Wire stripping tool

A tool and cable technology, applied in the field of wire stripping tools, can solve the problems of complex wire stripping operations, achieve the effect of simple and convenient wire stripping process, and avoid the effect of cable scurrying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

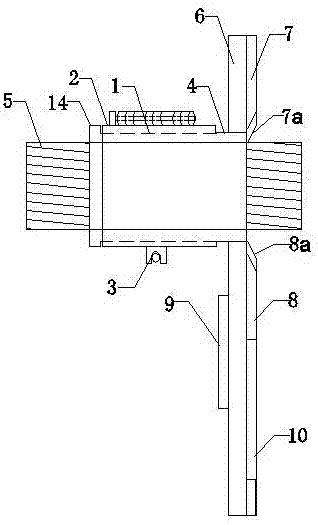

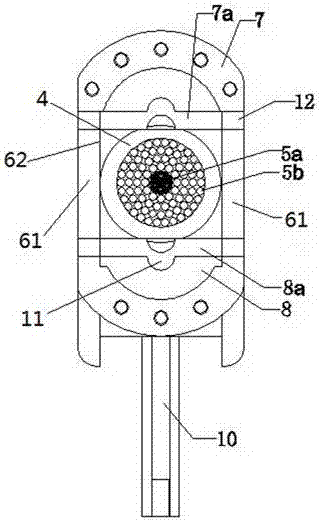

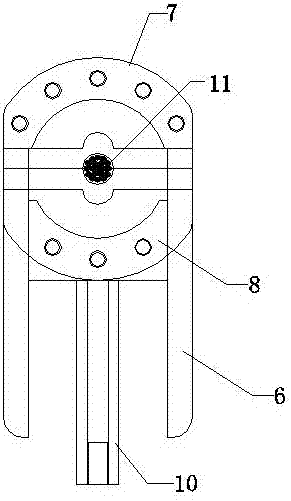

[0025] Embodiment 1 of a kind of stripping tool such as Figure 1~4 Shown: including the cutting mechanism and the cable positioning sleeve, the cable positioning sleeve includes the outer sleeve 2 and the inner sleeve 1 detachably connected to the outer sleeve by screws, the inner hole of the inner sleeve is the inner hole of the cable positioning sleeve, which is used for Cooperate with the concentric positioning of the corresponding cables 5 , in this embodiment, the extending direction of the inner hole of the inner sleeve 1 is defined as the left and right directions. The cable positioning sleeve is a buckle-type structure, that is to say, the inner sleeve and the outer sleeve of the cable positioning sleeve are two-piece structure, one end is hinged, and the other end is connected by a lock 3 (or other connecting parts such as bolts). It can be conveniently buckled on the cable 5, and the inner sleeve is detachable relative to the outer sleeve, so a suitable inner sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com