Patents

Literature

54results about How to "Uniform dimensions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

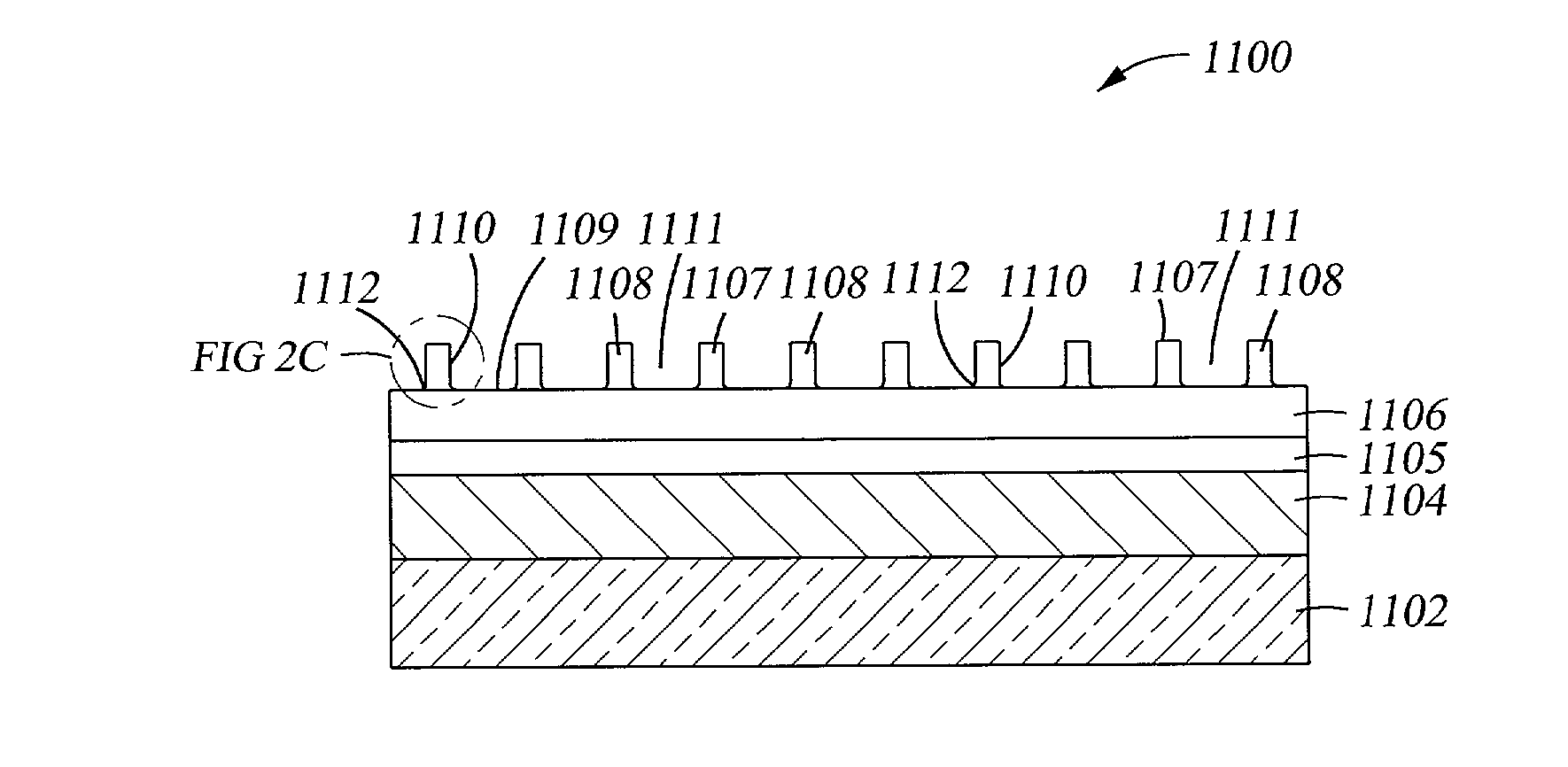

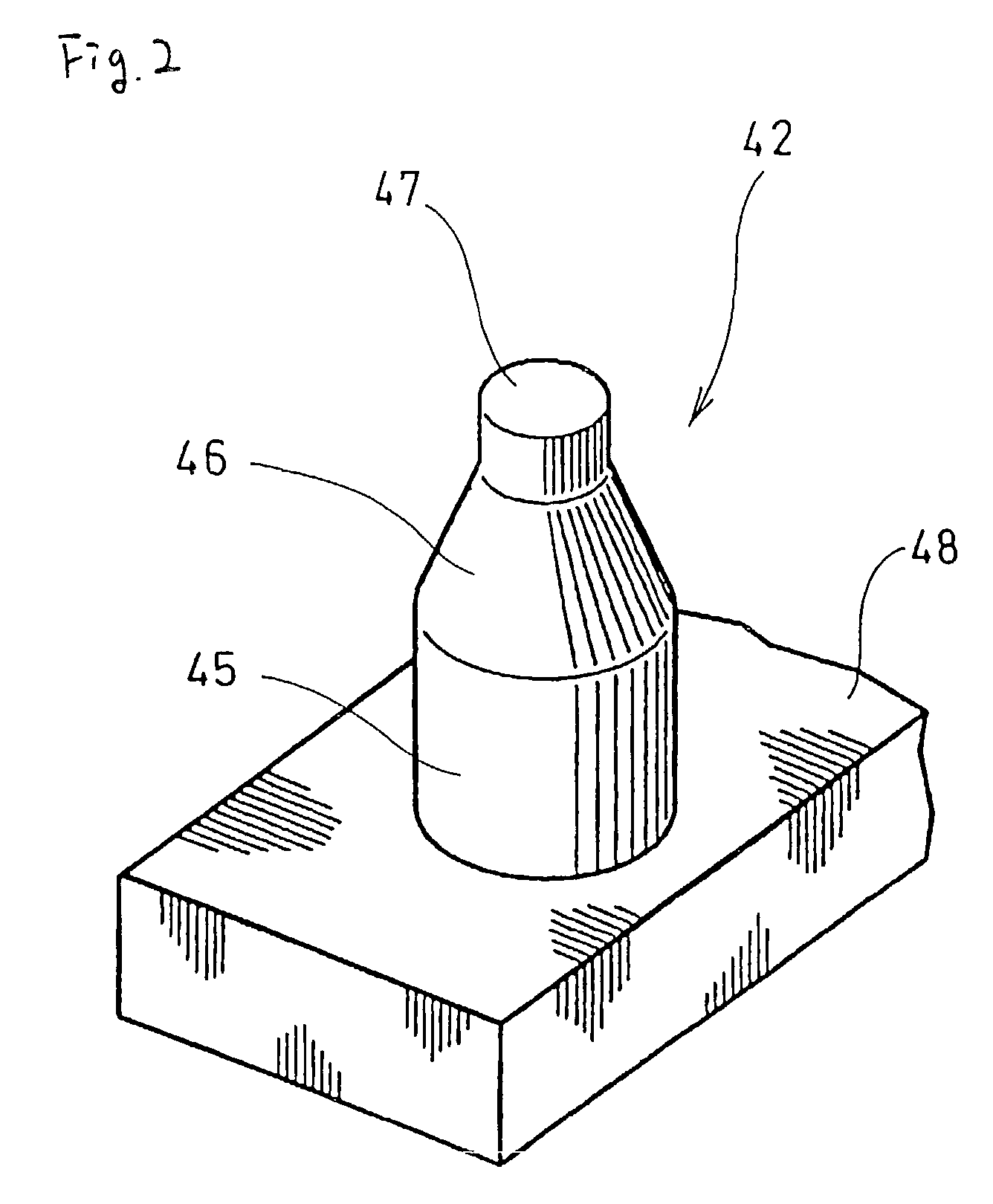

Projection lens arrangement

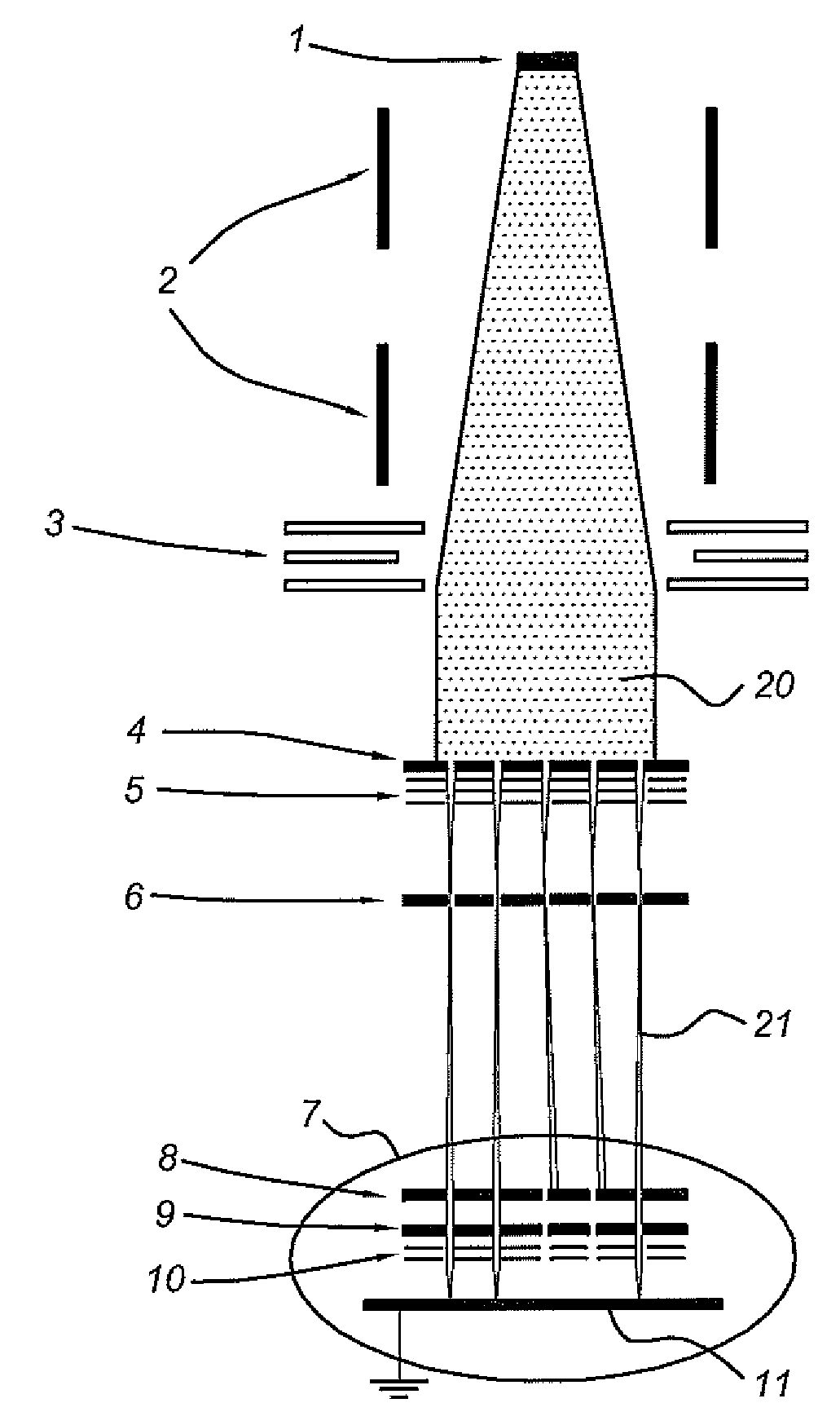

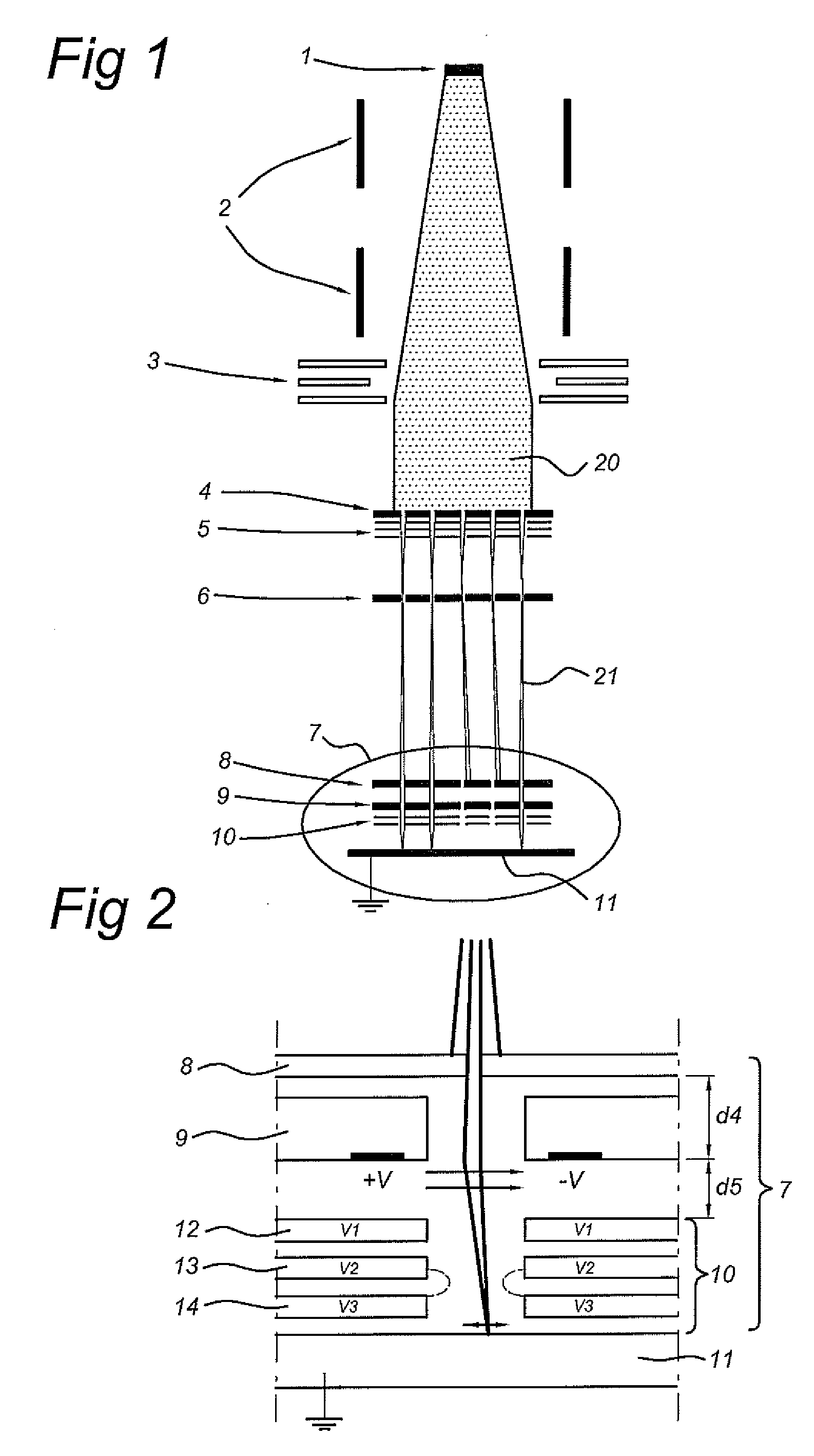

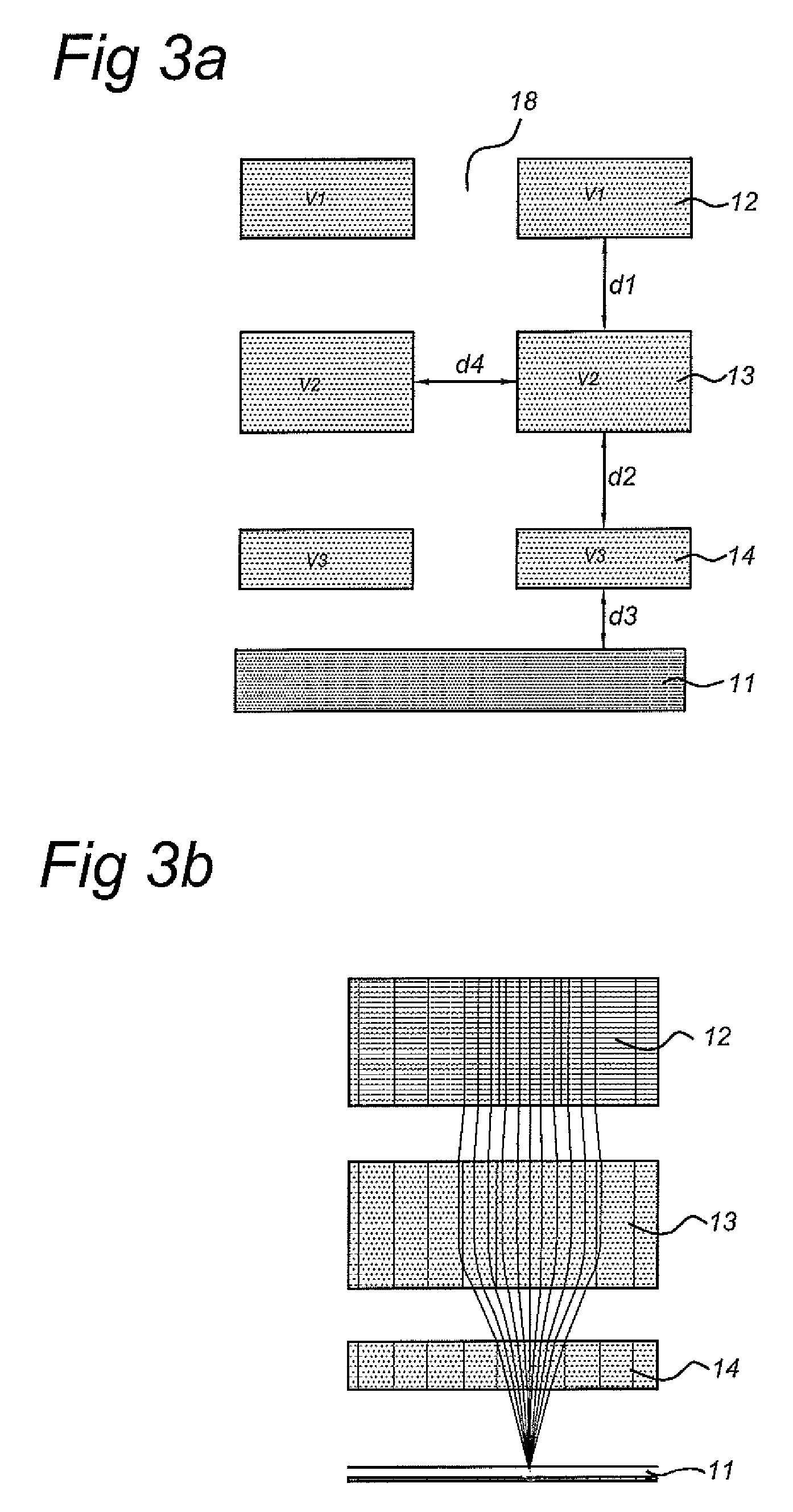

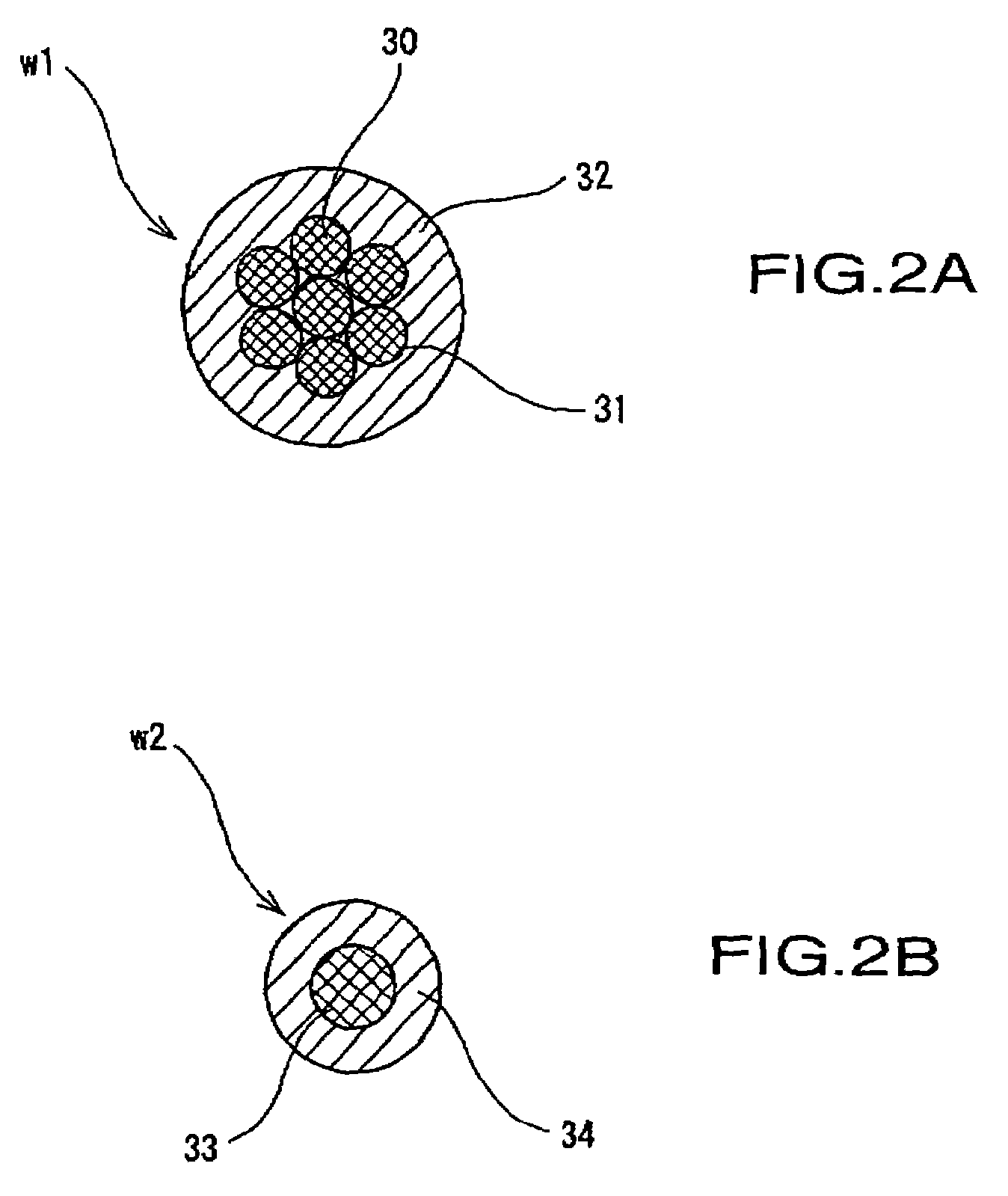

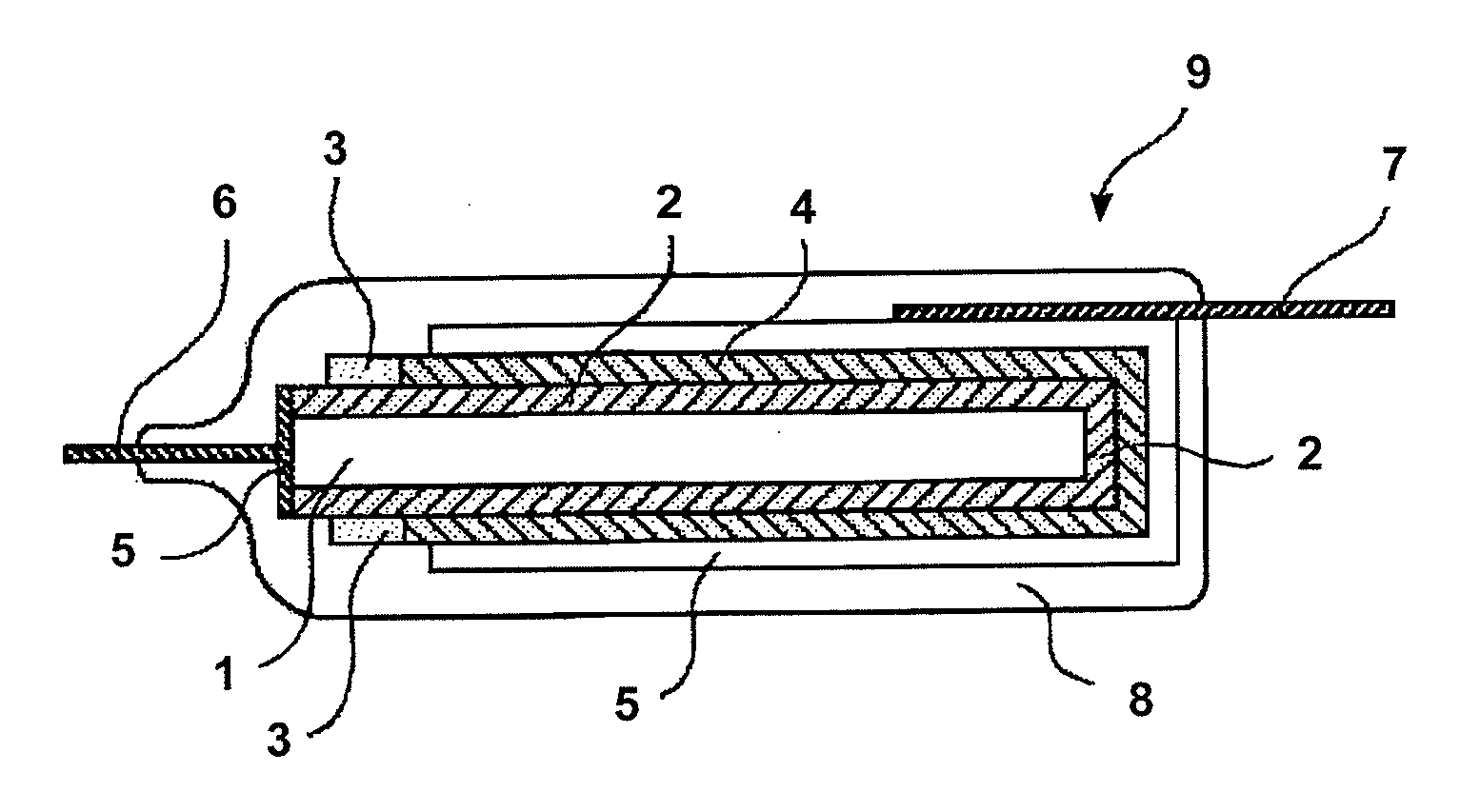

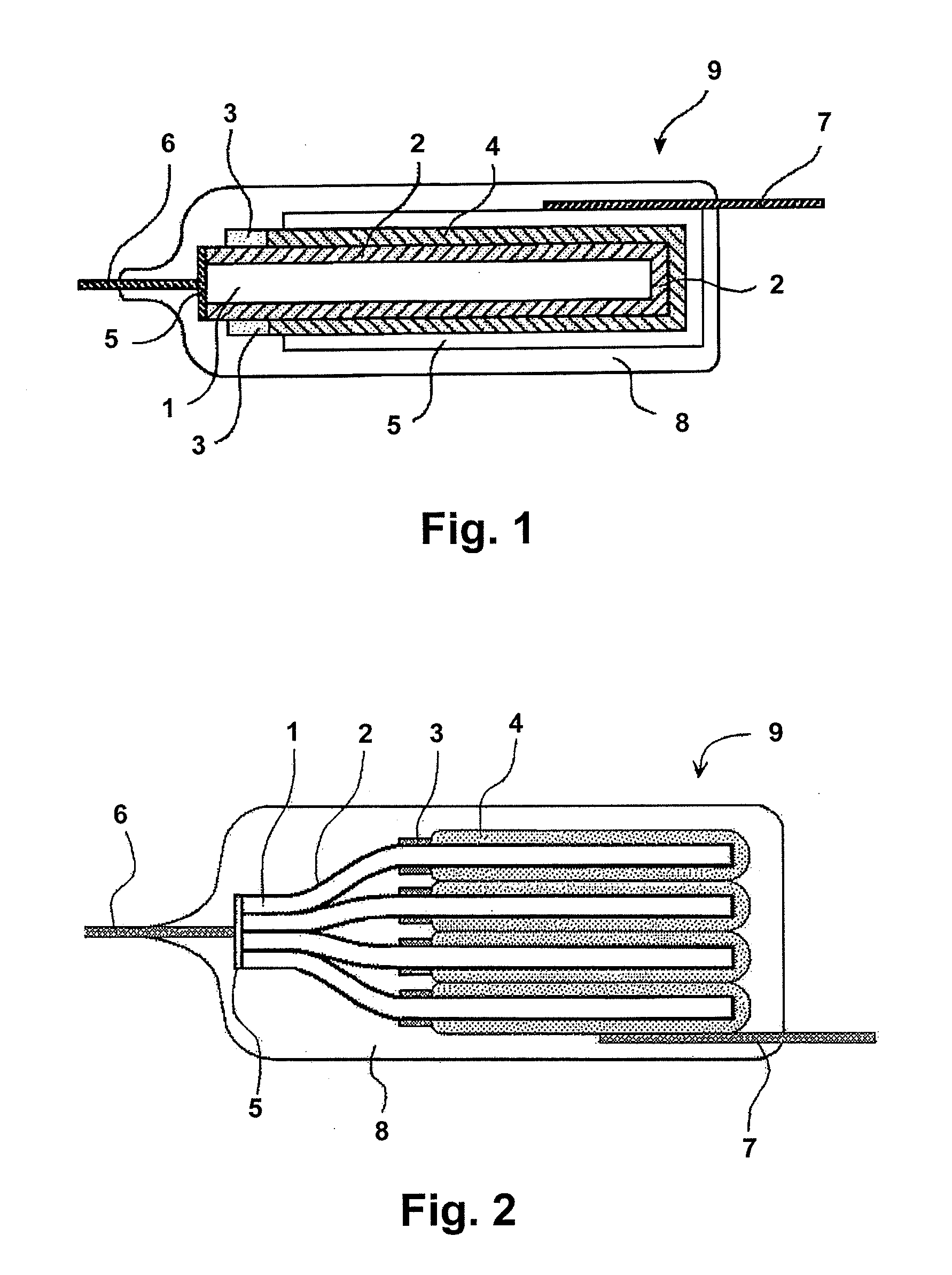

ActiveUS20090212229A1Uniform placementUniform dimensionsThermometer detailsStability-of-path spectrometersProjection lensElectron

A charged particle multi-beamlet system for exposing a target using a plurality of beamlets. The system comprises a first plate having a plurality of holes formed in it, with a plurality of electrostatic projection lens systems formed at the location of each hole so that each electron beamlet passes through a corresponding projection lens system. The holes have sufficiently uniform placement and dimensions to enable focusing of the beamlets onto the surface of the target using a common control voltage. Preferably the electrostatic projection lens systems are controlled by a common electrical signal to focus the electron beamlets on the surface without correction of the focus or path of individual electron beamlets.

