Patents

Literature

109results about How to "Prevent scurrying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

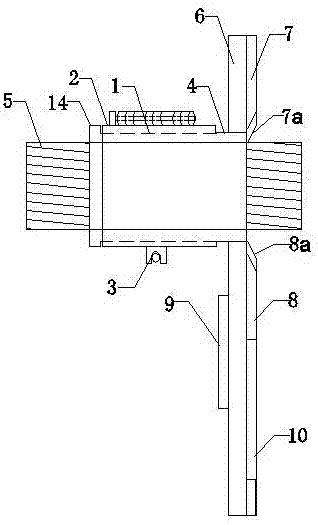

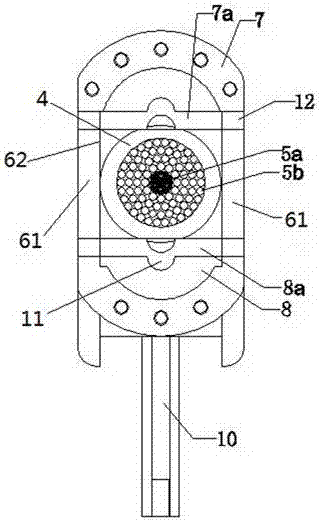

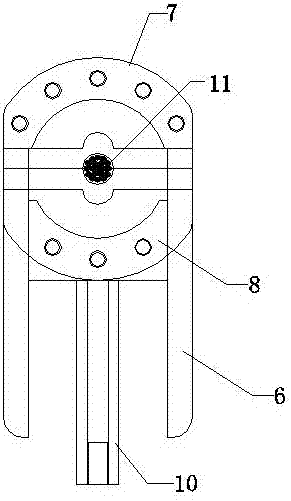

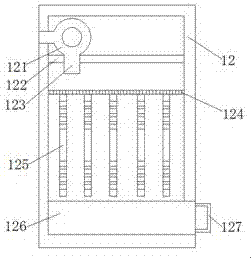

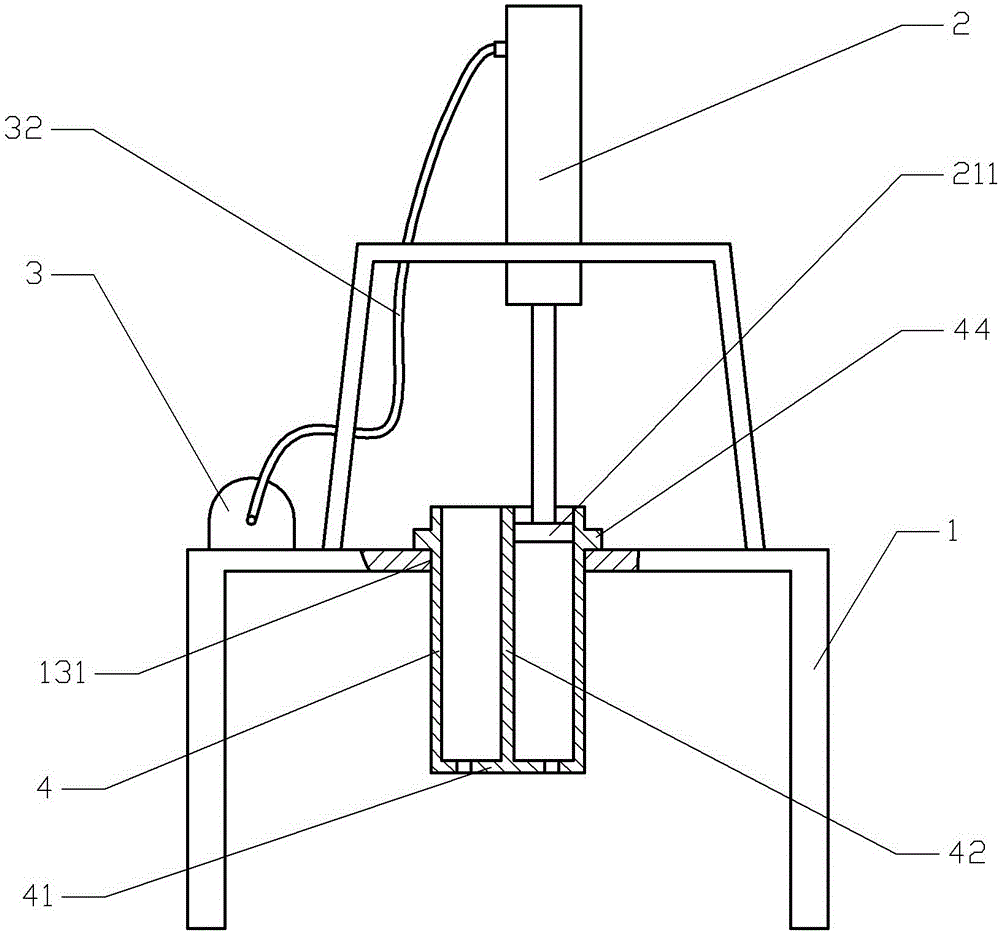

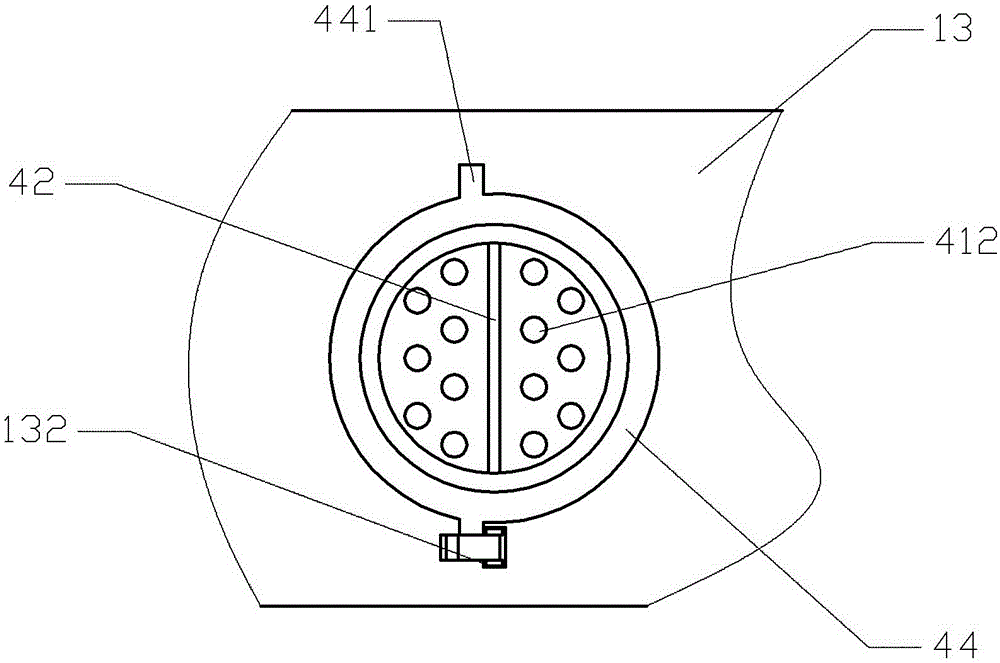

Wire stripping tool

ActiveCN107147050APrevent scurryingGuaranteed radial position relationshipApparatus for removing/armouring cablesEngineeringMechanical engineering

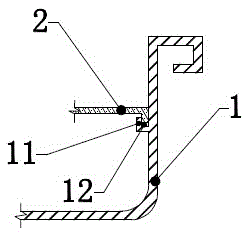

The invention relates to a wire stripping tool comprising a cutting mechanism and a cable locating sleeve, wherein the cable locating sleeve is provided with an inner hole having an axial line extending along the left and right direction and used for locating and penetrating through a corresponding cable, the cutting mechanism comprises a mechanism seat, a locating sleeve guide mechanism forming guide movement fit with the cable locating sleeve along a direction vertical to the left and right direction is arranged on the mechanism seat, two cutter bodies used for cutting an aluminum stranded wire on the outer side of a steel core are further arranged on the mechanism seat, wherein at least one cutter body is a movable cutter body in guide movement fit with the mechanism seat, the guide movement direction of the movable cutter body is consistent with the guide movement direction of the cable locating sleeve relative to the mechanism seat, and steel core evasion grooves used for evading the corresponding steel core are formed in the cutting edges of the fixed cutter body and the movable cutter body. The wire stripping tool provided by the invention solves the problem that a conducting wire or the wire stripping tool needs to be rotated, resulting in complex wire stripping operation in the prior art.

Owner:HENAN POWER TRANSMISSION & TRANSFORMATION CONSTR CO LTD +2

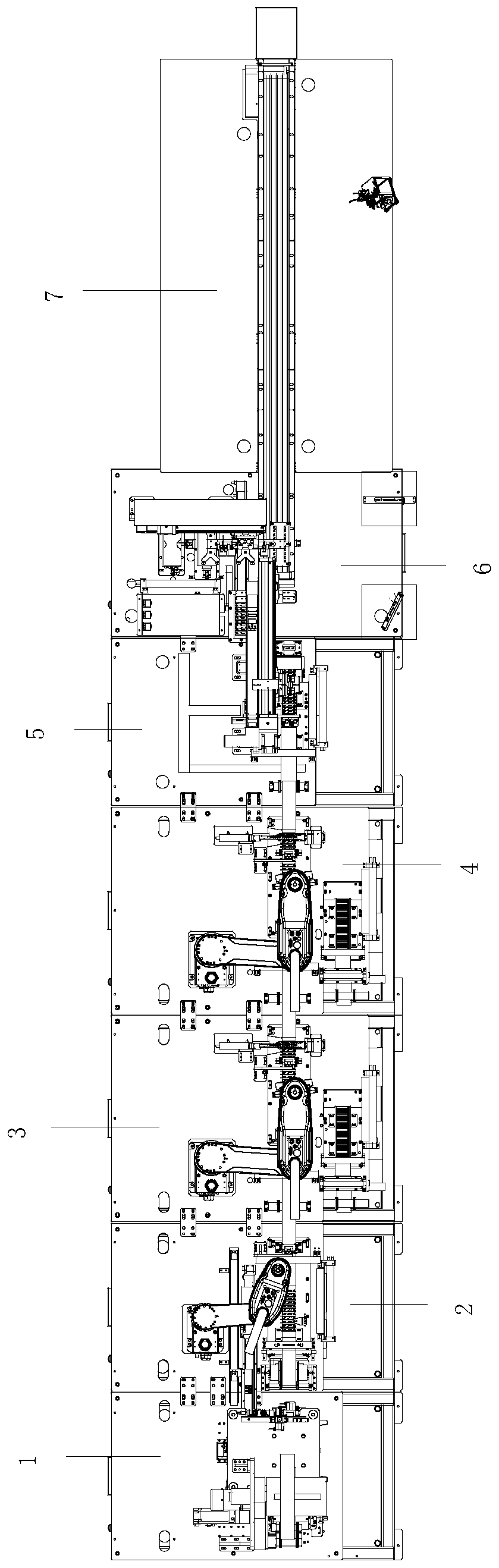

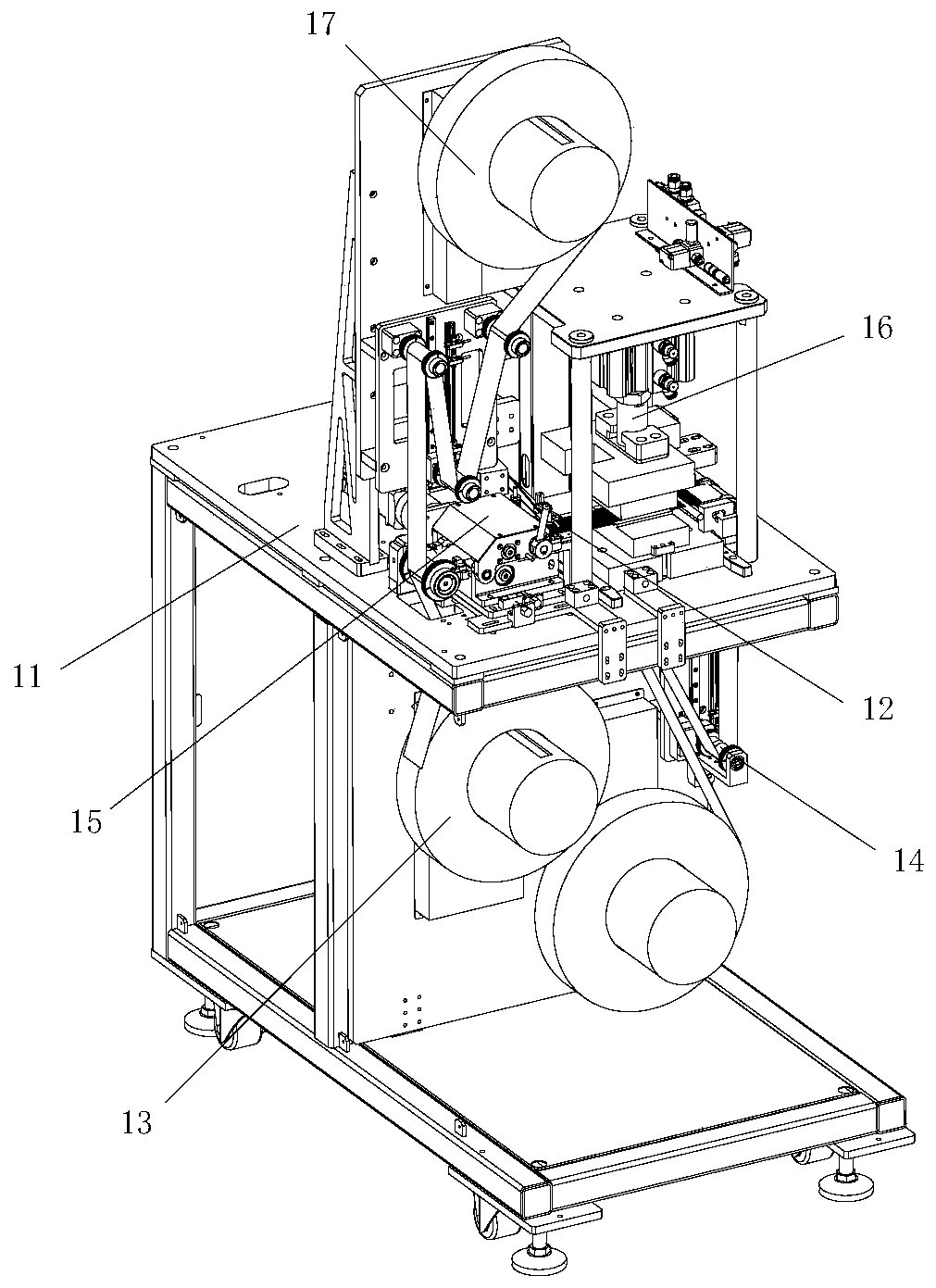

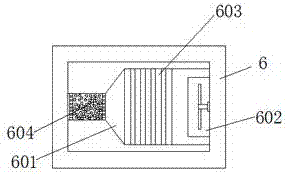

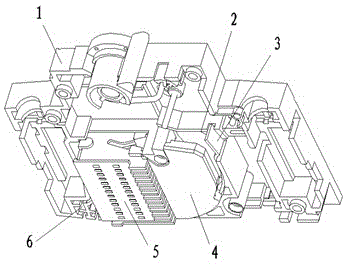

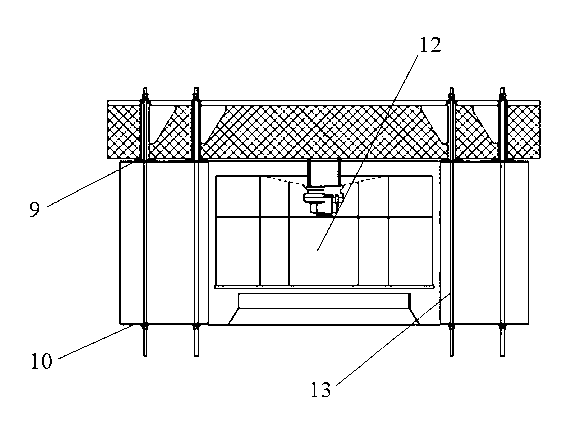

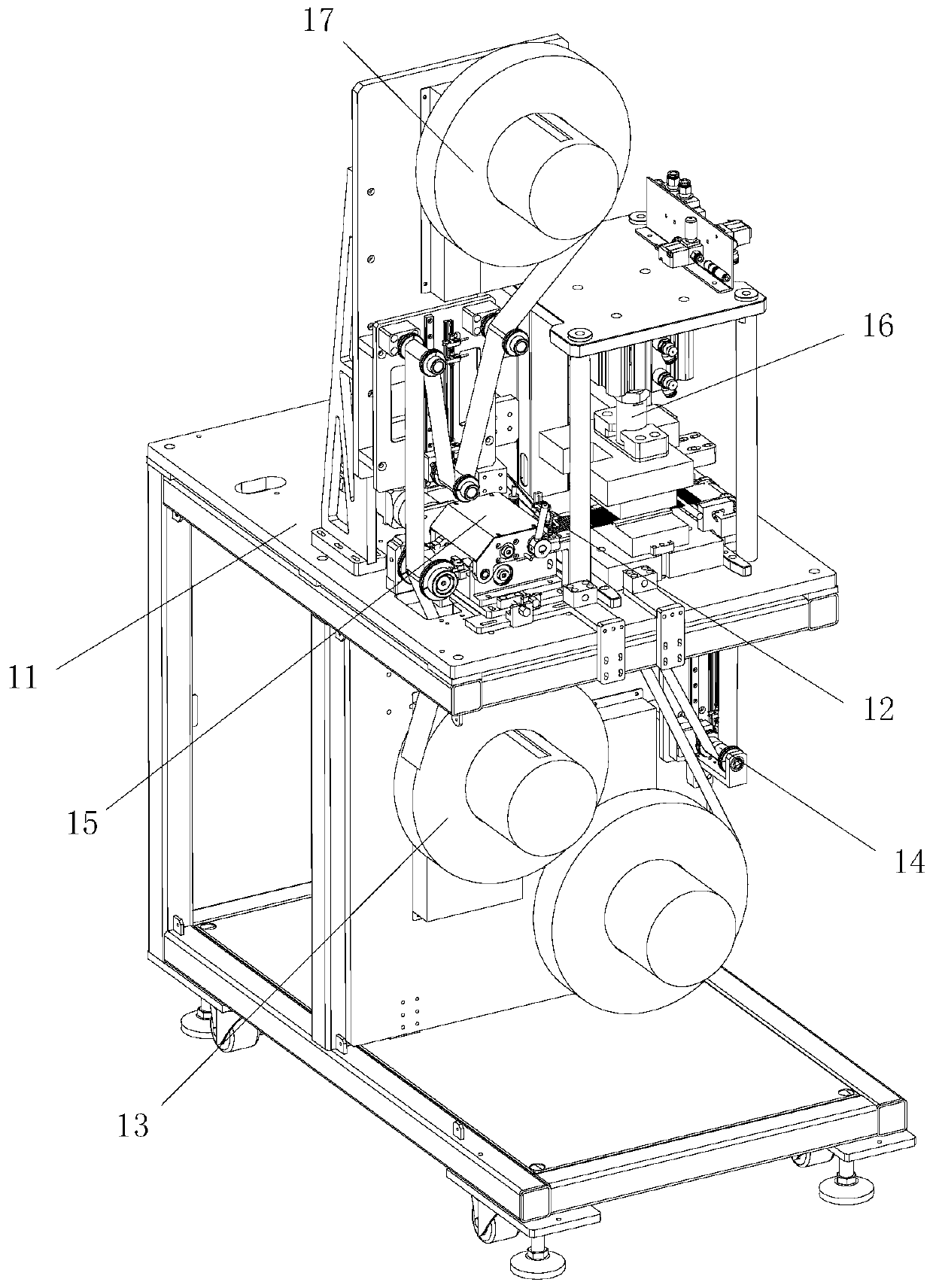

Full-automatic production line for attaching and laminating 3C product steel sheet

PendingCN111331998AGuaranteed flatnessAvoid damageLamination ancillary operationsLaminationAdhesiveManufacturing engineering

The invention discloses a full-automatic production line for attaching and laminating a 3C product steel sheet. The full-automatic production line for attaching and laminating the 3C product steel sheet comprises a steel sheet punching device, a steel sheet attaching device, a black adhesive laminating device, a back adhesive laminating device, a product detecting and stripping device, a finishedproduct collecting device and a manual detection table which are sequentially arranged in a butt joint manner, the cut steel sheet is grabbed by the steel sheet punching device and then is conveyed toa PC film at the steel sheet attaching device, the PC film is attached with black glue after passing through the black glue attaching device, the PC film is attached with back glue after passing through the back glue attaching device, the PC film is detected and stripped by the product detecting and stripping device, a stripped product is attached with a carrier film at the finished product collecting device, and a finished product is manually detected on the manual detection table. The full-automatic production line is compact in structure, stable in operation, capable of integrating steel sheet cutting, steel sheet laminating, back gum laminating, black gum laminating, product stripping and carrier film laminating, capable of replacing manpower and high in automation degree.

Owner:SUZHOU LANGKUN AUTOMATION EQUIP CO LTD

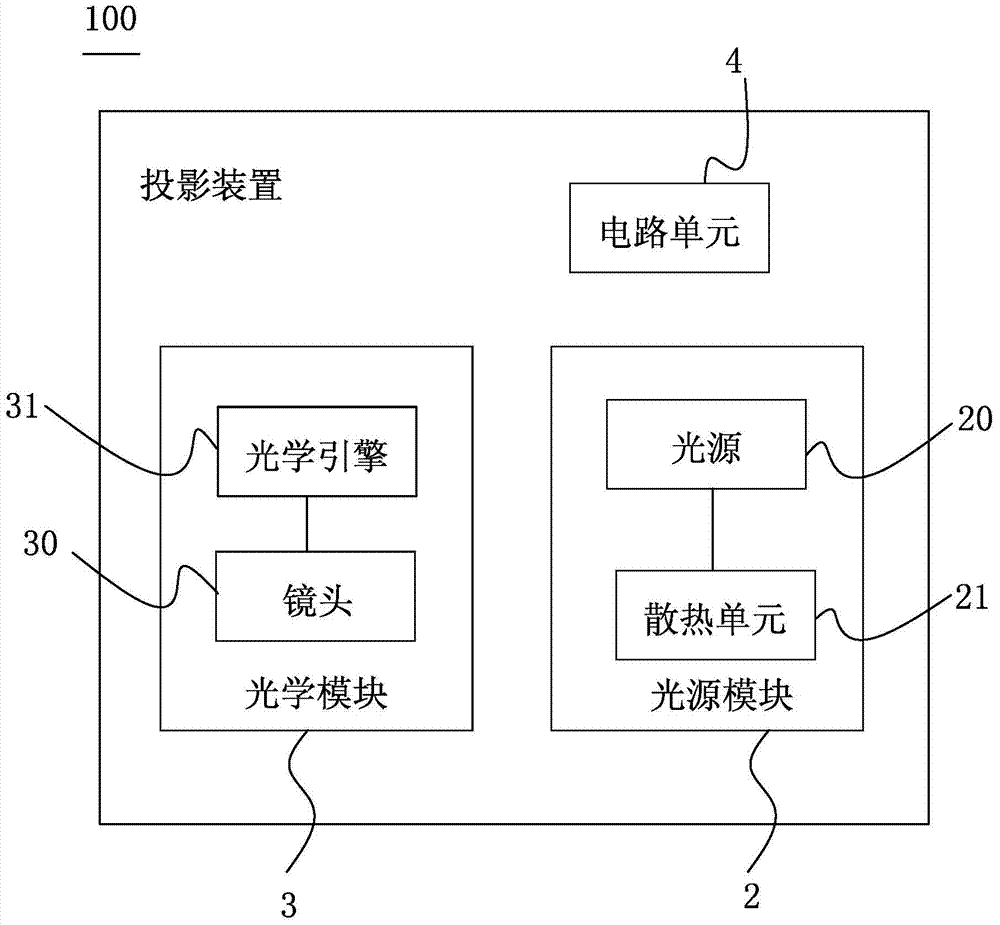

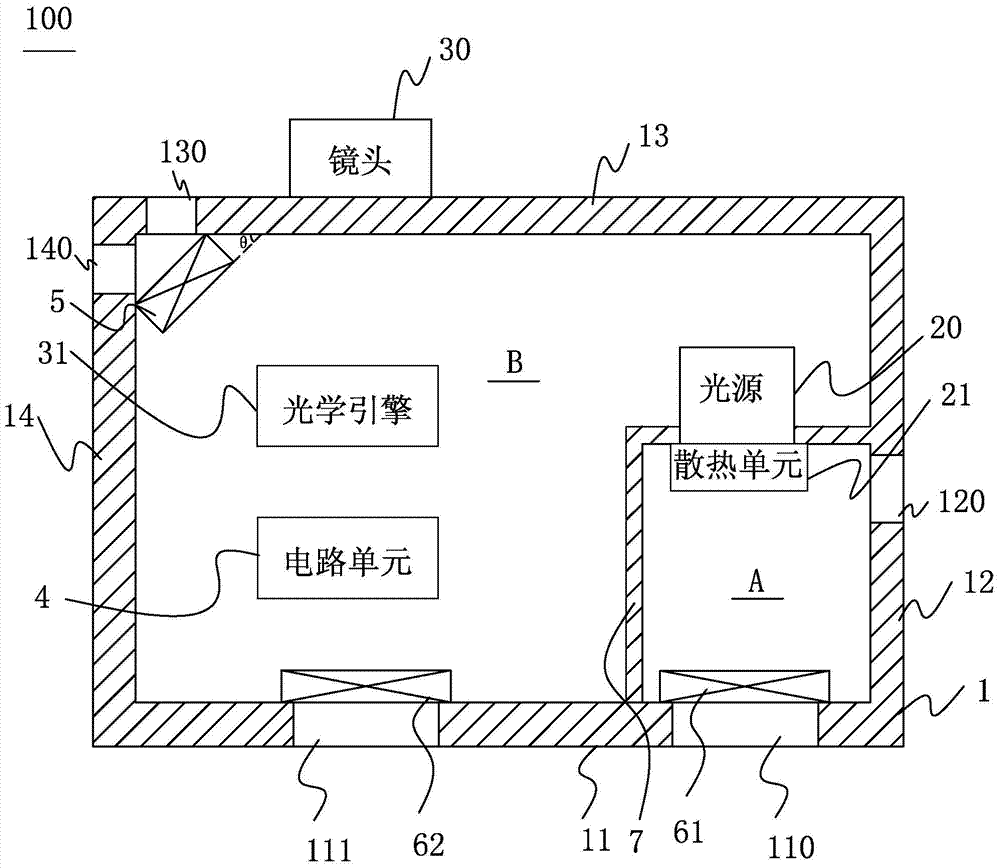

Projection device

The invention provides a projection device which comprises a shell, a light source module and a heat dissipation unit. The shell is provided with first heat dissipation space and second heat dissipation space isolated with the first heat dissipation space. The shell comprises a first side wall provided with a first air inlet, a second side wall provided with a first air outlet and adjacent to the first side wall, and a third side wall oppositely arranged with the first side wall. The light source module comprises a light source which is arranged in the second heat dissipation space. The heat dissipation unit is connected with the light source, used for guiding heat generated by the light source and arranged in the first heat dissipation space. The first air inlet and the first air outlet are connected with the first heat dissipation space. First heat dissipation airflow flows through the first heat dissipation space through the first air inlet and flows out of the shell through the first air outlet, and the first heat dissipation airflow flows through the heat dissipation unit.

