Circulating air arc-control device for small breaker

A small circuit breaker and circulating airflow technology, applied in the direction of circuit breaker components, etc., can solve the problems of back blowing, no current limiting function, no magnetic blowing and air blowing functions, etc., to prevent arc reignition, increase arc voltage, The effect of preventing arc running

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

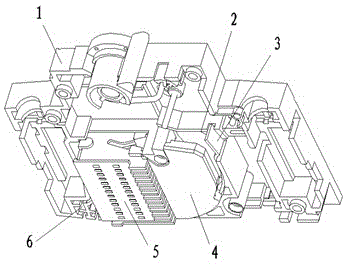

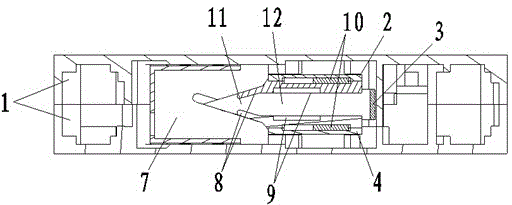

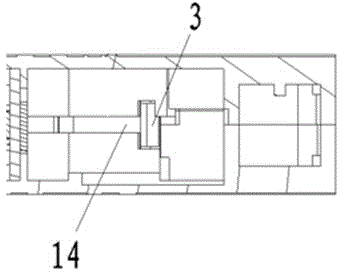

[0020] to combine figure 1 , figure 2 , image 3 : The circular air flow arc extinguishing device used for small circuit breakers of the present invention includes a housing 1, and a grid arc extinguishing chamber 5, an upper partition 4, a lower partition 2, an air outlet 6 and an arc strike plate 3 are installed in the housing , in the contact area and the head area of the arc striker, the upper partition 4 and the lower partition 2 make the arc extinguishing system form a semi-closed form up and down, and a contact movement groove 14 is reserved in the partition to ensure that the contact movement cannot be interfered , the upper partition 4 and the lower partition 2 separate the arc extinguishing chamber 5 from the circuit breaker mechanism, so that a certain gas pressure can be stored, and the pressure rise caused by the arc energy in the arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com