Owner:ASML NETHERLANDS BV

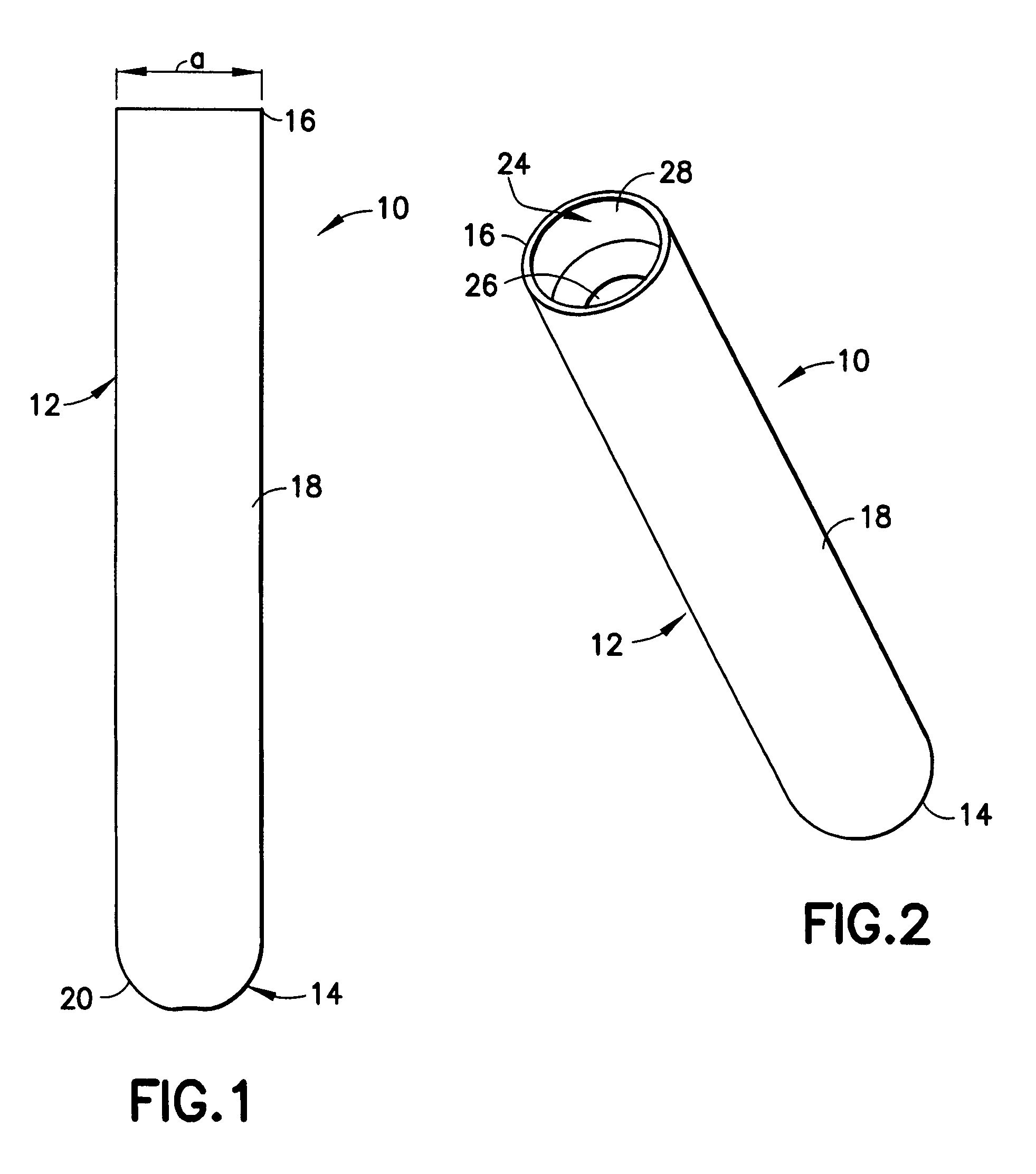

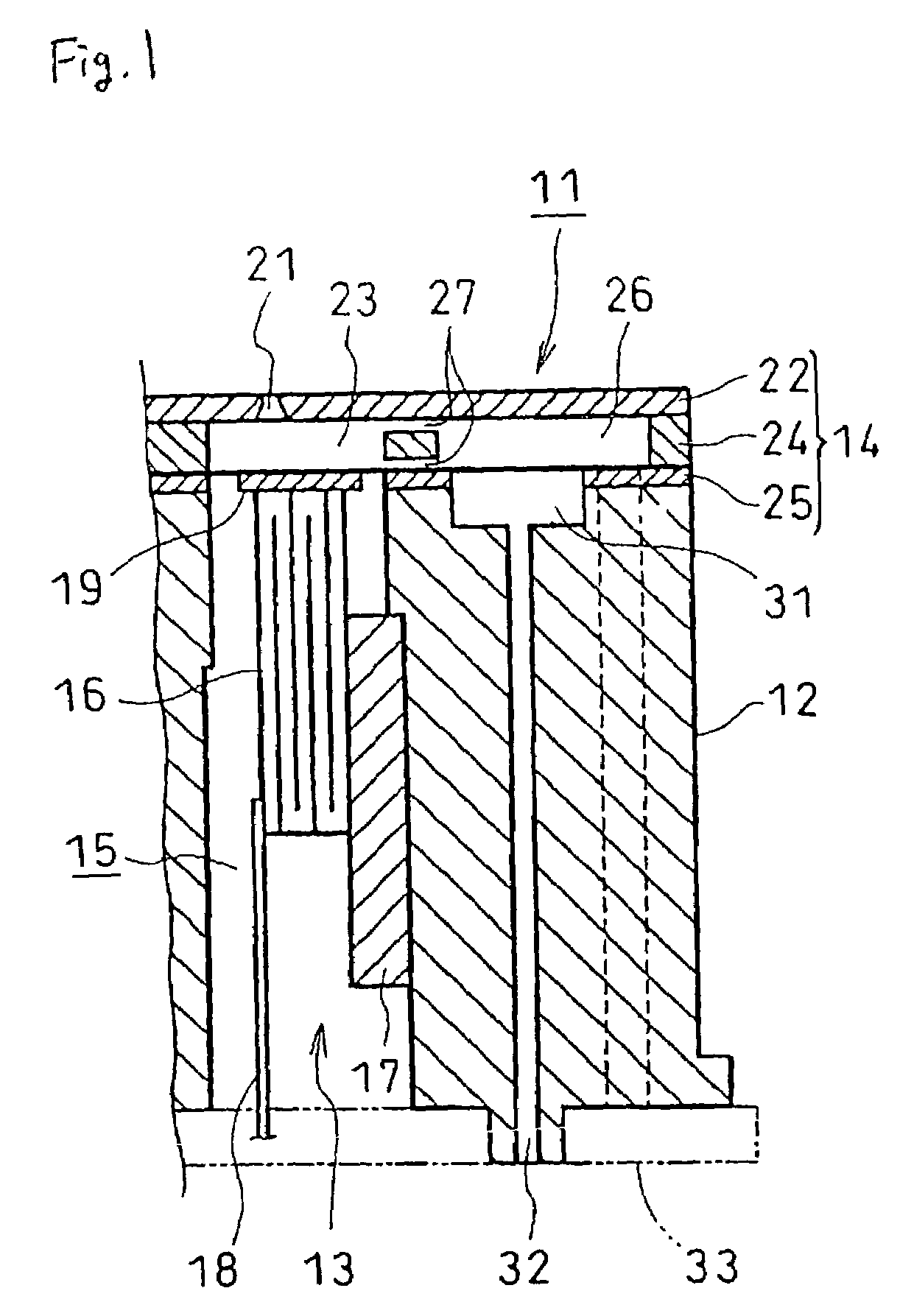

Collection assembly

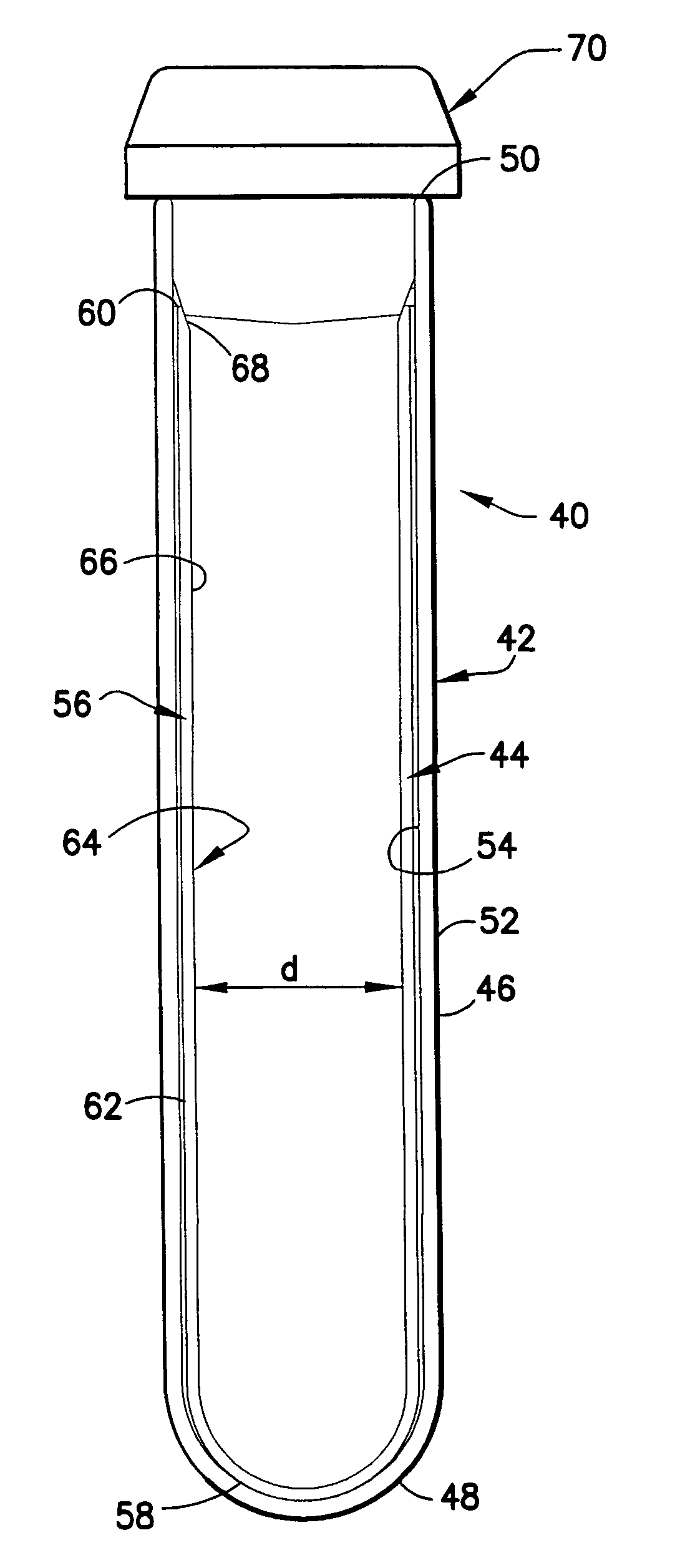

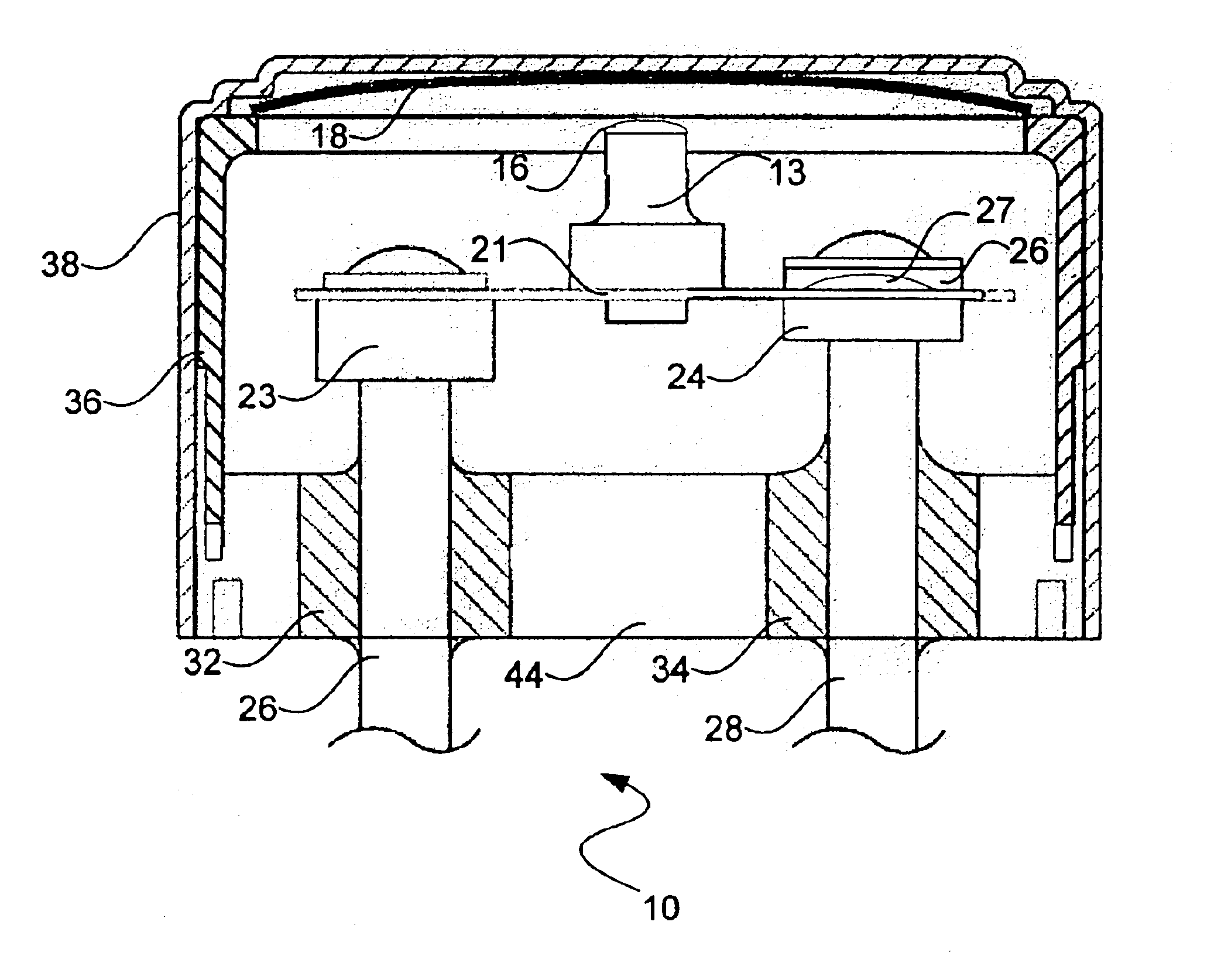

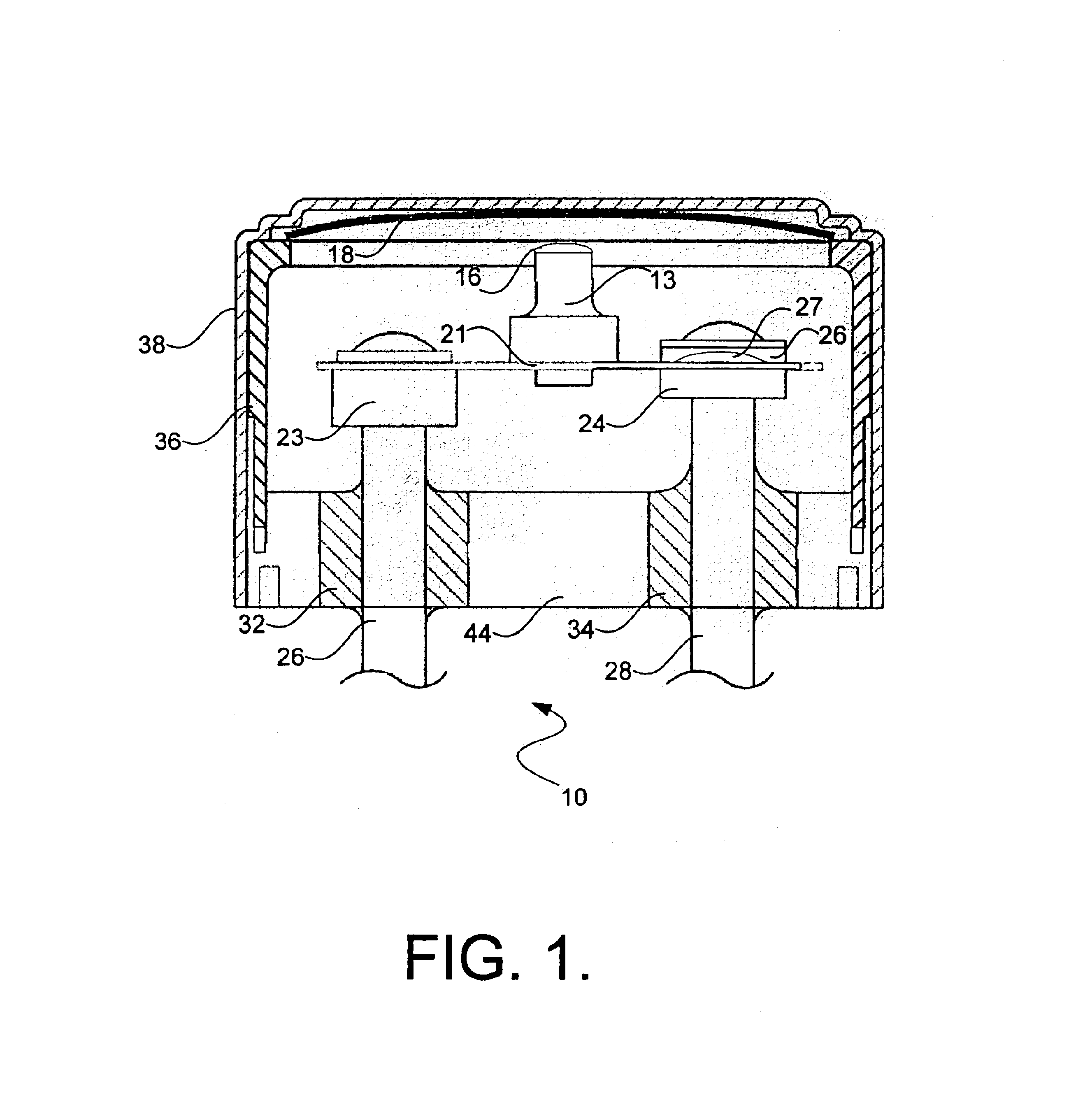

ActiveUS7507378B2Small and substantially uniform head spaceLower the volumeCombination devicesWithdrawing sample devicesEngineeringExterior dimension

A plurality of container assemblies are provided. Each container assembly has substantially identical external dimensions. However, the internal volumes of certain container assemblies differ from the internal volumes of other container assemblies. The container assemblies are configured in accordance with the required volume of material to be collected or maintained in the respective container assemblies and to enable uniform head spaces despite the different volumes of materials in the respective container assemblies. Each container assembly may have an inner container and an outer container. The inner and outer containers may be assembled together or formed integrally by molding.