Owner:QISDA OPTRONICS (SUZHOU) CO LTD +1

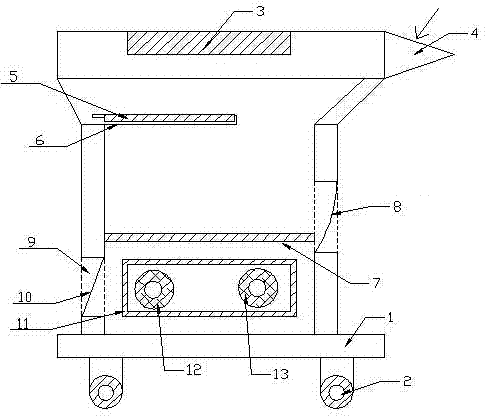

Efficient horizontal garment thread residue adsorbing machine

ActiveCN104259141AIncrease air volumeAvoid cloggingDispersed particle filtrationCleaning using gasesCentrifugal fanMechanical engineering

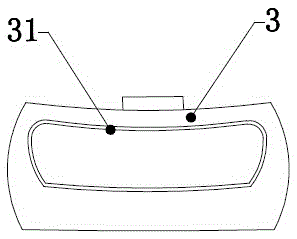

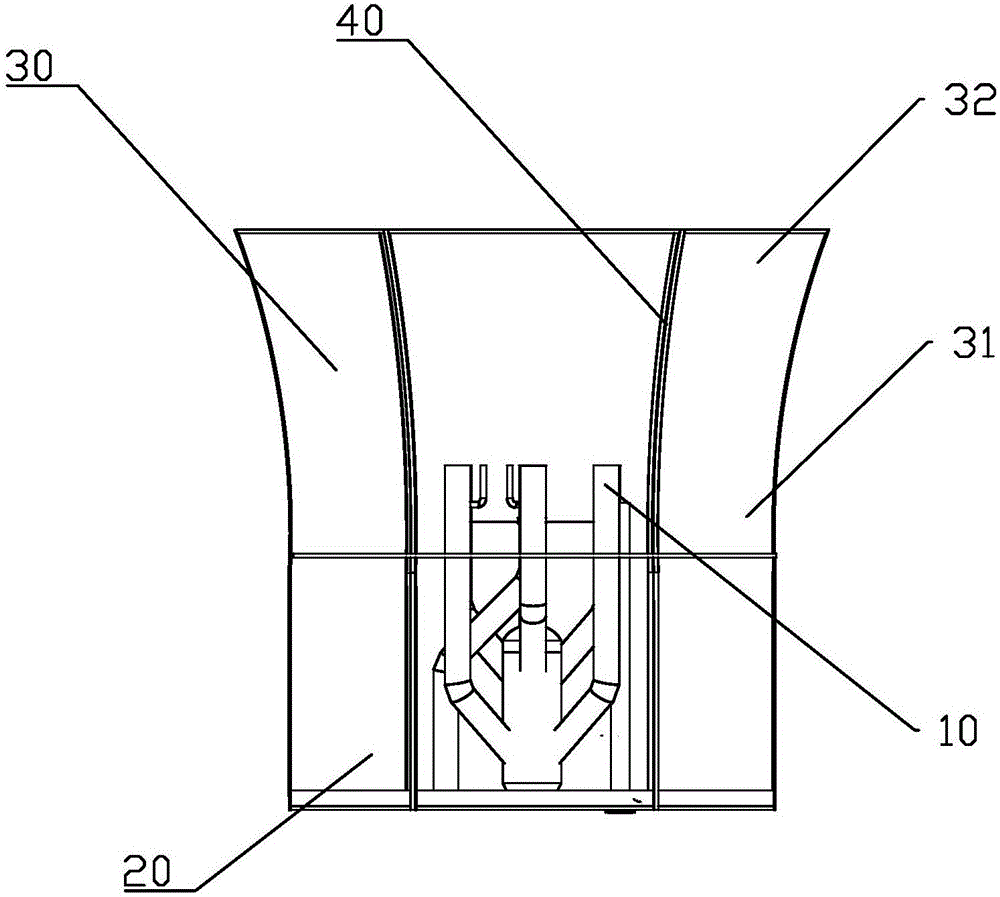

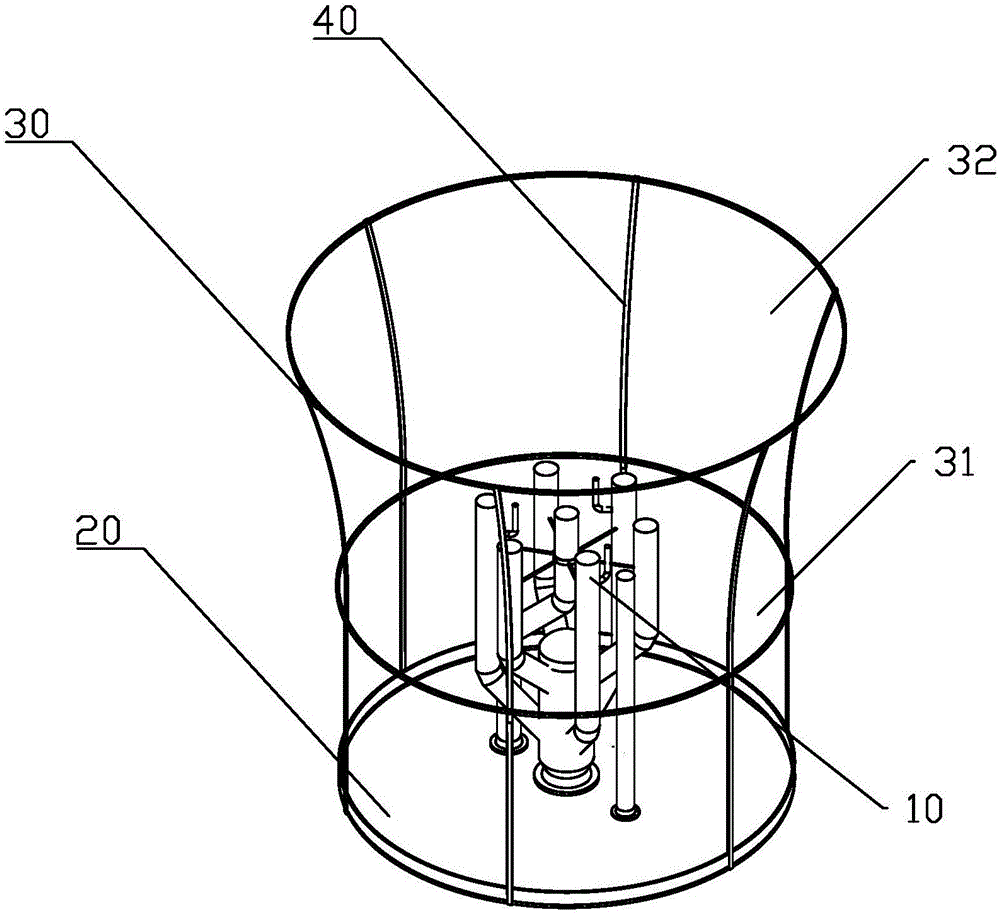

The invention belongs to the technical field of garment production machines and particularly discloses an efficient horizontal garment thread residue adsorbing machine. The efficient horizontal garment thread residue adsorbing machine comprises a rack box, an observation window arranged on the rack box, an air inlet formed in the rack box and located in one side of the observation window, a first filter plate arranged in the rack box, a second filter plate arranged in the rack box and located below the first filter plate, a motor installation frame arranged in the rack box and located below the second filter plate, a first motor, a second motor and an air outlet formed in one side of the motor installation frame, wherein the first motor and the second motor are installed in the motor installation frame. The efficient horizontal garment thread residue adsorbing machine is high in working efficiency and good in adsorbing effect through centrifugal fans of the first motor and the second motor; adsorbed thread residues and dust can be initially filtered through the first filter plate arranged on a guide rail, the guide rail can prevent the thread residues and the dust from scattering around, the parallel air inlet is matched with the centrifugal fans of the first motor and the second motor, air inlet volume is large, the speed is high, and adsorbing force is strong.

Owner:TAICANG SANYI HEATING & CHILLING PROJECT CO LTD +1

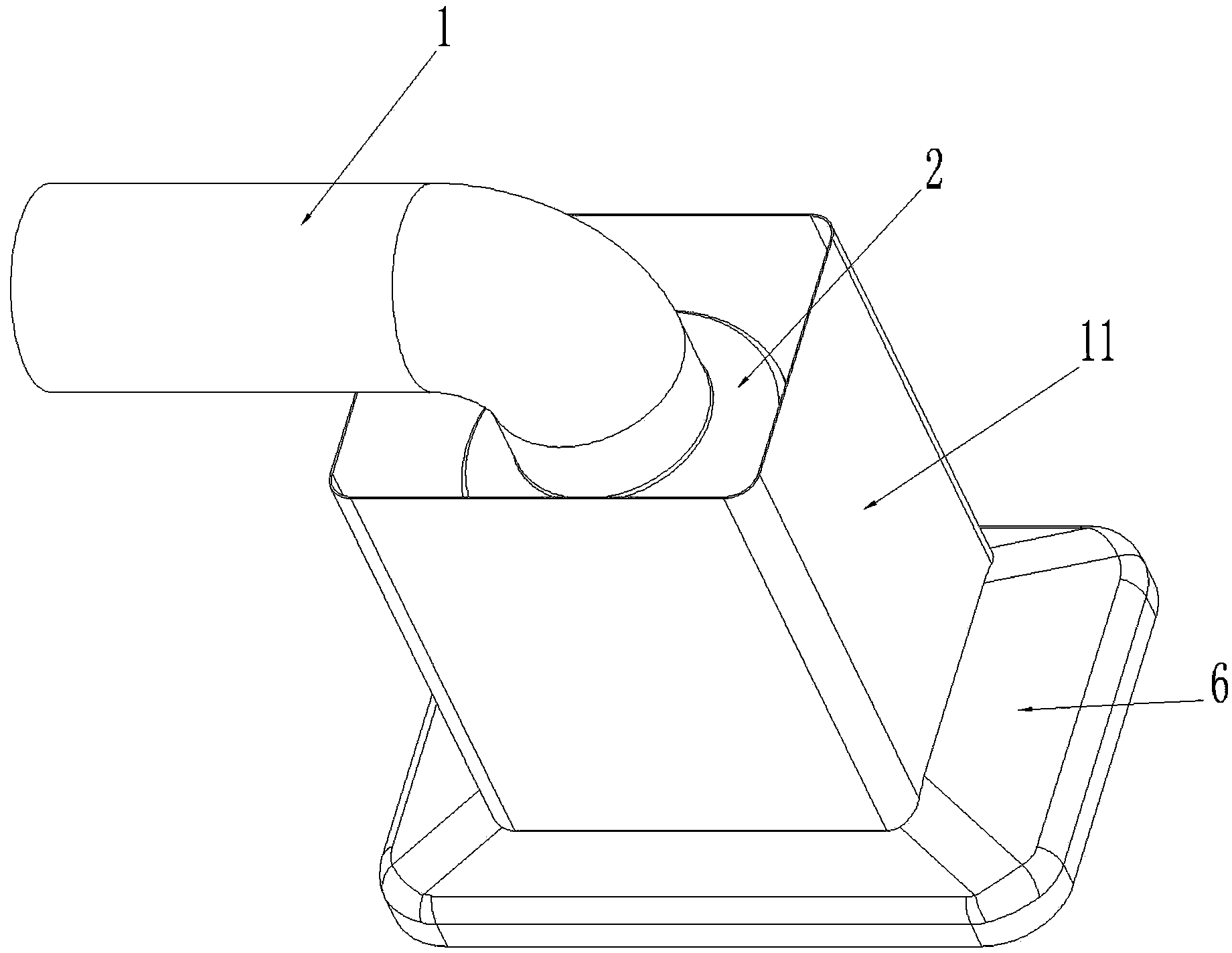

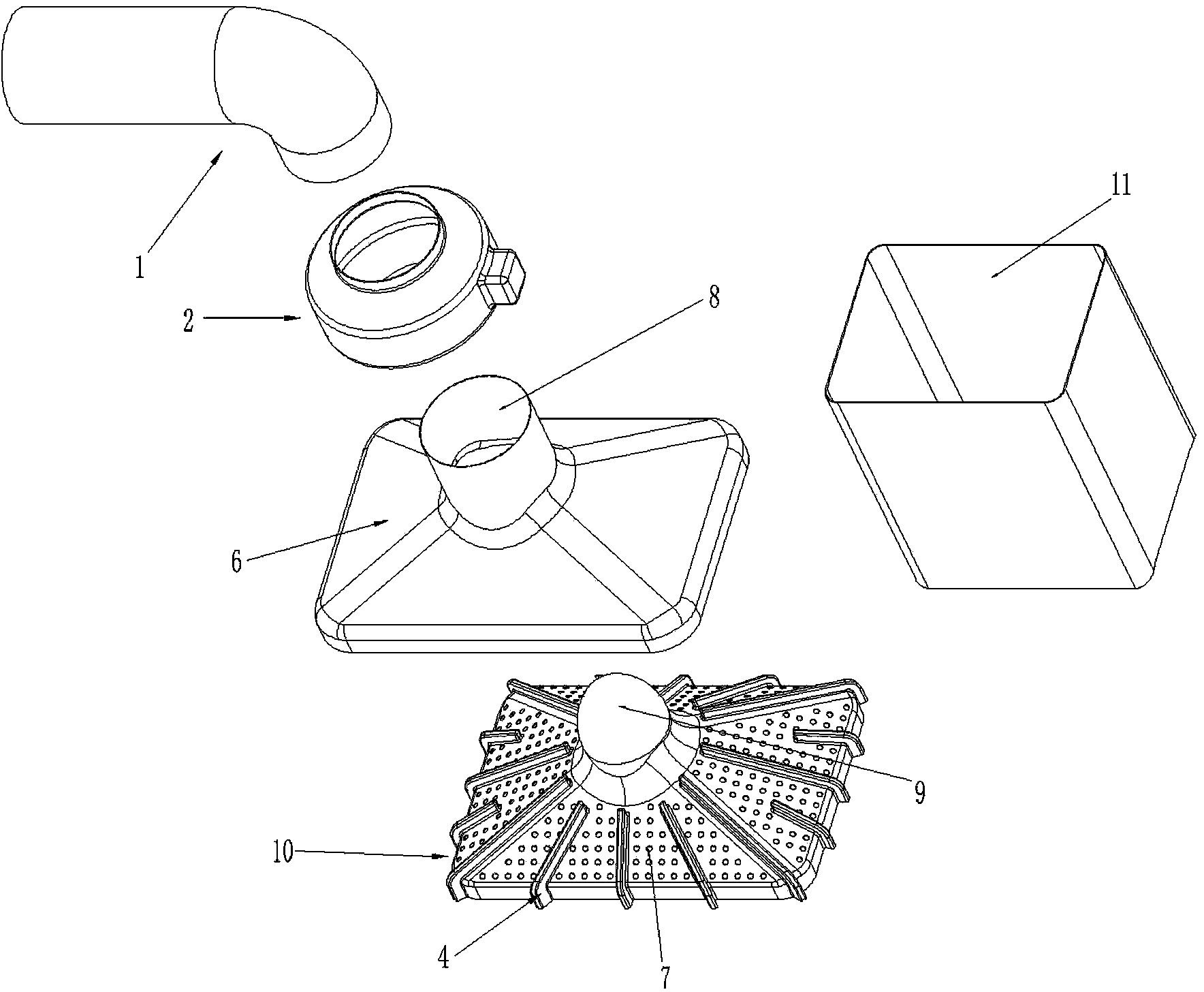

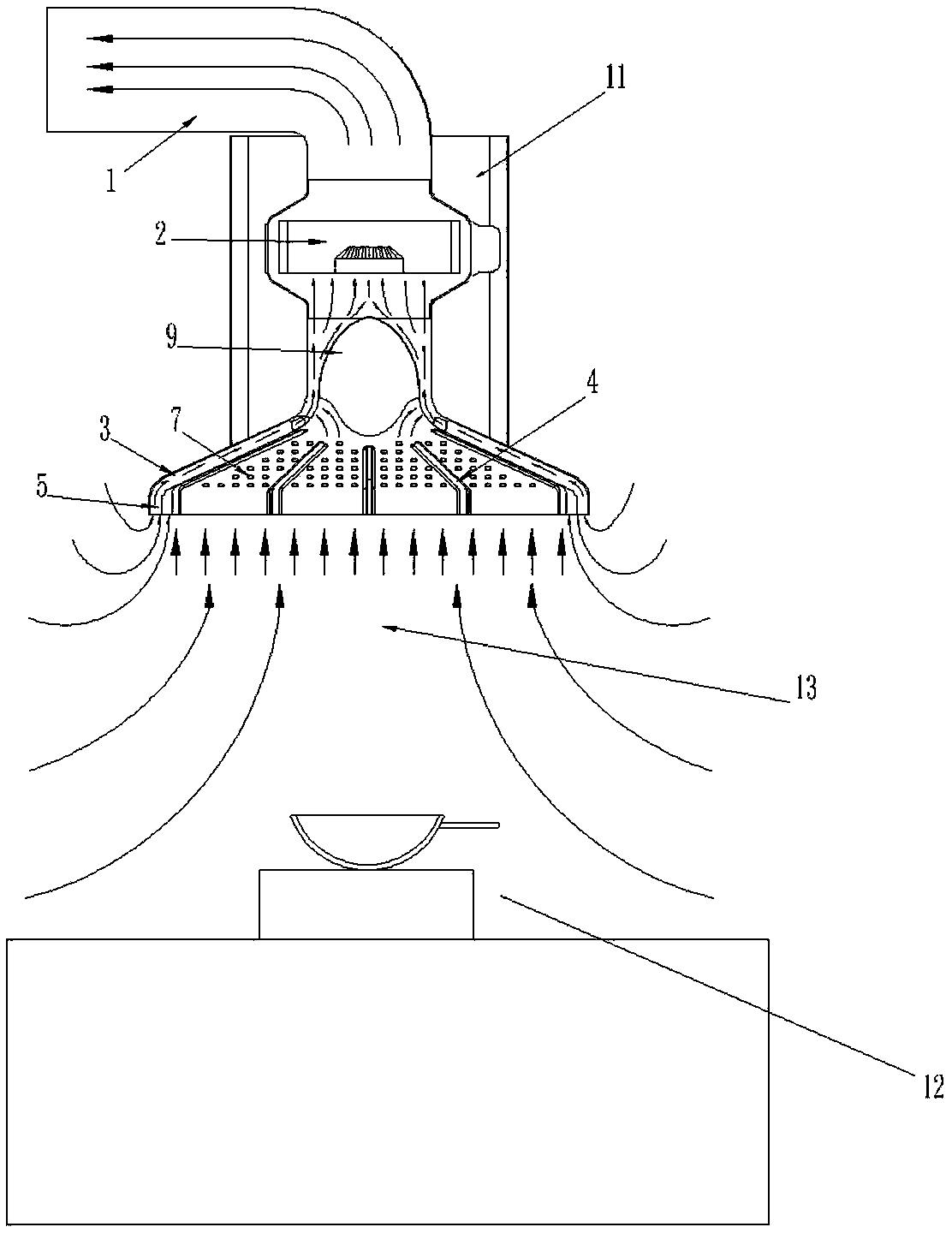

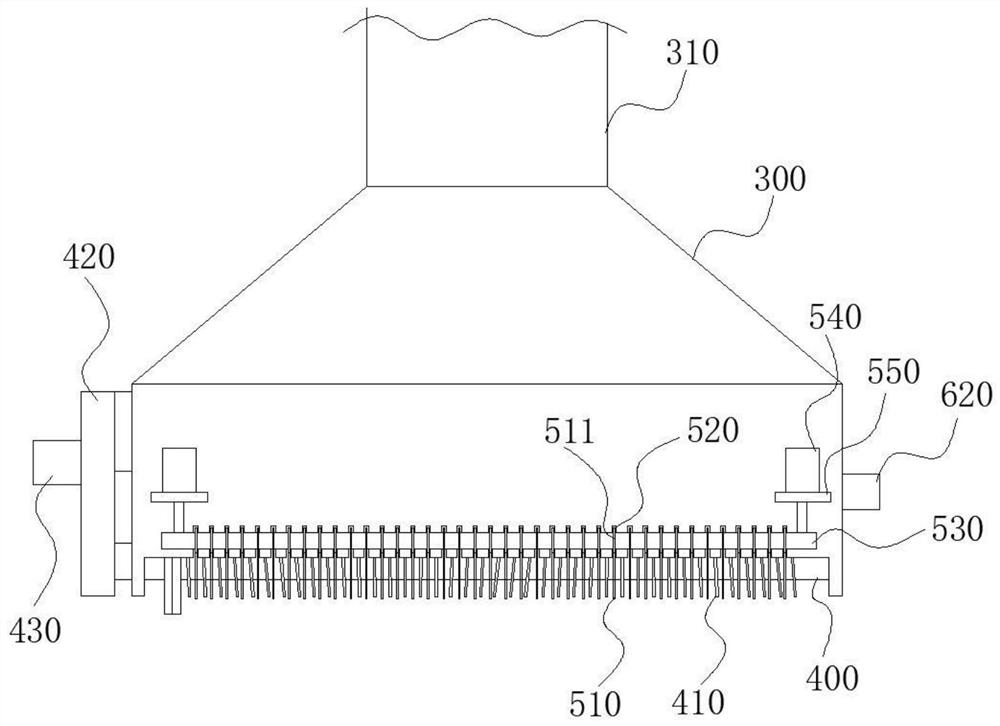

Range hood with rectifying function

ActiveCN104296219AReduce the level of pollutionAvoid running aroundDomestic stoves or rangesLighting and heating apparatusFlueEngineering

The invention discloses a range hood with a rectifying function. The range hood comprises a fume collecting hood, a flue and a fan, wherein the fume collecting hood comprises an inner layer and an outer layer; a gap is formed between the inner layer and the outer layer, and forms a flow guide air duct; the flow guide air duct is uniformly divided by flow guide baffles; a gap is formed between the bottoms of the inner and outer layers, and forms a vertically downward gas inlet; siphon holes are uniformly formed in the inner layer of the fume collecting hood; a flow guide cone is arranged between a gas outlet in the top of the fume collecting hood and the fan. According to the range hood, the inner layer of the fume collecting hood is designed to be an inner wall with the siphon holes, and the fan forms a low-air-pressure zone in the fume collecting hood through the siphon holes by a siphon principle, so that cooking fume uniformly floats to the fume collecting hood and the spread of the cooking fume is avoided; the gas inlet is formed in the bottom of the fume collecting hood, and a reverse air curtain is formed under the action of the suction force of the fan, so that the cooking fume is prevented from spreading outwards; the cooking fume is rectified into laminar flow gas before entering the fan under the combined action of the flow guide air duct, the siphon holes, the flow guide baffles and the flow guide cone, so that the fan is prevented from working under the turbulent flow gas condition and the exhaust efficiency of the fan is greatly improved.

