invention, and FIG. 6 shows Figure 5 An explanatory diagram of the installation operation of the installation structure A of the embedded appliance shown.

[0080] And, with figure 1 The components that are the same as those shown in FIG. 4 are given the same reference numerals, and their introductions are omitted, and only the features of the various embodiments are introduced at this time.

[0081] The mounting structure A of this embedded appliance is characterized in that both ends 23c are pivotally supported on the flap portion 22d formed by bending both sides of the base plate 22a of the operation piece 22, and the front is penetrated to the support portion of the mounting frame 1. A set of ring-shaped toggle levers 23 formed by the shaft holes 13e on the 13;

[0082] That is, the toggle link 23 shown in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com