Motorhauben-gelenkhalterung und befestigungsstruktur

A technology of hinge bracket and connecting structure, applied in the directions of superstructure, superstructure sub-assembly, transportation and packaging, etc., can solve the problems of finely adjusting the position of the hood hinge bracket 107, difficult to adjust the hood hinge bracket 107, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, embodiments of the present invention are described in detail with reference to the accompanying drawings.

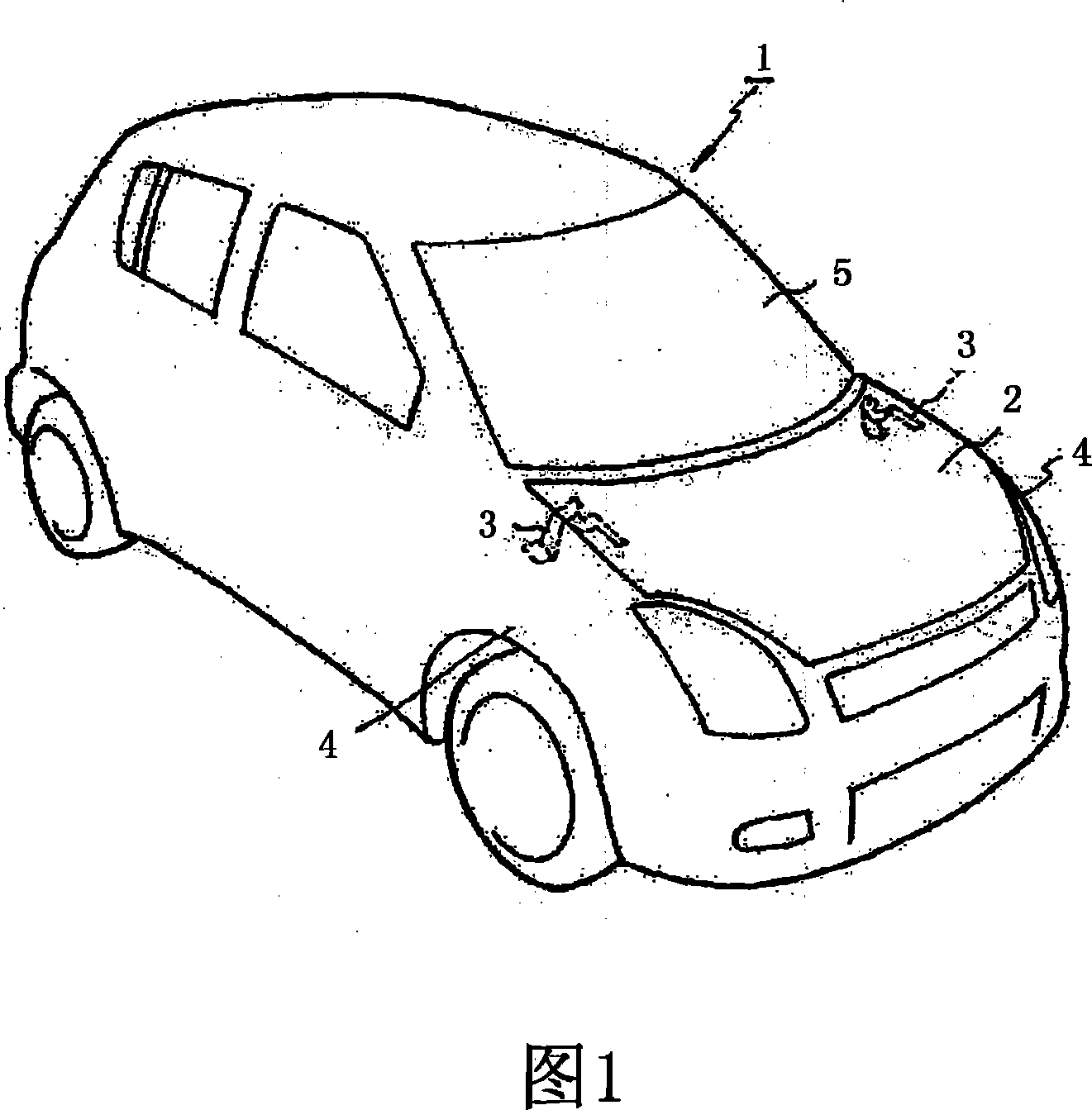

[0049] As shown in FIG. 1 , the vehicle body front portion of a vehicle 1 has a front hood 2 for opening and closing an engine room, which is pivotally supported on the right side and the right side of the vehicle body by a pair of hood hinges 3 . left side. Note that reference numeral 4 denotes front fenders on the right and left sides, and reference numeral 5 denotes a front window.