Owner:郭军

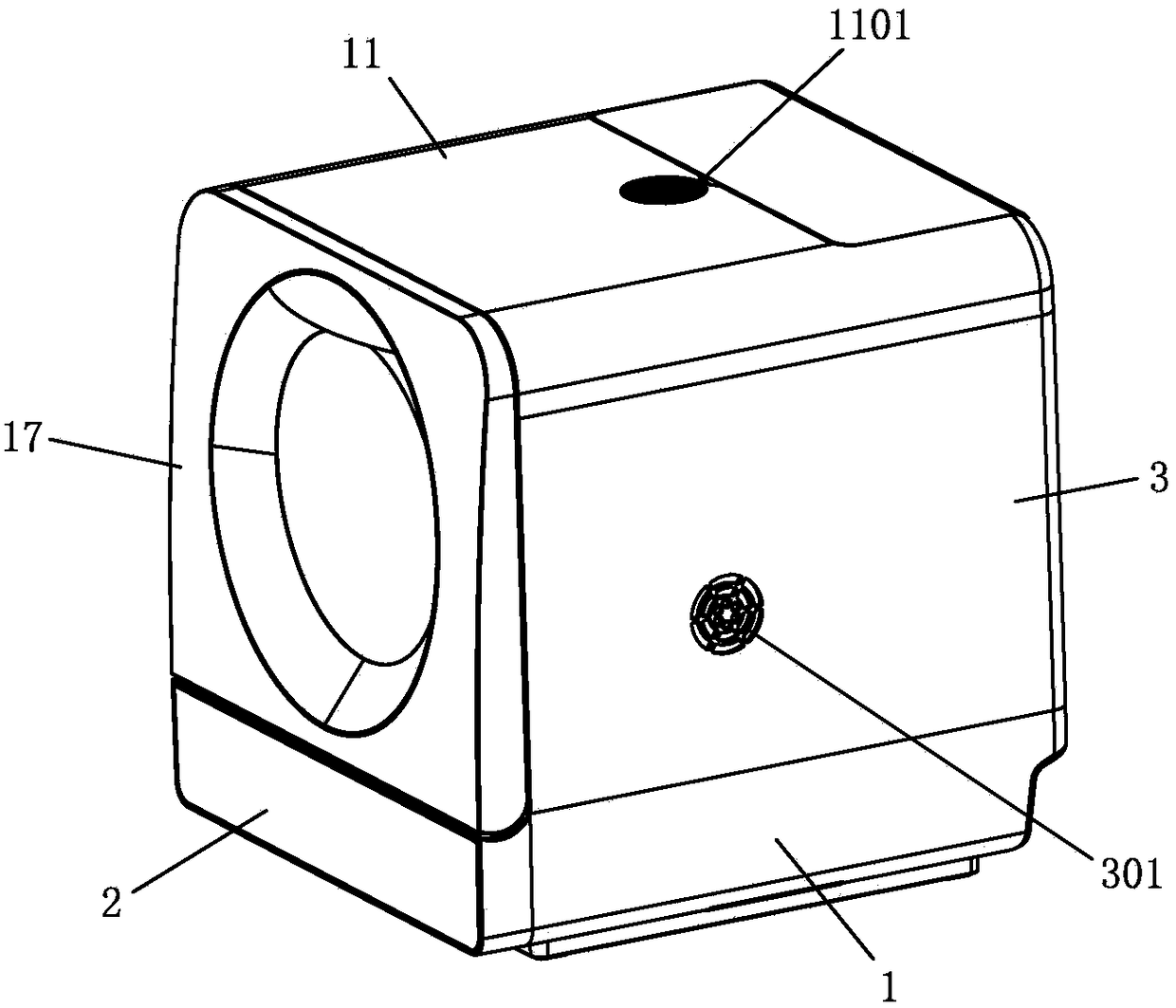

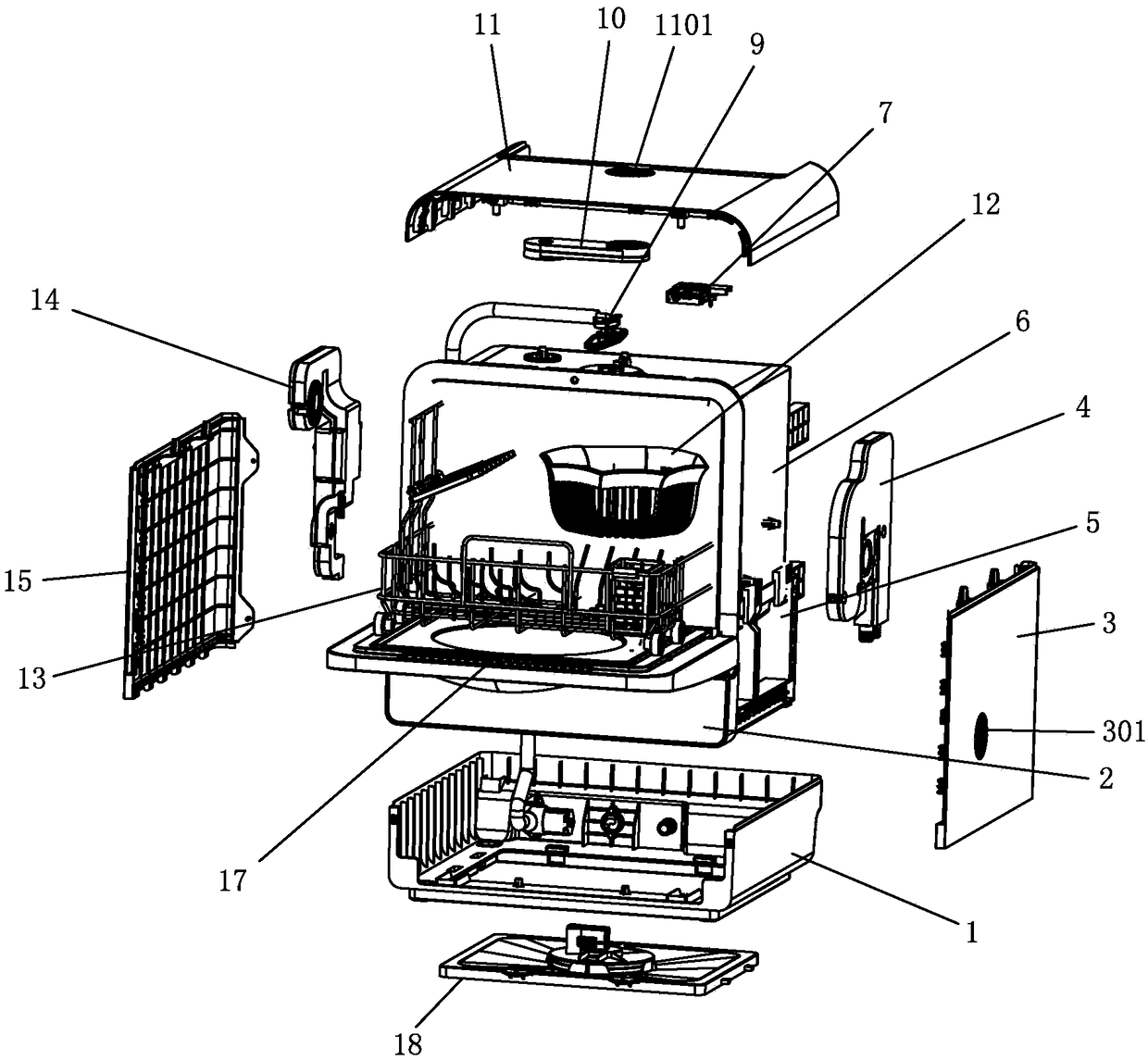

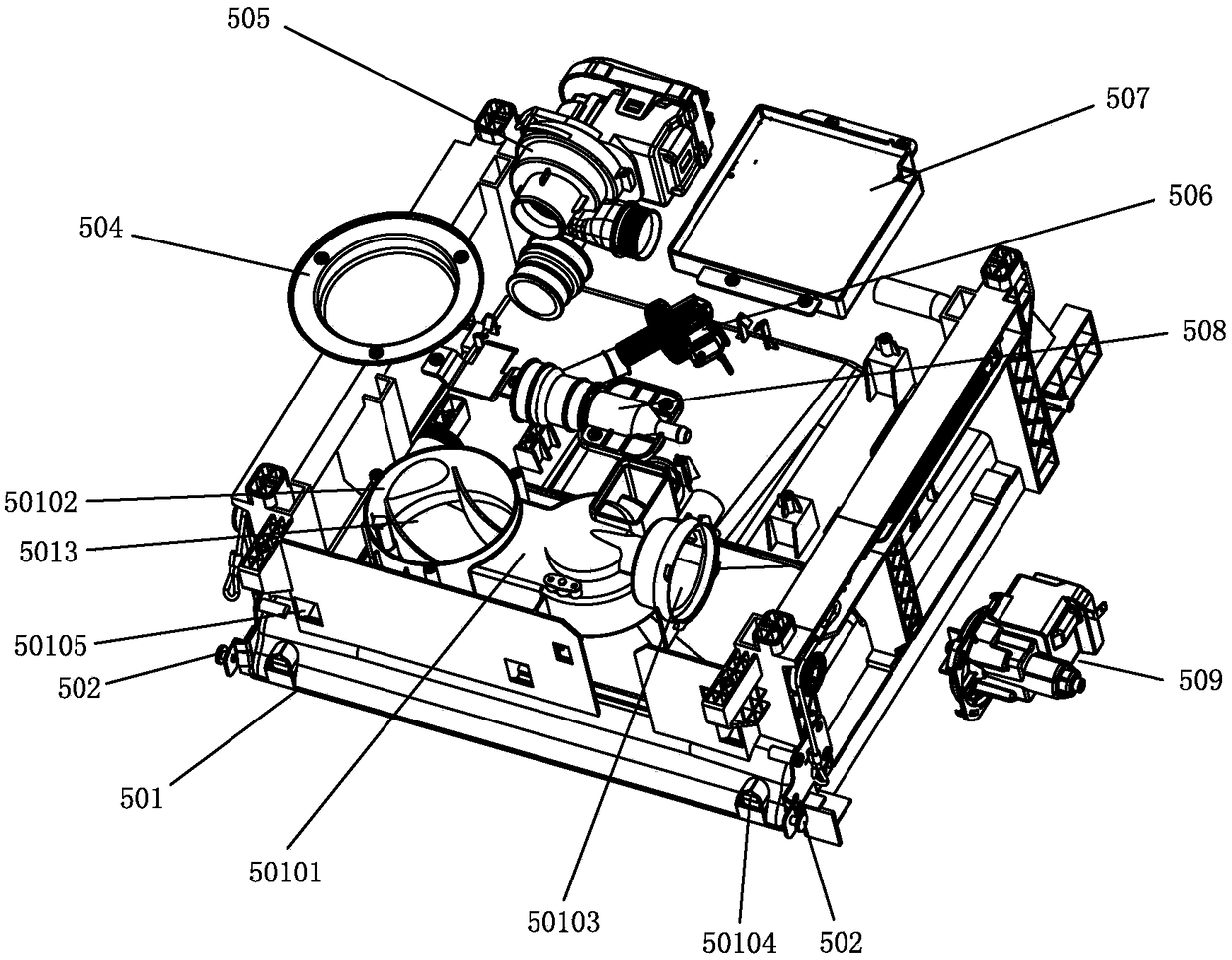

Small desk type dish-washing machine

PendingCN108378800AEasy layout designImprove performanceTableware washing/rinsing machine detailsDeskEngineering

The invention relates to a small desk type dish-washing machine. The small desk type dish-washing machine comprises a machine body bottom plate, a base assembly, a liner assembly, a PCB, a door plateassembly, and a shell composed of a first side plate, a second side plate and a top plate, wherein an upper spray arm assembly is arranged on the top of the liner assembly, and a lower spray arm assembly is arranged on the base assembly; an air blowing assembly is arranged between the first side plate and the liner assembly, an air inlet of the air blowing assembly corresponds to and communicateswith a side plate air inlet in the first side plate, and an air outlet of the air blowing assembly corresponds to and communicates with a liner air inlet in the liner assembly; an air exhaust assemblyis arranged between the second side plate and the liner assembly, and an air inlet of the air exhaust assembly corresponds to and communicates with a first liner air outlet in the liner assembly. Thesmall desk type dish-washing machine provided by the invention is small and exquisite in structure size, the restricted problems including that the space of a kitchen is small, but users are in soreneed of a dish-washing machine, are solved, certain desire and demands of the users are fully satisfied, meanwhile, a fan drying system is configured, and thus the property of the machine is sufficiently improved.

Owner:中山市吉相电器有限公司

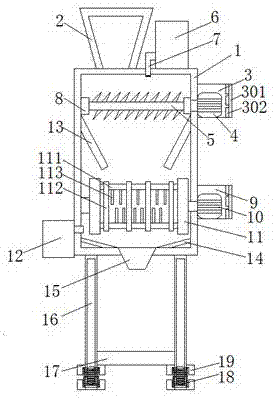

Crusher with multiple functions

The invention provides a multi-functional pulverizer, which includes a casing, a feeding funnel is fixedly installed on the top of the casing, a first motor box is fixedly installed on the right side of the casing, and the bottom of the inner cavity of the first motor box is fixedly installed. There is a first motor, the shaft of the first motor extends to the inside of the casing and the cutting device is connected to the cutting device through a coupling, the inside of the casing is fixedly installed with an inclined baffle, and the lower side of the first motor box is provided with a second motor. The bottom of the casing, the inner cavity of the second motor casing is fixedly equipped with a second motor, the rotating shaft of the second motor extends to the inside of the casing and is connected with a crushing device through a coupling transmission, and a discharge funnel is fixedly installed at the bottom of the casing. The multi-functional pulverizer can cut the target object for the first time by setting the cutting device, and by setting the pulverization device, the target object cut for the first time can be pulverized for the second time, so that the pulverization effect of the target object is better. Thus avoiding repeated crushing of the target object.

Owner:扬州市大悦信息科技有限公司

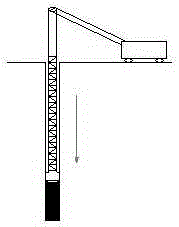

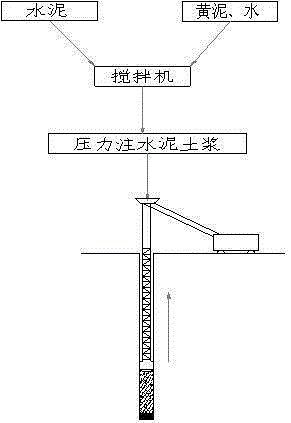

Improving method for open caisson sinking construction in geology of sludge layer

InactiveCN105256819APrevent slope collapsePrevent scurryingCaissonsBulkheads/pilesSludgeWell drilling

The invention relates to an improving method for open caisson sinking construction in geology of a sludge layer. Sinking stability piles are changed from cement powder spraying piles into after-drilling injection grouting pillars. Construction of the after-drilling injection grouting pillars comprises the steps that (1) site leveling is conducted, surveying and lining are conducted to determine the positions of the after-drilling injection grouting pillars, and a drill is put in a position; (2) holes are formed by drilling an open caisson with the adoption of a single spiral drill; and (3) after the holes are formed, grouting is conducted to hole bottoms, after the hole bottoms are solidified, grouting is conducted while a drill bit is lifted, the after-drilling injection grouting pillars are formed until the drill bit is retreated from the formed holes. The after-drilling injection grouting pillars are stable in structure and good in uniformity. No large chiseling height difference is generated when opposite-chiseling is conducted. The open caisson sinking process is more stable.

Owner:CHINA FIRST METALLURGICAL GROUP

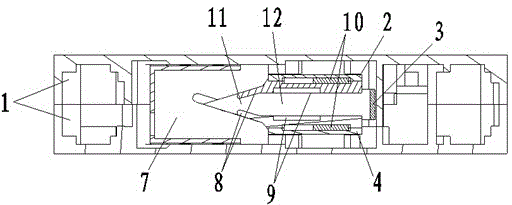

Circulating air arc-control device for small breaker

InactiveCN104064418AGood sealing performancePrevent arc franticCircuit-breaking switch detailsDirectivityAirflow

The invention discloses a circulating air arc-control device for a small breaker. The circulating air arc-control device comprises a shell, a grating sheet arc extinguish chamber, an upper baffle, a lower baffle, an air outlet and a run-on plate, wherein the grating sheet arc extinguish chamber, the upper baffle, the lower baffle, the air outlet and the run-on plate are arranged in the shell, one sides of the upper baffle and the lower baffle are buckled with the grating sheet arc extinguish chamber, and arcing rings are arranged in the upper baffle and the lower baffle; a necking is formed in the tail end of each arcing ring and is matched with an electric arc of the grating sheet arc extinguish chamber, and the air outlet is arranged at the bottom of the grating sheet arc extinguish chamber; after the electric arc is generated and leaves away from a contact, the electric arc enters the grating sheet arc extinguish chamber along the run-on plate and the necking sequentially, and gas is discharged by the air outlet after the arc extinction. The circulating air arc-control device provided by the invention is good in sealing capability, is capable of preventing the electric arc from stampeding and guaranteeing the directivity of magnetic blow-out and air-blowing, namely, the reserve blowing function of the electric arc can be prevented, the phenomenon that the electric arc is effectively driven to enter the grating sheet arc extinguish chamber and is quenched, the electric arc is reburnt and punched on the back can be prevented, and the electric arc voltage can be quickly improved, therefore, the good limit effect can be achieved.

Owner:BOER YIXING POWER SYST

Protection device for duck breeding and rice growing with function of integrated rice-duck farming and using method of protection device

ActiveCN110235719APlay a blocking rolePrevent scurryingAnimal repellantsPlant protectionPaddy fieldBiology

The invention discloses a protection device for duck breeding and rice growing with the function of integrated rice-duck farming and a using method of the protection device, and particularly relates to a device capable of achieving simultaneous integrated rice-duck farming in a paddy field. Ducks are utilized for disinsection, weed removal and organic fertilizer dressing for the paddy field, the growth of rice is promoted, and the ducks are fed with grass seeds, fishes, tadpoles and the like in the paddy field; the upper portion of an upper edge plate is fixedly connected with a mounting plate which is provided with a motor through flanged mounting, and a worm is connected to the output end of the motor, penetrates through the mounting plate and is in bearing connection with the mounting plate; the lower portion of the worm is rotatably meshed to a worm wheel on the upper edge plate, the worm is connected with a stretching wheel located at the lower position through a conveying belt, the stretching wheel is also rotatably arranged in the upper edge plate, and a rotary center of the stretching wheel overlaps with the rotary center of the upper end of a driving rod; a rotary pillar is fixedly connected to the edge of one side of the stretching wheel and rotatably connected to the upper portion of the driving rod.

Owner:LIAONING AGRI COLLEGE

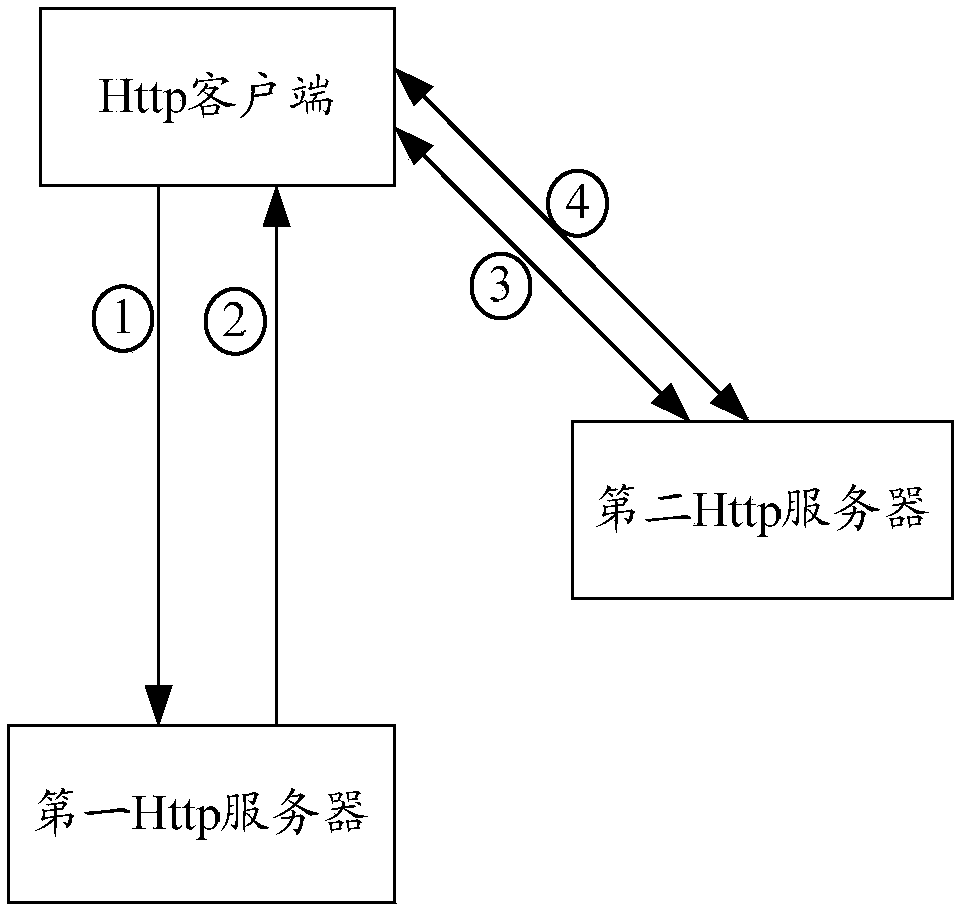

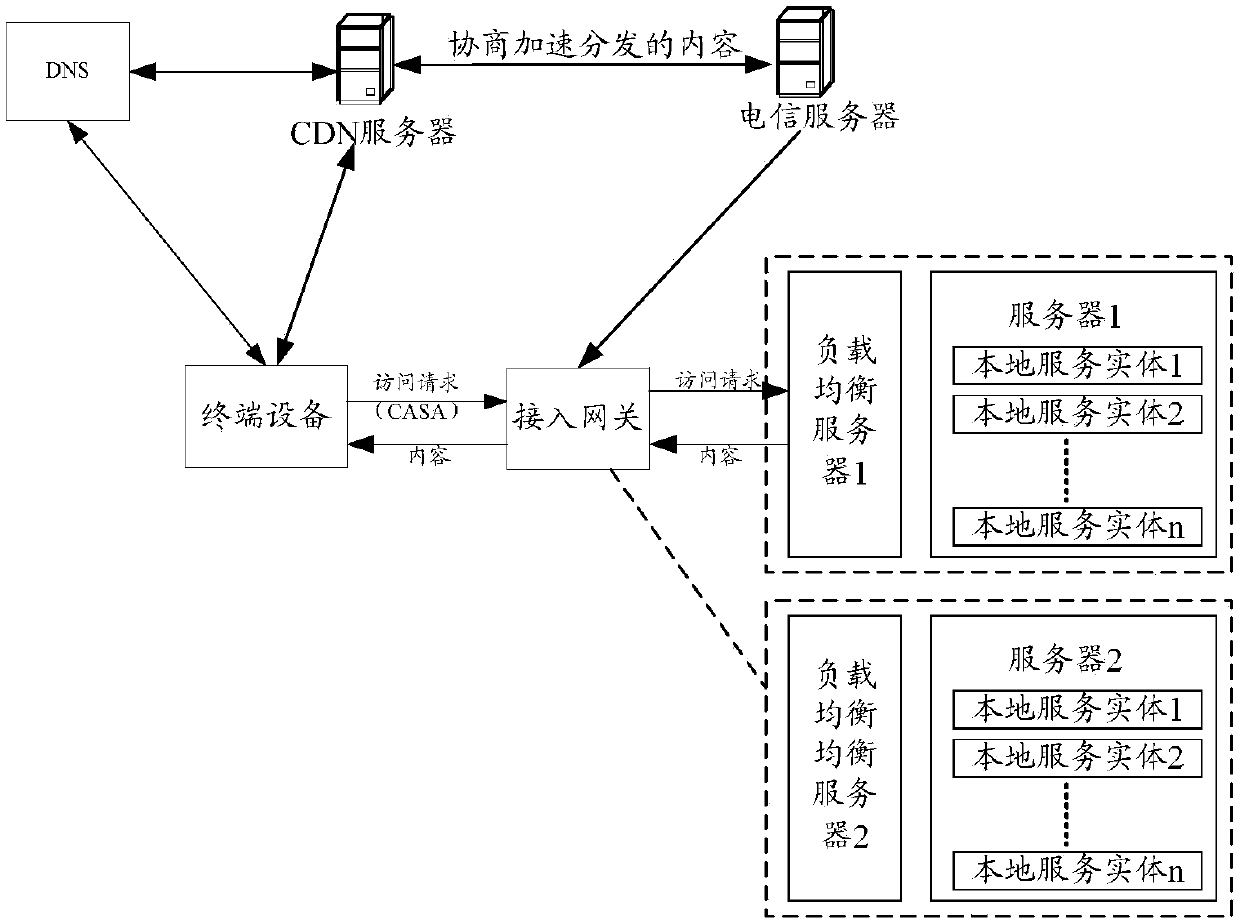

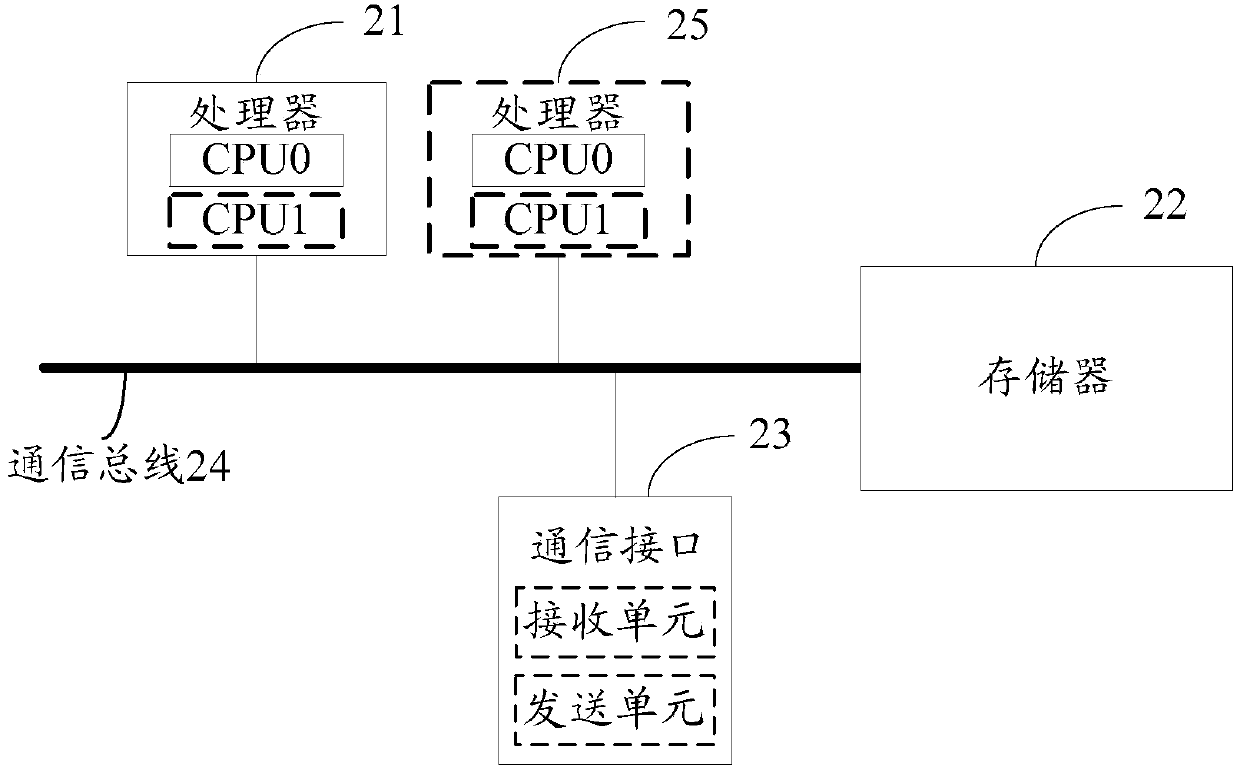

Content distribution method, device and system

ActiveCN109672698AAvoid Inaccurate ProblemsPrevent scurryingTransmissionSecurity arrangementTraffic capacityContent distribution

The application discloses a content distribution method, device and system, relates to the technical field of communications, and solves the problem of chaotic traffic in existing HTTP redirection. The specific solution is as follows: a first access gateway receives a configuration command, and configures a correspondence between a configuration identifier and a traffic-direction policy accordingto the configuration command; the first access gateway receives a first access request, wherein the first access request carries a first identifier, and is used to request content accessed by a terminal device; when a traffic-direction policy corresponding to the first identifier exists in the correspondence, the first access gateway directs the first access request to a first server; and the first access gateway receives content returned by the first server, and sends the content to the terminal device. The application is used for a content distribution process.

