Improving method for open caisson sinking construction in geology of sludge layer

A technology for silt layer and caisson, which is applied in the direction of caisson, foundation structure engineering, sheet pile wall, etc. It can solve problems such as inclination, achieve good uniformity, fast drilling speed, and prevent slurry from running around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

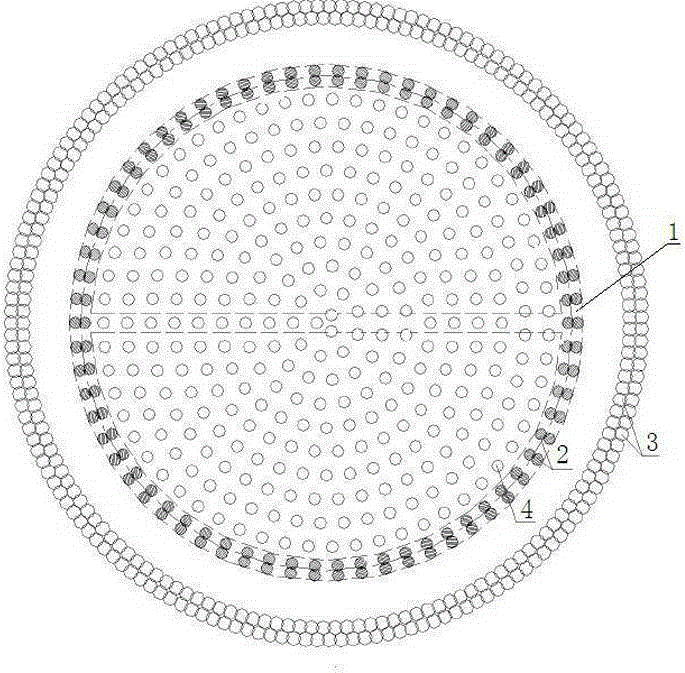

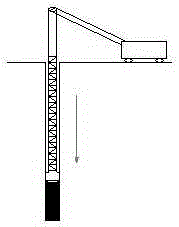

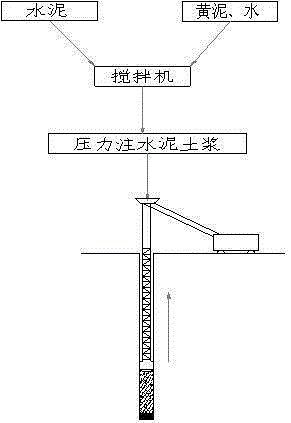

[0021] Such as figure 1 Shown, be the distribution schematic diagram of water barrier curtain 3, sinking stabilizing pile 2 and composite foundation 4 in the method for the sinking construction of existing geology being the caisson of silt layer (in order to prevent sinking stable pile 2 and composite foundation 4 from being sunk caisson 1 is blocked by caisson 1, and caisson 1 is indicated by a dotted line), before caisson 1 sinks, water-proof curtains 3 are arranged around the outside of caisson 1 wall, and two non-continuous lowering curtains are arranged at the place where caisson 1's blade foot starts to sink. The sinking stabilizing piles 2 are arranged in the well wall of the caisson 1 with a composite foundation 4; when the caisson 1 sinks, the sinking stabilizing piles 2 are removed symmetrically to ensure the stable sinking of the caisson 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com