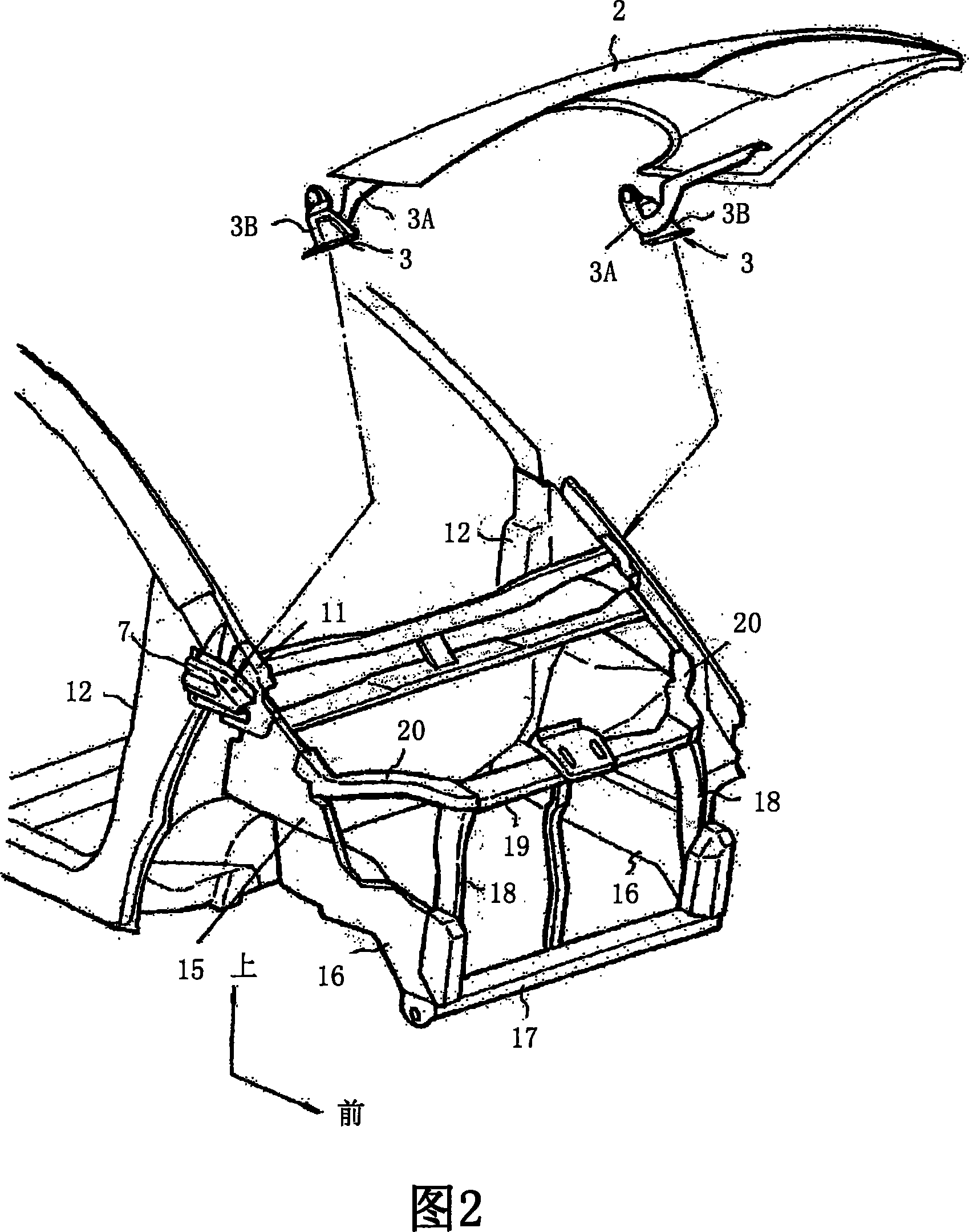

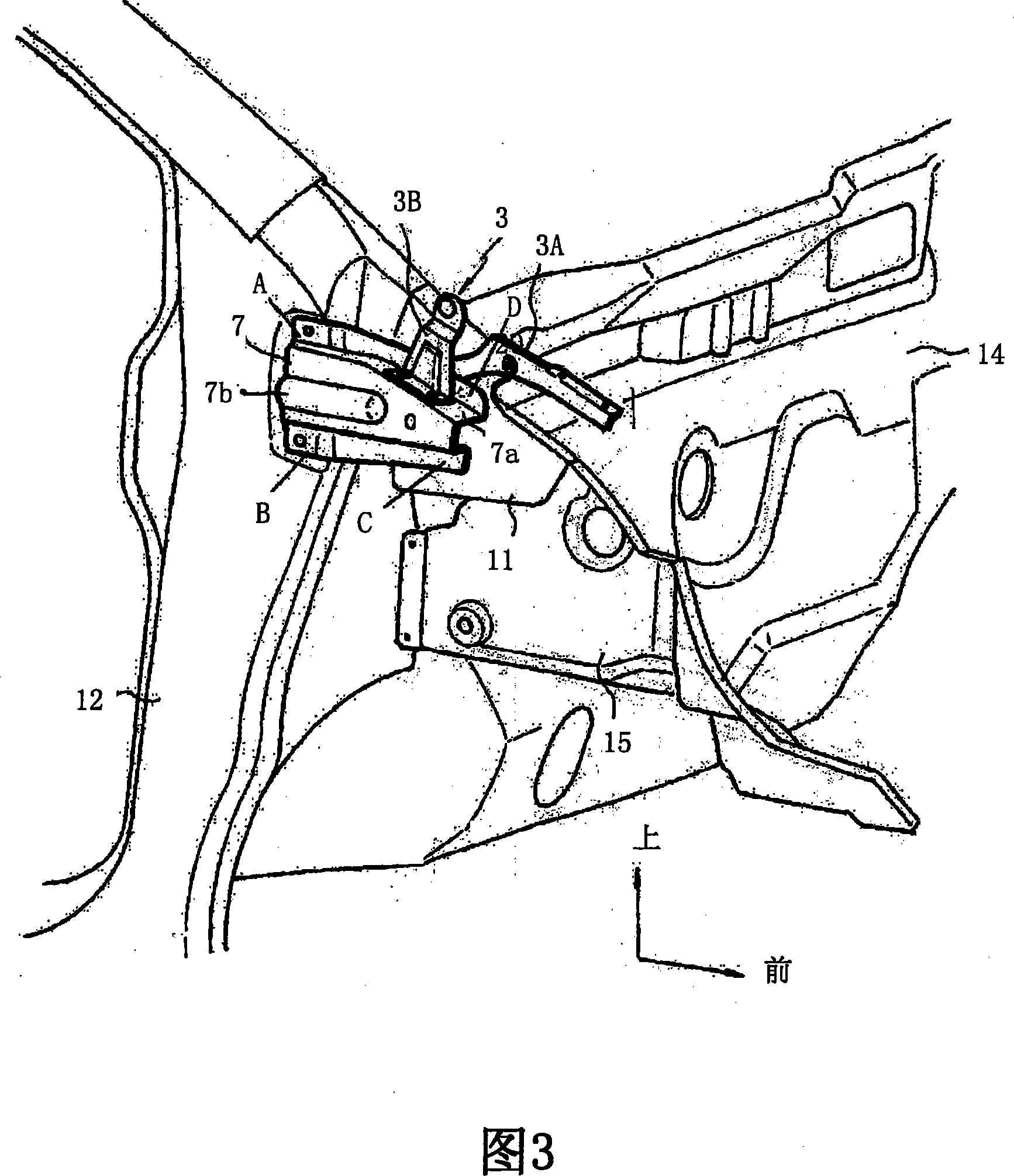

[0050]Incidentally, as shown in FIGS. 2 to 5 , the hood hinges 3 on the right and left sides are constituted by hinge arms 3A and hinge brackets 3B, respectively. As shown in FIG. 2 , one end of each hinge arm 3A is connected to the underside of the rear end at one end of the front hood 2 in the width direction by two bolts (not shown). The other end of the hinge arm 3A is connected to one end (upper end) of each hinge bracket 3B on the right and left sides by hinge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com