Owner:XFUSION DIGITAL TECH CO LTD

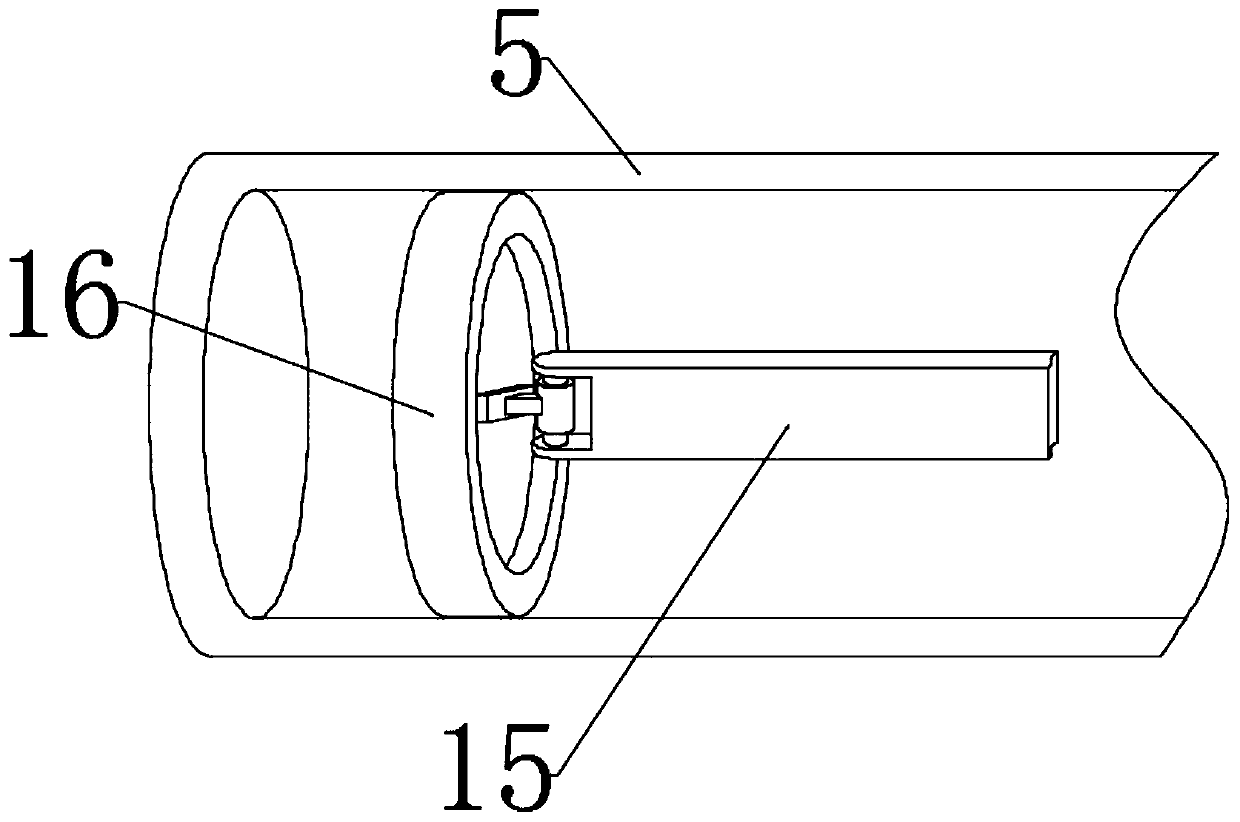

Noodle processing device

InactiveCN105145711ARapid positioningPrevent scurryingDough shaping and cutting apparatusDough extruding machinesEngineeringAir compressor

The invention discloses a noodle processing device. The noodle processing device comprises a rack, a pressurizing air cylinder, an air compressor and a dough drum; the dough drum is in a drum shape and partitioned by a partition plate in the center, a flange protruding outwards is arranged at the top of the dough drum, a cutter is arranged at the bottom of the dough drum, and noodle outlet holes are formed in the cutter and staggered from the partition plate in the center of the dough drum to the two sides; a table top is arranged on the rack, a dough drum positioning hole penetrating through the table top is formed in the table top, and the dough drum is inserted into the dough drum positioning hole and can rotate freely; the pressurizing air cylinder and the air compressor are fixedly installed on the rack, the pressurizing air cylinder is located above the dough drum, and a pressing disc is fixedly connected with a piston rod of the pressurizing air cylinder, in a semicircular shape and can be inserted into the dough drum. In the noodle processing process, noodles will not adhere to one another when broken in a lifted mode, dough at the other side can be squeezed by rotating the dough drum, and it will not waste too much time to load the dough.

Owner:CHONGQING YUXI FLOUR PROD

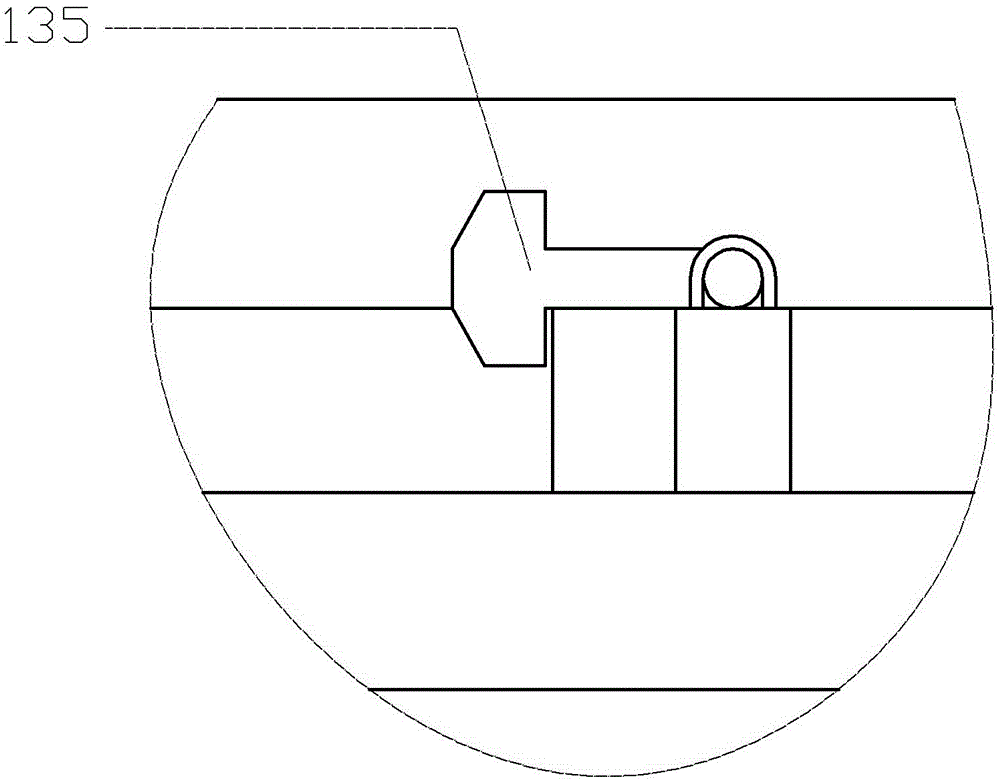

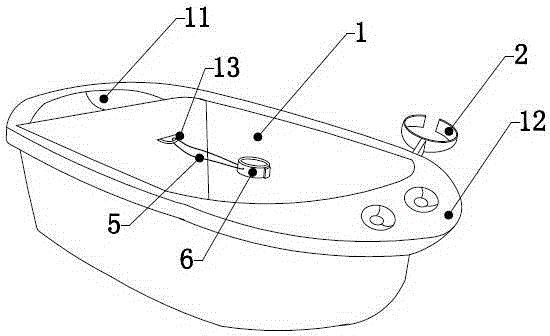

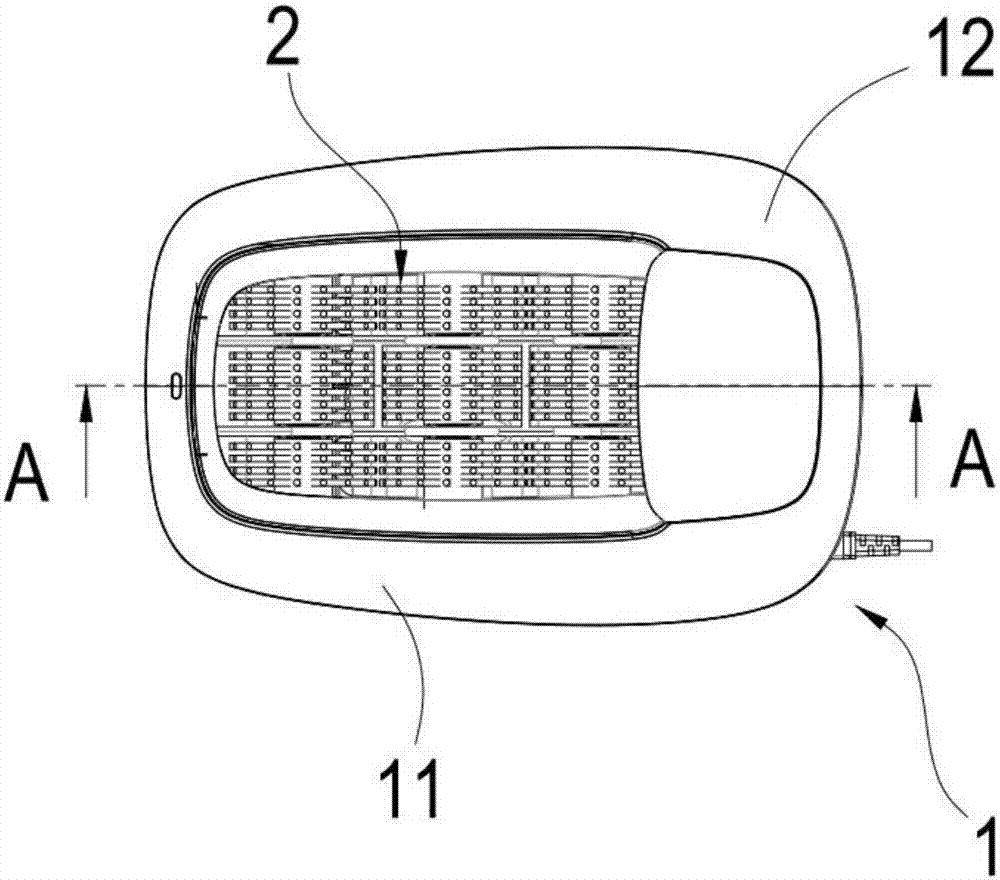

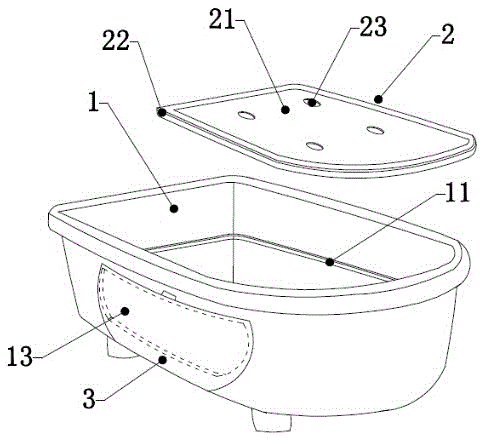

Pet bathtub capable of fixing shower head

The invention discloses a pet bathtub capable of fixing a shower head. The pet bathtub comprises a tub body with a water storage cavity in the middle. The pet bathtub is characterized in that one side of the tub body is provided with a cavity used for holding the head of a pet, the other side of the tub body is provided with a bathing article storage table, a shower head clamping head rotationally installed on the tub body is arranged on the outer wall of the tub body and on one side of the bathing article storage table, the cross section of the shower head clamping head is in a C shape, and the opening end of the shower head clamping head faces towards the outer side of the tub body. By means of the pet bathtub capable of fixing the shower head, bathing articles and the shower head which are required during bathing can be placed, and use is quite convenient. Meanwhile, belts capable of sleeving four limbs of the pet are further arranged in the tub body, rubber connected with sleeve rings in the tub body in a sleeving mode is arranged on the belts, the belts can adapt to the sizes of the four limbs of various pets, and the bathtub is convenient to use and practical.

Owner:济宁高新科达科技项目服务有限公司

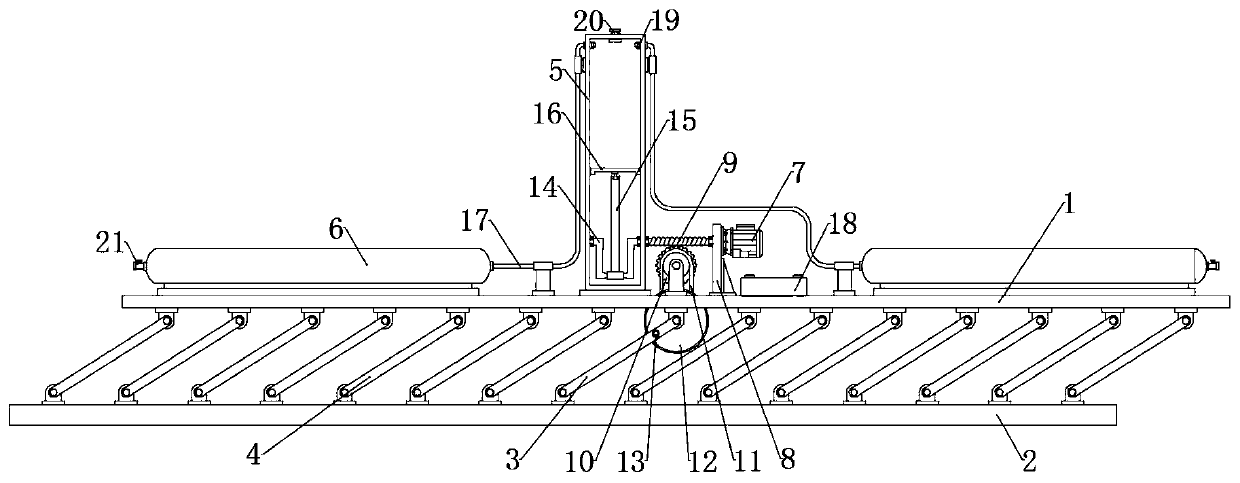

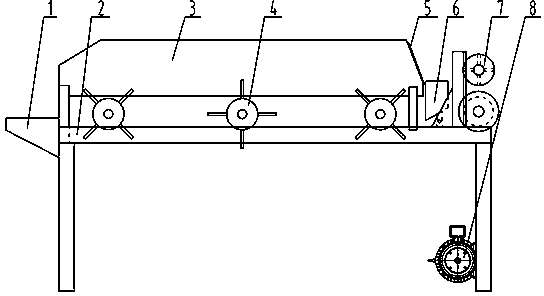

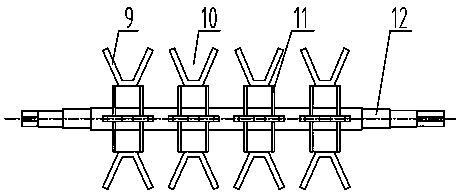

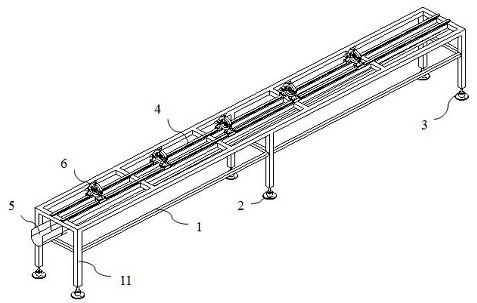

Quantitative feeding device for corn stalk husk-stuff separator

The invention discloses a quantitative feeding device for a corn stalk husk-stuff separator. The quantitative feeding device is characterized in that a frame (2) is sequentially provided with a feeding table (1), conveying mechanisms (4) in transmission connection with a power mechanism (8), a dividing plate (3) uniformly arranged and vertical to the conveying mechanisms (4), a slopping baffle (5) connected with the tail end of the dividing plates (3), a feeding guide plate (6), and an output roller assembly (7) in the transmission connection with the power mechanism (8) from front to back. The quantitative feeding device can be used for performing directional and quantitative feeding operation specially aiming at corn stalks, and has the characteristics of being simple in structure, high in working efficiency, low in power consumption, safe and reliable to use and the like.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Double-chamber single air suction type guiding device

ActiveCN102978364AInhibition dispersionPrevent scurryingFurnace typesHeat treatment furnacesAtmosphereWind speed

The invention provides a double-chamber single air suction type guiding device. The double-chamber single air suction type guiding device comprises a circulating fan, a fan guiding device, a horizontal guiding plate, a corner angle air deflector, bilateral air duct deflectors, bilateral air duct jet devices, middle air duct jet device, an air suction inlet, and a wind area baffle. The circulating fan is placed inside the fan guiding device. The horizontal guiding plate is respectively connected with the fan guiding device, the middle air duct jet device and the bilateral air duct jet devices. The corner angle air deflector is welded with the top and the lateral wall of an aging furnace. The lateral air duct jet devices are connected with the middle air duct jet device through the wind area baffle and the horizontal guiding plate. The air suction inlet is installed in the air suction position of the circulating fan and is connected with the fan guiding device. The wind area baffle is installed on the middle position between two wind areas. The double-chamber single air suction type guiding device enables circulating air to be distinct in gradation and even in distribution, section steel inside the aging furnace is enabled to be heated in a gradational manner, the speed of the circulating air is greatly increased, and atmosphere of the furnace and temperature uniformity of the section steel are effectively improved.

