Material conveying system based on industrial bulk material pneumatic conveying technology

A pneumatic conveying and conveying system technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of high work intensity, long conveying pipe length, physical damage, etc., and achieve the goal of improving processing efficiency and conveying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

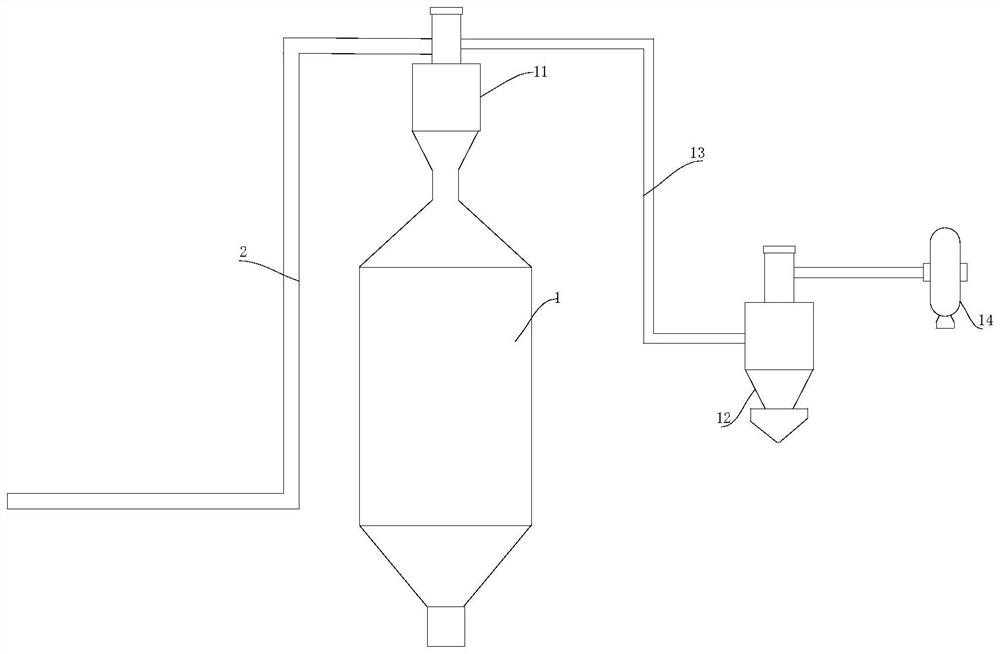

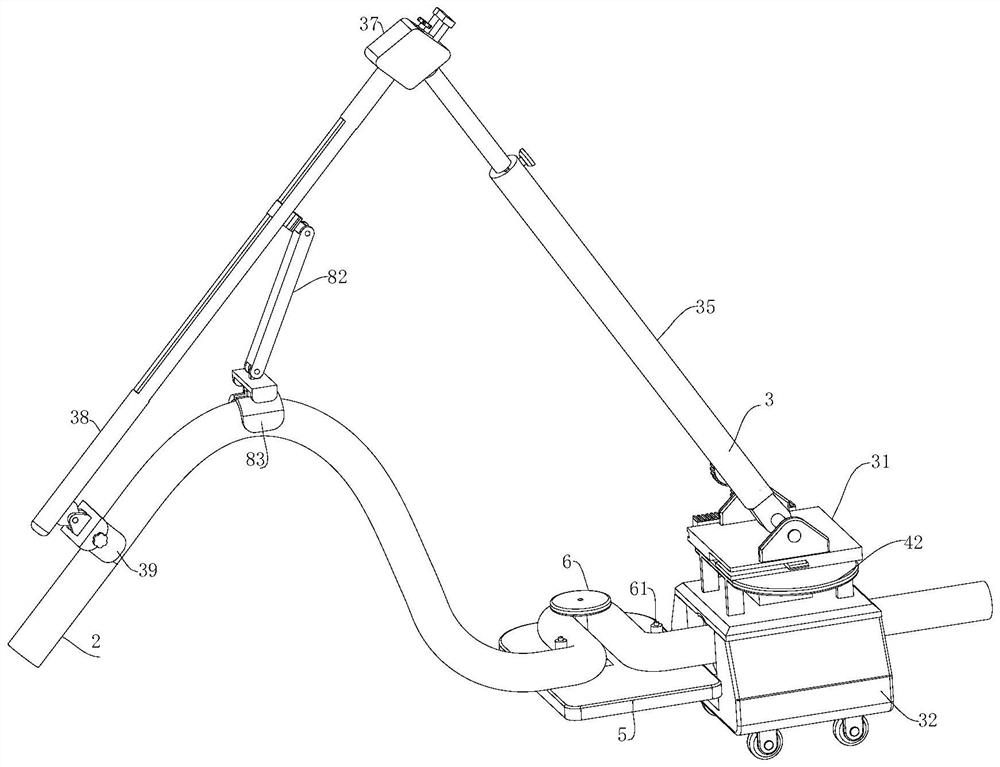

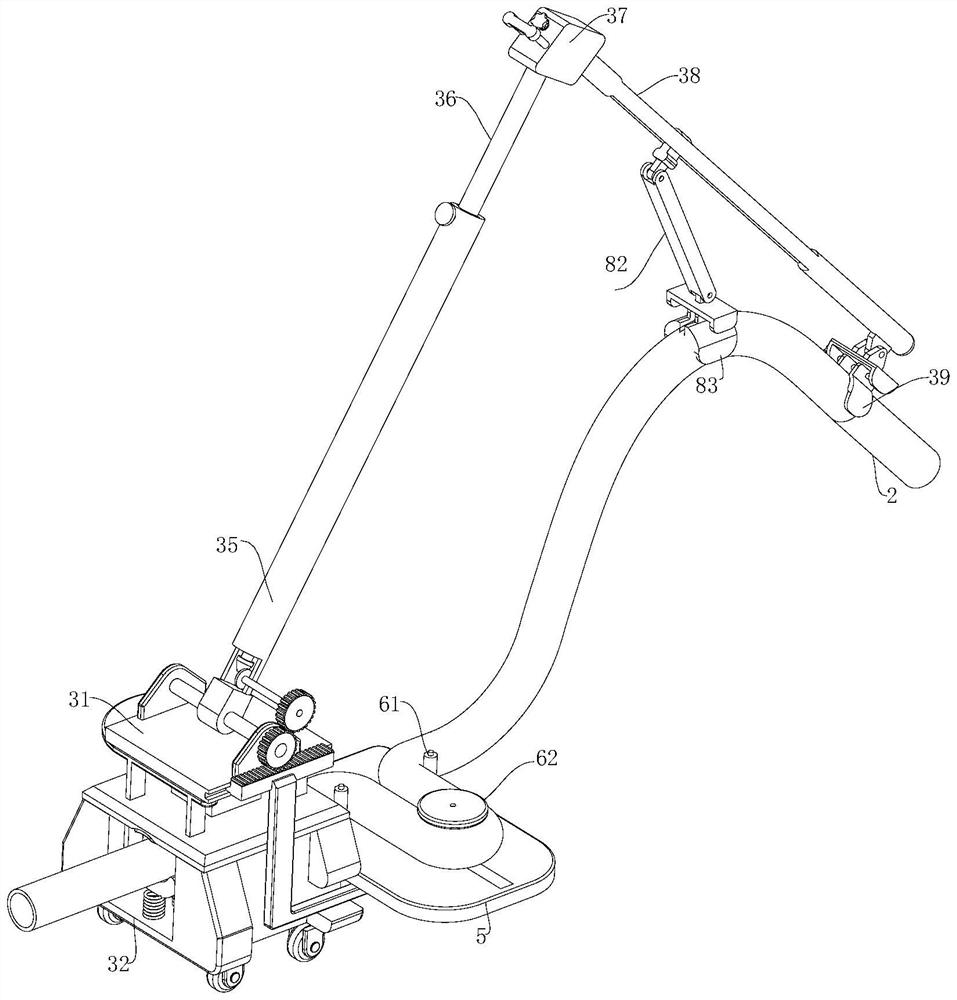

[0041] A material conveying system based on industrial bulk material pneumatic conveying technology includes a silo 1, a first cyclone separator 11 arranged on the silo 1, and a conveying pipe 2 and a guide pipe 13 are communicated with the first cyclone separator 11, The guide pipe 13 is connected with the second cyclone separator 12, and the second cyclone separator 12 is connected with the fan 14, the material is introduced into the silo 1 through the conveying pipe 2 and the first cyclone separator 11, and the end of the conveying pipe 2 is provided with The support mechanism 3 for supporting and guiding it, and one end of the support mechanism 3 is connected with a support seat 31, the bottom of the support seat 31 is fixedly connected with a reinforcement block 32, and the reinforcement block 32 is placed on the ground, and the reinforcement block 32 is arranged in a trapezoid shape, The bottom of the reinforcement block 32 is provided with a universal wheel, and the univ...

Embodiment 2

[0062]Both the first clamp and the second clamp are two clamping plates sleeved on the outside of the conveying pipe 2, a guide shell is slidably connected between the tops of the two clamping plates, and a bidirectional threaded rod is rotatably connected inside the guide shell, and A handle is installed at the end of the two-way threaded rod located outside the guide shell, and the two clamping plates are both threadedly sleeved on the outside of the two-way threaded rod, so that by rotating the handle, the two-way threaded rod is further rotated inside the guide shell, providing two The driving force in the opposite direction of the clamping plates makes the two clamping plates fix or disengage the conveying pipe 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com