Owner:BECTON DICKINSON & CO

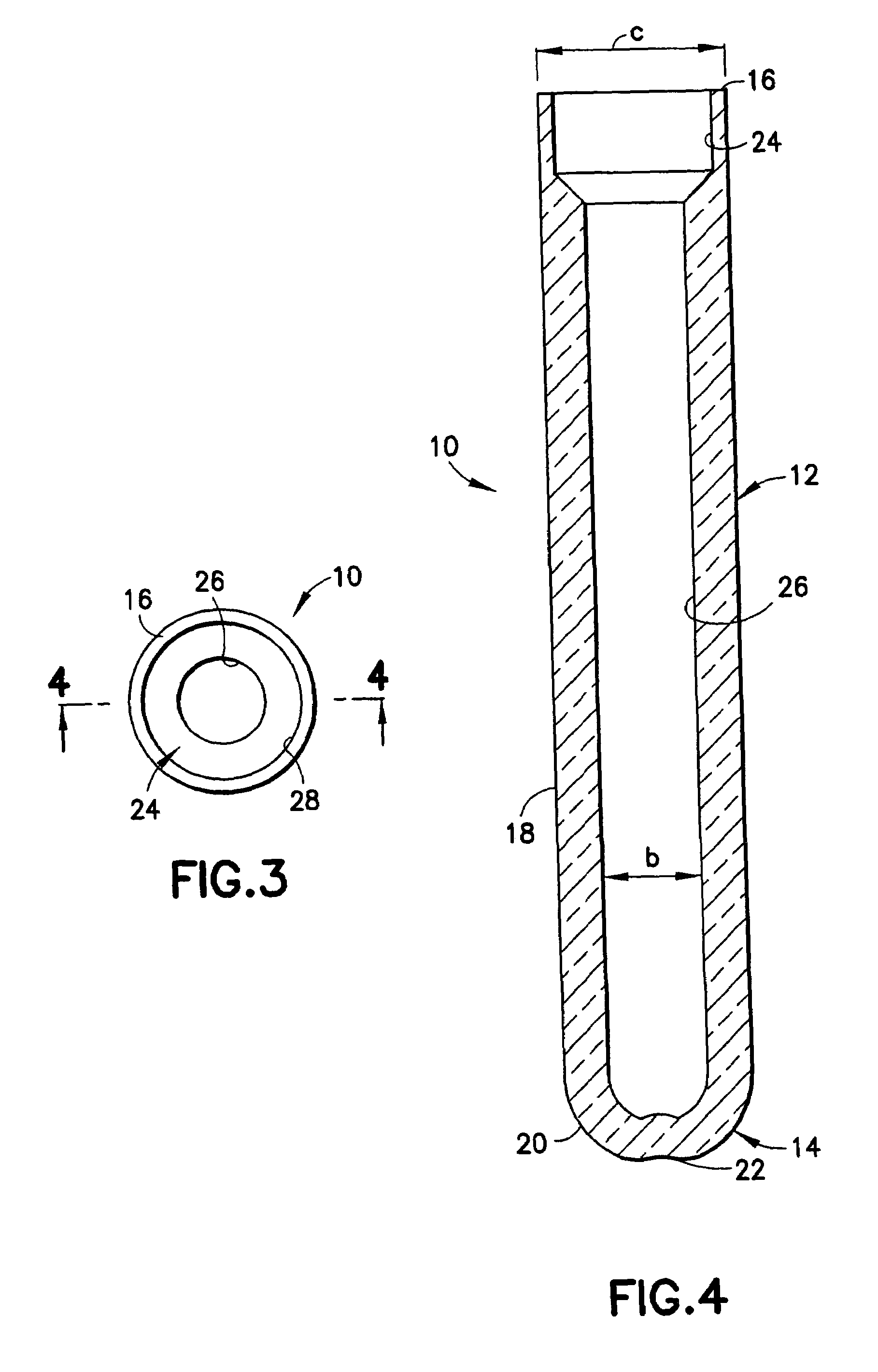

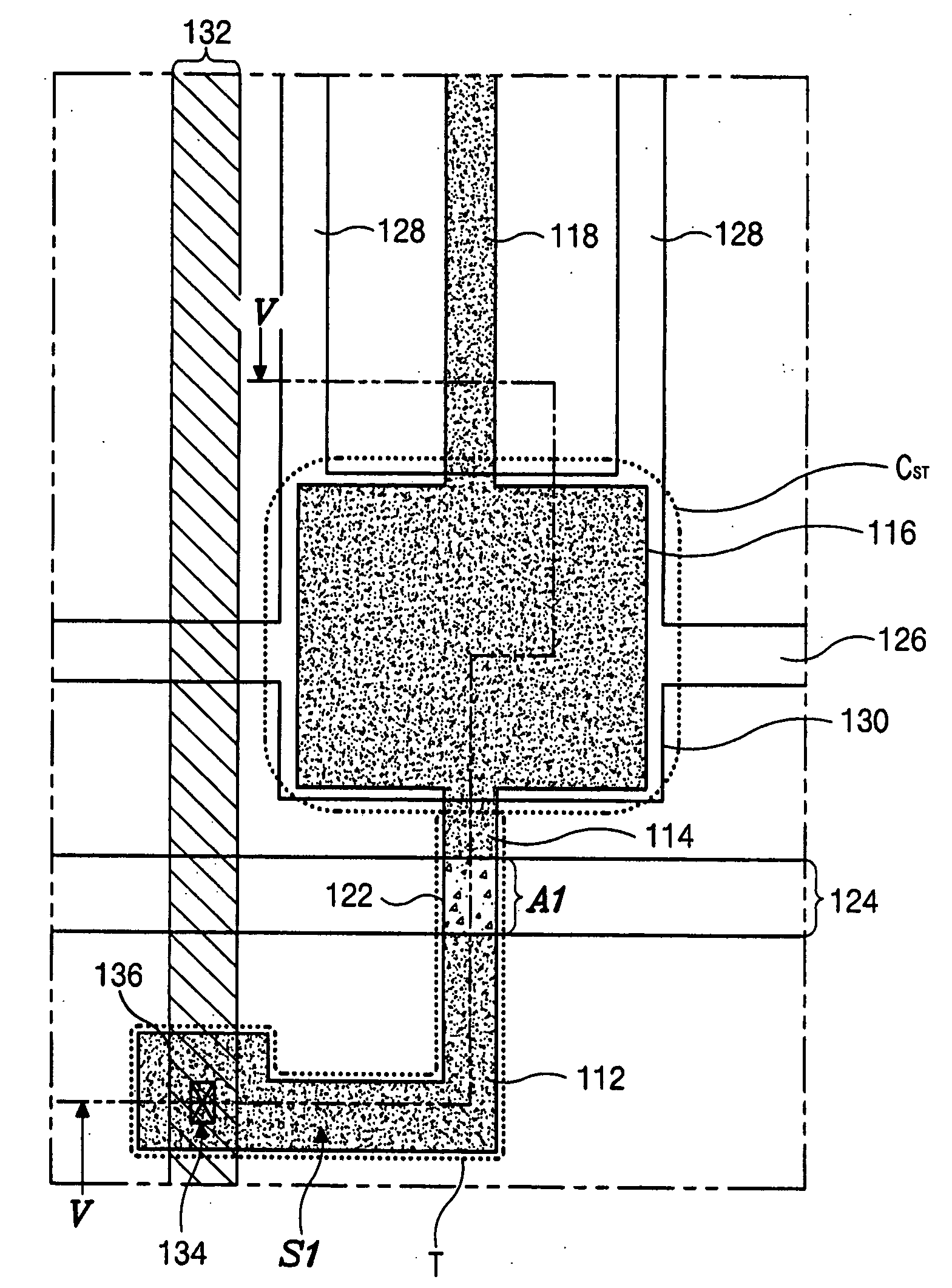

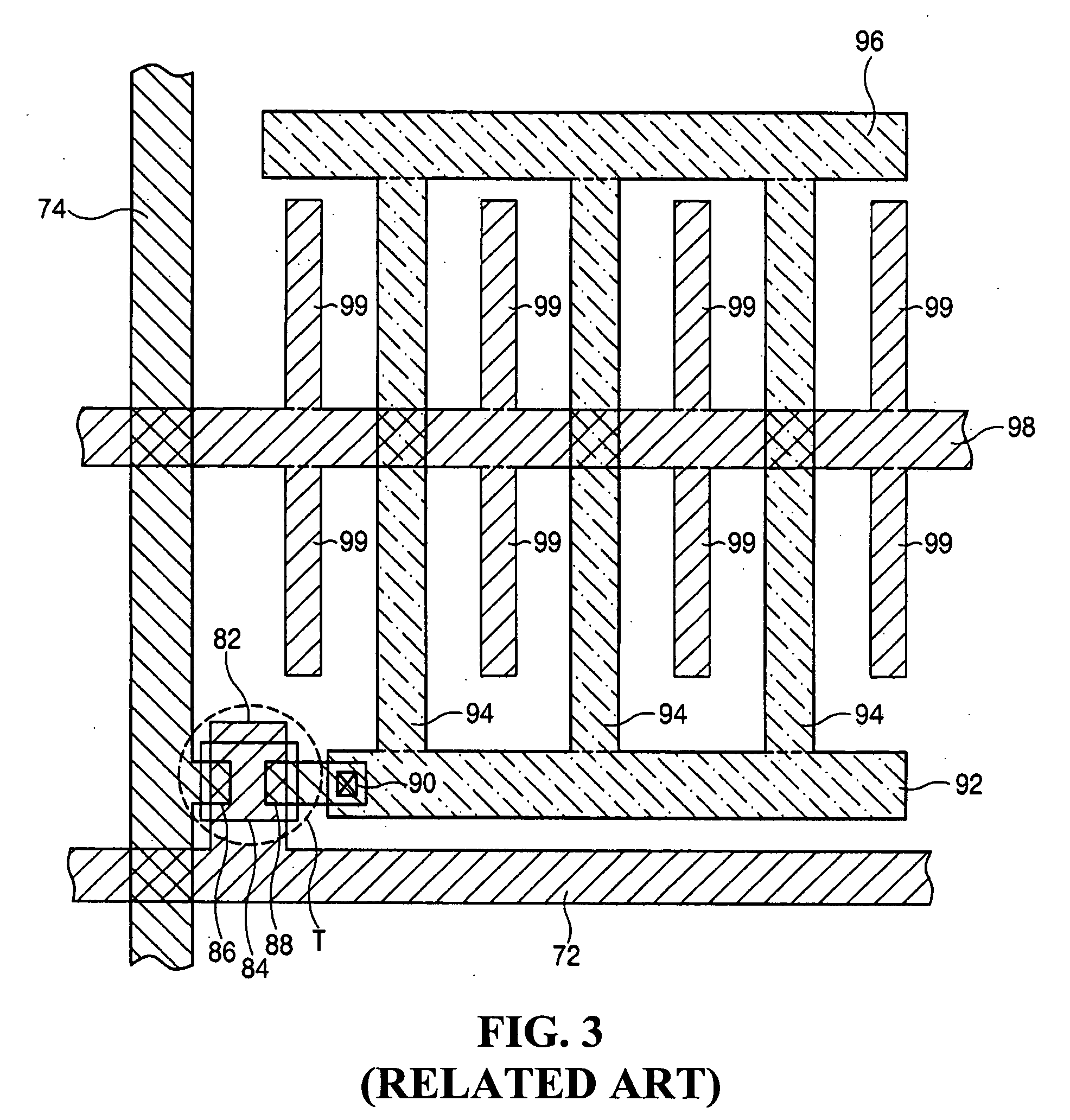

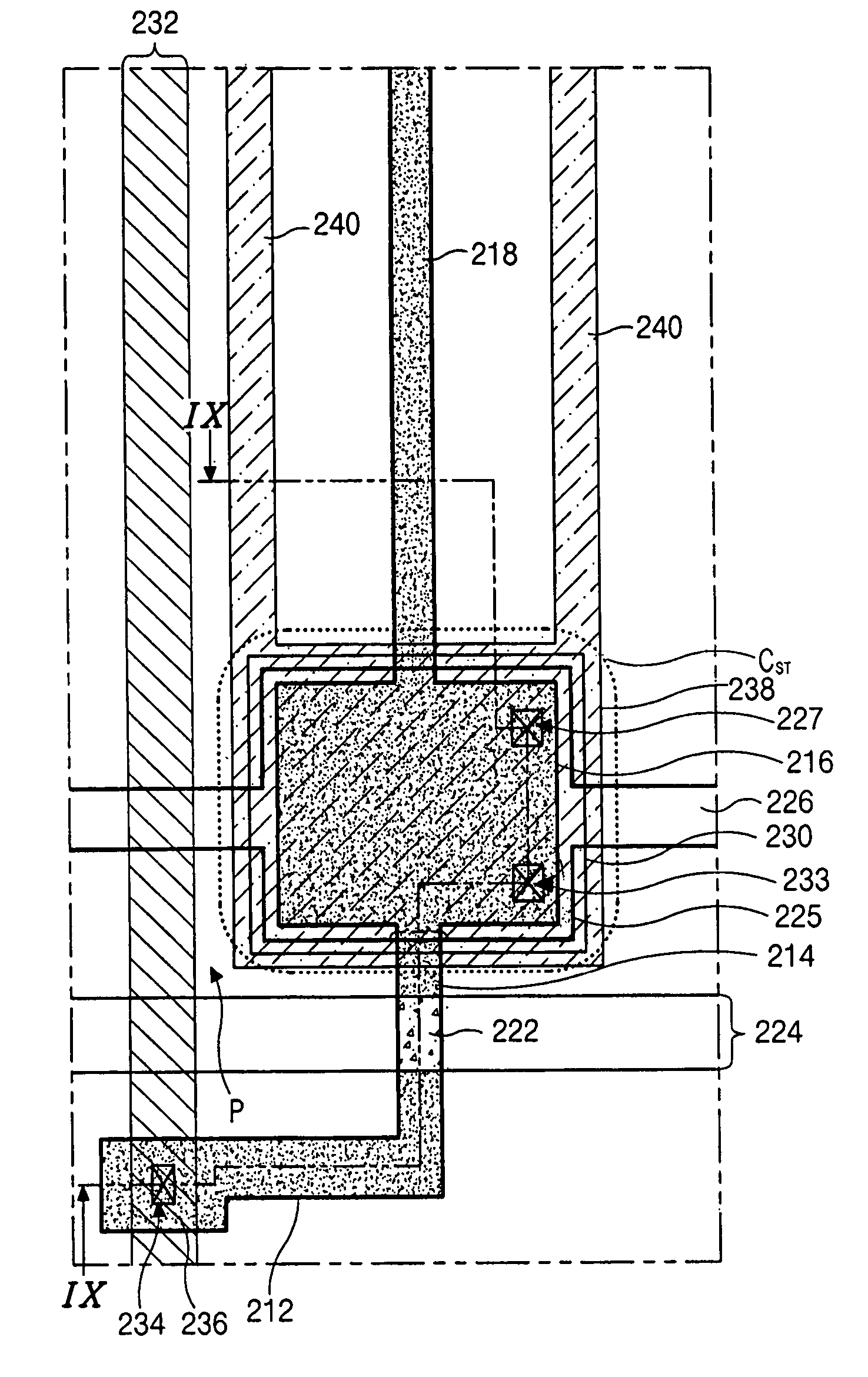

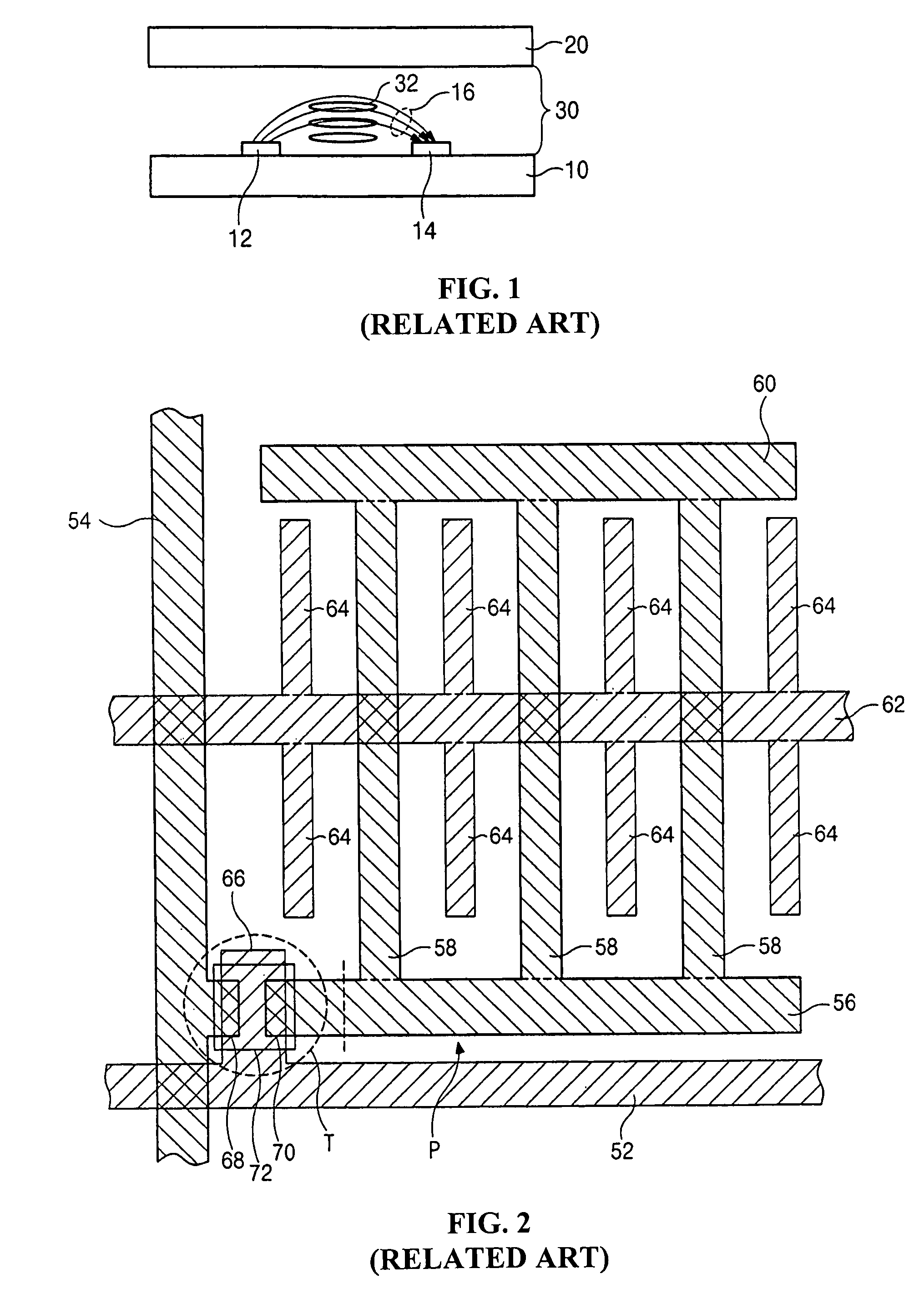

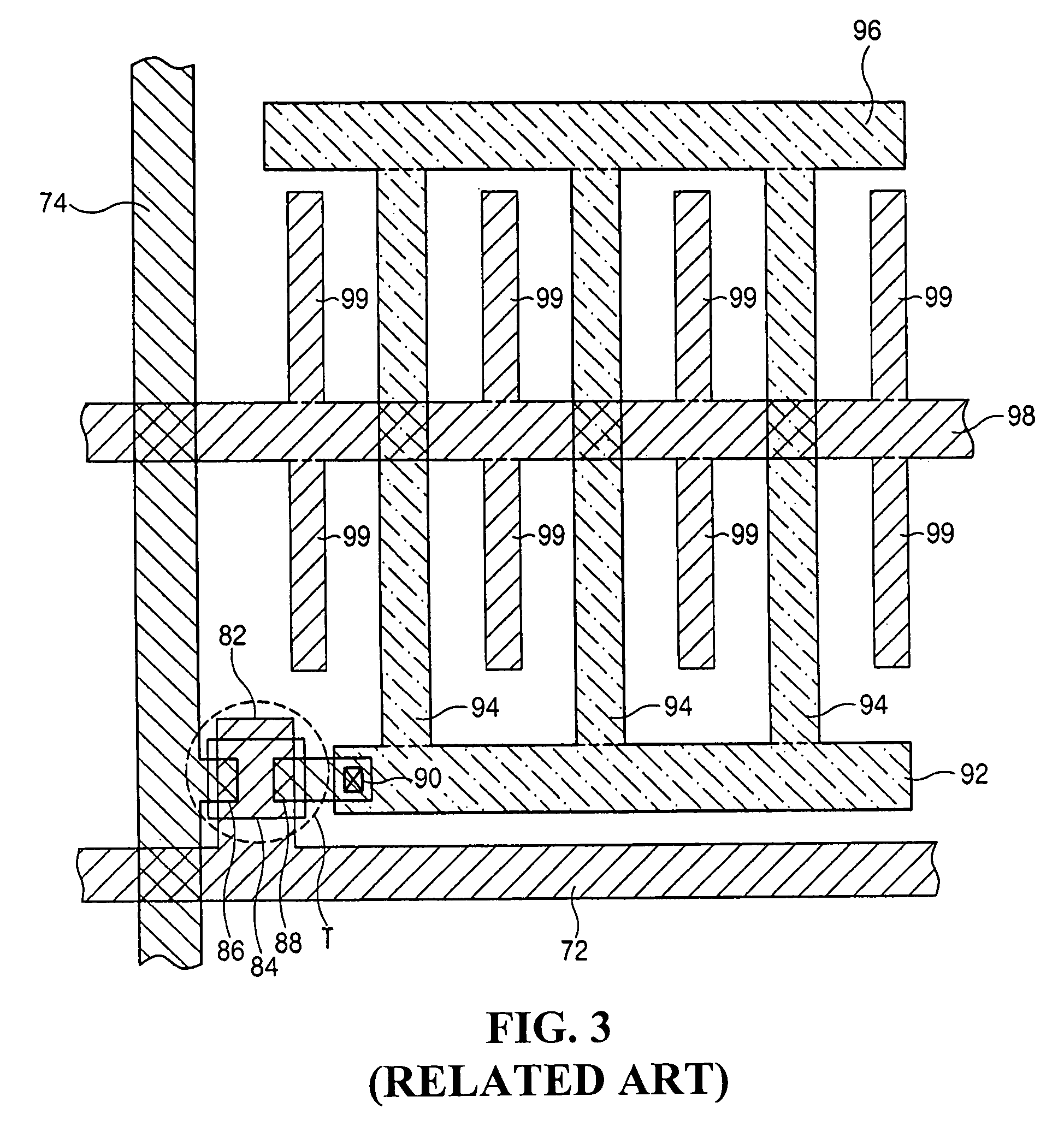

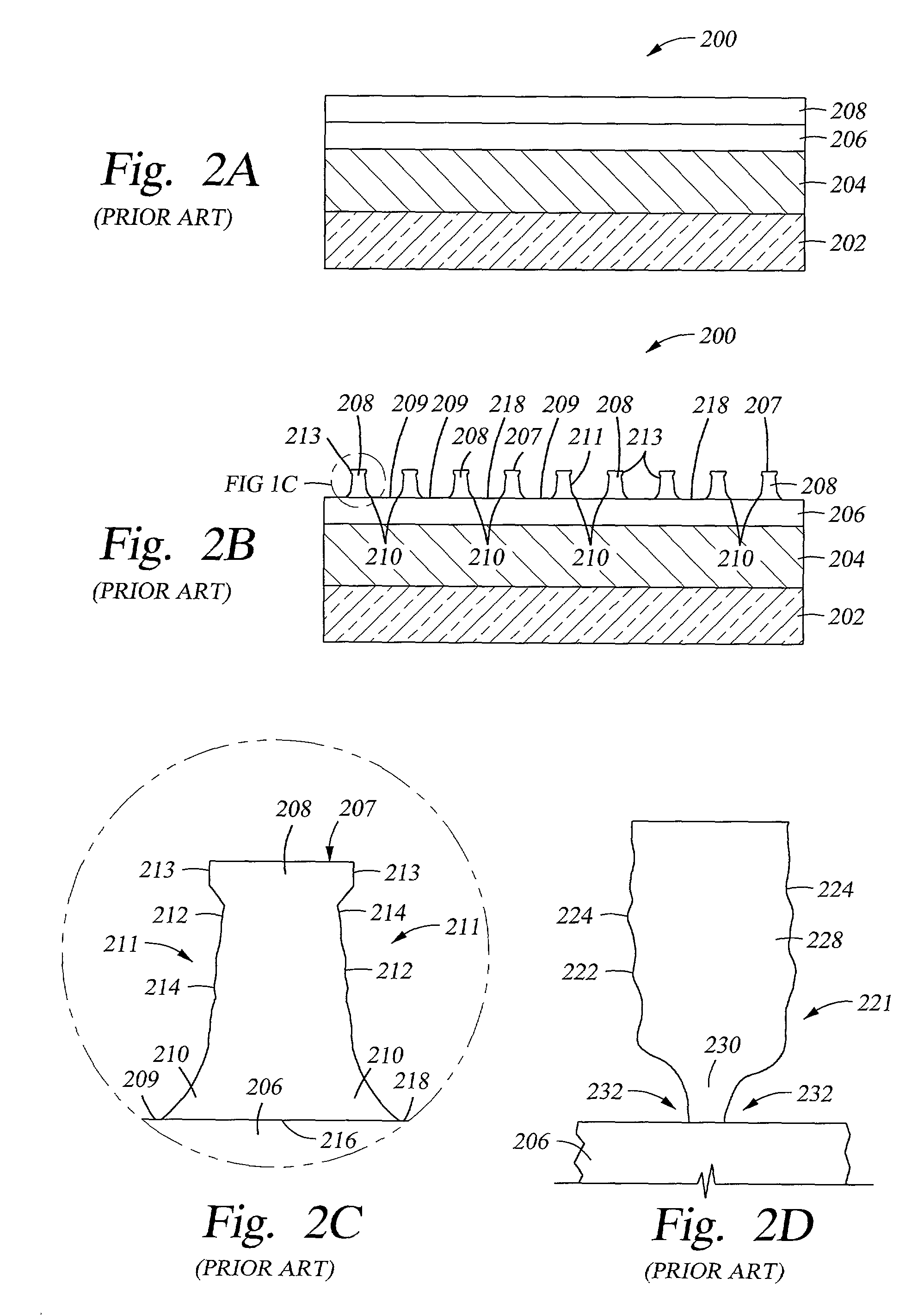

Array substrate for in-plane switching liquid crystal display device with polycrystalline silicon pixel electrode and method of manufacturing the same

ActiveUS20070013820A1Increase the aperture ratioUniform dimensionsNon-linear opticsCapacitanceIn plane

Owner:LG DISPLAY CO LTD

Array substrate for in-plane switching liquid crystal display device and method of fabricating the same with polycrystalline silicon pixel electrode

ActiveUS7130010B2Increase the aperture ratioUniform critical dimensionNon-linear opticsIn planeLiquid-crystal display

An array substrate for in-plane switching liquid crystal display device includes a gate line on a substrate, a data line crossing the gate line to define a pixel region, a semiconductor layer including an active area and a source area, wherein the active area overlaps the gate line and the source area overlaps the data line, a drain electrode connected to the semiconductor layer, a first capacitor electrode in the pixel region and connected to the drain electrode, a pixel electrode connected to the first capacitor electrode and substantially in parallel to the data line, a common line substantially parallel to the gate line, a second capacitor electrode connected to the common line and overlapping the first capacitor electrode, and a common electrode connected to the common line and alternatively arranged with the pixel electrode, wherein the source area of the semiconductor layer, the drain electrode, the first capacitor electrode and the pixel electrode include doped polycrystalline silicon.