Owner:SUZHOU LONGRAY THERMAL TECH

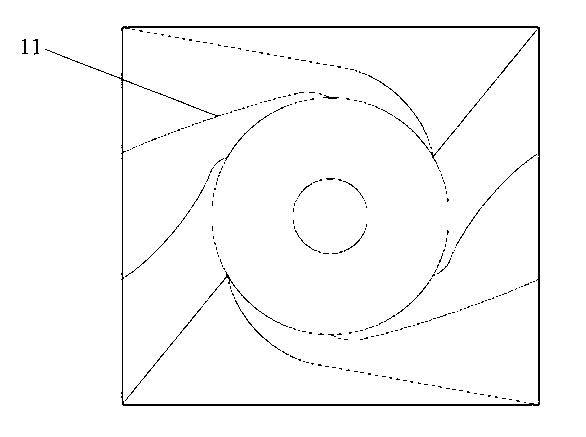

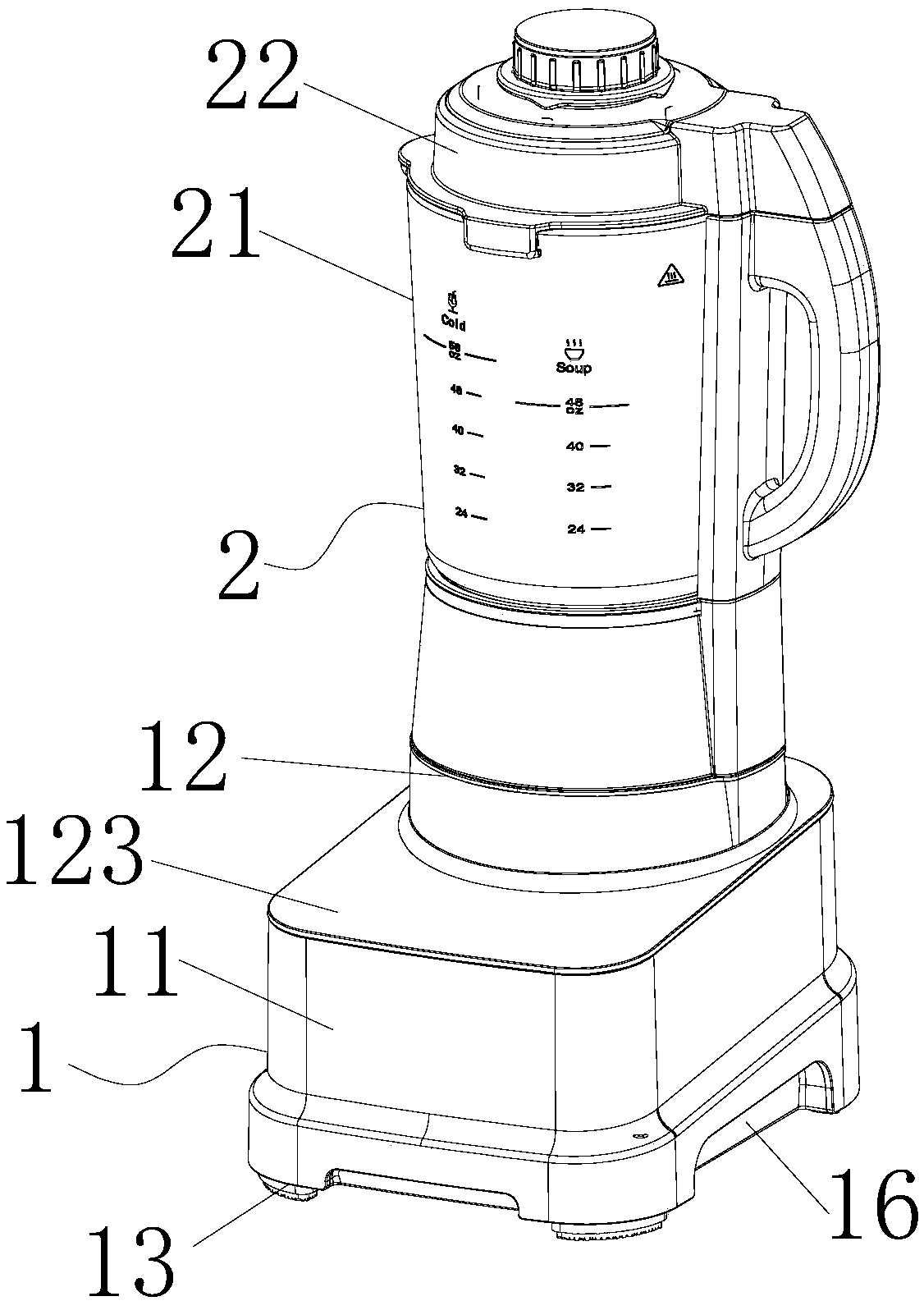

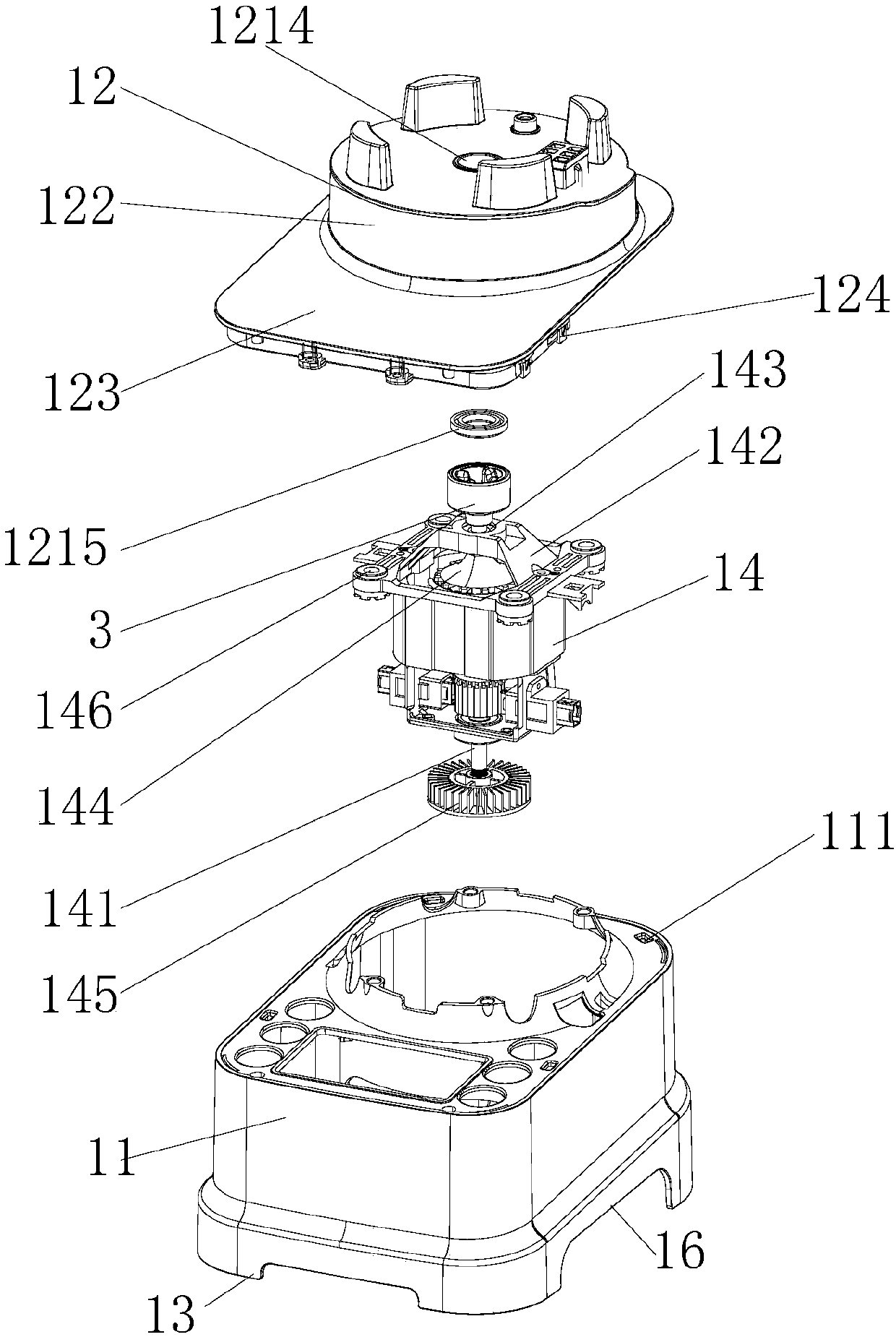

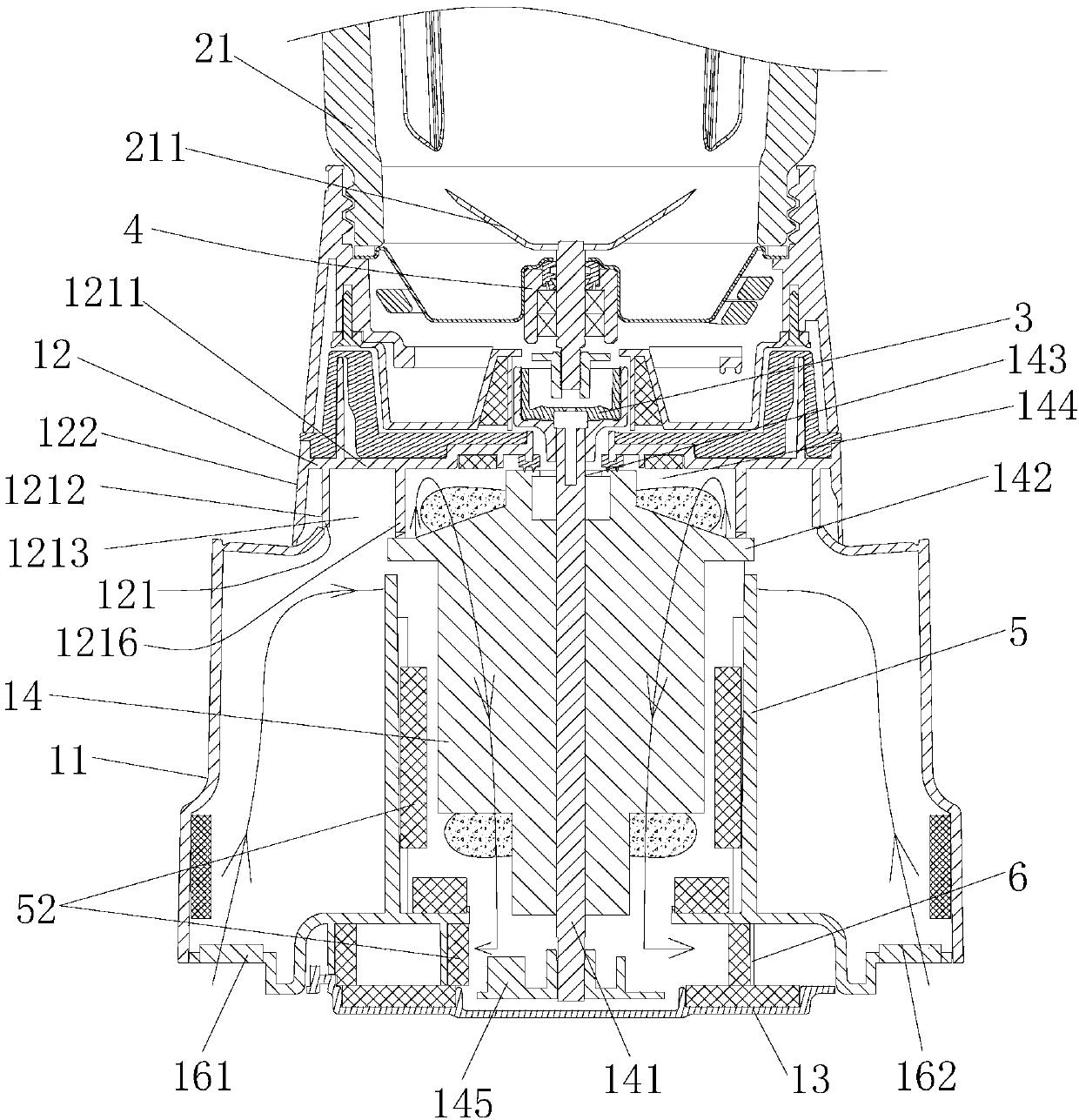

Low-noise food processor

ActiveCN110876571AEffective coolingPlay a guiding roleKitchen equipmentElectric machineryControl theory

The invention discloses a low-noise food processor. The low-noise food processor comprises a machine base with a motor, a stirring cup connected with the machine base and a pulverizing cutter arrangedin the stirring cup. A fan is arranged at the lower end of a motor shaft of the motor; the machine base is provided with an air inlet and an air outlet. The air outlet is positioned on one side belowthe machine base; the machine base comprises a machine shell, a top cover and a bottom cover. A motor cylinder used for containing a motor is arranged in the machine shell. A motor support is arranged at the upper end of the motor, the motor support is mounted at the top of the motor barrel; a shaft hole through which the upper end of the motor shaft penetrates is formed in the center of the motor support; the motor support is provided with a communication port communicated with the interior of the machine shell. The top cover is provided with a wind scooper; the wind scooper stretches into the machine shell and covers the upper portion of the motor support. When the motor works, the fan is driven to rotate, so that external air enters the machine shell from the air inlet and flows into the motor barrel through the communicating opening after being guided by the a wind scooper, and the wind scooper can play a role in guiding airflow and can prevent noise generated in the working process of the motor from being exhausted outwards.

Owner:JOYOUNG CO LTD

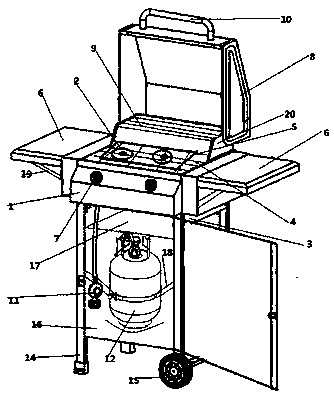

Gas barbecue grill

The invention discloses a gas barbecue grill, comprising a grill body, a head, a support frame and a grill net. The gas barbecue grill is characterized in that the grill body is fixed to the support frame, the head is a gas stove head arranged in the grill body, a head protective cover is arranged right above the head, the grill net is arranged above the head protective cover, holding terraces arearranged on the left and right of the grill body, an ignition switch is arranged right in the front of the grill body, a grill cover is arranged at the top of the grill body, an insulation net is arranged in the grill cover, the inside of the support frame includes a gas cylinder storage area and a storage area, the bottom of the gas cylinder storage area is provided with a recess, a fixing tapeis arranged above the recess in the gas cylinder storage area, the recess and the fixing tape are jointly used to fix a gas cylinder, the holding terraces are movably connected with the grill body andcan be opened or lowered, and two support rods are arranged on the two sides of the holding terraces of the grill body respectively for supporting the opened holding terraces.

Owner:丹阳宝联五金制品有限公司

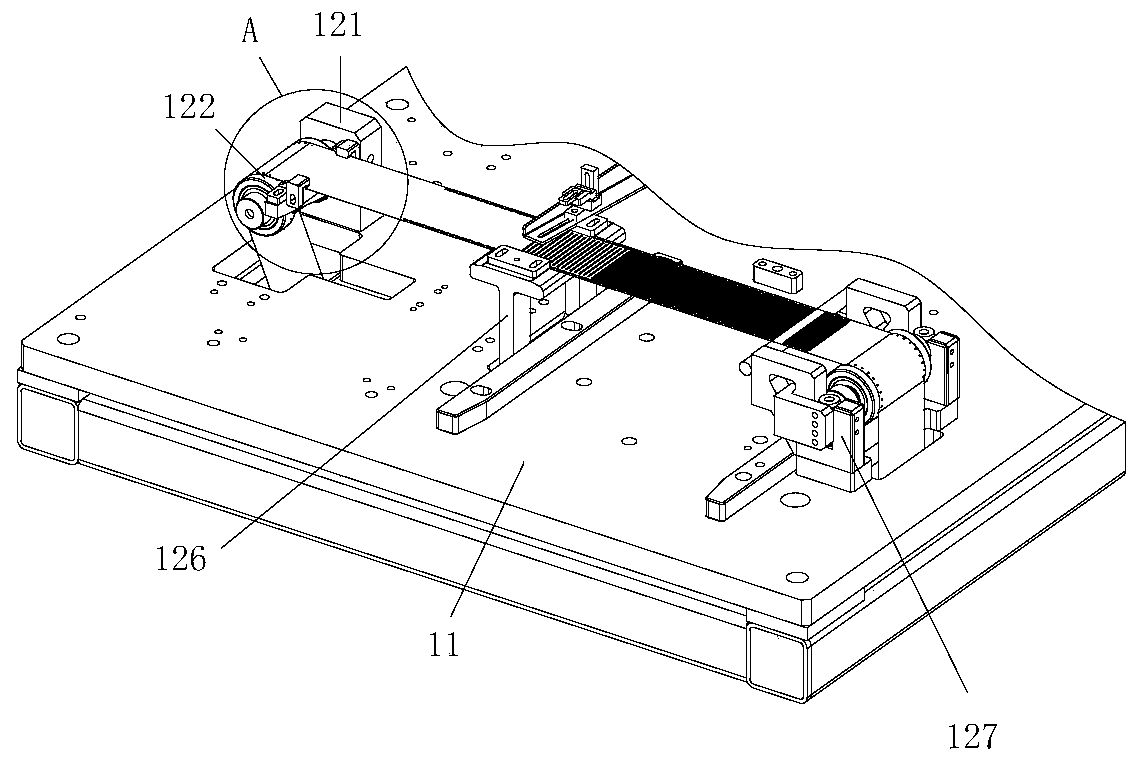

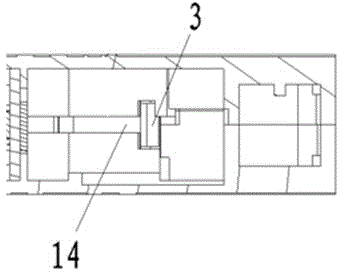

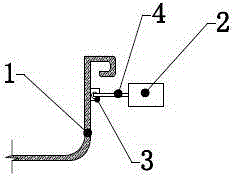

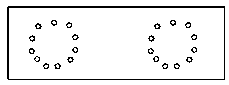

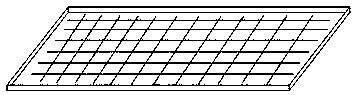

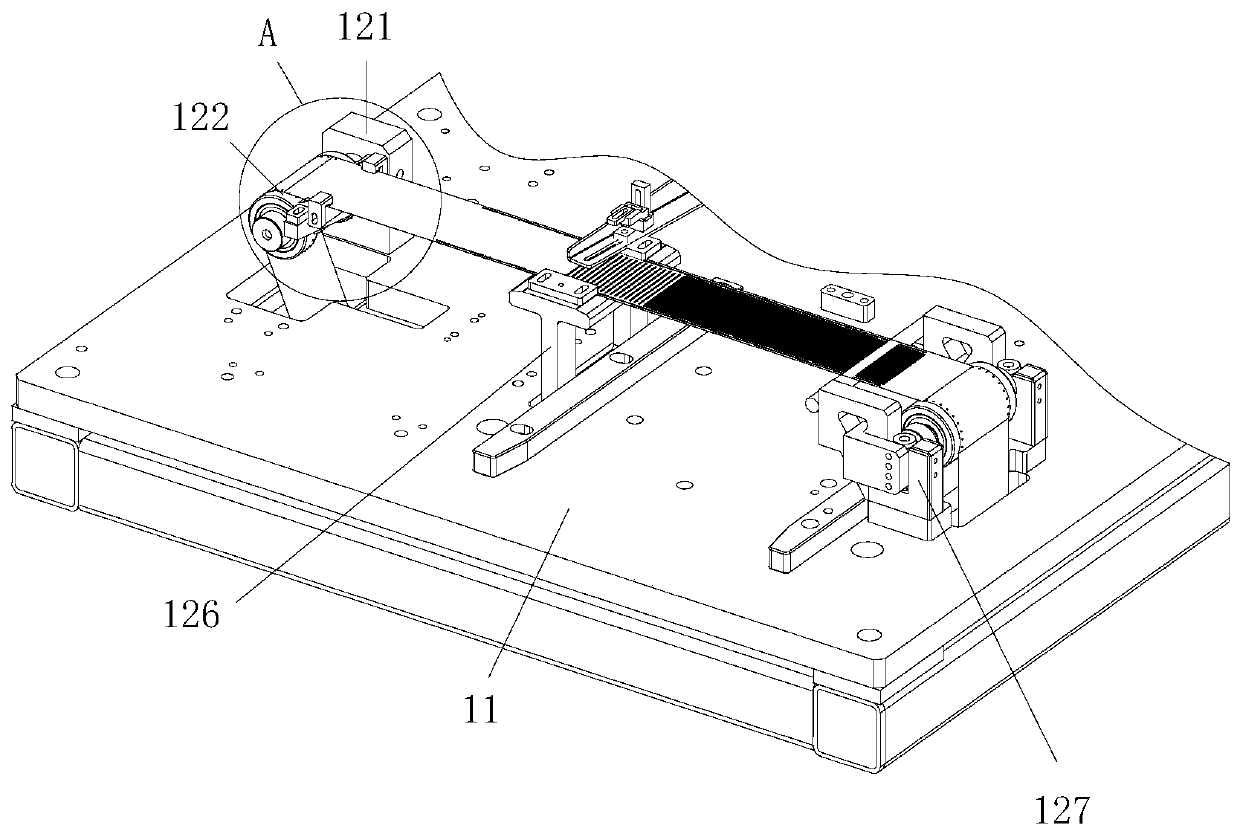

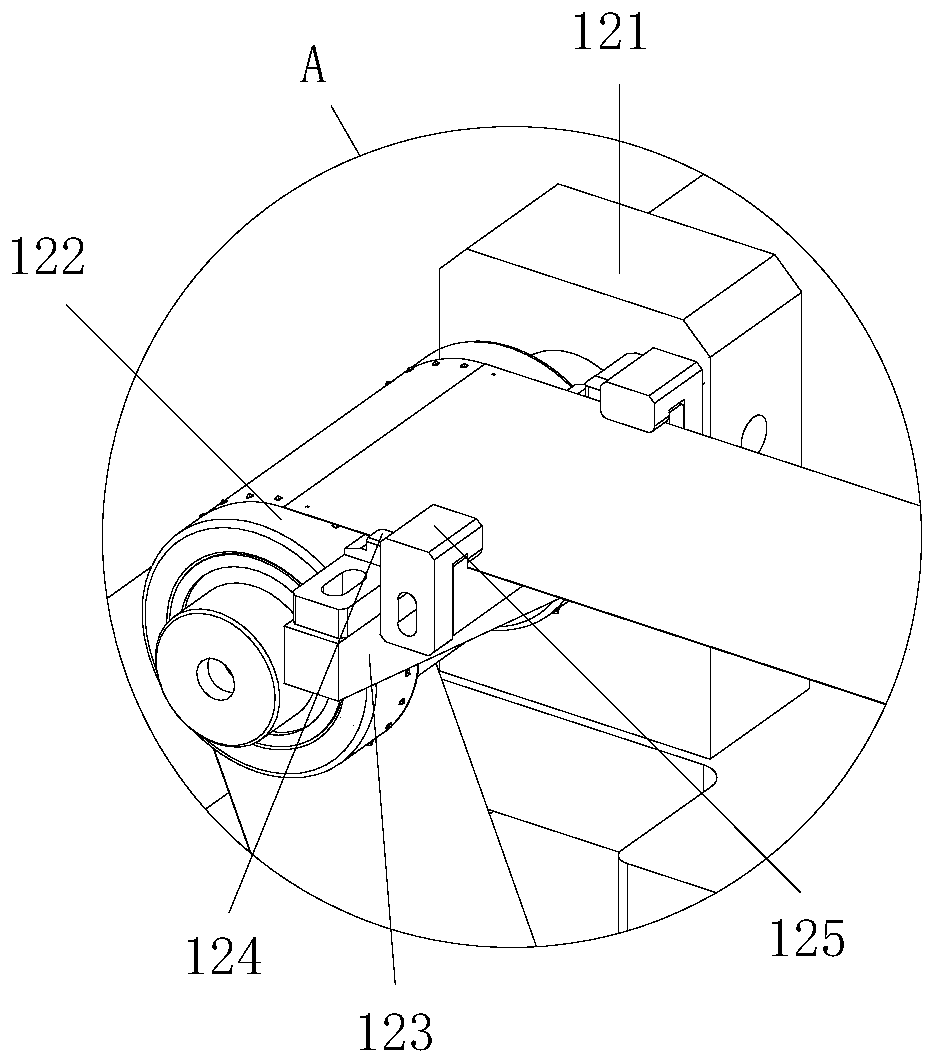

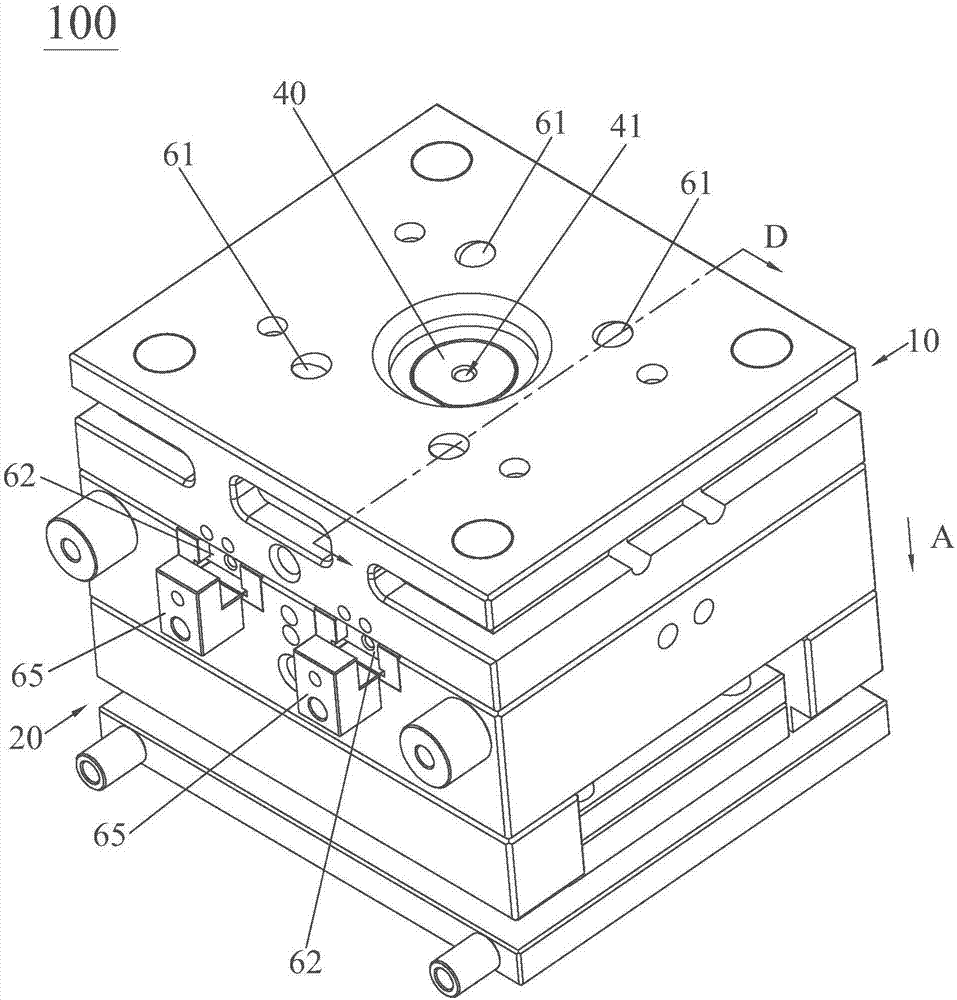

Sheet steel punching device

PendingCN111331027ARestricted degrees of freedomGuaranteed flatnessFouling preventionMetal-working feeding devicesSheet steelPunching

The invention discloses a sheet steel punching device. The sheet steel punching device comprises a punching support, a steel strip positioning assembly, a steel strip material tray, a steel strip feeding mechanism, a backing paper material receiving mechanism, a cutting machine and a cover film retrieving material tray. The steel strip feeding mechanism is arranged at the front end of the steel strip positioning assembly in a butt joint manner. The cutting machine is arranged on the steel strip positioning assembly. The steel strip material tray and the backing paper material receiving mechanism are arranged at the bottom of the punching support. A steel strip on the steel strip material tray is conveyed to the backing paper material receiving mechanism after passing by the steel strip feeding mechanism and the steel strip positioning assembly. The cover film retrieving material tray is arranged on a workbench of the punching support. A cover film on the steel strip is retrieved into the cover film retrieving material tray. In this way, the sheet steel punching device can position the steel strip in the conveying process, and the flatness of the steel strip during cutting is guaranteed while pull damage caused to the steel strip by punching cutting is avoided; because feeding is carried out in an extrusion manner, the sheet steel punching device can adapt to feeding of steel strips of different thicknesses, it can be avoided that the steel strip runs helter-skelter, and it can be prevented that cutting is affected by the force of retrieving materials.

