Spherical core-shell type LaNiAl-SiO2 compound hydrogen storage material and preparation method thereof

The technology of a hydrogen storage material and a composite material is applied in the field of spherical core-shell LaNiAl-SiO2 composite hydrogen storage material and its preparation, which can solve the problems of metal hydride running out, unstable particles, etc. Uniform, small error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides the above-mentioned spherical core-shell LaNiAl-SiO 2 A method for preparing a composite hydrogen storage material, comprising the steps of:

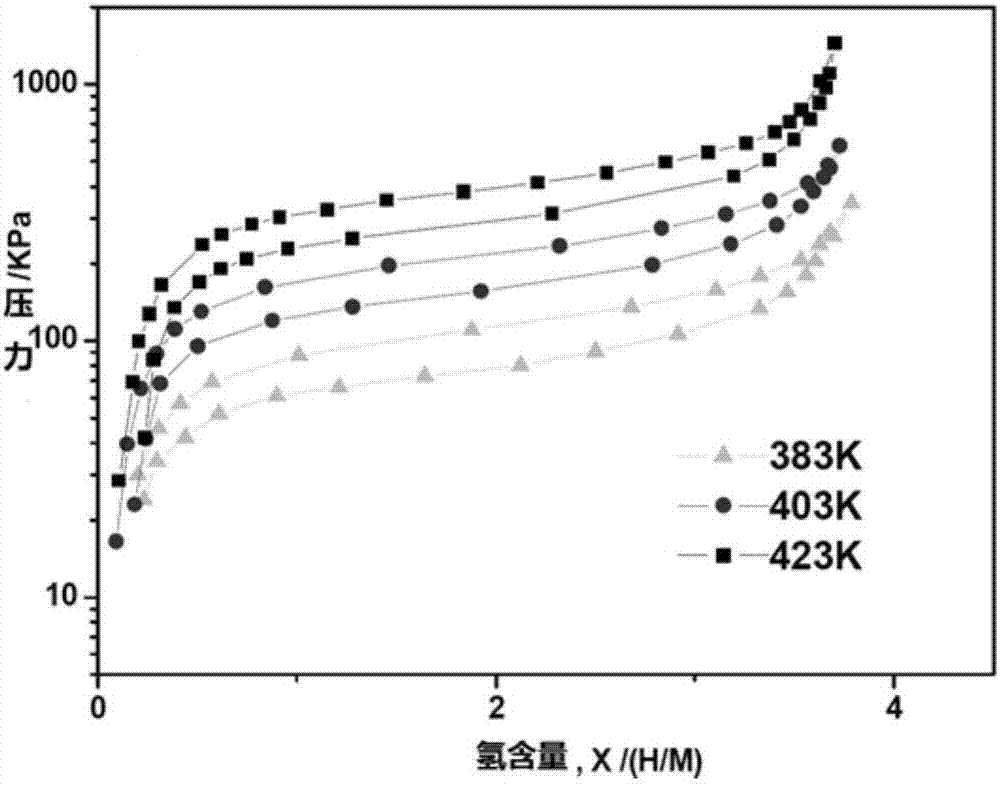

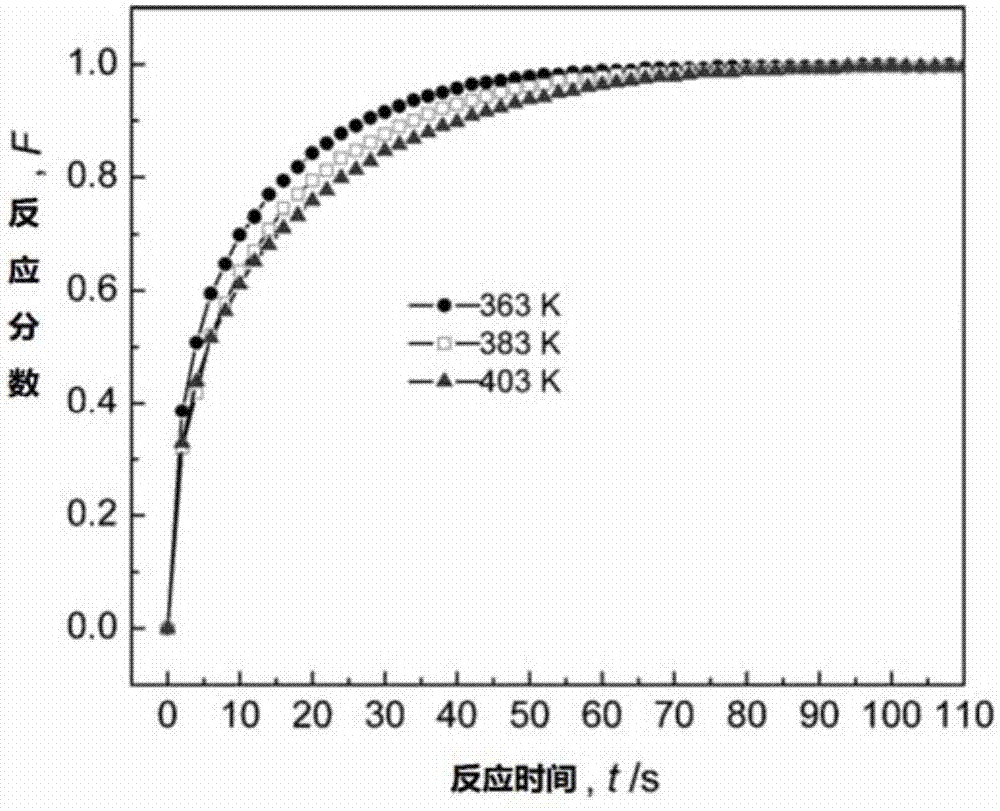

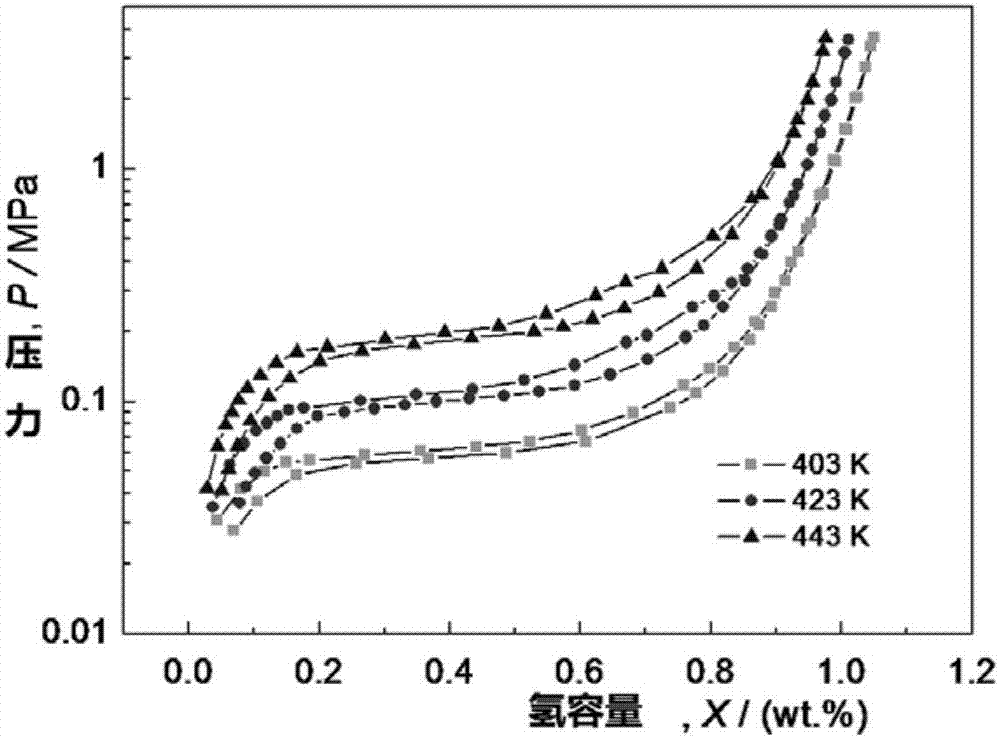

[0028] (1) Preparation of LaNiAl alloy powder: First, the LaNiAl alloy is smelted in a vacuum induction furnace or an electric arc furnace. The general formula of the composition of the LaNiAl alloy is LaNi 5-x al x, where 0≤x≤2. The metal purity used was La: 99.3 wt%, Ni: 99.9 wt%, Al: 99.7 wt%. After smelting, seal the alloy ingot in a vacuum quartz tube, put it into a heat treatment furnace for homogenization treatment, heat it up to 1100°C for 6 hours, and then cool it down with the furnace. Weigh a certain weight of heat-treated LaNiAl alloy ingot and mechanically crush it into millimeter-sized particles, and then perform 20-30 cycles of hydrogen absorption and desorption on a fully automatic Sieverts device, wherein the hydrogen charging pressure is 1-2 MPa, and the water bath temperat...

Embodiment 1