Owner:LG DISPLAY CO LTD

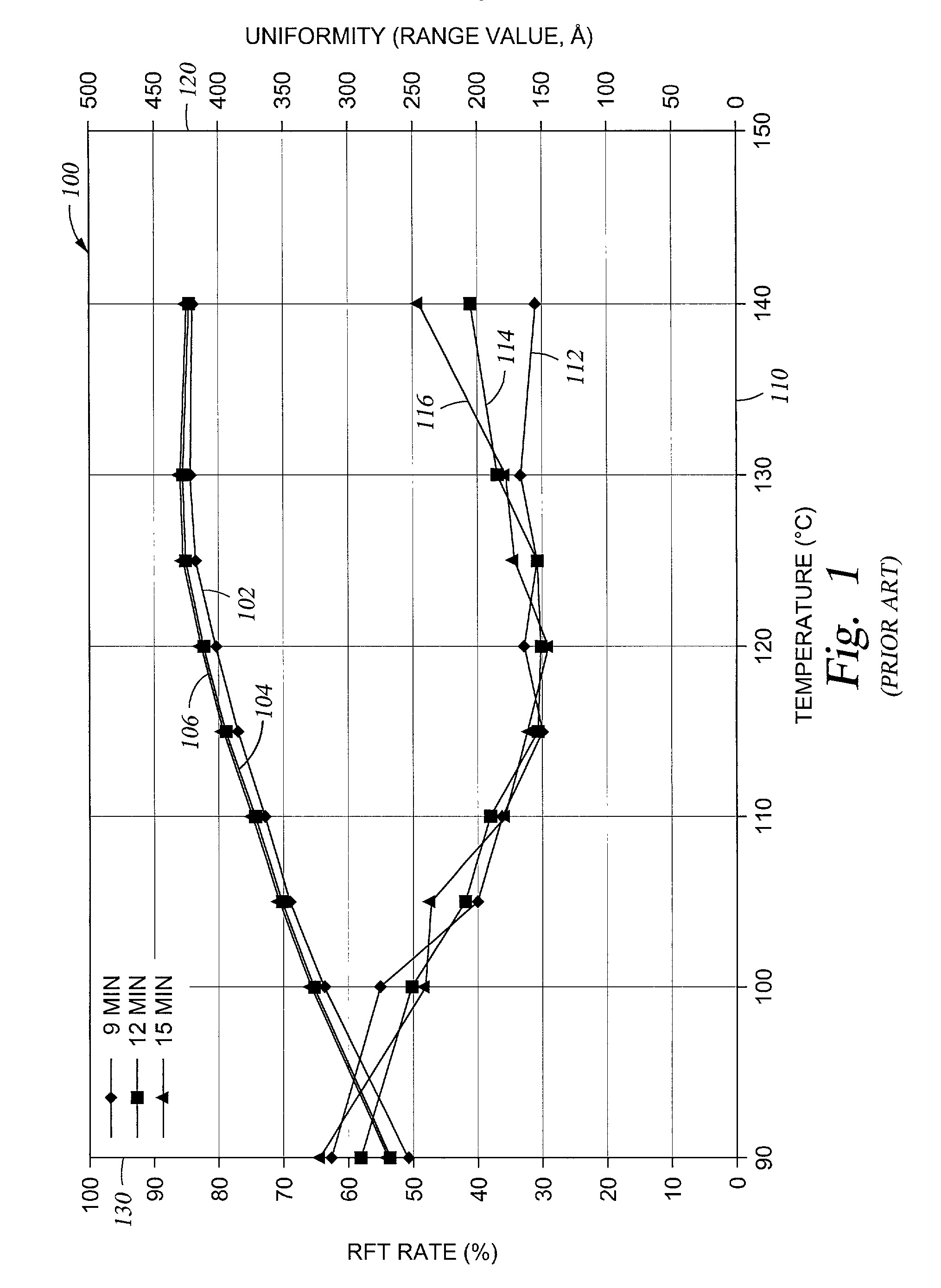

Method of preparing optically imaged high performance photomasks

InactiveUS20030027083A1Uniform critical dimensionLong stable periodRadiation applicationsSemiconductor/solid-state device manufacturingContinuous waveLength wave

One principal embodiment of the disclosure pertains to a method of optically fabricating a photomask using a direct write continuous wave laser, comprising a series of steps including: applying an organic antireflection coating over a surface of a photomask which includes a chrome-containing layer; applying a chemically-amplified DUV photoresist over the organic antireflection coating; post apply baking the DUV photoresist over a specific temperature range; exposing a surface of the DUV photoresist to the direct write continuous wave laser; and, post exposure baking the imaged DUV photoresist over a specific temperature range. The direct write continuous wave laser preferably operates at a wavelength of 244 nm or 257 nm. In an alternative embodiment, the organic antireflection coating may be applied over an inorganic antireflection coating which overlies the chrome containing layer.

Owner:APPLIED MATERIALS INC

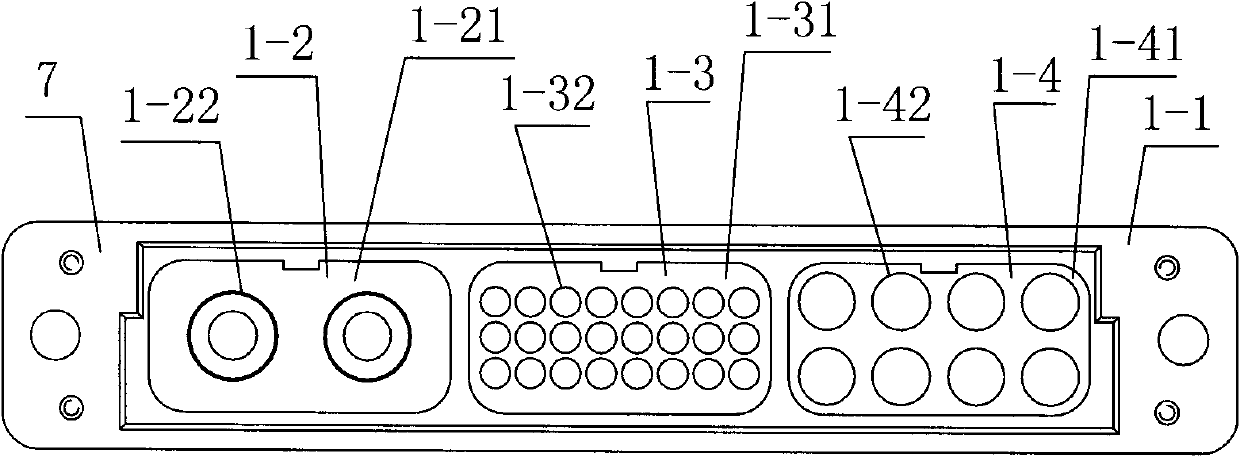

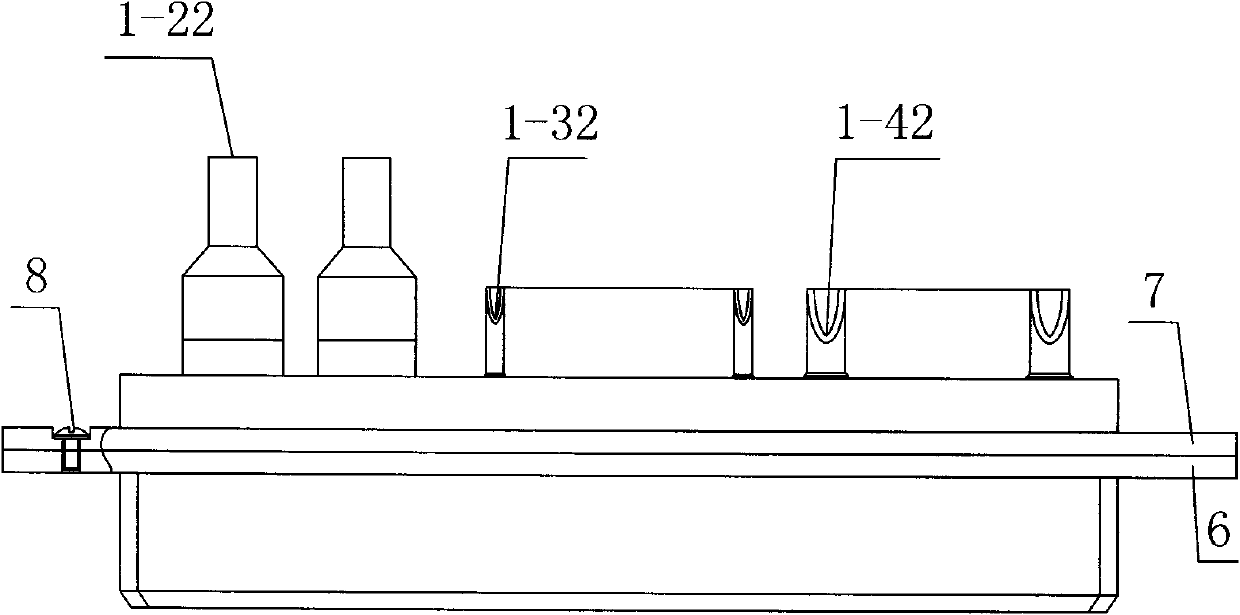

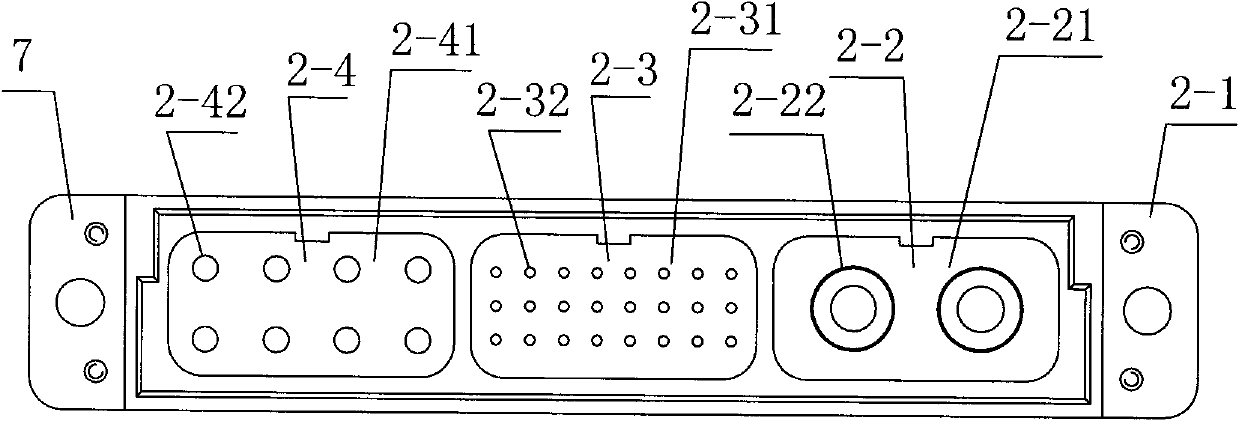

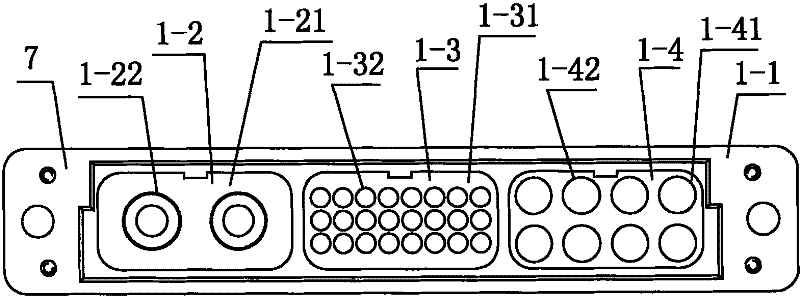

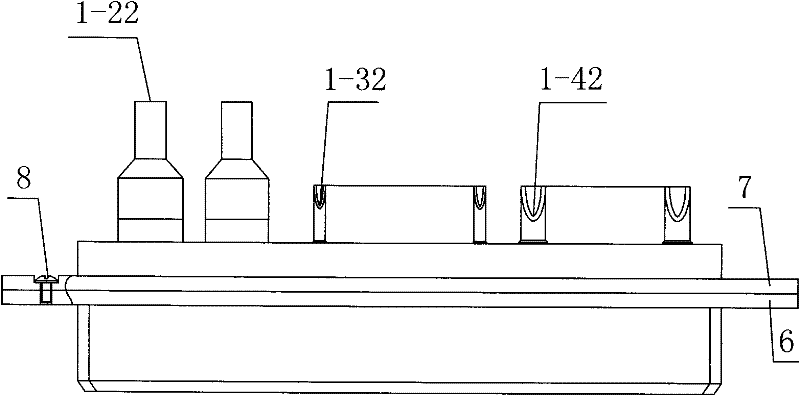

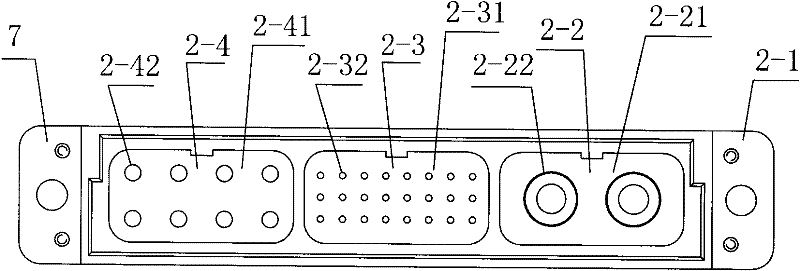

On-site combined type rectangular high-low frequency mixed loading connector

ActiveCN101771223AUniform dimensionsUnified installation sizeCoupling device detailsTwo-part coupling devicesComputer moduleEngineering

The invention discloses an on-site combined type rectangular high-low frequency mixed loading connector, which comprises a connector plug and a connector socket, wherein the connector plug comprises a plug outer shell and a plurality of plug modules which can be arranged on the plug outer shell in a plurality of assembling modes to correspondingly form a plurality of types of combined type plugs and comprise a high-frequency plug module and a low-frequency plug module; the connector socket comprises a socket outer shell and a plurality of socket modules which can be arranged on the socket outer shell in a plurality of assembling modes to correspondingly form a plurality of types of combined type sockets and comprise a high-frequency socket module and a low-frequency socket module; and the structure of the combined type sockets corresponds to that of the combined type plugs. The on-site combined type rectangular high-low frequency mixed loading connector has the advantages of simple structure, convenient processing and manufacturing, standardized batch production, convenient assembly, disassembly and maintenance and stable and reliable working performance, can be used for assembling and replacing a plurality of types of the plugs and sockets randomly on site, and simultaneously realizes integrated transmission of a plurality of types of signals of high and low currents, high and low frequencies and the like.

Owner:SHAANXI SILING ELECTRONICS

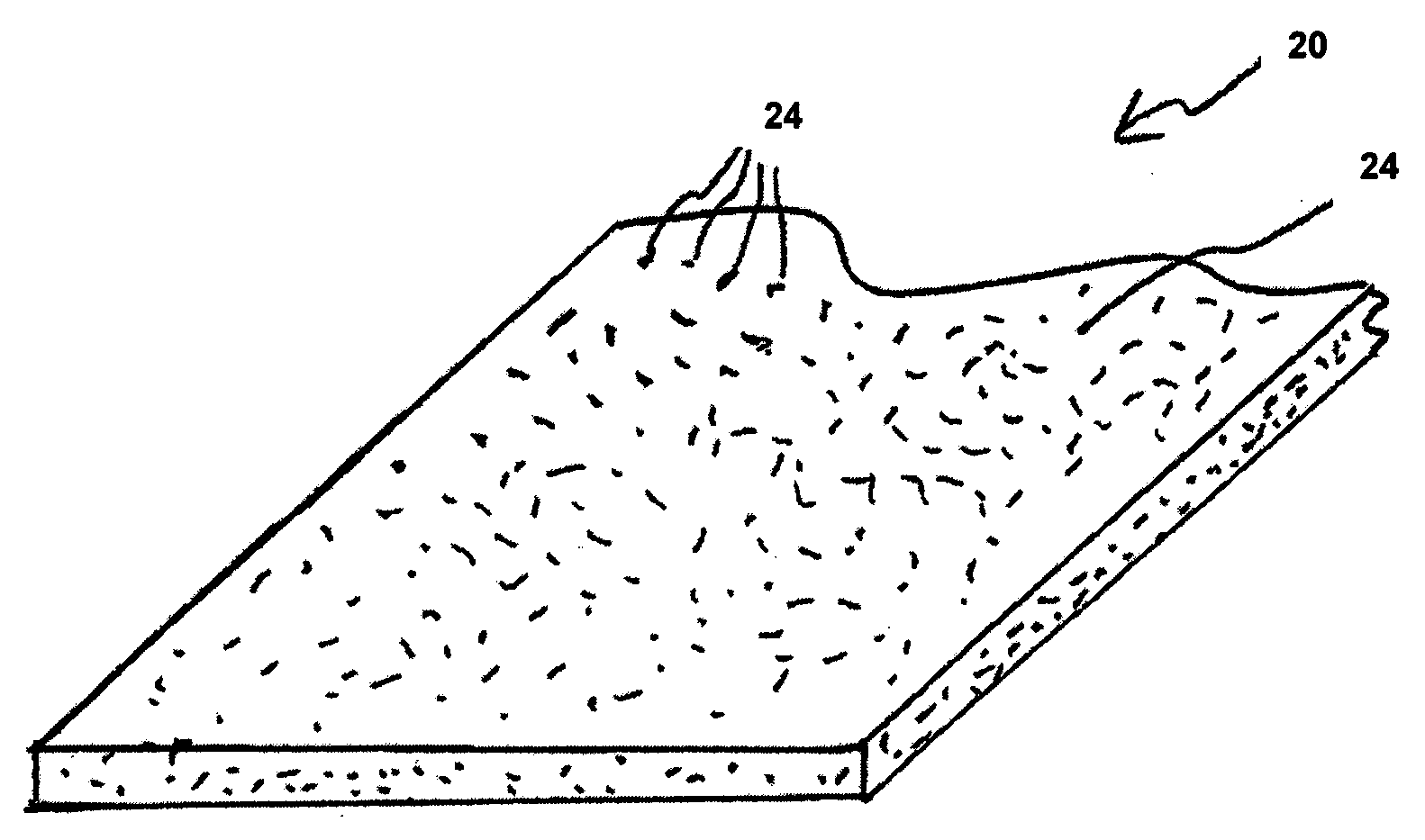

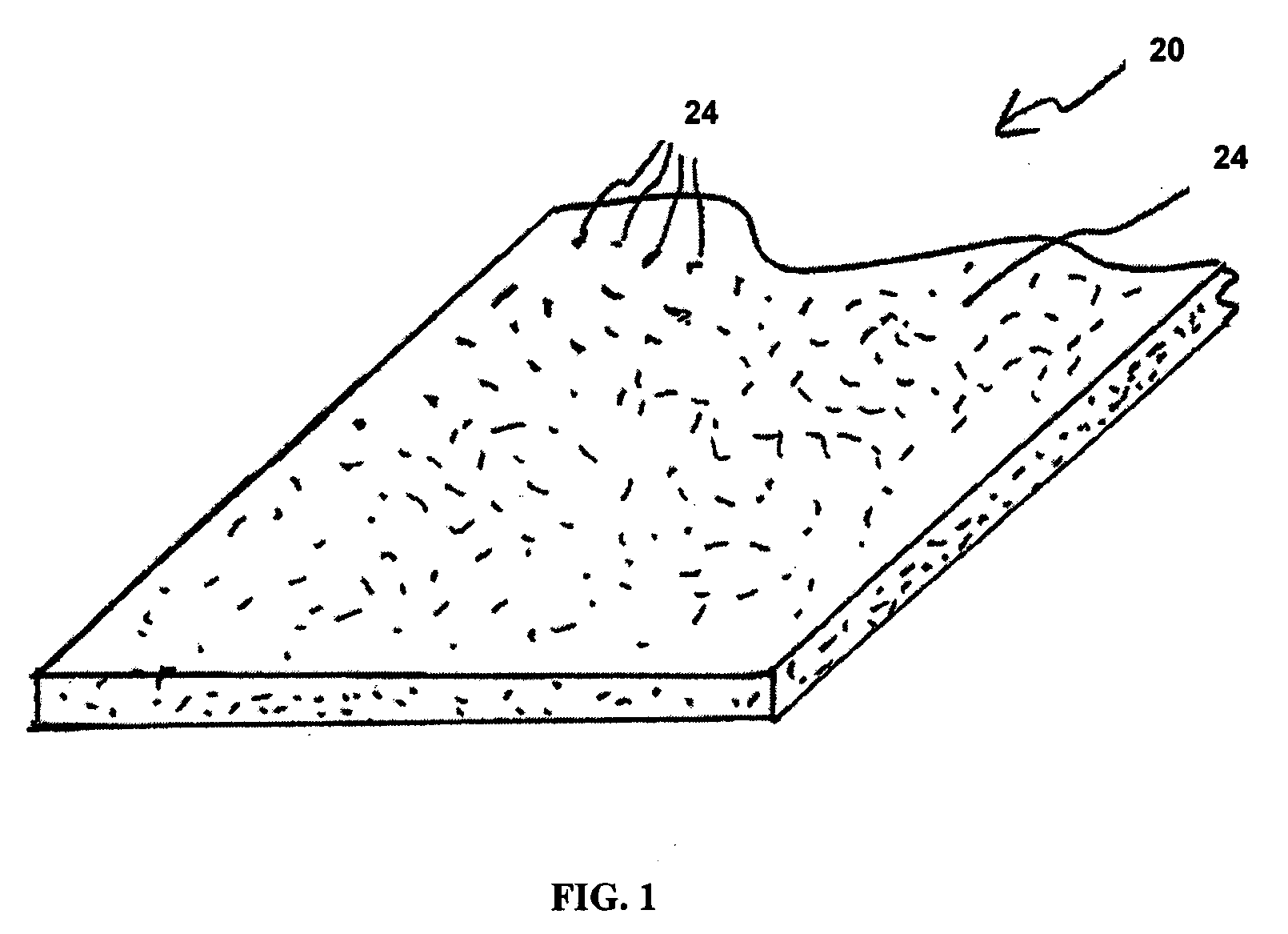

Abrasive Dental Floss and Method of Making Same

InactiveUS20090241983A1Uniform dimension of thicknessUniform dimension of widthGum massageDental flossFiberDental floss

Polytetrafluoroethylene (PTFE) flosses have abrasives added to the floss fiber that increase the abrasion to teeth surfaces, and thus result in a floss that provides enhanced cleaning of surfaces of teeth that face interstices between teeth. Floss fiber is formed by loading a PTFE resin with an abrasive filler. The PTFE resin and filler are processed to form a floss fiber with a surface that provide enhanced abrasion properties.

Owner:COLTEC IND

Paperboard sheet slitter-scorer apparatus and control method for correcting the positions of slitter knives and scorers thereof