Owner:SUZHOU LANGKUN AUTOMATION EQUIP CO LTD

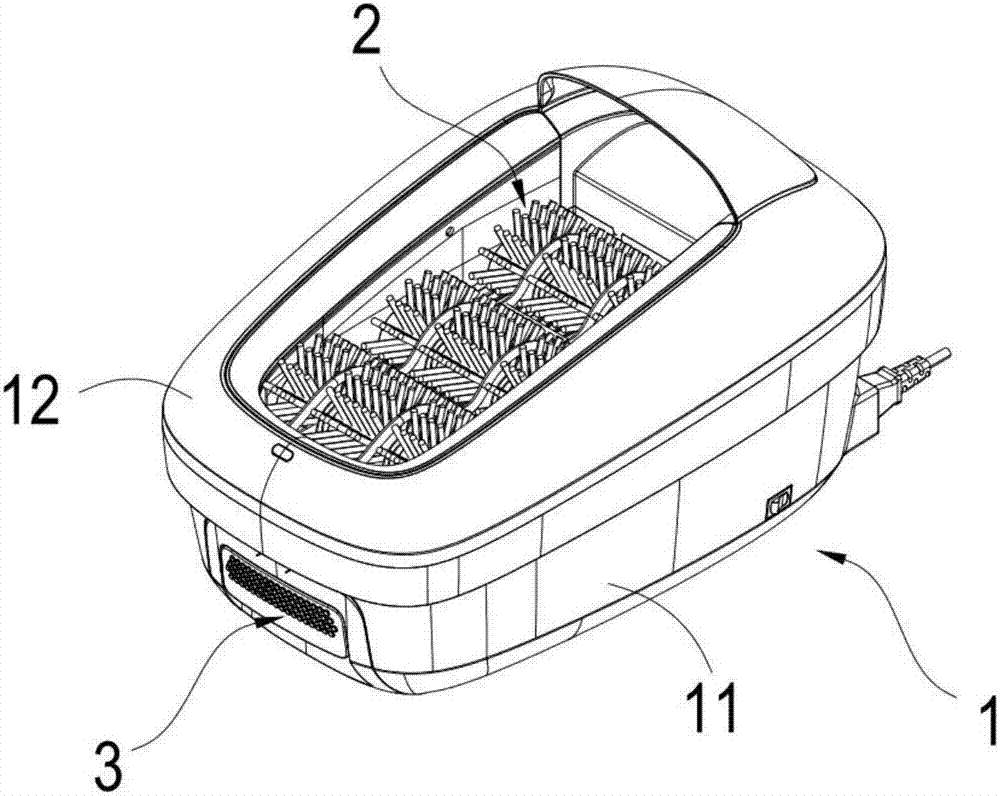

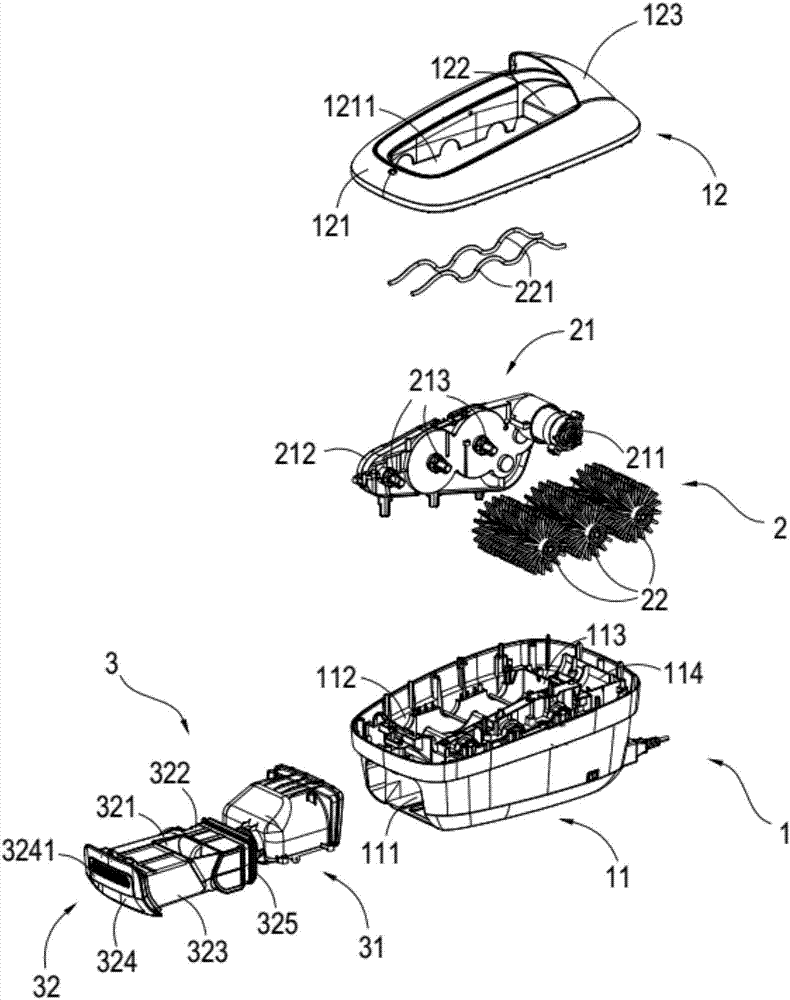

Shoe polishing machine

PendingCN107456197ASave body spaceImprove dust collection efficiencyFootwear cleanersInterior spaceEngineering

The invention discloses a shoe polishing machine. The machine comprises a machine body which has a certain internal space, a shoe polishing assembly and a dust collection assembly, and the shoe polishing assembly and the dust collection assembly are arranged inside the machine body, wherein the machine body comprises a machine case and a top hood, the machine case is opened at the upper portion, the top hood is connected to the upper portion of the machine case, and comprises an opening for shoes to be put in and taken out of, and the dust collection assembly is located under the shoe polishing assembly in a spaced mode. According to the shoe polishing machine, a shoe sole is conveniently and quickly cleaned, and the indoor pollution can be prevented.

Owner:KINGCLEAN ELECTRIC

Constant-flow constant-pressure water supply control device

ActiveCN112392102AReduce the pass areaPrevent scurryingHydro energy generationService pipe systemsPistonPiston cylinder

The invention discloses a constant-flow constant-pressure water supply control device. The constant-flow constant-pressure water supply control device comprises a shell body, a power mechanism is arranged and installed in the shell body, a supporting mechanism is arranged and installed at the top end of the shell body, a transmission mechanism is arranged and installed at the top end of the supporting mechanism, and the transmission mechanism is arranged and installed at the position, located on one side of the supporting mechanism, of the top end of the shell body; through power rotating holes are formed in the peripheral side of the shell body, piston cylinders are fixedly arranged on the position, located on one sides of the power rotating holes, of the peripheral side of the shell body, and through piston holes are formed in the top ends of piston cylinders. By arranging the power mechanism, when a water flow or water pressure is too large, the water flow drives turbine fan bladesto rotate in an accelerated mode, the accelerated rotation enables the transmission mechanism to be in power connection, a moving piston of a moving mechanism moves downwards, the water flow passing area is reduced, the water flow is subjected to flow reducing and pressure reducing before flowing into a hose, and the hose is prevented from moving disorderly and exploding.

Owner:彩虹(合肥)液晶玻璃有限公司

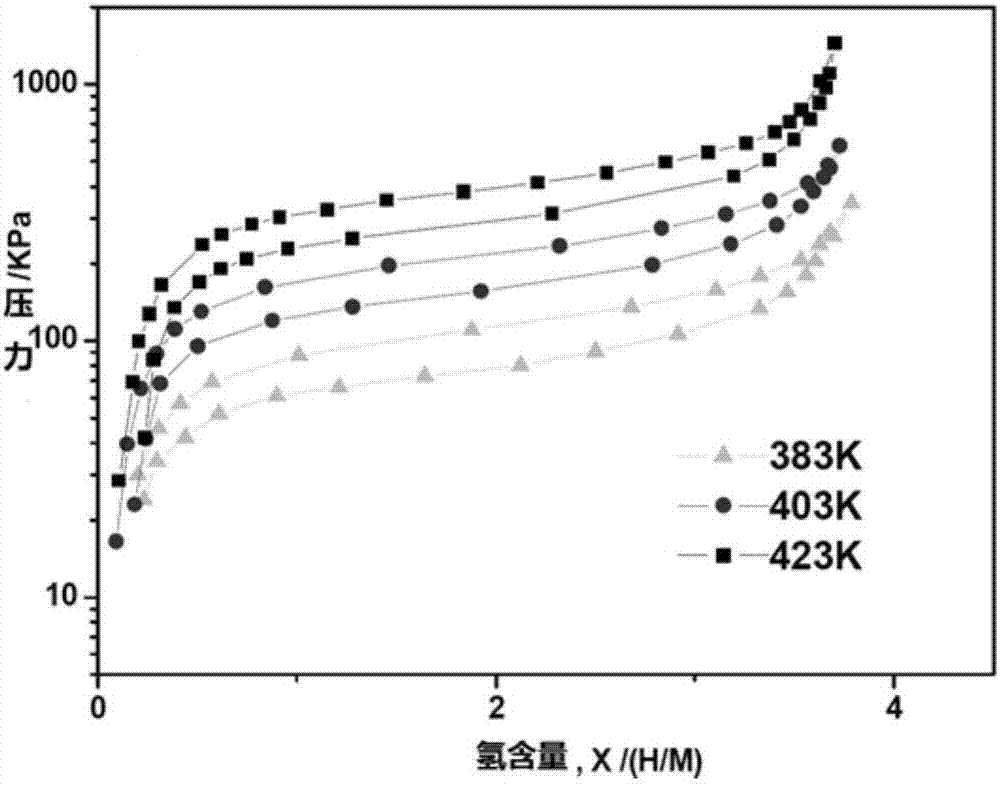

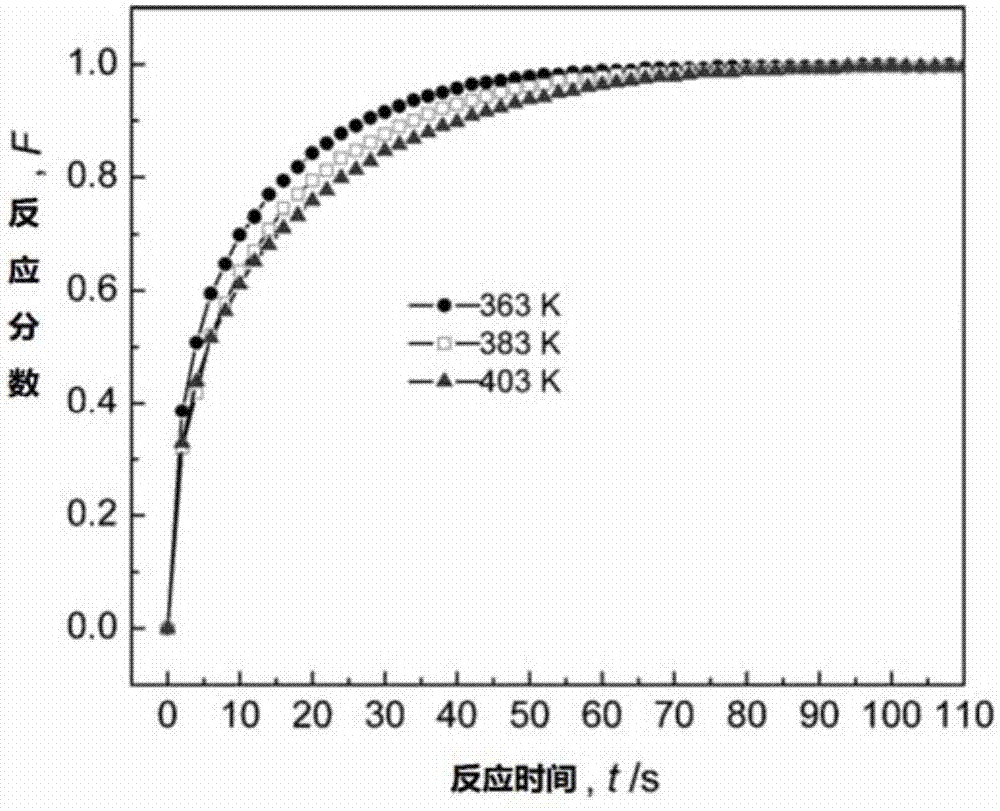

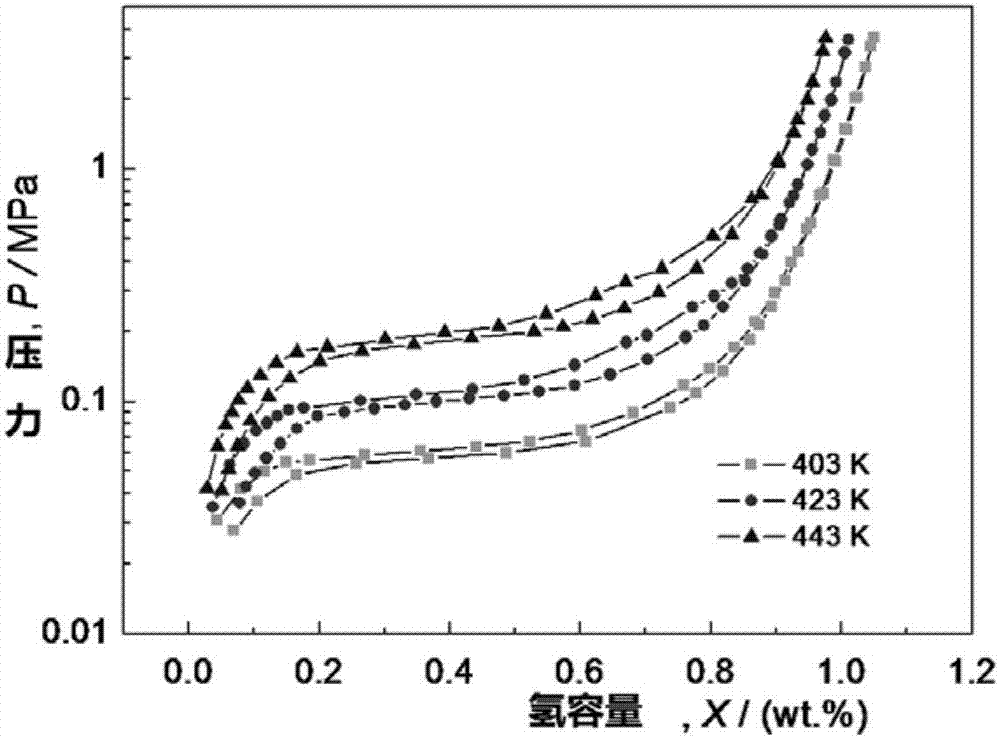

Spherical core-shell type LaNiAl-SiO2 compound hydrogen storage material and preparation method thereof

The invention relates to a spherical core-shell type LaNiAl-SiO2 compound hydrogen storage material applicable to hydrogen separation and a preparation method thereof, and belongs to the field of hydrogen storage materials. LaNiAl alloy has a composition general formula of LaNi5-xAlx, wherein x is more than or equal to zero and less than or equal to 2; the spherical material has an outer diameter of 4-6mm, an intermediate main ingredient of LaNiAl alloy, a porous SiO2 appearance and a thickness of 1-2mm. The preparation process of a material comprises the steps of melting and powdering alloy; stirring, mixing and granulating the alloy powder with silica sol; coating with gaseous SiO2; and performing aging and hydrothermal removing treatment. The preparation method of the compound hydrogen storage material has high automatic degree, uniform appearance and size and small airflow resistance, has maximal filling capacity in a reactor, cannot be ground or further pulverized, and cannot block a filter or cause self-compaction, so that toxicity of CO, O2, NH3, H2S and other impure gases for LaNiAl alloy can be greatly reduced, and the service life is greatly prolonged. The spherical core-shell type LaNiAl-SiO2 compound hydrogen storage material can be used in a hydrogen separating process.