[0035] First, vacuum induction furnace or electric arc furnace is used to smelt LaNi 4.25 Al 0.75 Alloy, the metal purity used is La: 99.3%, Ni: 99.9%, Al: 99.7%. After smelting, seal the alloy ingot in a vacuum quartz tube, put it into a heat treatment furnace for homogenization treatment, heat it up to 1100°C for 6 hours, and then cool it down with the furnace. Weigh a certain weight of heat-treated LaNi 4.25 Al 0.75 The alloy ingots were mechanically crushed into millimeter-sized particles, and then 20 cycles of hydrogen absorption and desorption were performed on the fully automatic Sieverts device. The hydrogen filling pressure was 1 MPa, and the temperature of the water bath was 90 °C. Powdered LaNi 4.25 Al 0.75 The highly active surface of the alloy is passivated, and then the reaction chamber is opened to make the powdered LaNi 4.25 Al 0.75 The alloy is exposed to the air and left to stand for 3 days to further passivate the surface, pass through a 220 mesh siev...

Embodiment 2

[0038] First, vacuum induction furnace or electric arc furnace is used to smelt LaNi 4 Al alloy, the metal purity used is La: 99.3%, Ni: 99.9%, Al: 99.7%. After smelting, seal the alloy ingot in a vacuum quartz tube, put it into a heat treatment furnace for homogenization treatment, heat it up to 1100°C for 6 hours, and then cool it down with the furnace. Weigh a certain weight of heat-treated LaNi 4 Al alloy ingots are mechanically crushed into millimeter-sized particles, and then 30 hydrogen absorption and desorption cycles are performed on the fully automatic Sieverts device. The hydrogen filling pressure is 2 MPa, the water bath temperature is 110 ° C, and finally 1 MPa high-purity argon is filled into the Sieverts device. Pulverized LaNi 4 The highly active surface of Al alloy is passivated, and then the reaction chamber is opened to make the powdered LaNi 4 The Al alloy was exposed to the air and left to stand for 3 days to further passivate the surface. After the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com