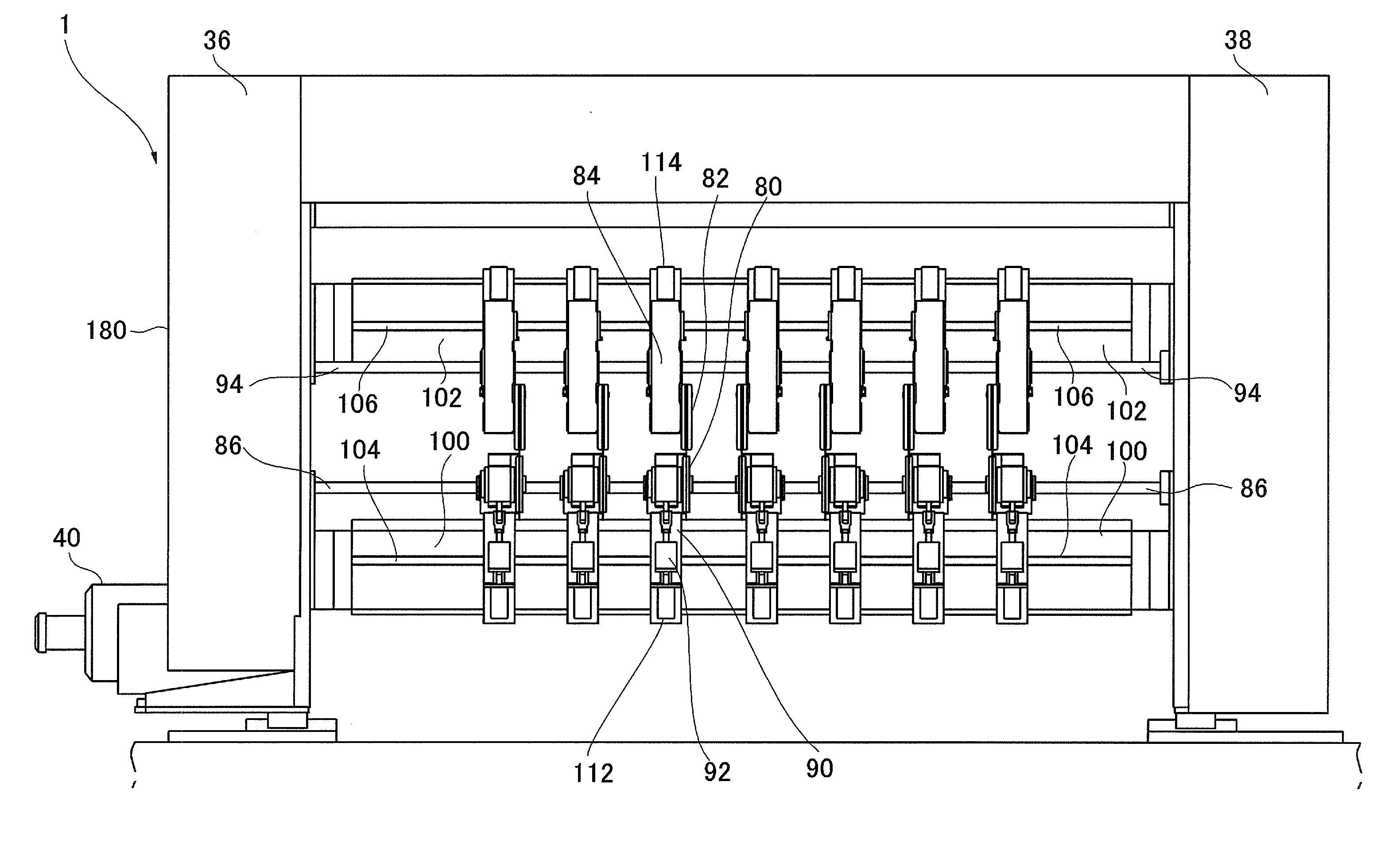

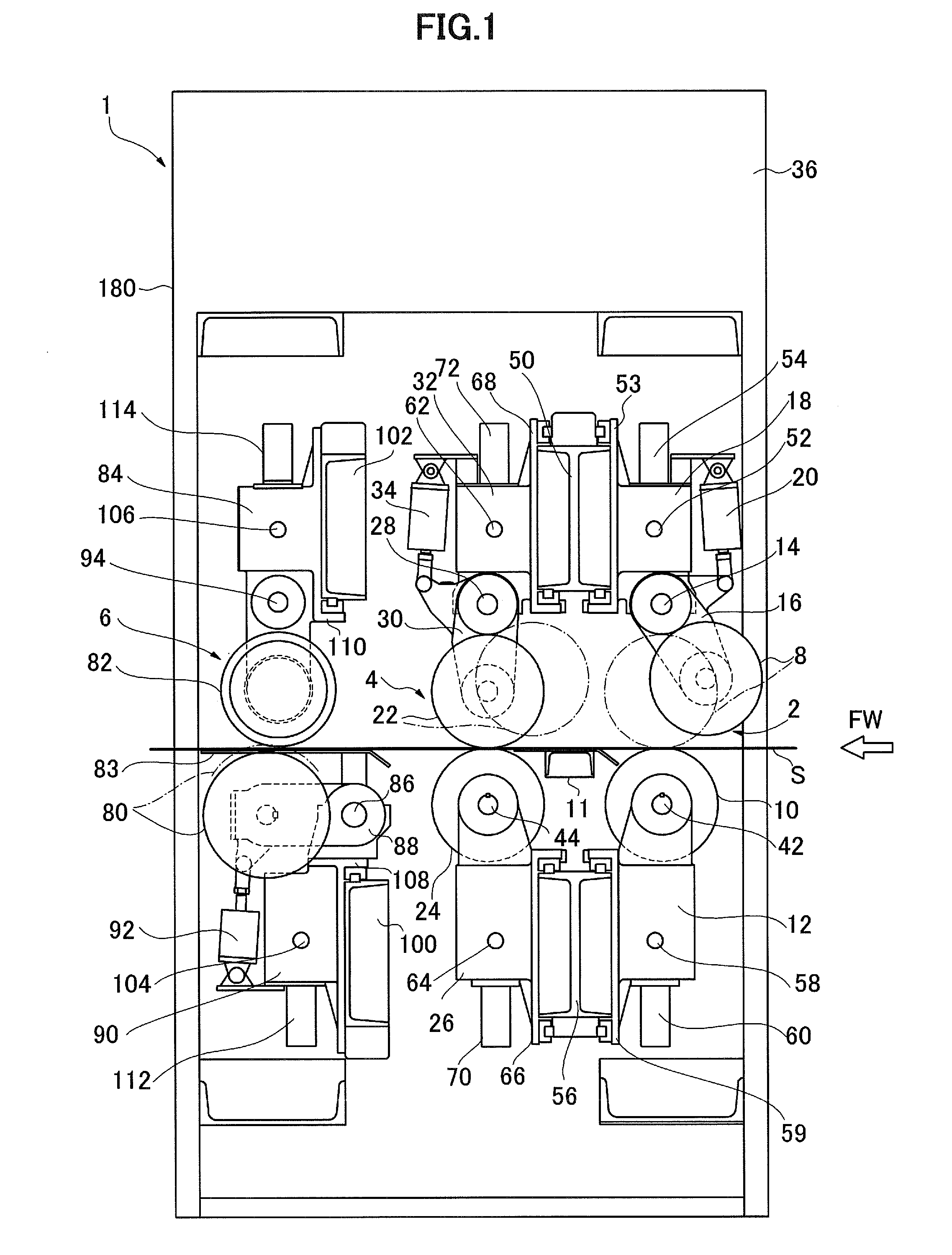

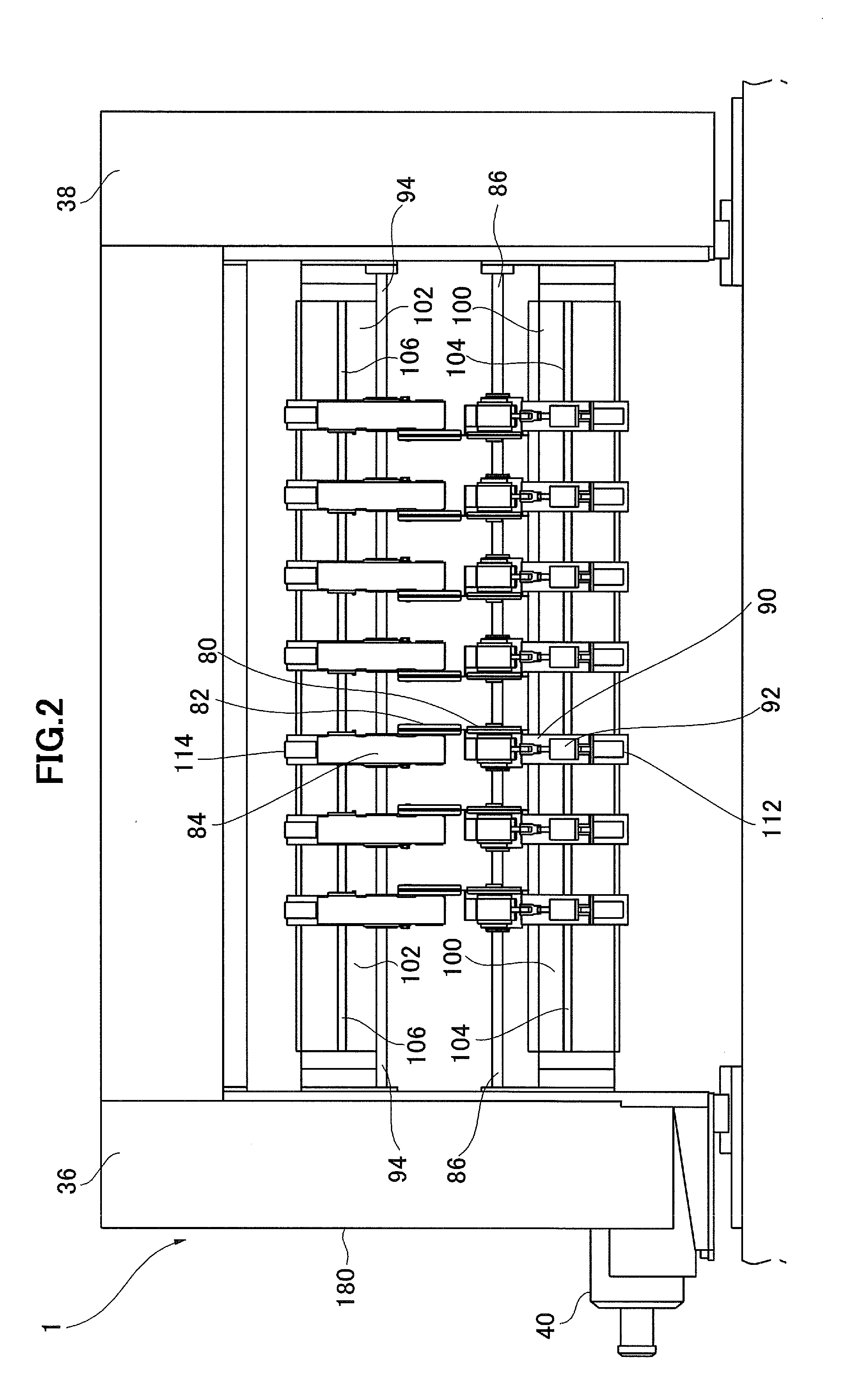

InactiveUS20120031251A1Effective positioningReduce laborMechanical working/deformationMetal working apparatusPaperboardEngineering

A slitter-scorer apparatus is provided, capable of effectively positioning slitter knives in the width direction so that a paperboard sheet of a desired sheet width can be obtained. The slitter scorer apparatus 1 of the present invention comprises a plurality of slitters 6 having slitter knives 80 and 82 paralelly disposed in the width direction relative to the supply direction of a paperboard sheet, for cutting the sheet; slitter width-direction moving means 90, 112, 104, 84, 114, and 16 for respectively independently moving the plurality of slitters in the width direction of the sheet; and a control means for selecting a utilized slitter from among the plurality of slitters based on a production order, calculating a width-direction correction amount relative to an initial position based on the desired paperboard sheet width-direction dimension according to the amount of shearing by the slitter knife, and controlling the slitter width-direction moving means so as to position the slitter knives at a position based on that calculated correction amount.

Owner:ISOWA IND CO LTD

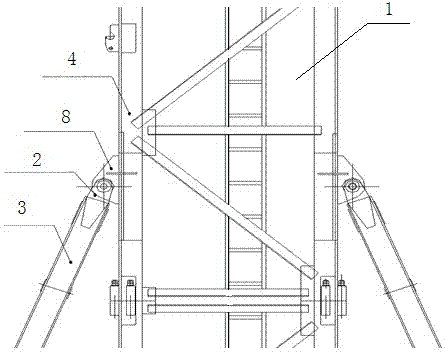

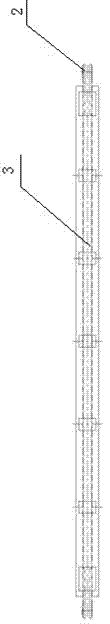

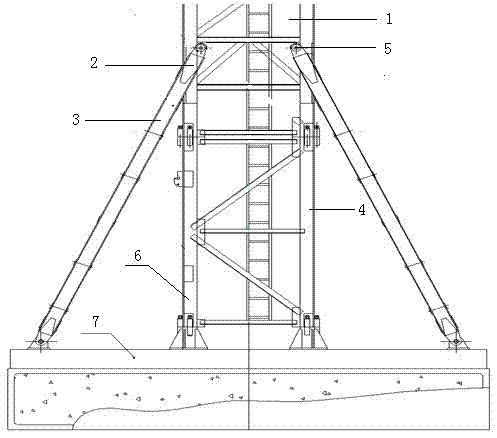

Inserted chassis diagonal-brace structure of tower crane

The invention discloses an inserted chassis diagonal-brace structure of a tower crane and belongs to the technical field of the tower crane. The diagonal-brace structure of the tower crane comprises a base section, a chassis section and a diagonal brace, wherein the bottom end of the base section is vertically and fixedly connected to a crossed beam; the bottom end of the chassis section is fixedly connected to the top surface of the base section; the diagonal brace is arranged to be inclined to the crossed beam, the bottom end of the diagonal brace is fixedly connected with the crossed beam, while the top end of the diagonal brace is fixedly connected with the chassis section, a double-lug plate with a U-shaped structure and fixedly connected with the diagonal brace is arranged at the top end of the diagonal brace, and the inner width dimension of the U-shaped structure of the double-lug plate is matched with the width dimension of a main chord; the top end of the diagonal brace is sleeved on the main chord of the chassis section through the double-lug plate, and the top end of the double-lug plate is fixedly connected with the main chord of the chassis section through a connecting piece. The chassis section is reduced in overall structure dimension and strong in transportation convenience, and simultaneously, the stress condition at the connection part is improved and the weld joint quality requirement is effectively reduced. The diagonal-brace structure of the tower crane is simple and is easy to manufacture and low in manufacturing cost.

Owner:XUZHOU CONSTR MACHINERY

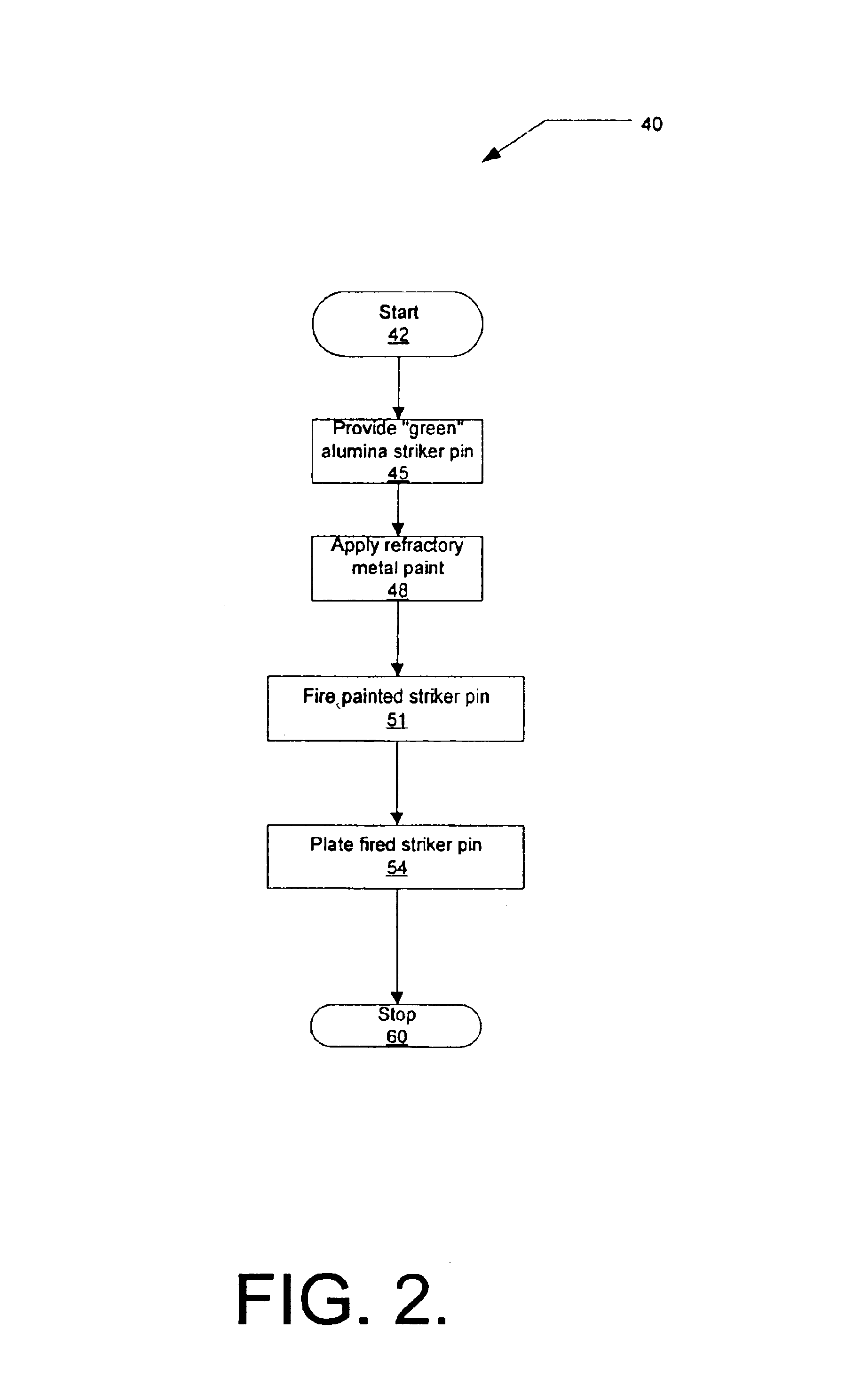

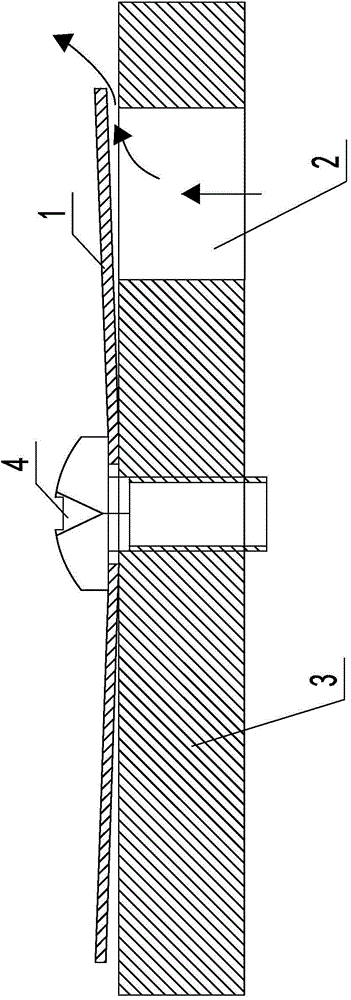

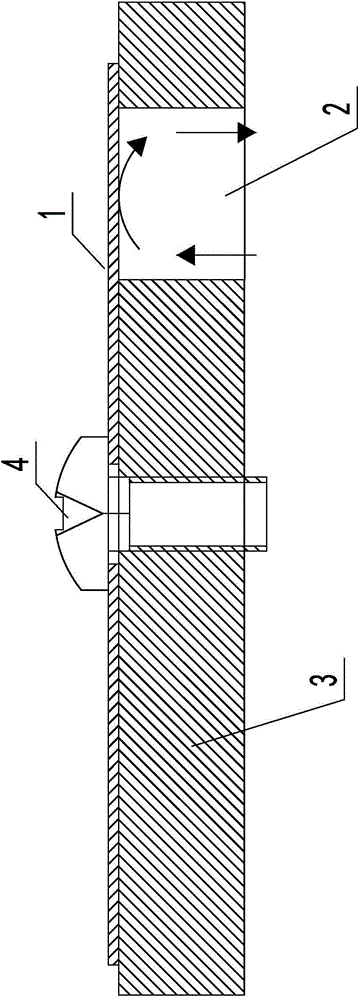

Thermal switch striker pin

InactiveUS6891464B2Reduce wearUniform dimensionsElectrothermal relaysHeating/cooling contact switchesEngineeringHeat sensitive

A striker pin in a thermal switch configured as a mechanical link between a bimetallic disk and an armature spring is provided. The striker pin includes a pin of molded ceramic material. The pin has a generally cylindrical shape, a first axial end, and a second axial end. The first axial end is fastenable in fixed relation to an armature spring. A metalizing film is fused to the second axial end. A metallic deposit is fused to the metalizing film such that the metallic deposit substantially covers the second axial end.