Owner:YANGZHOU UNIV

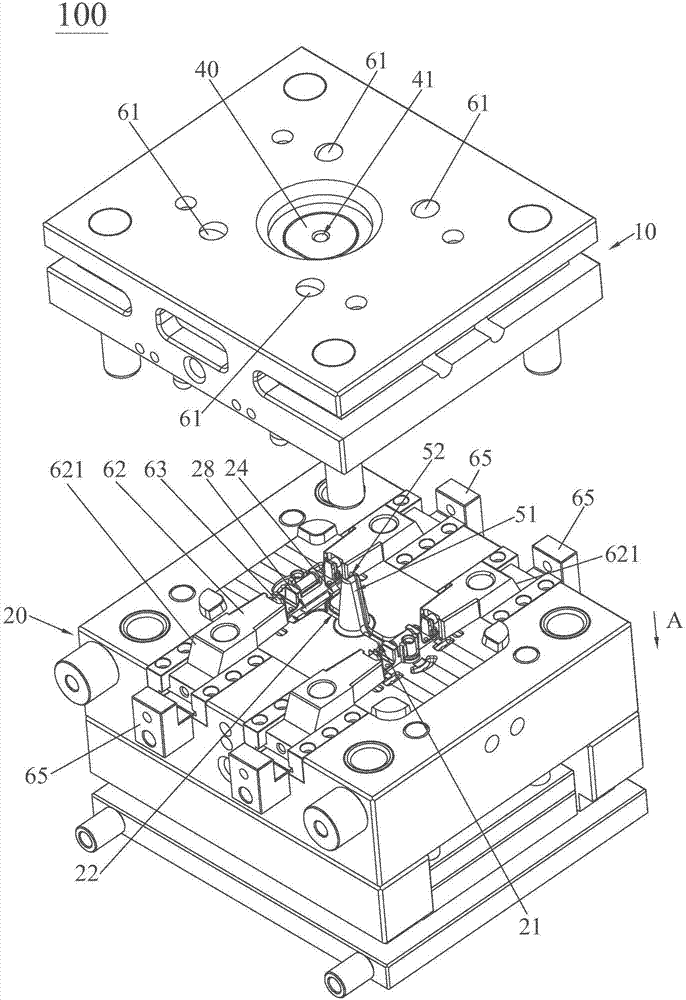

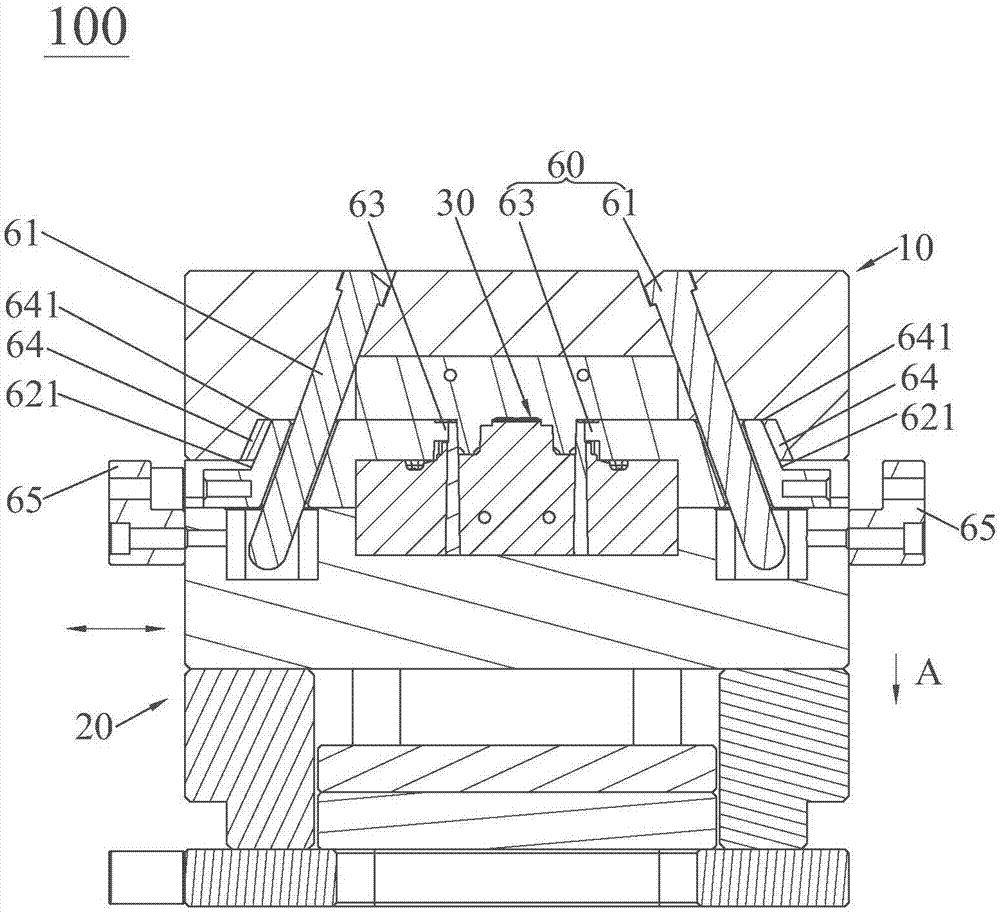

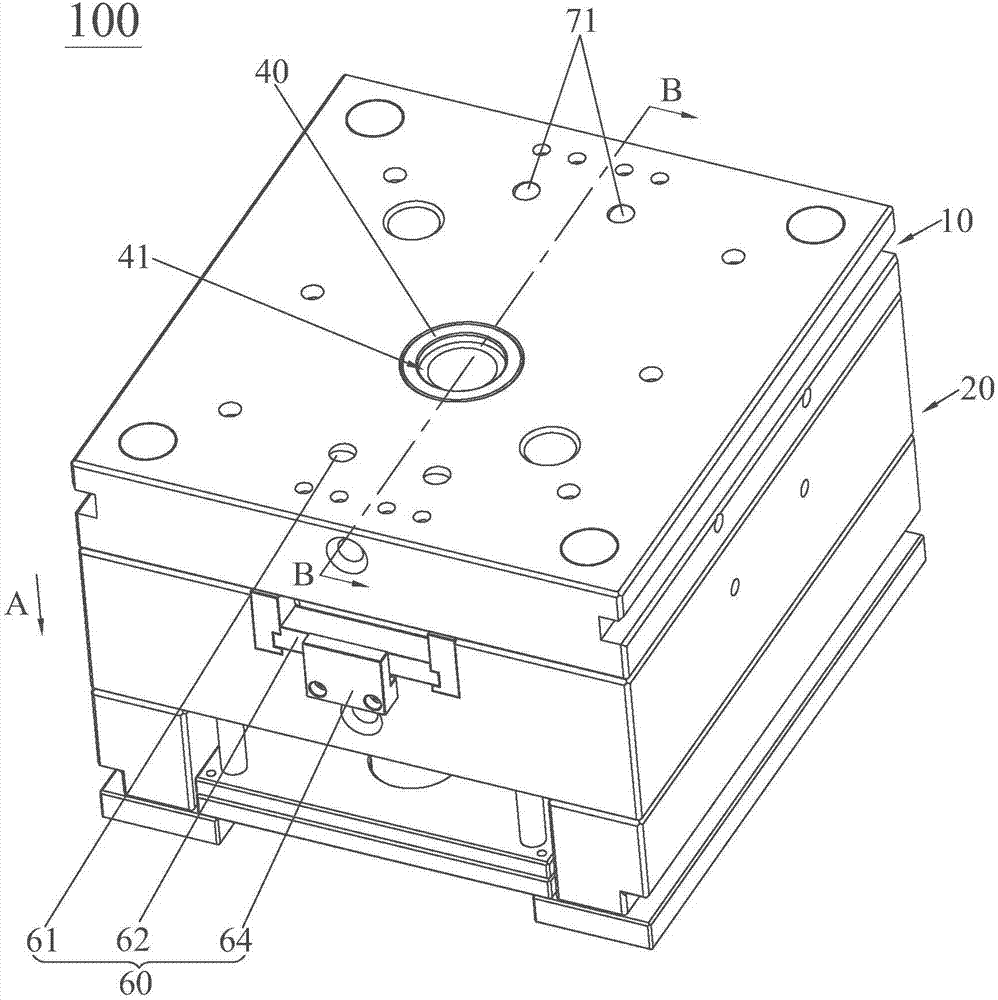

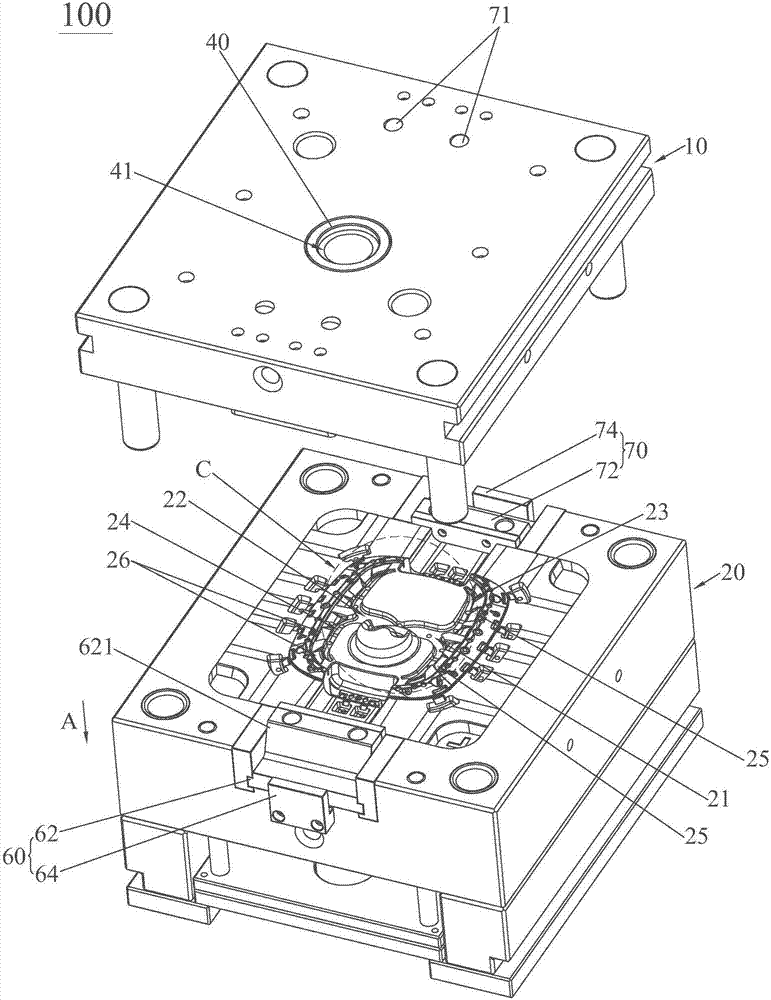

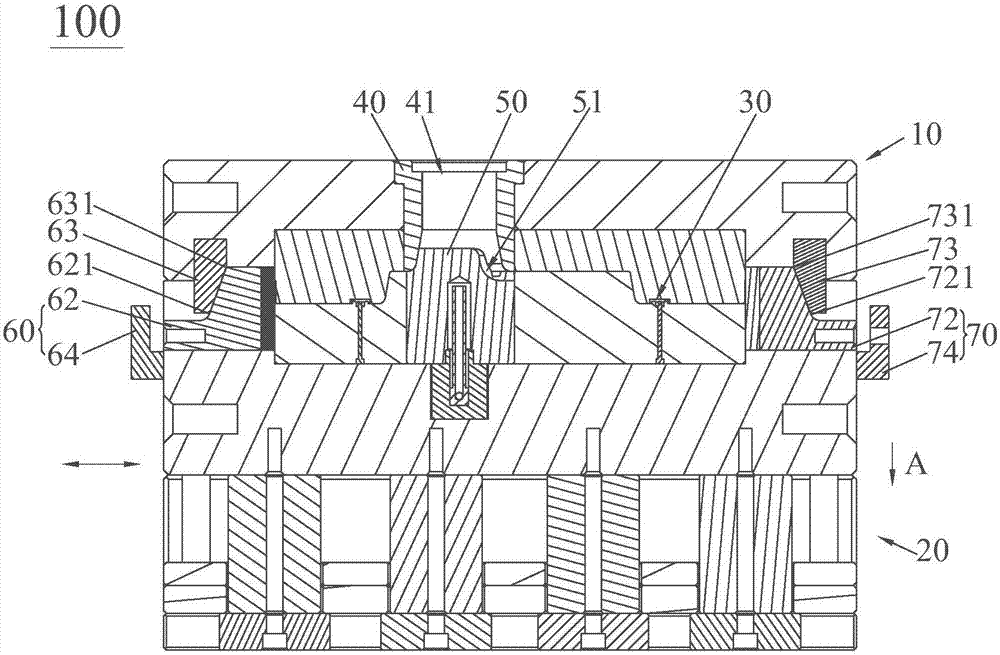

Pressure-casting mold for anti-theft lock cases

The invention discloses a pressure-casting mold for anti-theft lock cases. The pressure-casting mold comprises a pouring nozzle, a flow division cone, side core-pulling mechanisms, a stationary mold and a movable mold. After the stationary mold and the movable mold are closed, two molding cavities are defined. Each molding cavity is provided with the two corresponding side core-pulling mechanisms,wherein every two side core-pulling mechanisms are located at the left side and the right side of the corresponding molding cavity. The flow division cone is provided with a first flow division groove and a second flow division groove. Each side core-pulling mechanism comprises an inclined guide pillar, a side pulling slide block, a side core-pulling rod and a side pulling lock block. Each side pulling lock block is provided with a first inclined structure. Each side pulling slide block is provided with a second inclined structure. After being closed, the first inclined structures abut against the second inclined structures in a stopping manner. The movable mold is provided with first linear grooves, second linear grooves, first branch grooves, second branch grooves, first communicating grooves and second communicating grooves. The groove depth of each first communicating groove and the groove depth of each second communicating groove are arranged to be gradually decreased in the direction of being close to the molding cavities. The groove bottom face of each first communicating groove and the groove bottom face of each second communicating groove are inclined faces which are inclined upwards in the direction of being close to the molding cavities. By means of the pressure-casting mold, precise and rapid molding is achieved, and thus product quality is guaranteed.

Owner:CHANGCHANG DIE CASTING CO

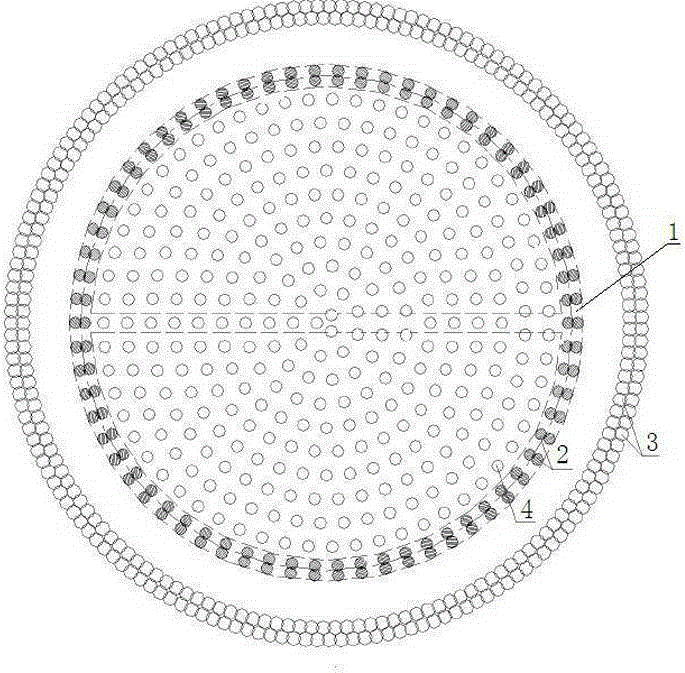

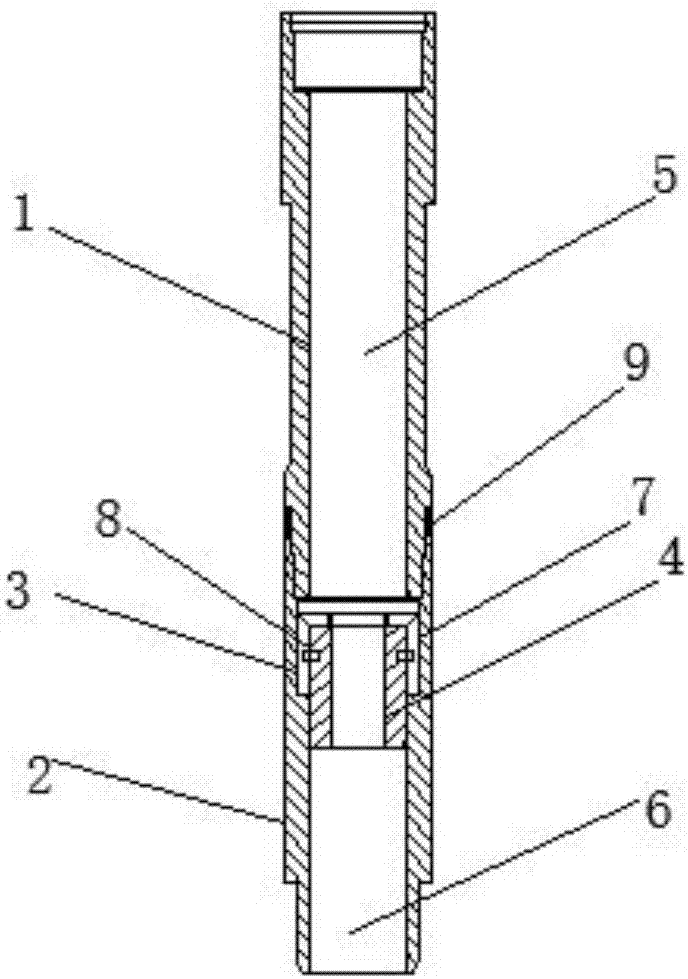

Annulus-pressurizing well cementing device

PendingCN107327284AGuaranteed operational reliabilityIncrease cementing pressureSealing/packingWell cementingEngineering

The invention relates to an annulus-pressurizing well cementing device. The annulus-pressurizing well cementing device comprises an upper connector, a lower connector, a fixed sleeve and a sliding sleeve, wherein the upper connector is installed on the upper portion of the lower connector, a first cavity is formed in the upper connector, a second cavity is formed in the lower connector, and the first cavity and the second cavity correspond to each other; and the fixed sleeve is arranged in the second cavity, and the sliding sleeve is arranged on the inner side of the fixed sleeve. The annulus-pressurizing well cementing device is simple in structure, convenient to use and capable of enhancing well cementing quality effectively.

Owner:YANGZHOU CHENGCHUANG GASOLINEEUM MACHINERY

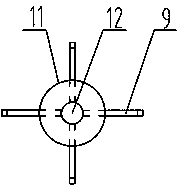

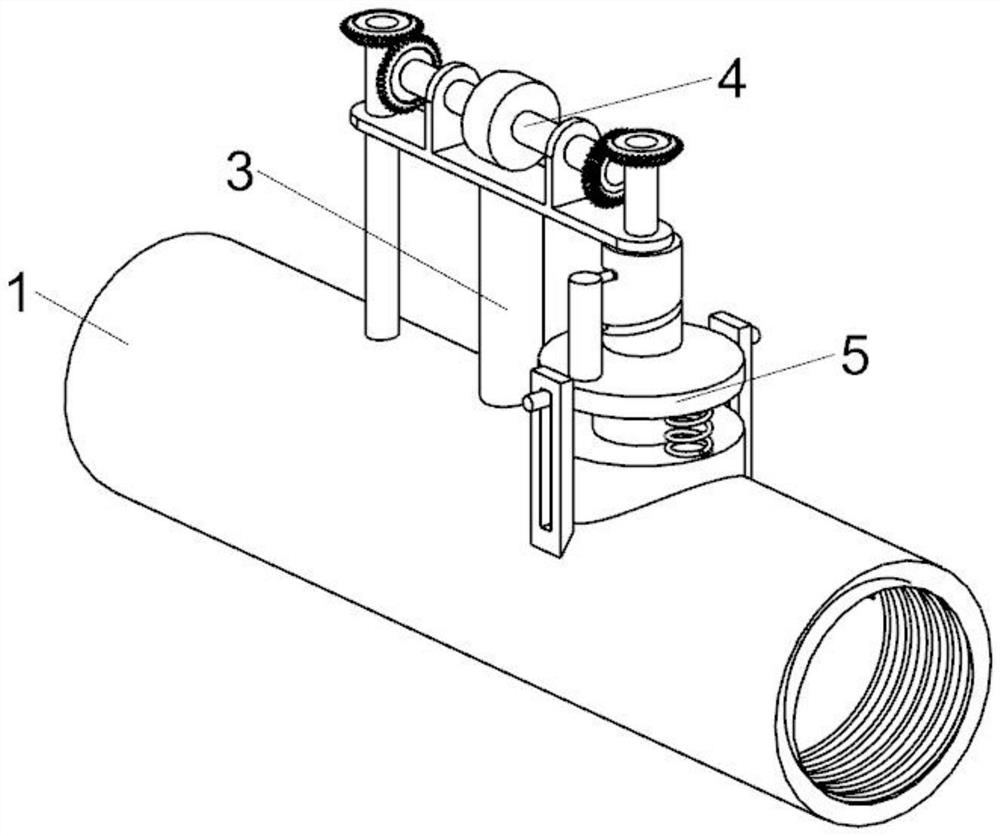

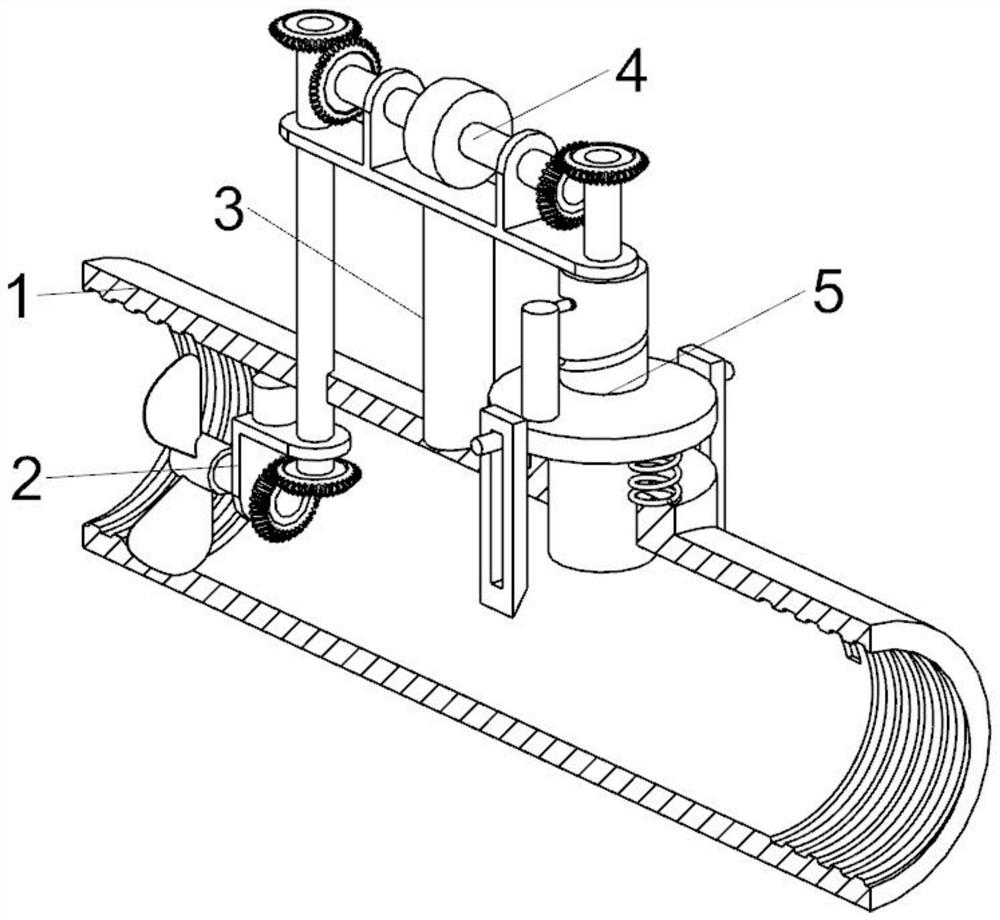

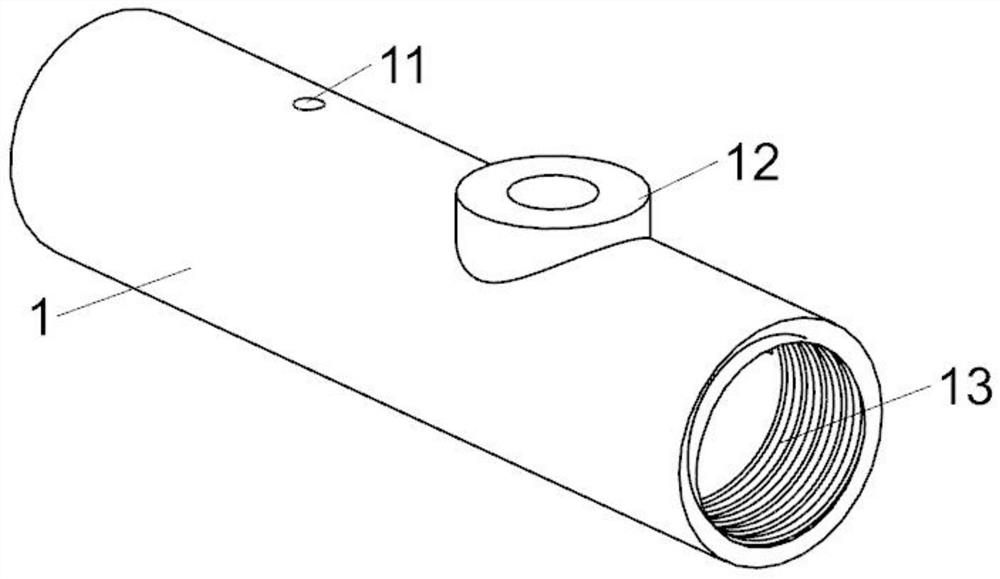

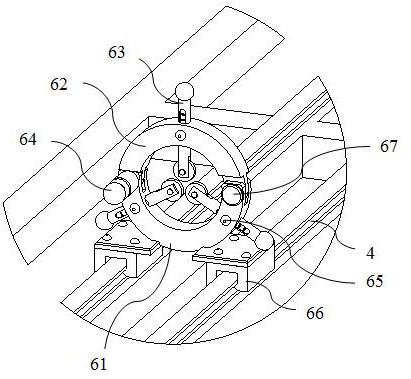

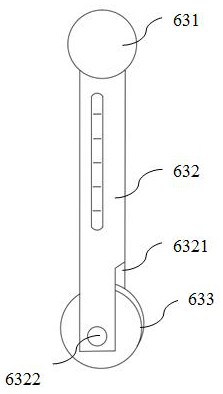

Auxiliary device for processing brake pipeline

ActiveCN111618622AAvoid shakingPrevent scurryingPositioning apparatusMetal-working holdersBrakeControl engineering

The invention discloses an auxiliary device for processing a brake pipeline. The auxiliary device comprises a movable type operation platform and a circular wheel clamping device, wherein a slide railis arranged on the movable type operation platform; the circular wheel clamping device is mounted on the slide rail; the circular wheel clamping device comprises a plurality of tube diameter meteringclamping columns, a plug pin, a circular wheel supporting disc and a slide block, the slide block is embedded into the slide rail. The tube diameter metering clamping columns are equally divided at an angle of 120 degrees to define an equilateral triangle, so that the pipeline is clamped through stability of the equilateral triangle, and therefore, shaking and jumping during pipeline cutting processing are prevented, and safety of processing the brake pipeline is improved; circular wheels are arranged on the tube diameter metering clamping tubes, and the circular wheels rotate along with thepipeline during pipeline cutting and rotating, so that vibrating and jumping caused by the too long pipeline are prevented, the pipeline is always kept on the same coaxiality, and pipeline processingprecision and efficiency is improved; and a guide device is a groove with a gradient, so that cutting waste liquid can be effectively recycled.

Owner:青岛中车四方轨道车辆有限公司

Preparation method of bio-based fiber degradable fabric

InactiveCN113604909APrevent scurryingMovement restrictionsFibre breaking machinesFibre breaking by toothed membersYarnPolymer science

The invention discloses a preparation method of a bio-based fiber degradable fabric, and relates to the technical field of fabric production. The preparation method comprises the steps of firstly, grabbing piled bio-based fiber cotton through a bale plucker; putting the bio-based fiber cotton grabbed by the bale plucker into a cotton blending machine; making the bio-based fiber cotton in the cotton blending machine into cotton rolls by using a lapper; carrying out opening, carding and impurity removal on the cotton rolls in the third step through a carding machine, preparing fiber cotton card slivers, and then carrying out pre-drawing treatment on the fiber cotton card slivers to obtain fiber cotton drawn slivers; performing first to fourth treatments on cotton made of other materials to obtain cotton drawn slivers; drawing the cotton drawn slivers obtained in the step 5 and the fiber cotton drawn slivers obtained in the step 4 by using a drawing frame, firstly spinning into rough yarns, then spinning into spun yarns, and then stranding and twisting through a spooling to prepare plied yarns; and making the plied yarns into a fabric by using a loom. The preparation method of the bio-based fiber degradable fabric provided by the invention has the advantages of convenience in use, high bale plucking efficiency of the bale plucker, difficulty in blockage of a bale plucking blade and the like.