Owner:HONEYWELL INT INC

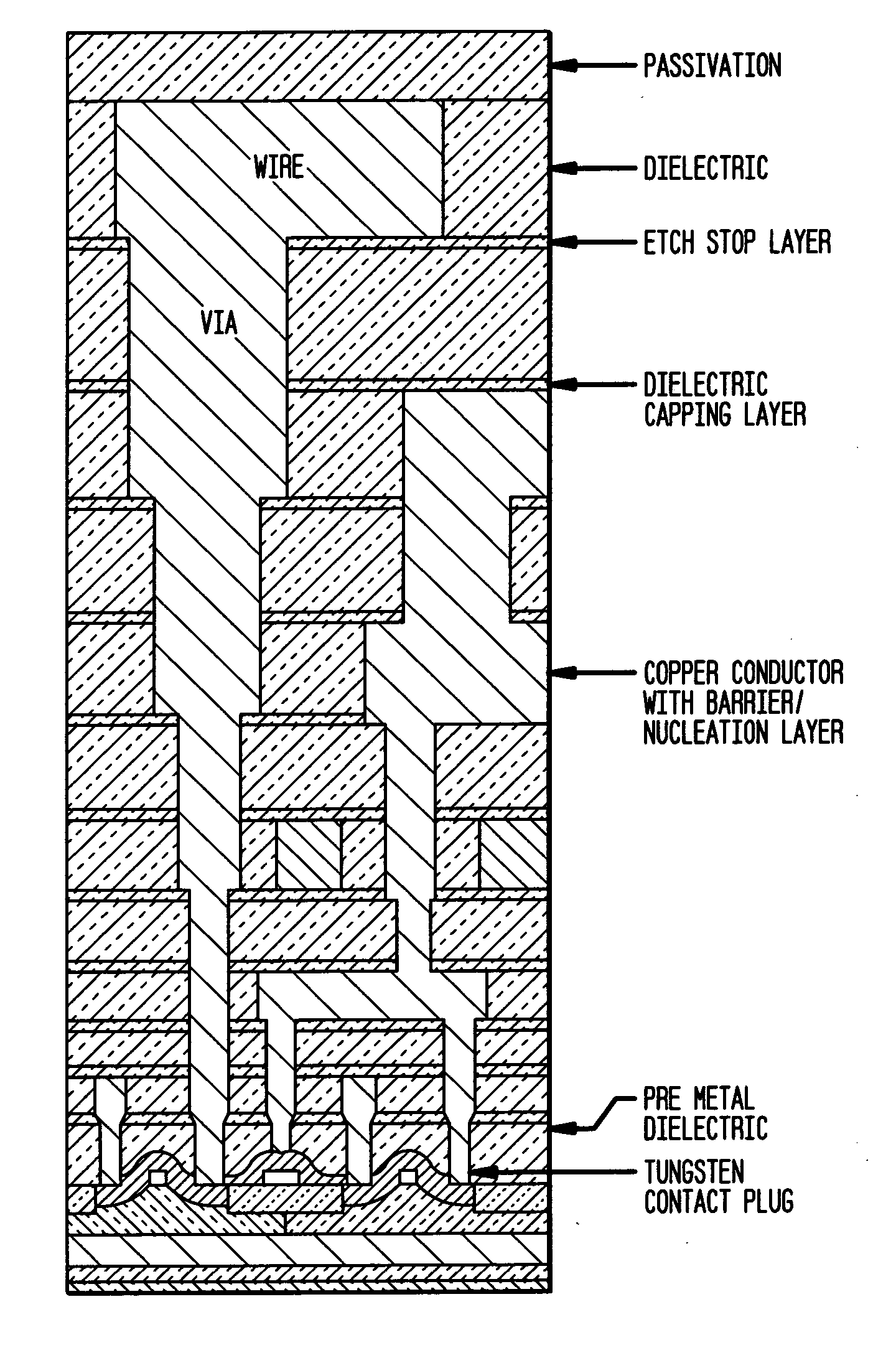

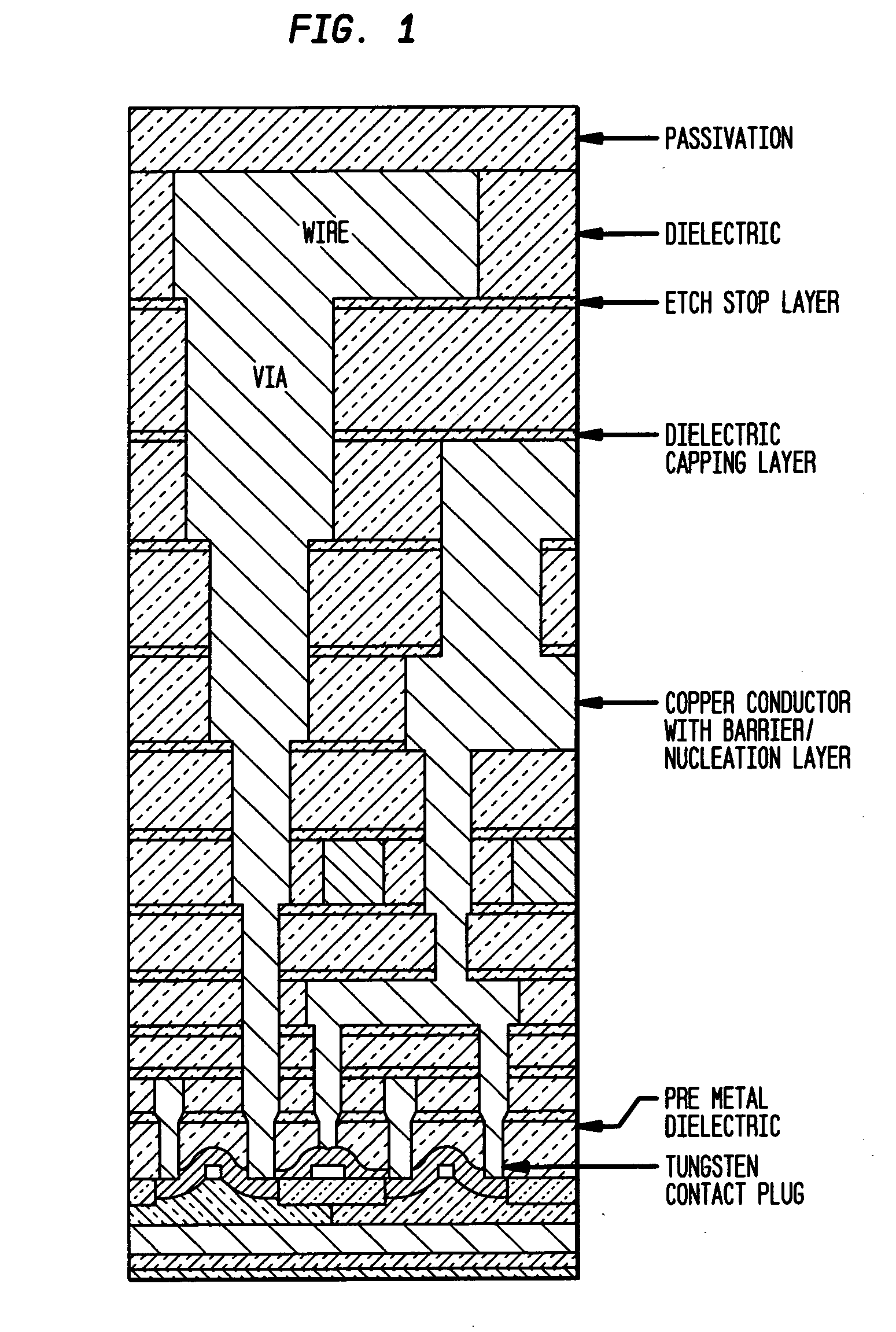

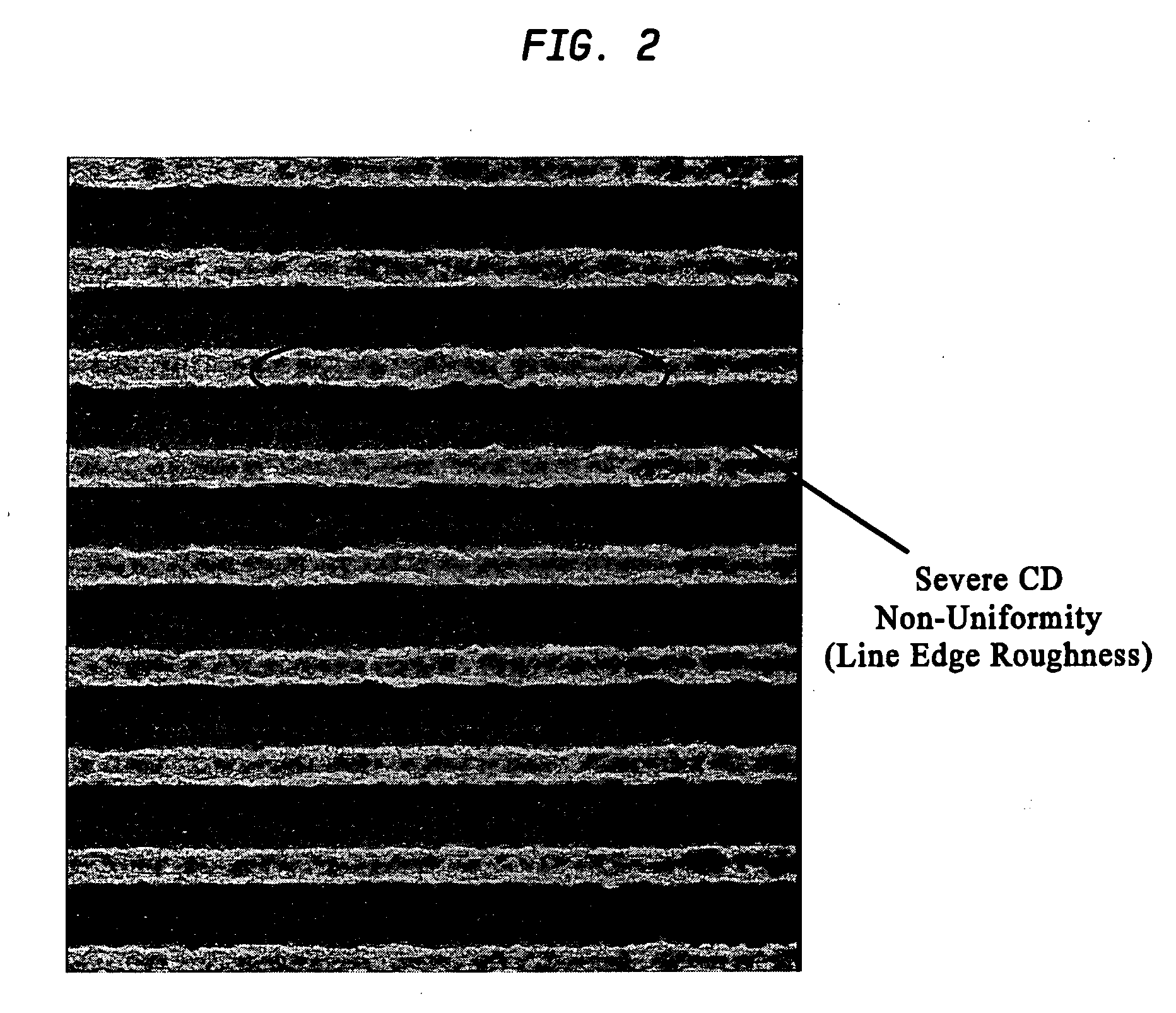

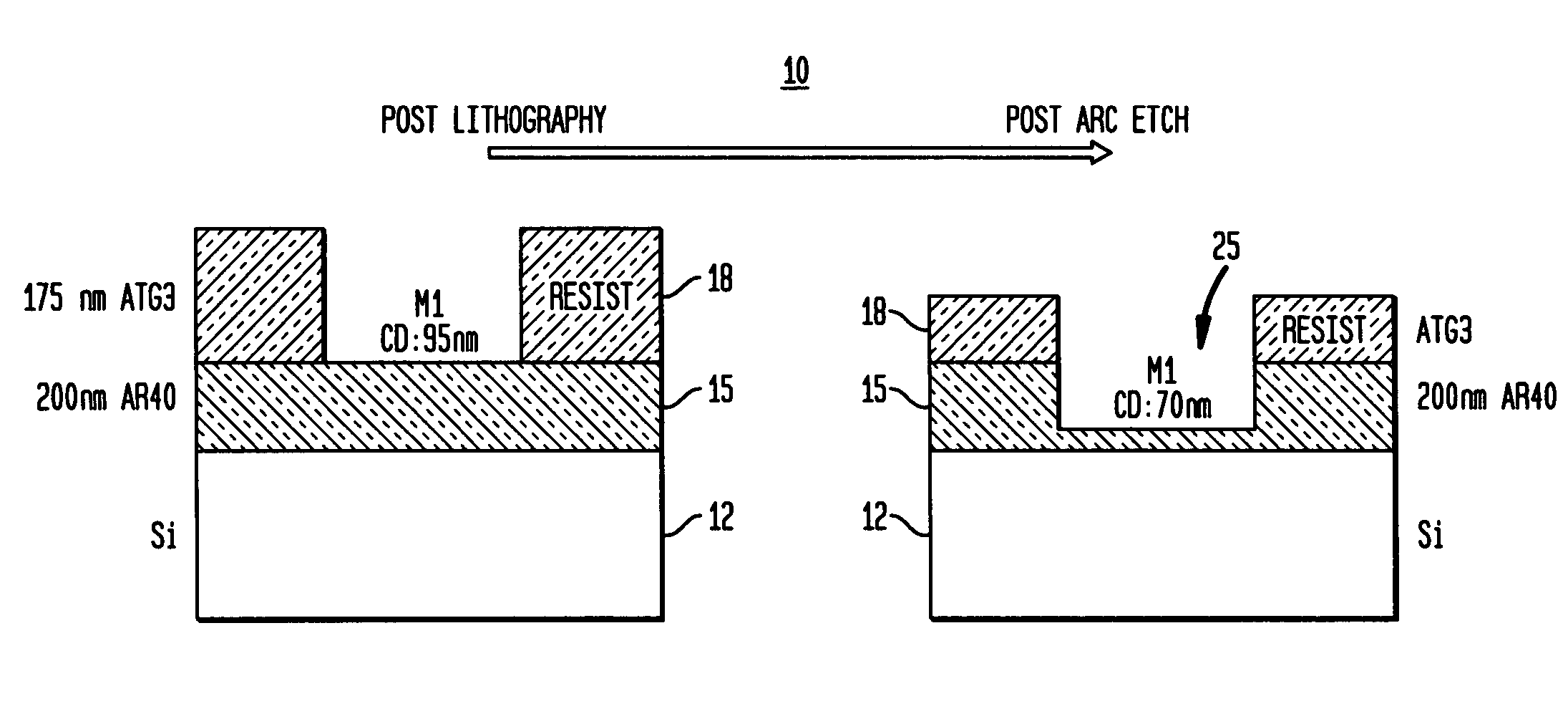

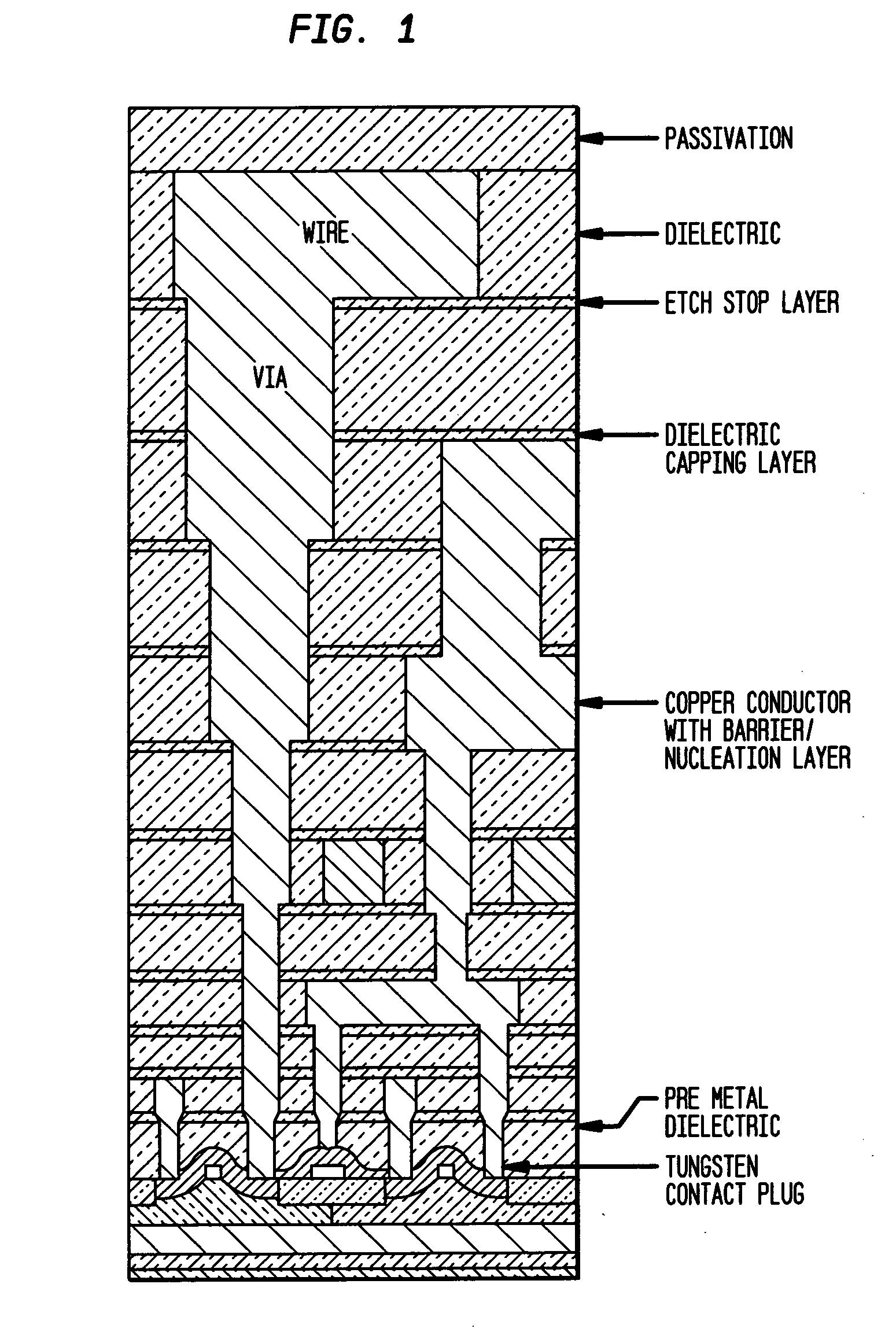

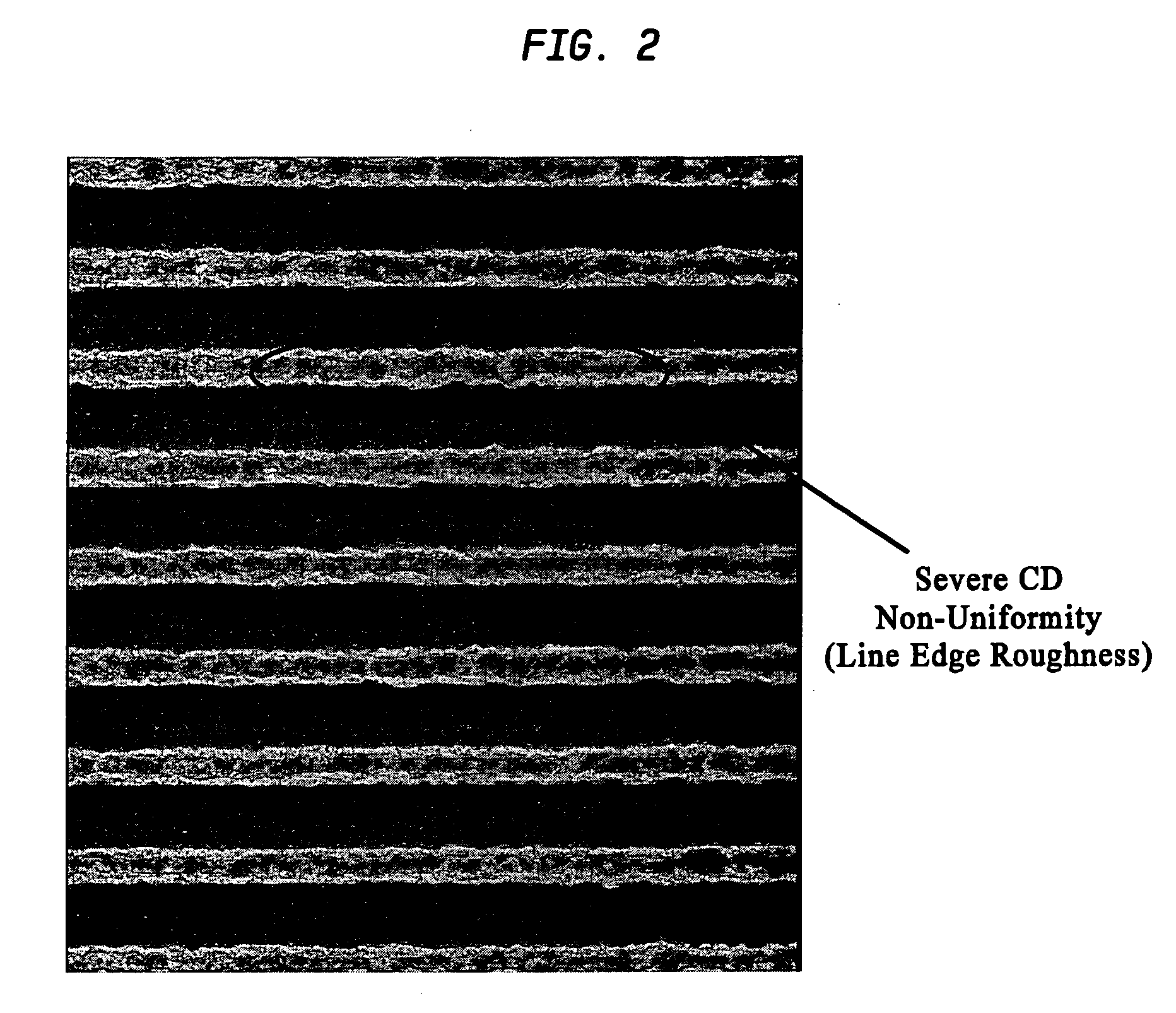

System and method for plasma induced modification and improvement of critical dimension uniformity

ActiveUS20060099816A1Reduce post lithographic CD non-uniformity LEREnhanced linerSemiconductor/solid-state device manufacturingBulk negative resistance effect devicesDevice materialEngineering

Novel interconnect structures possessing a OSG or polymeric-based (90 nm and beyond BEOL technologies) in which advanced plasma processing is utilized to reduce post lithographic CD non-uniformity (“line edge roughness”) in semiconductor devices. The novel interconnect structure has enhanced liner and seed conformality and is therefore capable of delivering improved device performance, functionality and reliability.

Owner:GLOBALFOUNDRIES US INC

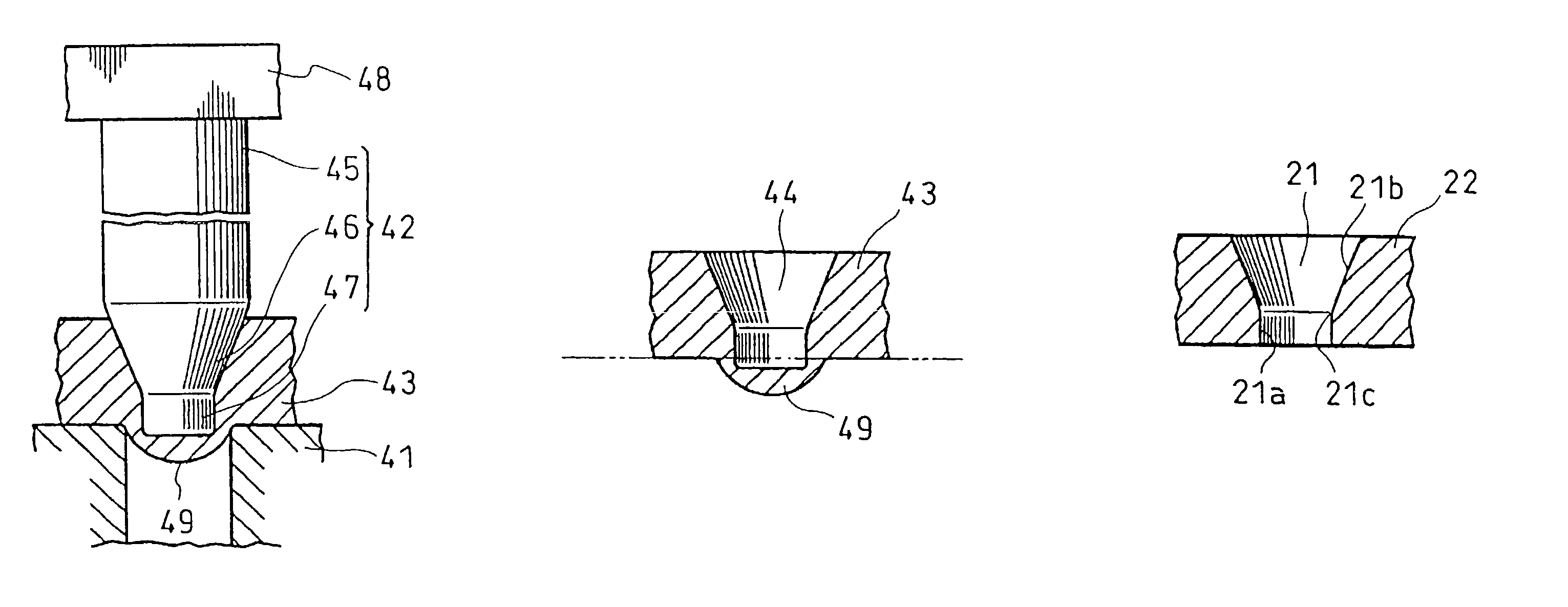

Method of manufacturing nozzle plate

InactiveUS6968616B2Simple regulationUniform dimensionsWriting implementsMetal working apparatusPunchingProviding material

A nozzle plate is manufactured by providing a material plate and a punch. The material plate is punched by the punch to form a provisional nozzle orifice hole on the material plate. The punching is repeated such that the provisional holes formed by a given punch are arranged in line. A bulged portion which is bulged on a back side of the material plate is removed to form the completed nozzle orifice.

Owner:SEIKO EPSON CORP

System and method for plasma induced modification and improvement of critical dimension uniformity

ActiveUS7196014B2Reduce unevennessImproved liner and seed conformalitySemiconductor/solid-state device manufacturingBulk negative resistance effect devicesEngineeringCritical dimension

Novel interconnect structures possessing a OSG or polymeric-based (90 nm and beyond BEOL technologies) in which advanced plasma processing is utilized to reduce post lithographic CD non-uniformity (“line edge roughness”) in semiconductor devices. The novel interconnect structure has enhanced liner and seed conformality and is therefore capable of delivering improved device performance, functionality and reliability.

Owner:GLOBALFOUNDRIES U S INC

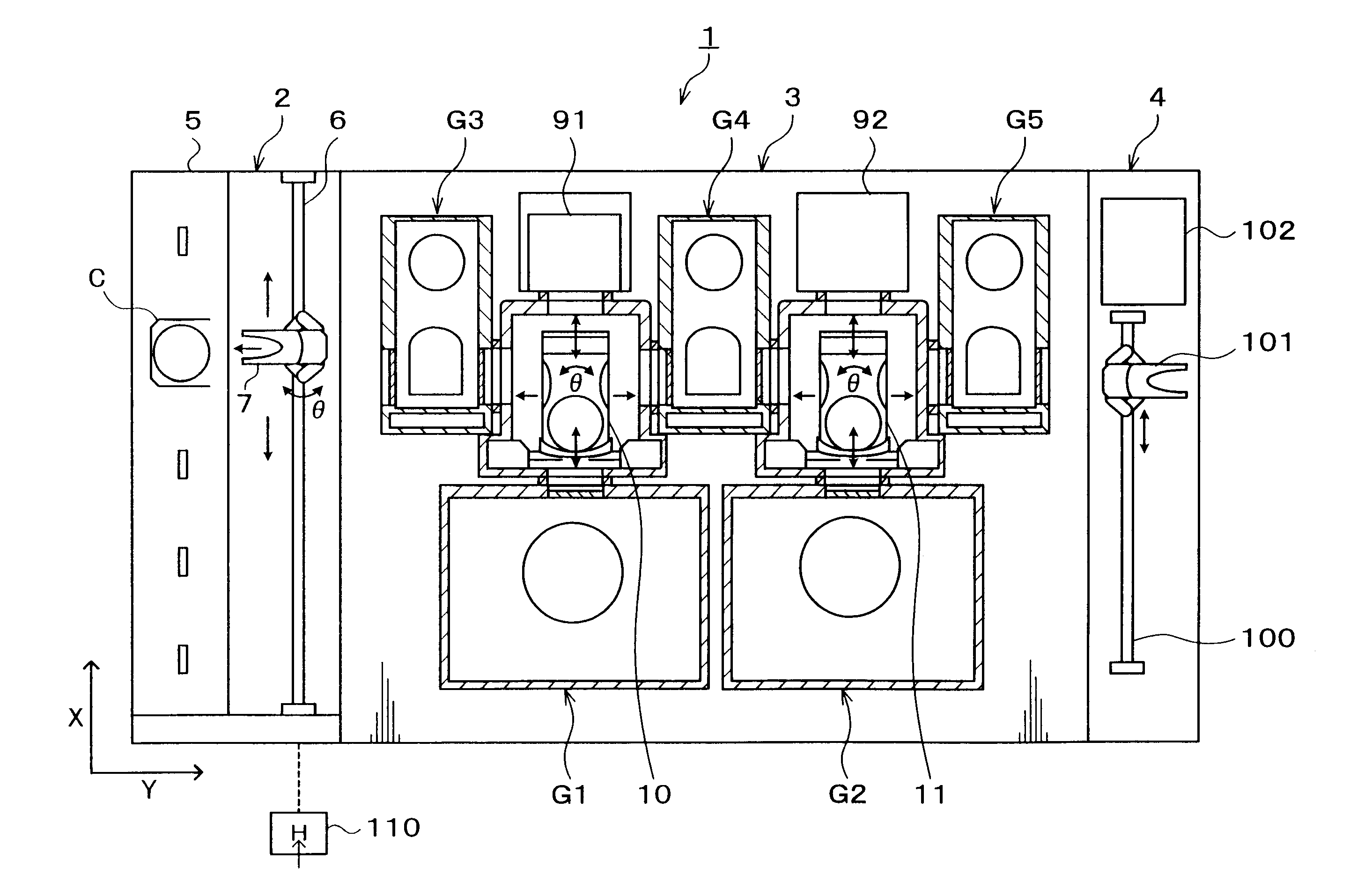

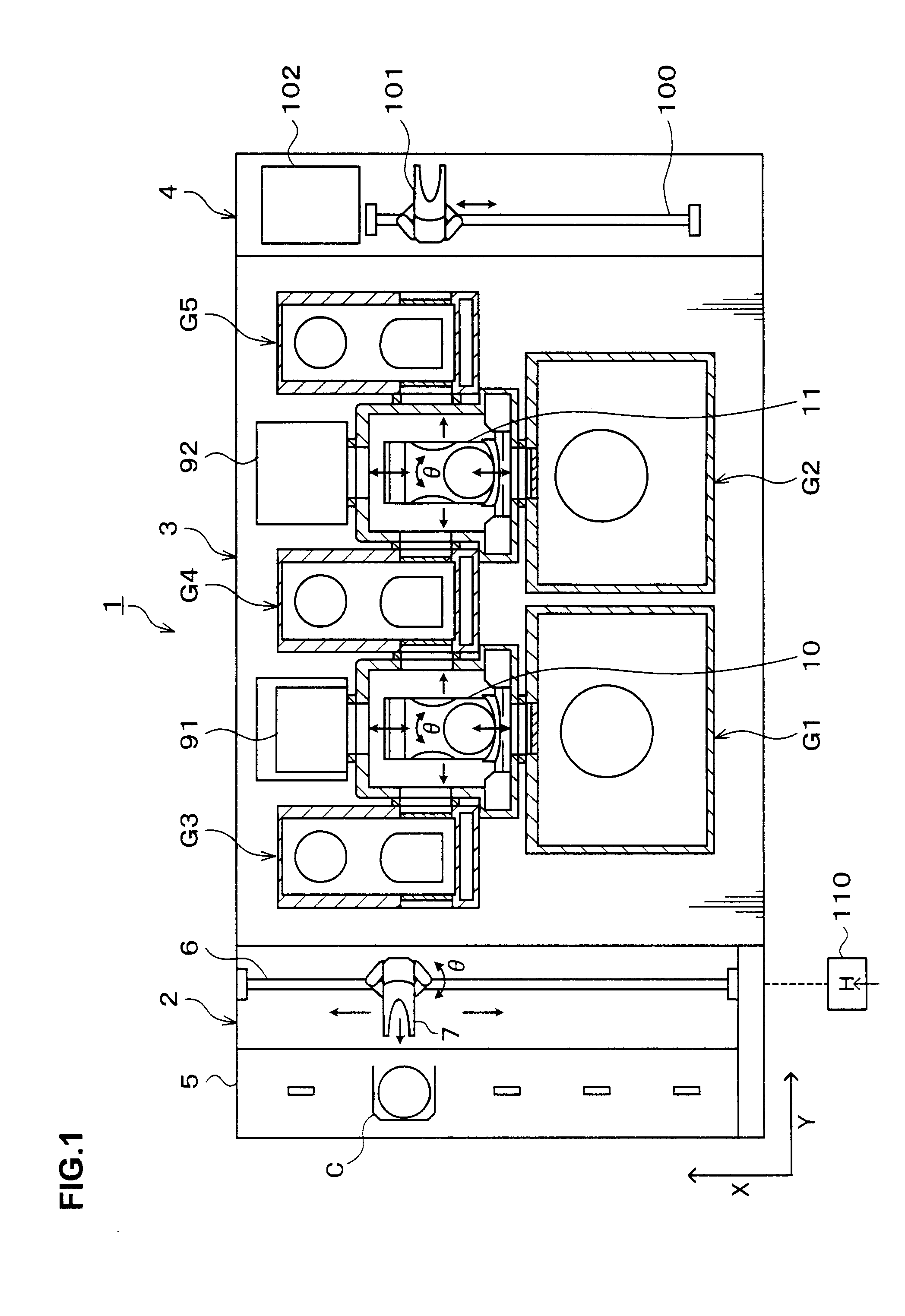

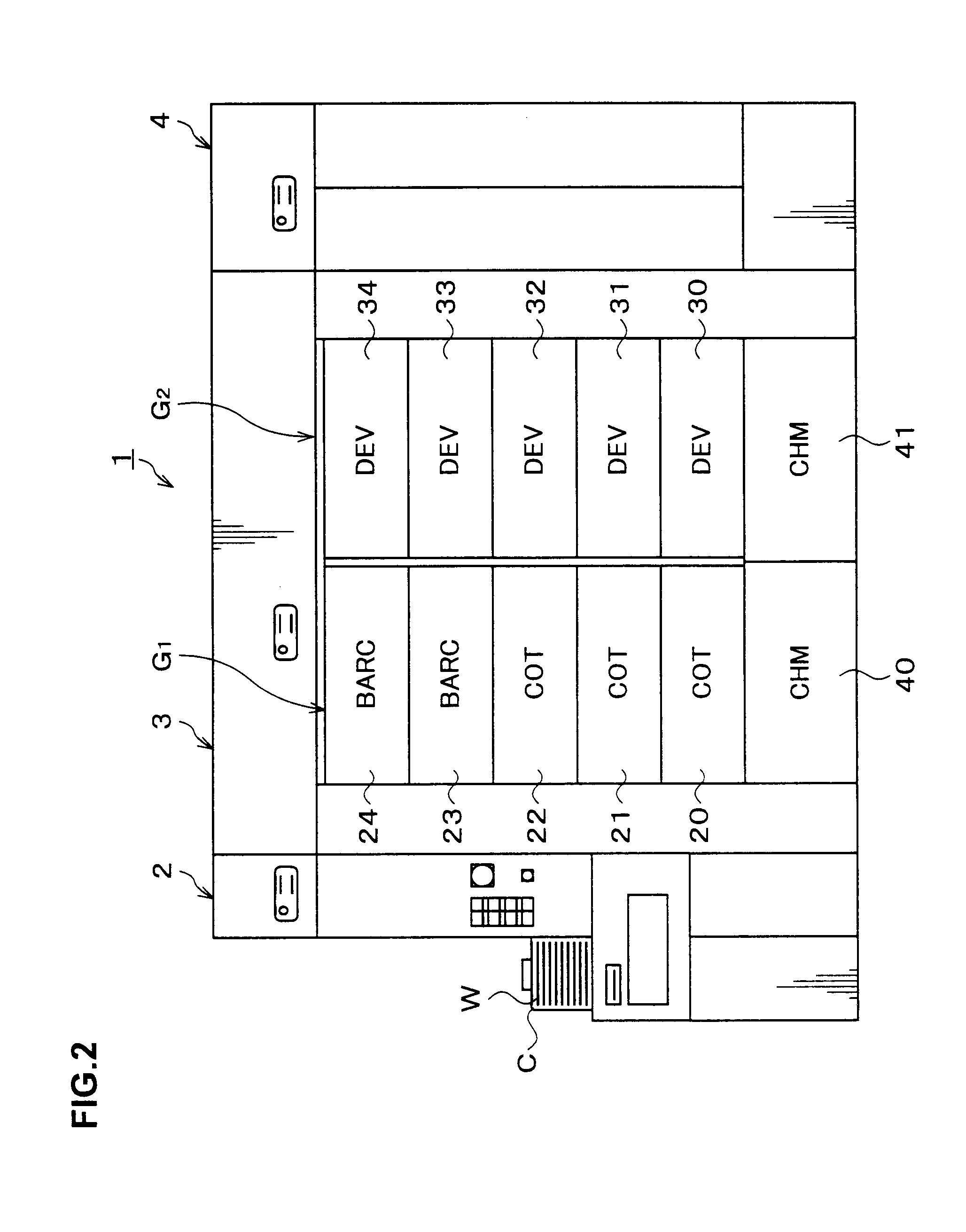

Substrate processing method, substrate processing system, and computer-readable recording medium recording program thereon

ActiveUS20080153181A1MiniaturizationUniform dimensionsLiquid surface applicatorsSemiconductor/solid-state device manufacturingCooking & bakingEngineering

In the present invention, the position of a substrate on a thermal plate is detected when baking after exposure is performed in a first round of patterning. In a second round of patterning, the setting position of the substrate is adjusted based on a detection result of the position before the substrate is mounted on the thermal plate in the baking after exposure. In the baking after exposure in the second round of patterning, the substrate is mounted at the same position with respect to the thermal plate as that in the baking after exposure in the first round of patterning. In performing a plurality of rounds of patterning on a film to be processed, a pattern with a desired dimension is finally formed above the substrate, and the uniformity of the pattern dimension within the substrate is ensured.

Owner:TOKYO ELECTRON LTD

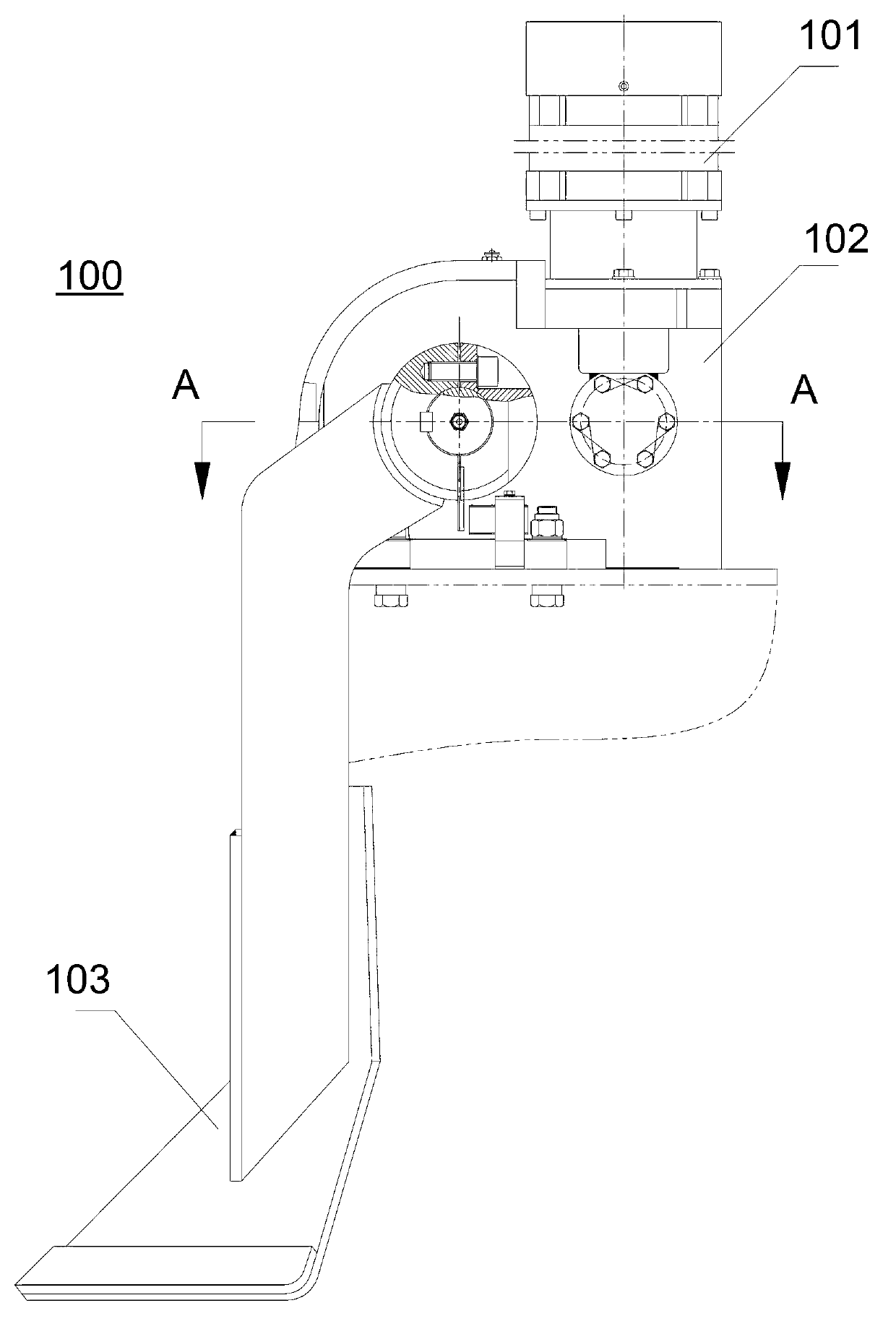

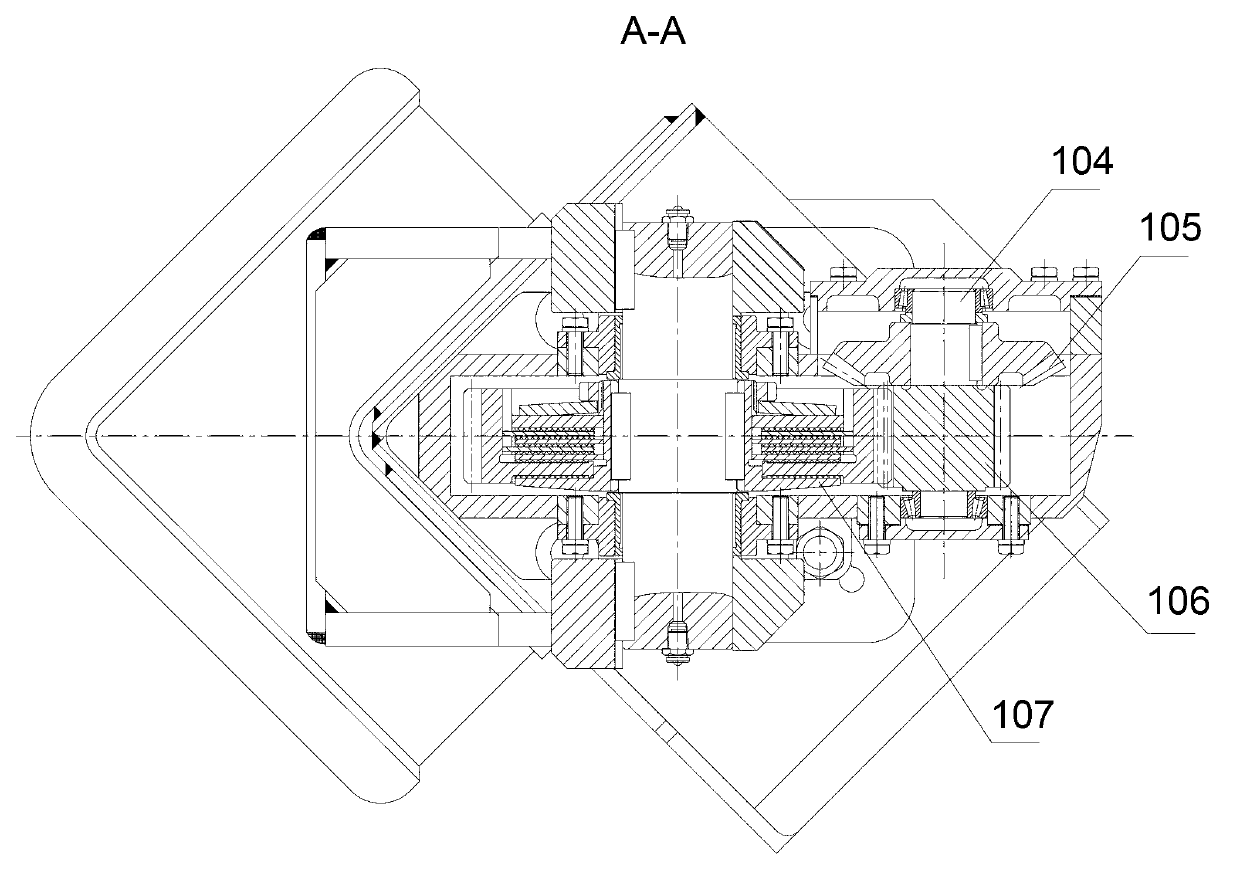

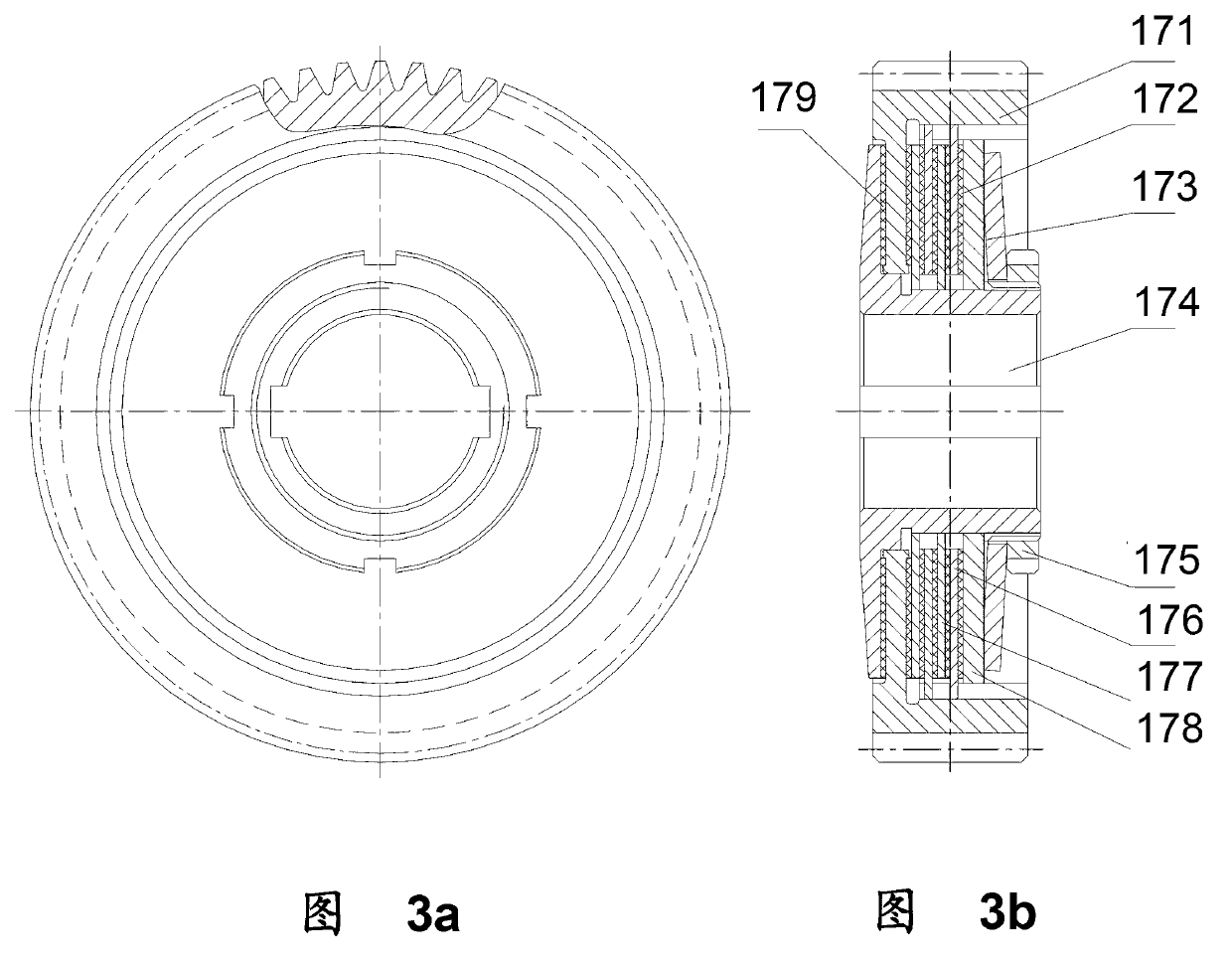

Electric guide plate and torque protection device thereof

ActiveCN103318766AUniform dimensionsGuaranteed versatilitySafety gearFriction torqueTorque transmission

The invention discloses a torque protection device of an electric guide plate. The torque protection device comprises a rotating sleeve, an inner backing plate, an outer backing plate, a pressing plate, a bull gear, friction plates and spring parts. The rotating sleeve is connected with a transmission shaft, and is used for transmission; the inner backing plate and the pressing plate are connected to the rotating sleeve, and rotate with the rotating sleeve; the outer backing plate is connected to the bull gear, and rotates with the bull gear; the friction plates are arranged among all the fitting surfaces of the rotating sleeve, the inner backing plate, the outer backing plate, the pressing plate and the bull gear, so that torque transmission is performed among the fitting surfaces by frictional force. The spring pats are used for pressing the bull gear, the inner backing plate, the pressing plate, and the outer backing plate against the rotating sleeve firmly, and the spring parts are locked on the rotating sleeve. When the torque protection device of the electric guide plate is subjected to external impact force, and the impact force exceeds a friction torque threshold of the friction plates, the fitting surfaces will slide relatively to release the impact force. An internal friction fitting position is employed to release overloaded impact force, so that a problem of conventional electric guide is solved, wherein the problem is that parts are damaged because of hard transmission performed directly through a gear mechanism.

Owner:SHANGHAI ZHENHUA HEAVY IND +1

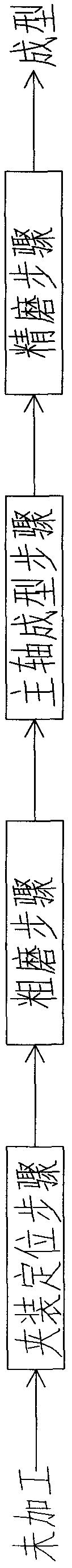

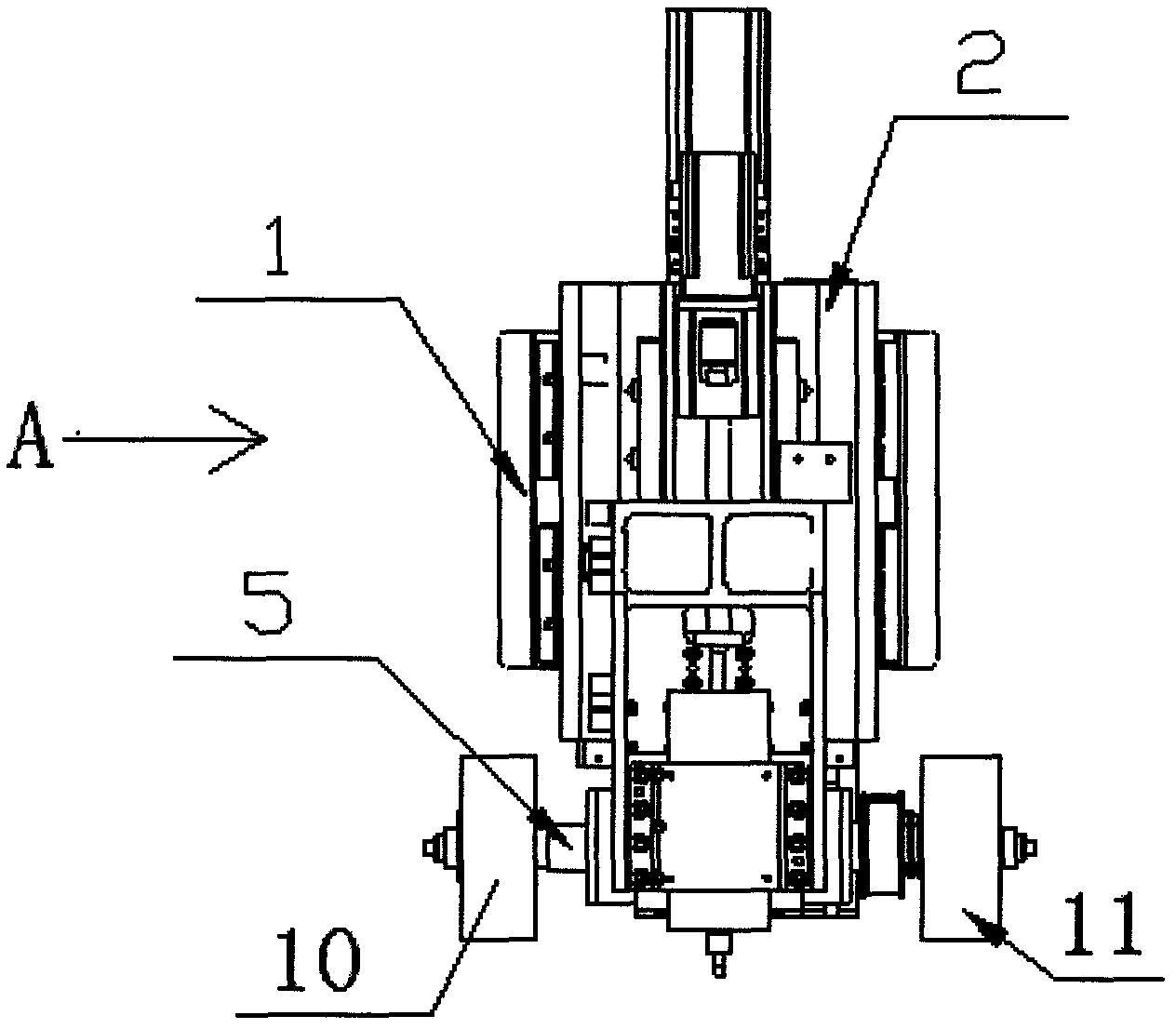

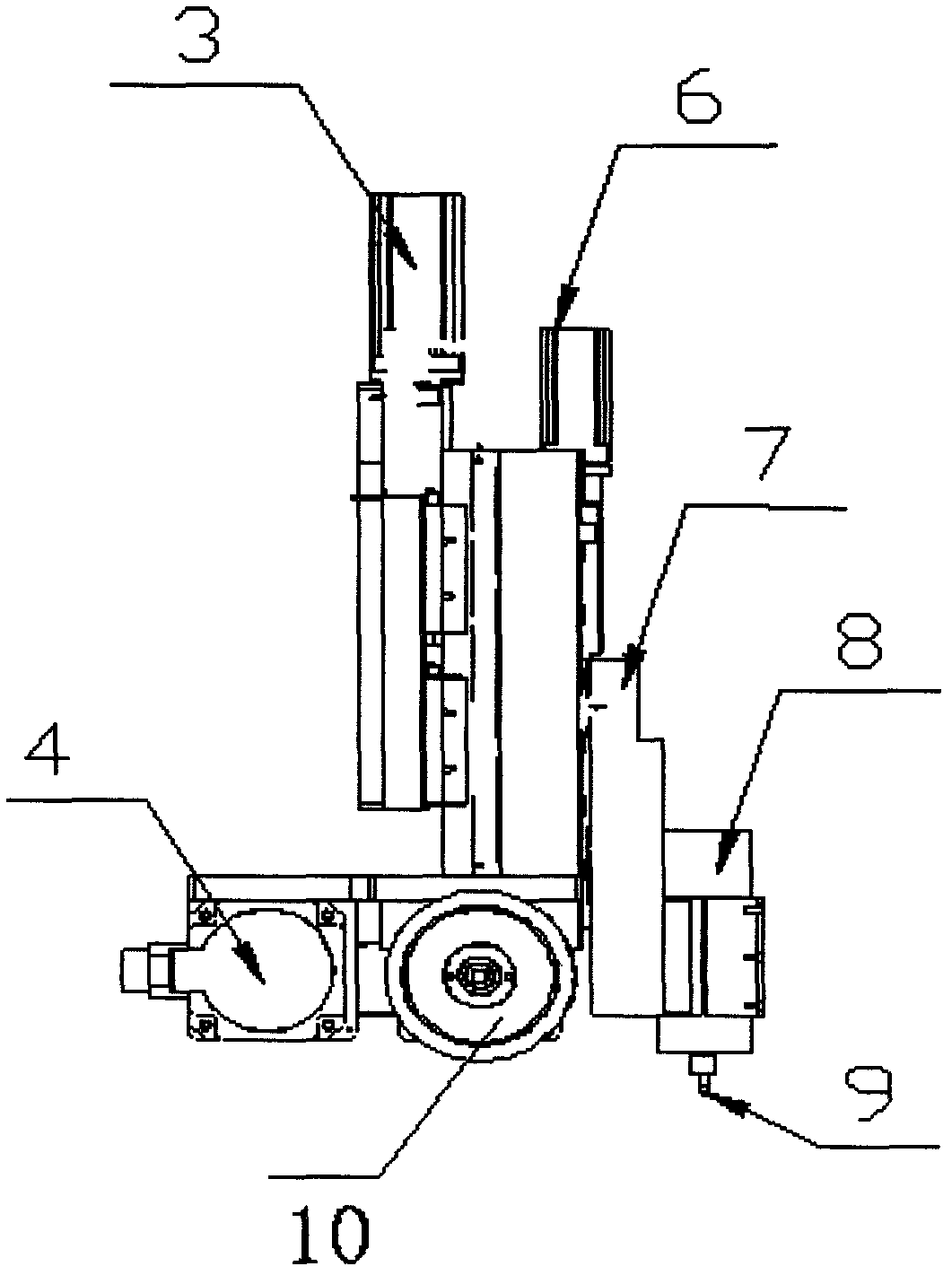

2.5 D forming process method of glass panels or rear glass cover plates

ActiveCN102528598AImprove processing efficiencyUniform dimensionsGrinding work supportsPlane surface grinding machinesEngineeringSurface plate

The invention discloses a 2.5 D forming process method of glass panels or rear glass cover plates, which comprises a clamping and positioning step, a horizontal-axis grinding step and a main-axis forming step, wherein the horizontal-axis grinding step comprises a rough grinding step and an accurate grinding step; the clamping and positioning step, the rough grinding step, the main-axis forming step and the accurate grinding step are sequentially executed through a Z-axis accurate-rough grinding device; and unprocessed glass panels or rear glass cover plates sequentially pass through the clamping and positioning step, the rough grinding step, the main-axis forming step and the accurate grinding step and then respectively form formed glass panels or rear glass cover plates. According to the 2.5 D forming process method of glass panels or rear glass cover plates, the glass panels or rear glass cover plates are clamped and positioned for only one time, the processing quality and the processing efficiency of the formed glass panels or rear glass cover plates can be simultaneously ensured, the processing cost is also reduced, and the using demands of users are met.