Owner:安徽宜民服饰股份有限公司

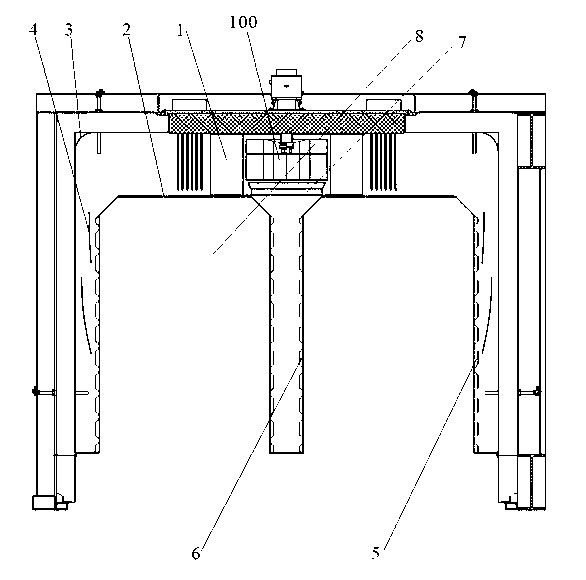

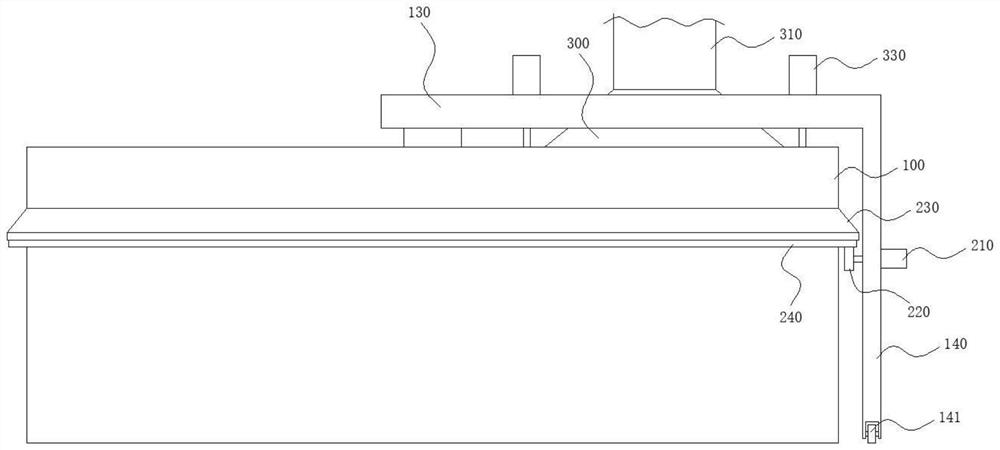

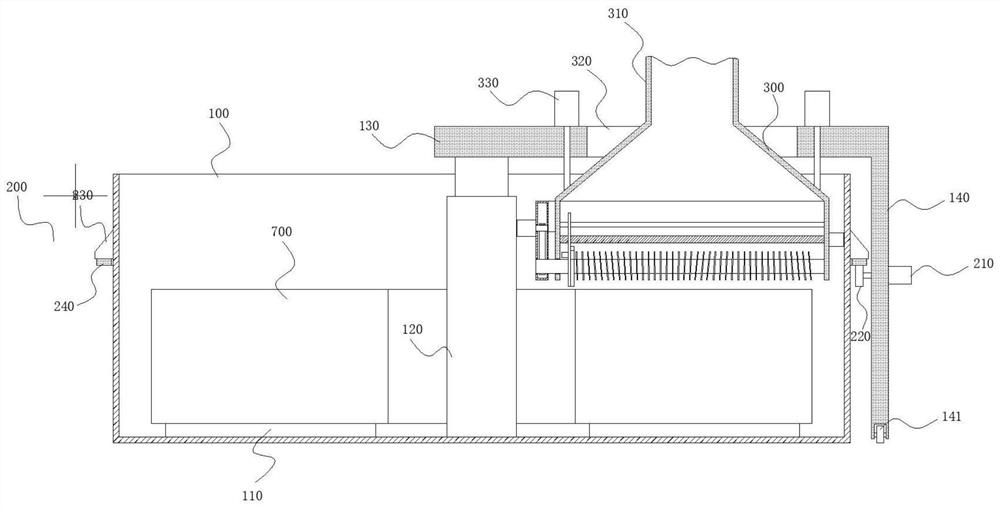

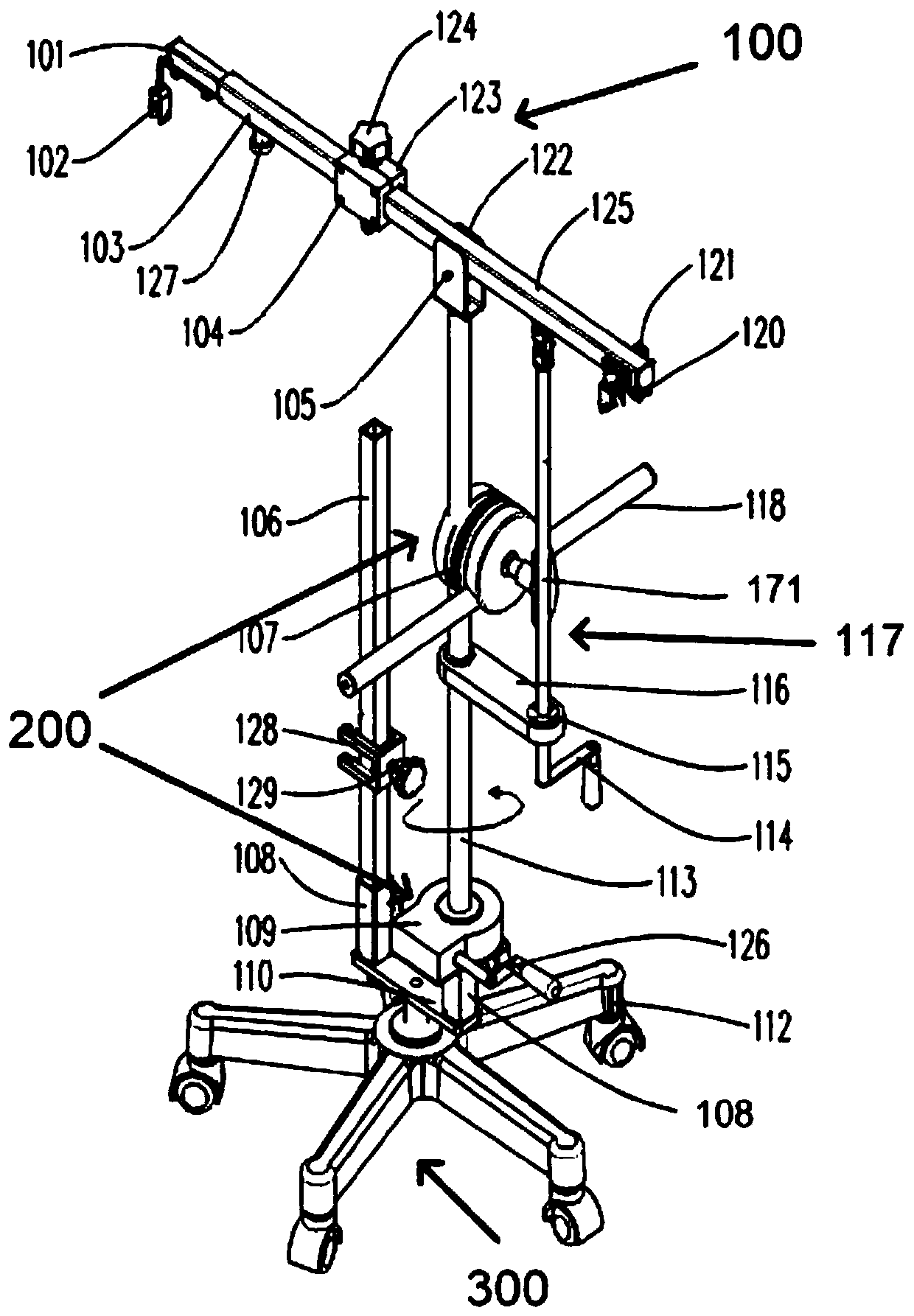

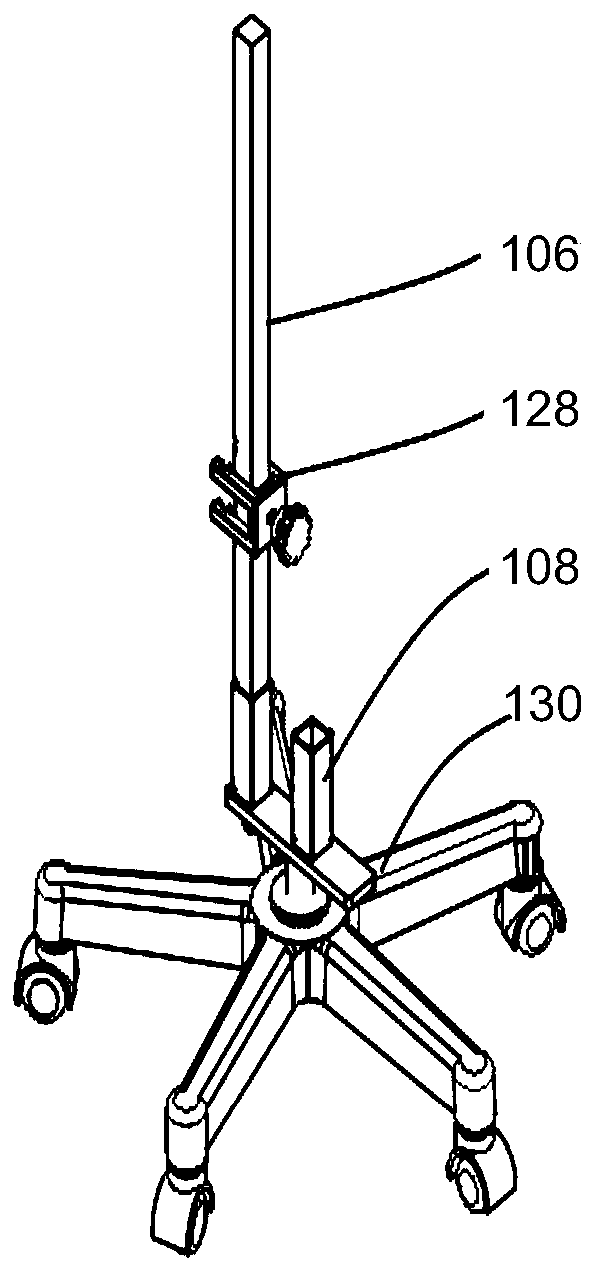

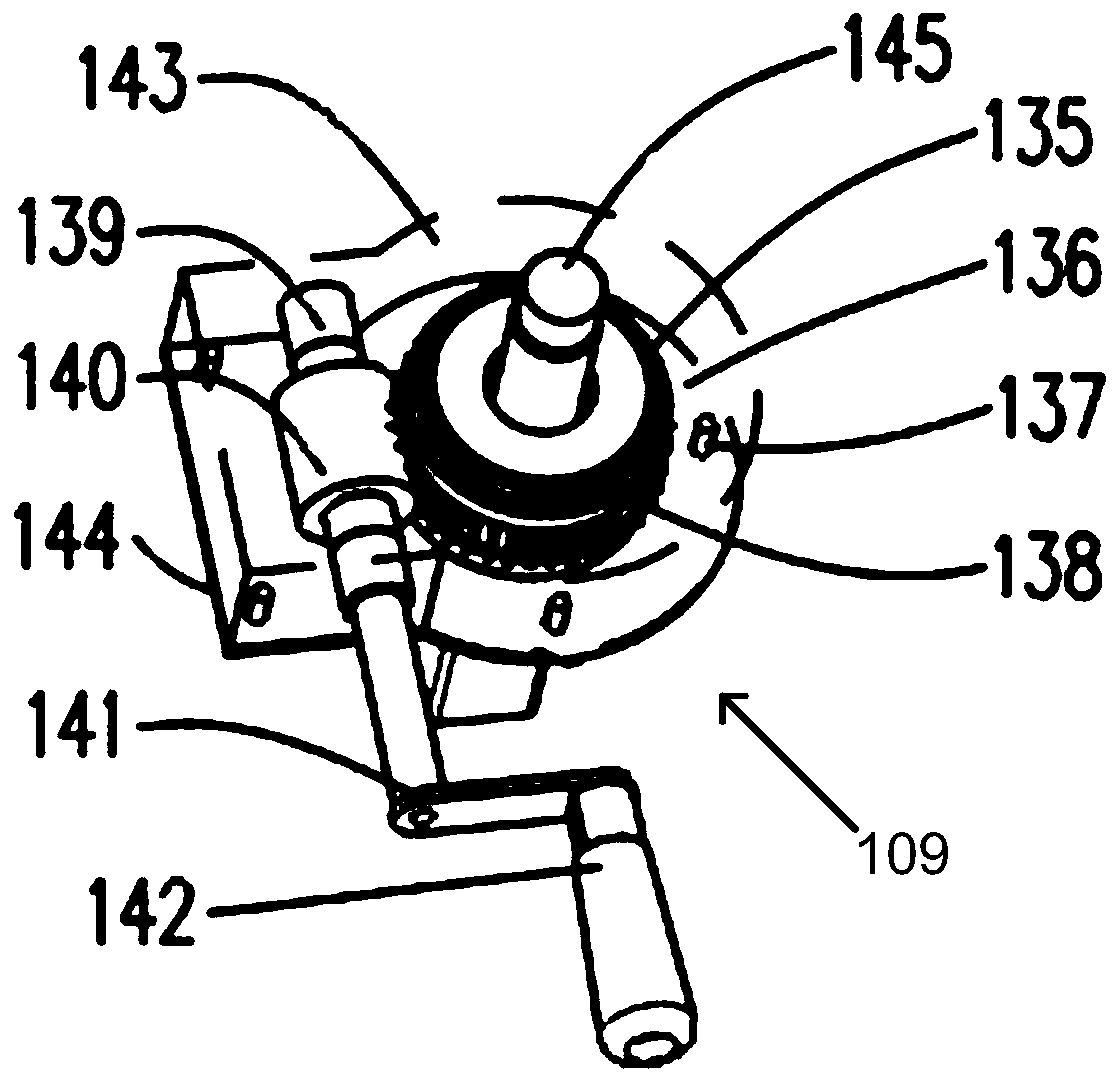

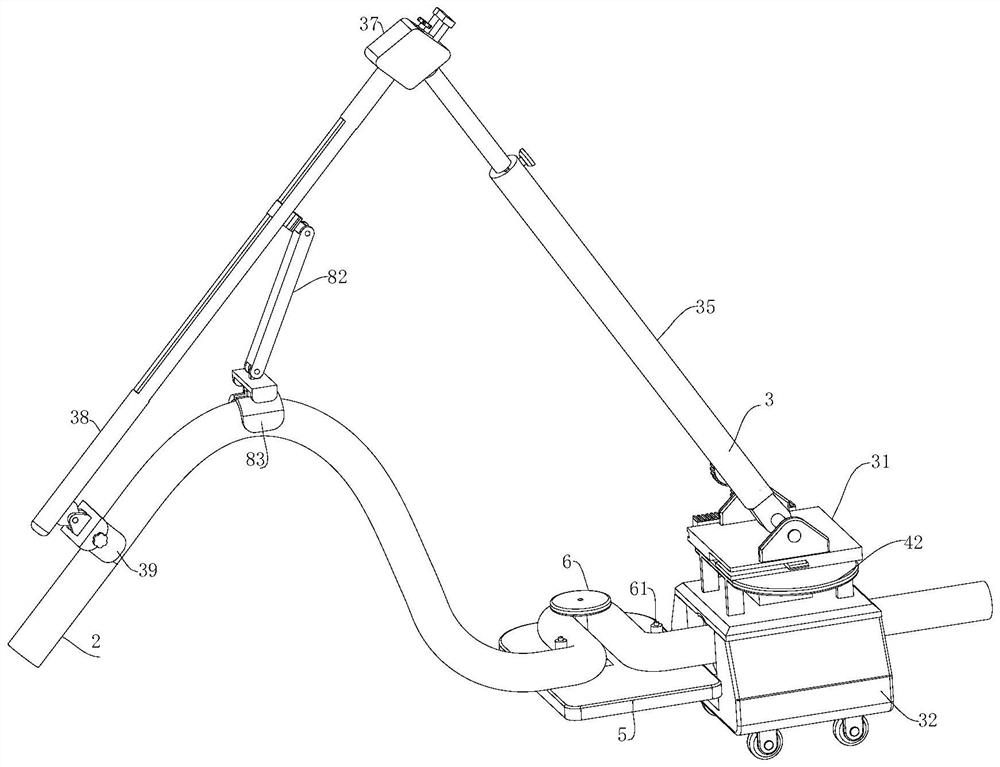

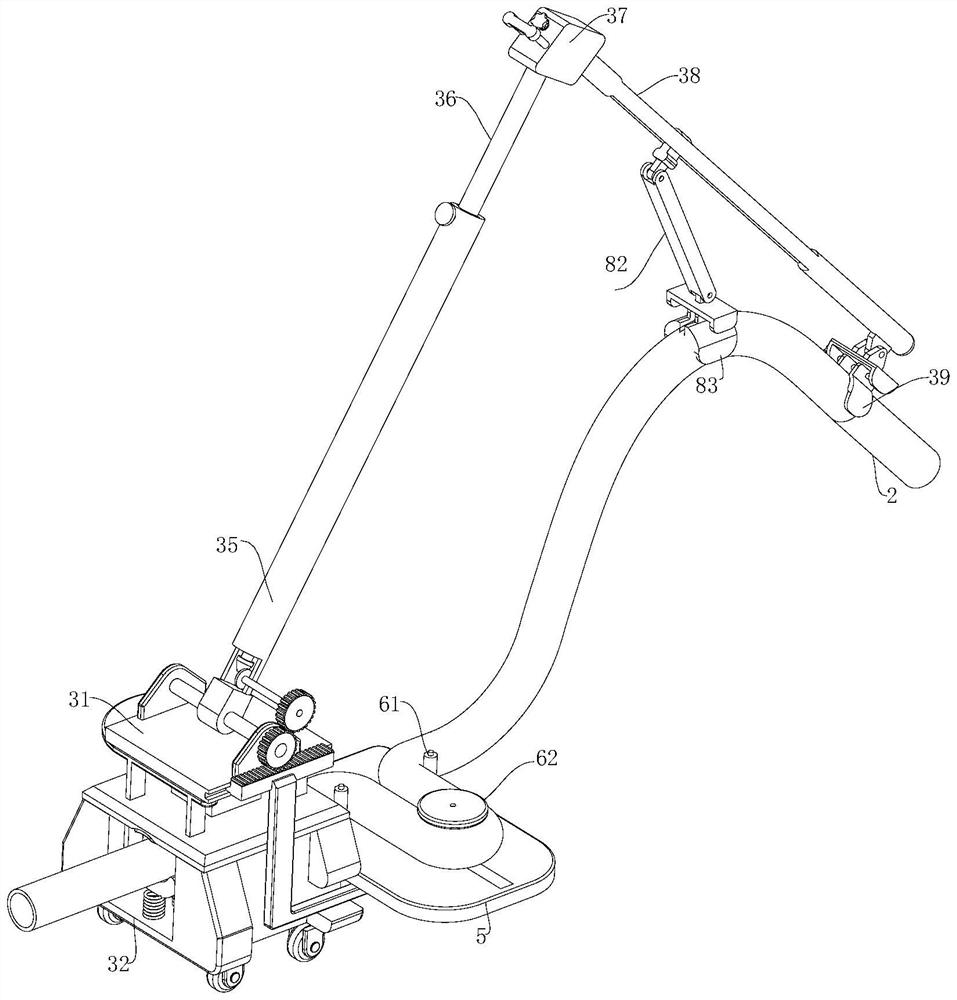

Side-lying position traction device for shoulder arthroscopy

PendingCN110840580AEasy accessEasy to pushInstruments for stereotaxic surgeryPhysical medicine and rehabilitationGear wheel

The invention provides a side-lying position traction device for shoulder arthroscopy. The side-lying position traction device comprises a traction mechanism (100), an adjustment mechanism (200) and awheel component (300). The traction mechanism (100) is connected with the adjustment mechanism (200). The adjustment mechanism (200) is mounted on the wheel component (300). The traction mechanism (100) comprises a retractable cantilever (103), a support frame (113) and a gear adjustment component (107). The retractable cantilever (103) is connected with the support frame (113). The gear adjustment component (107) is mounted on the support frame (113). The side-lying position traction device for the shoulder arthroscopy has the advantages that the side-lying position traction device can be simply fastened to a rail of an operating table through a locking and fastening clamp block, and fastening and unfastening can be realized only through an adjusting nut; the device is simple and convenient in structure, easy to process, and easy to mount and demount.

Owner:SHANGHAI LIGETAI BIOTECH CO LTD

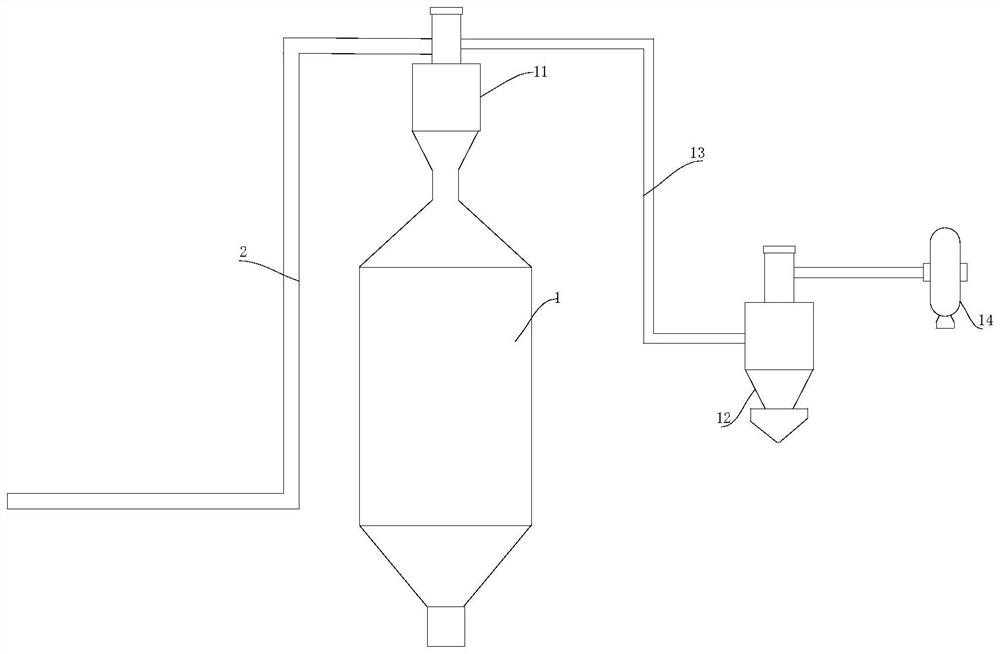

Material conveying system based on industrial bulk material pneumatic conveying technology

ActiveCN114852693AImprove delivery efficiencyPrevent scurryingHuman health protectionBulk conveyorsProcess engineeringPipe

The invention discloses a material conveying system based on an industrial bulk material pneumatic conveying technology, which comprises a stock bin and a first cyclone separator arranged on the stock bin, the first cyclone separator is communicated with a conveying pipe and a guide pipe, and the material conveying system based on the industrial bulk material pneumatic conveying technology can prevent the phenomenon that the material flows out of the conveying pipe in a disordered manner, so that the material conveying efficiency is improved. A supporting mechanism is arranged on the supporting base, the supporting mechanism can support the handheld part and achieve the labor-saving effect, meanwhile, adjustment can be conducted according to the position, needing to suck the industrial bulk materials, of the industrial bulk materials, the length of the conveying pipe can be shrunk while the conveying pipe is adjusted, and the conveying pipe is convenient to use. According to the industrial bulk material pneumatic conveying fluidization technology, the materials are effectively separated from the gas through the conveying pipeline and the supporting mechanism of the conveying pipeline, and the industrial bulk material machining efficiency is effectively improved.

Owner:ZHEJIANG GUTE PNEUMATIC MACHINERY

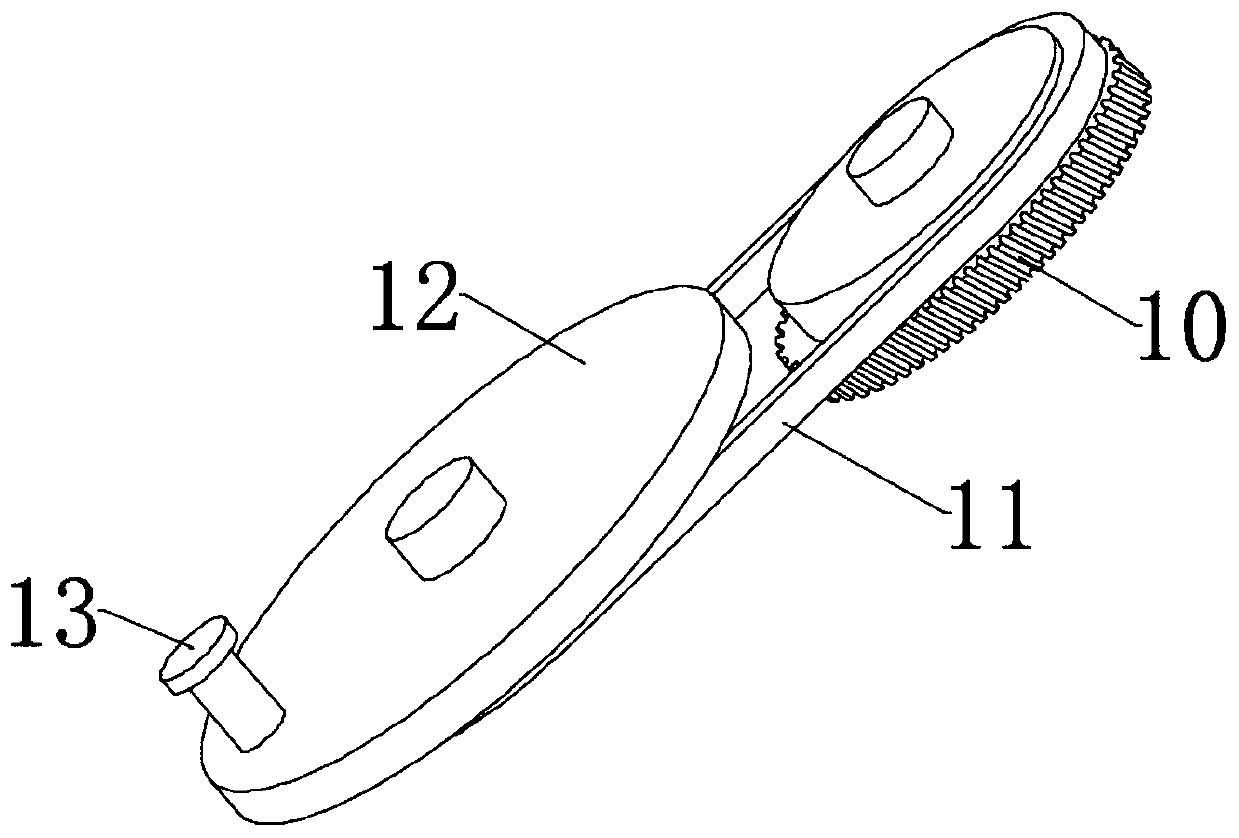

Medium and large pet bathtub

InactiveCN105594613APrevent scurryingQuick and easy to bring inGrooming devicesWater storageEngineering

The invention discloses a medium and large pet bathtub which comprises a bathtub body with a water-storage concave cavity in the middle. The medium and large pet bathtub is characterized in that the inner wall of the bathtub is provided with an annular partition which extends towards the middle part along the inner wall of the bathtub; the partition is parallel to the bottom of the bathtub, and the tail end of the partition is bent upwards to form a groove; the bathtub body is also internally provided with a fixing plate which is buckled with the groove and used for fixing limbs of a pet; the fixing plate is provided with two rows of mutually parallel through holes, and at least two through holes are formed in each row; one side wall of the bathtub body is provided with a pet inlet / outlet and an airtight door, one end of the airtight door is rotatably connected with the side wall, and the other end of the airtight door is buckled with the junction of the side wall and the bottom of the bathtub. The medium and large pet bathtub disclosed by the invention is capable of fixing the limbs of the pet so as to prevent the pet from fidgeting; the medium and large pet bathtub is provided with the airtight door which is openable and closable, so that the pet can get into and get out of the bathtub conveniently.

Owner:CHONGQING YUEFA COMMODITY

Flare tower with isolation cover

InactiveCN106838938APlay the role of wind protectionPrevent heat radiationIncinerator apparatusCombustionEngineering

The application discloses a flare tower with a partition, including a flare head, a base and a partition, the base is set as a hollow cylinder, the flare head is arranged in the inner cavity of the base, and the partition is provided with a connecting portion and a diverging The connection part is fixedly connected with the base, the diameter of the end of the divergence part away from the connection part is greater than the diameter of the connection end of the divergence part and the connection part, and the partition is set in a net shape. By setting the partition on the base of the flare tower, the partition There is a connection part and a divergence part. The diameter of the end of the divergence part away from the connection part is larger than the diameter of the connection part between the release part and the connection part, which avoids excessive heat radiation to the operators on the hull and the hull itself by gas combustion, and makes the gas burn The heat generated can be dissipated through the air flow in time, and the shield can also play a role of wind protection, preventing the flame from being extinguished or running around due to excessive wind, and can solve the problems of heavy weight and poor heat dissipation of the flare tower system.

Owner:COSCO SHIPPING SHIPYARD (NANGTONG) CO LTD +1

Die-casting formation mold for annular shell

The invention discloses a die-casting formation mold for an annular shell. The die-casting formation mold for the annular shell comprises a pouring nozzle, a sprue spreader, a left side drawing mechanism, a right side drawing mechanism, a fixed mold and a movable mold. The fixed mold and the movable mold are combined and then jointly define an annular cavity with the head and the tail being closed. The left side drawing mechanism and the right side drawing mechanism each comprise inclined guide columns, a side drawing sliding block and a side drawing lock block. Each side drawing lock block isprovided with a first inclined structure. Each side drawing sliding block is provided with a second inclined structure. The inclined guide columns of each side drawing mechanism are arranged in the corresponding side drawing sliding block in penetrating and sliding manners. The movable mold is provided with a first main groove, a second main groove, a first branch groove, a second branch groove,first communicating grooves and second communicating grooves. The first branch groove is arranged along the outline of the inner cavity wall on the front side of the annular cavity. The second branchgroove is arranged along the outline of the inner cavity wall on the back side of the annular cavity. The groove depths of the first communicating grooves and the groove depths of the second communicating grooves are gradually reduced in the direction close to the annular cavity. The groove bottom faces of the first communicating grooves and the second communicating grooves are inclined faces inclined upwards in the direction close to the annular cavity. By the adoption of the die-casting formation mold for the annular shell, precise and rapid formation is achieved, and therefore the quality is ensured.

Owner:CHANGCHANG DIE CASTING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com