Owner:SHENZHEN DAYUCNC TECH

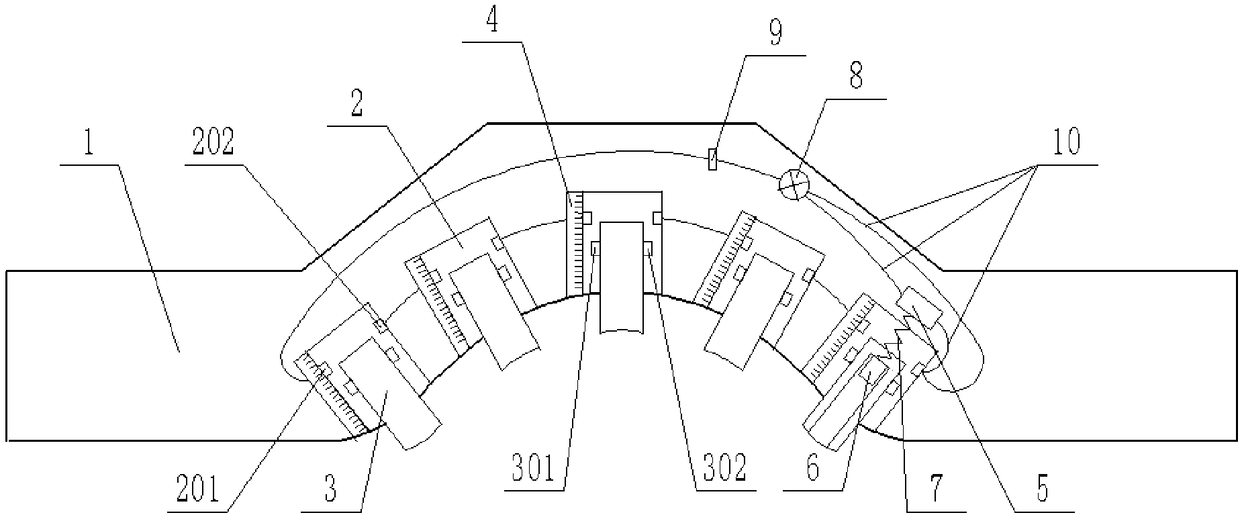

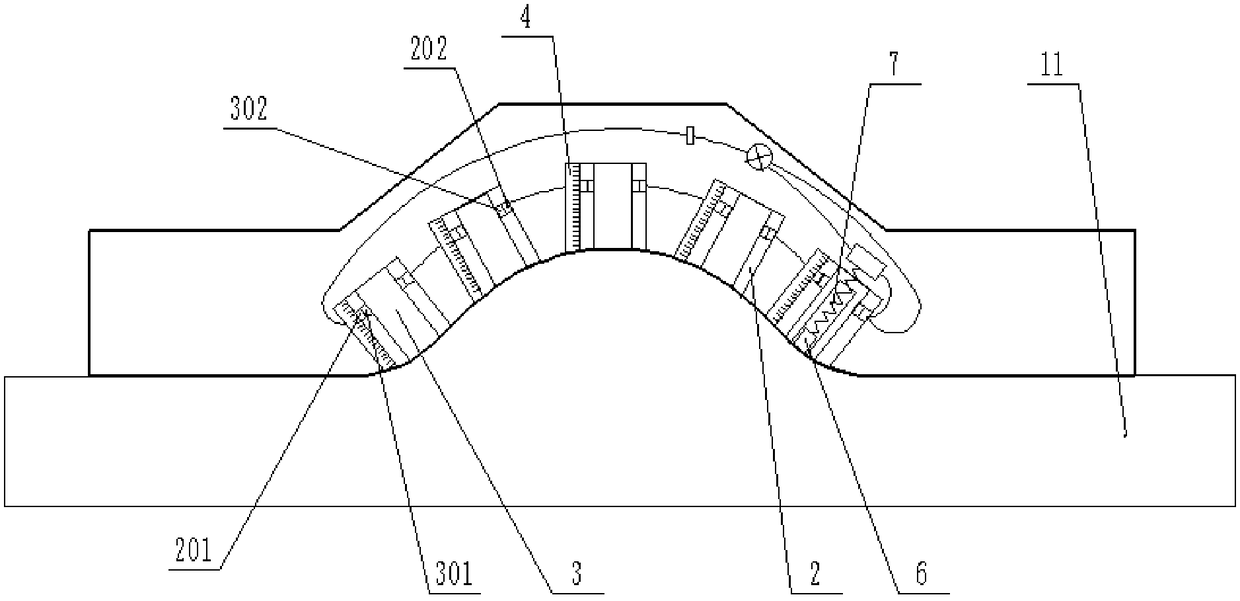

Method for detecting boundary dimension of curved plate

ActiveCN108286928AUniform dimensionsSolve the technical problems of inaccurate detectionAngles/taper measurementsEngineering

The invention belongs to the technical field of detection, and particularly relates to a method for detecting the boundary dimension of a curved plate. The comprises a step 1 of preparing a detectiontool and a curved plate to be detected; a step 2 of sleeving the curved surface of the curved plate with the detection tool; a step 3 of pressing down the detection tool to make the fitting surface ofthe detection tool abutted against the outline of the curved plate; a step 4 of moving a measuring block in a through groove and observing whether a prompting device sends a prompt signal, wherein ifthe boundary dimension of the curved plate is uniform and qualified, the prompting device sends the prompt signal and a marking block marks the curved plate with an mark, or if the boundary dimensionof the curved plate is not uniform, the prompting device does not sends the prompt signal. The method solves inaccurate detection of the boundary dimension of the curved plate in the prior art.

Owner:夏邑县华盛木业有限公司

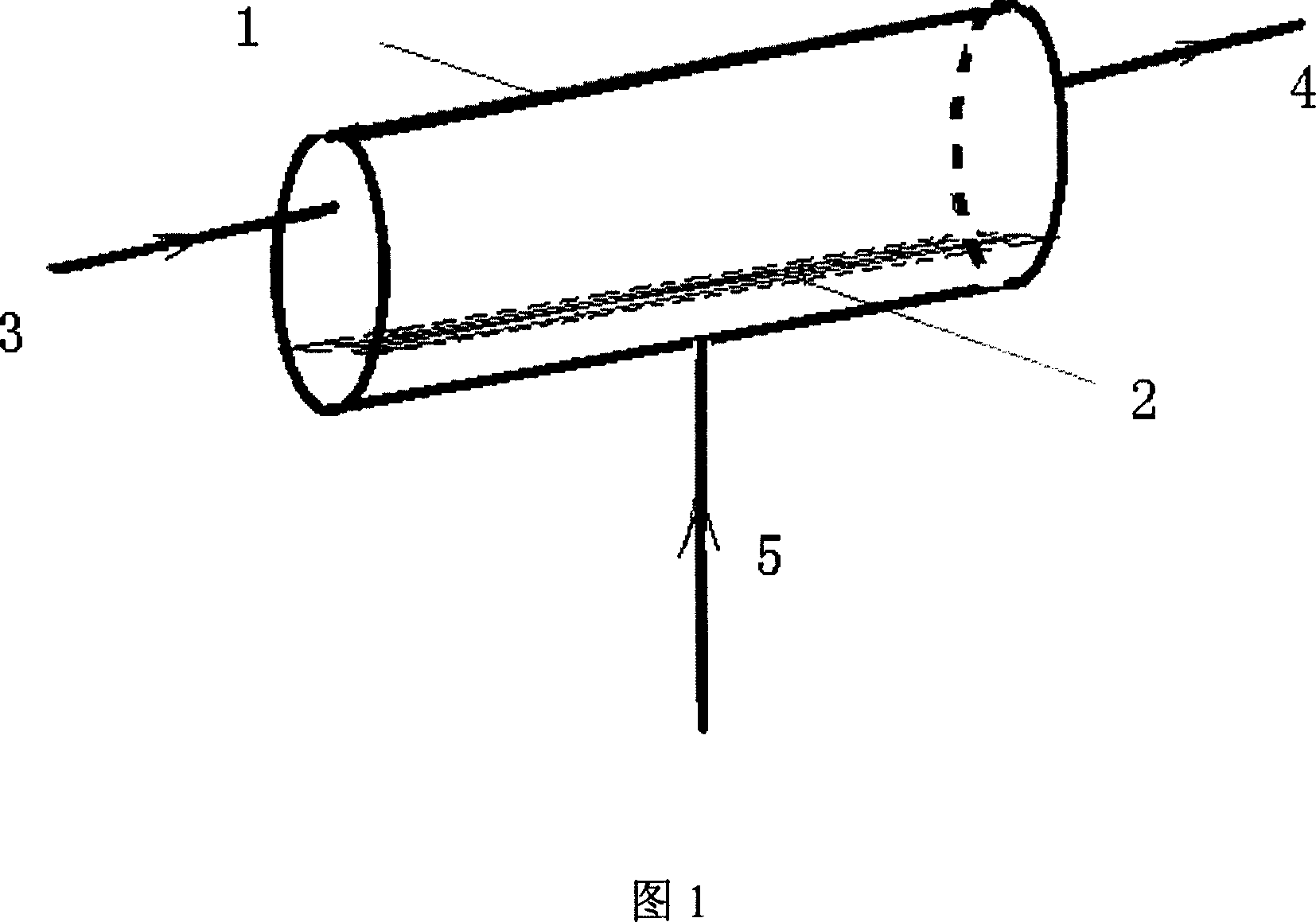

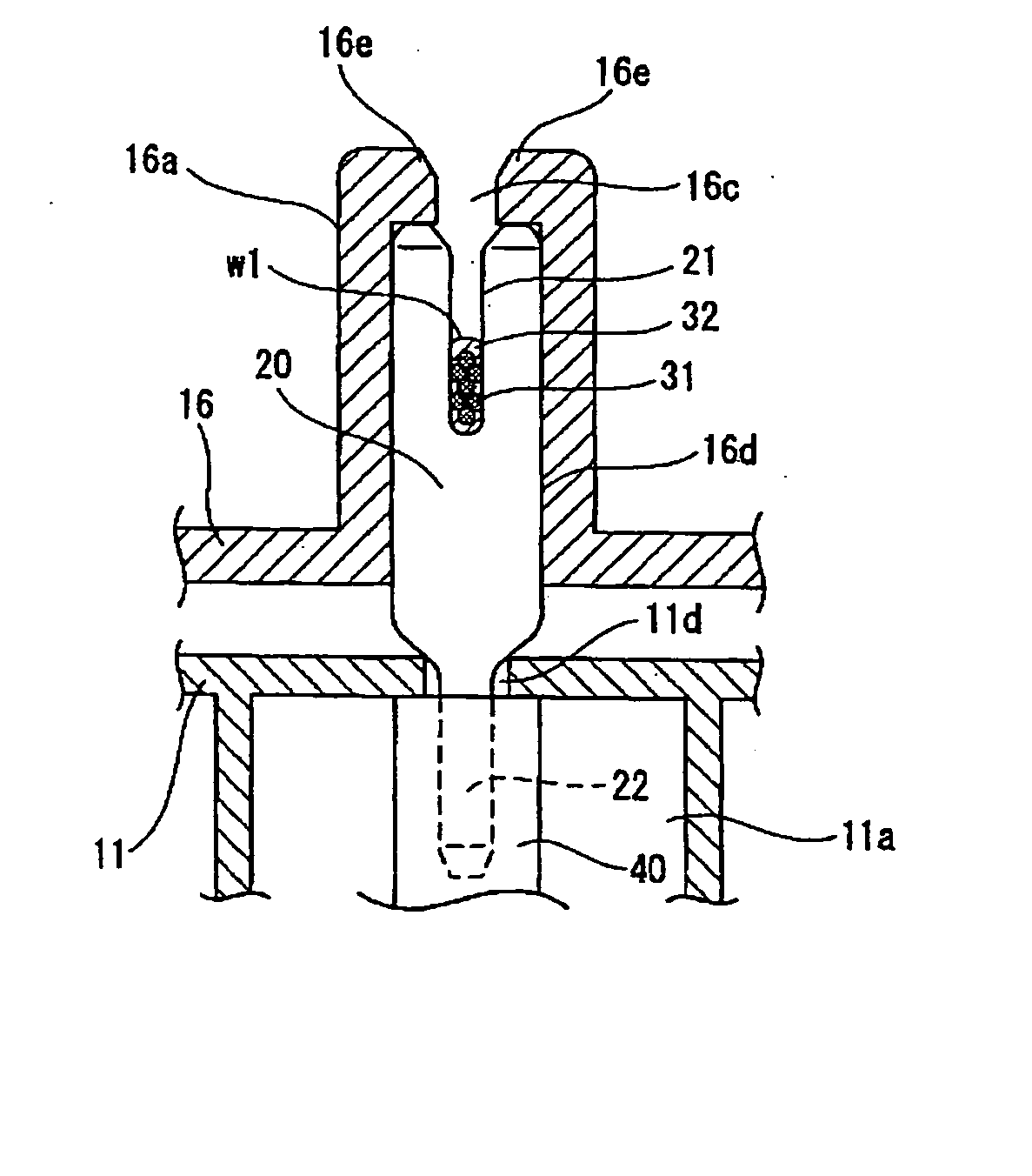

Method for preparing fibrous light cakium carbonate and reactor

ActiveCN1944263ASmall flow velocity disturbancePromote growthCalcium/strontium/barium carbonatesSlurryCarbonate

The present invention discloses process and reactor for preparing fibrous light calcium carbonate. The preparation process includes the following steps: heat the mixture of 1-5 % water slurry of Ca(OH)2 and MgCl26H2O in 2-4 times weight of Ca(OH)2 to 80-95 deg.C, carbonizing reaction of the slurry in a horizontal strip reactor and the introduced CO2 gas through one gas distributing member to carbonize the Ca(OH)2 in the slurry into fibrous calcium carbonate, and filtering and washing the effluent to obtain the fibrous light calcium carbonate. The said process has identical retaining time of Ca(OH)2 slurry inside the reactor and is favorable to the growth of fibrous light calcium carbonate to obtain fibrous light calcium carbonate in homogeneous size distribution.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

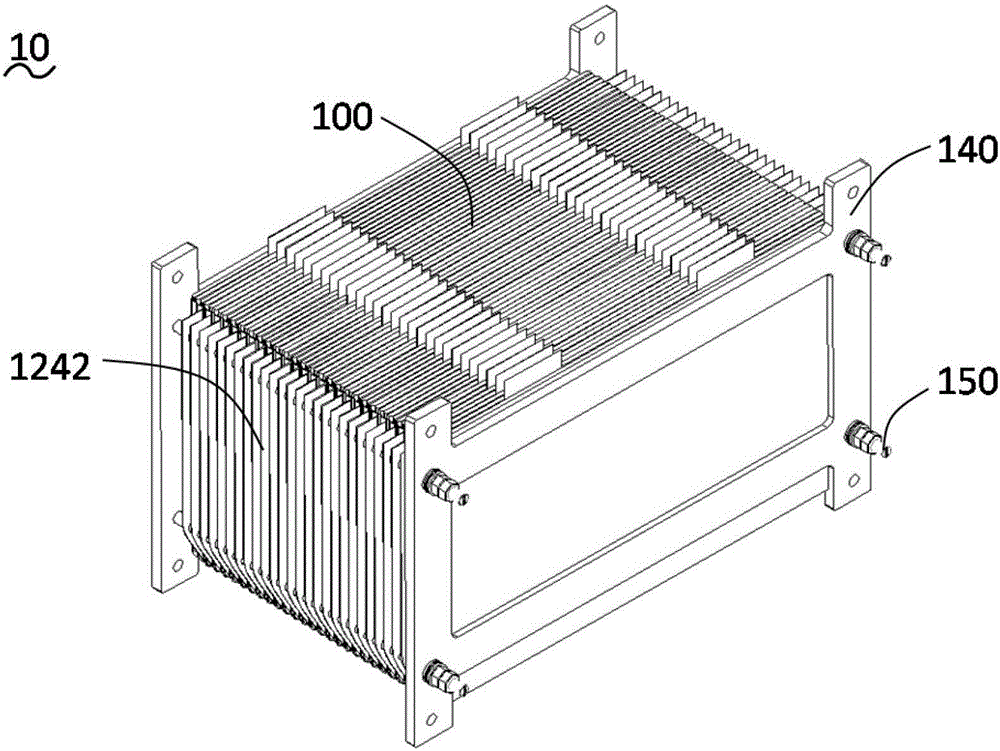

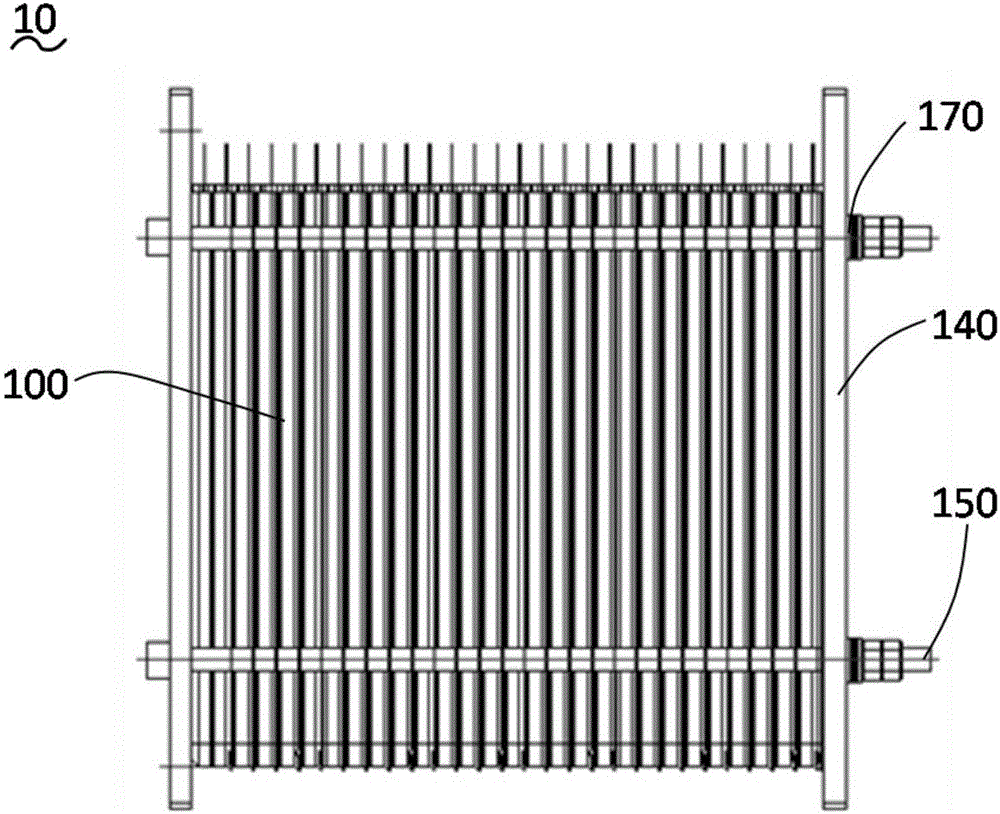

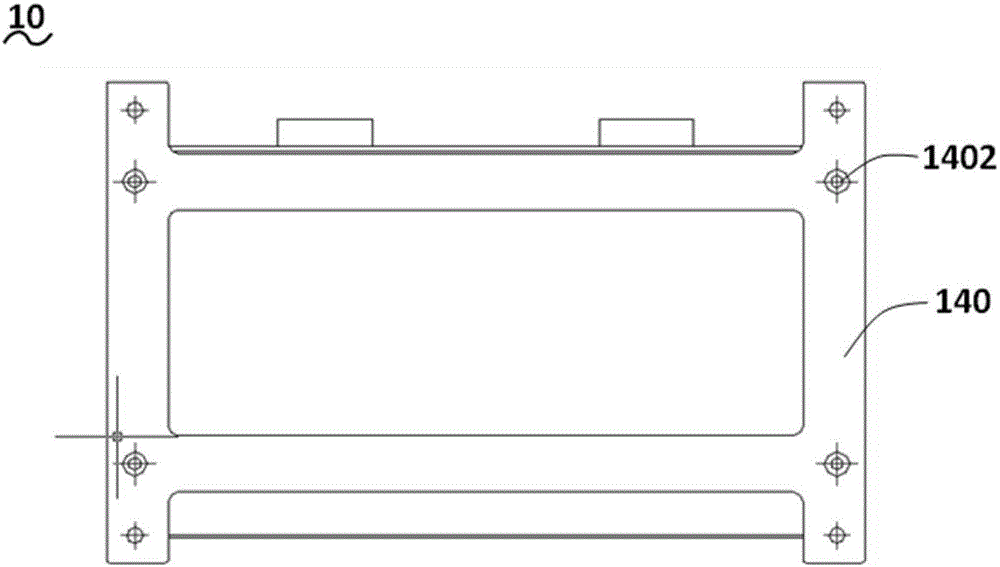

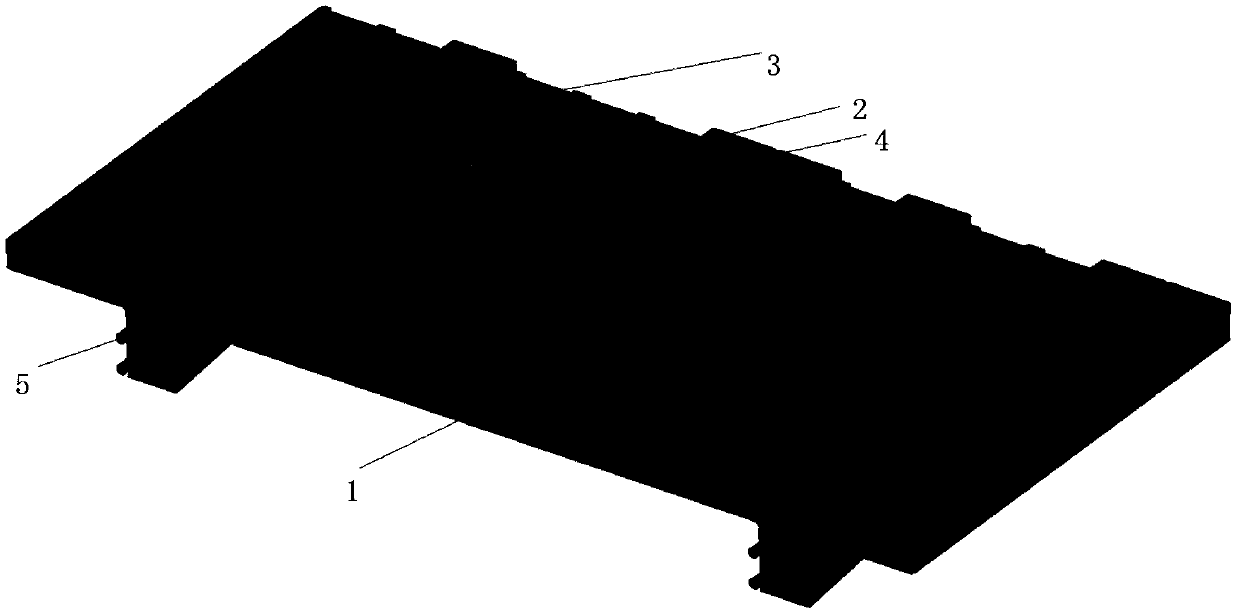

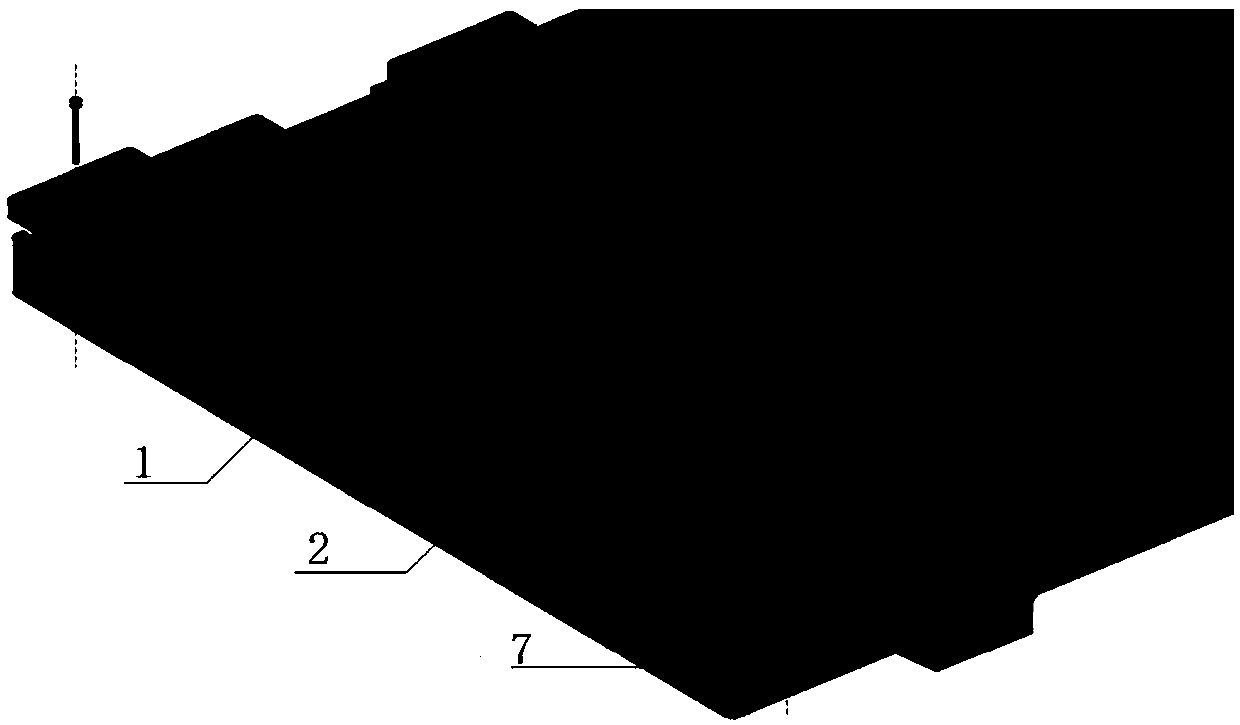

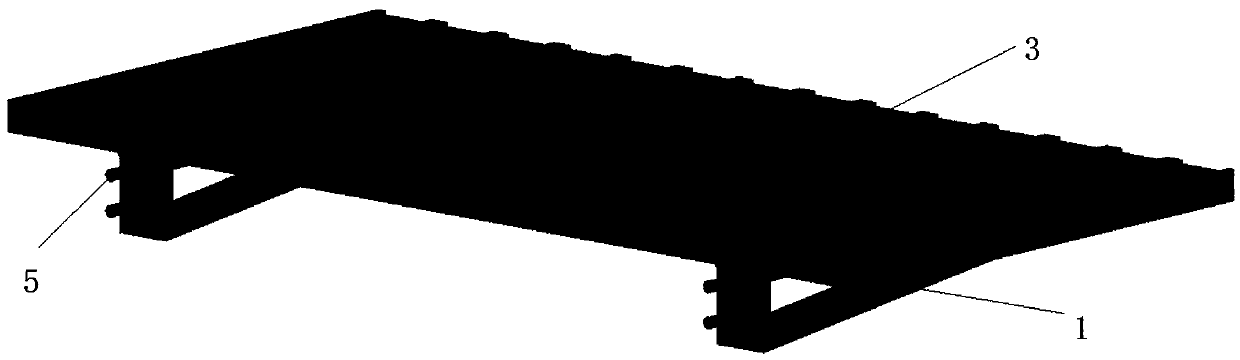

Battery module

PendingCN106684283AUniform dimensionsMeet thermal requirementsCell seperators/membranes/diaphragms/spacersSecondary cellsHeat conductingEngineering

The invention relates to a battery module, comprising multiple battery monomers and multiple heat conducting partition plates. The heat conducting partition plates and the battery monomers are mutually superposed in arrangement, the heat conducting partition plates are provided with a partition plate main body and multiple side plates connected with the partition plate main body, the partition plate main body and the multiple side plates form a containing space of the battery monomers together, and the edges of the side plates, which are far away from the partition plate main body, are bent and stretched to form heat dissipation fins.

Owner:JIANGSU HUADONG INST OF LI ION BATTERY +1

Flexible tray for automated mounting of bulk components

ActiveCN109661164AGood adaptability and versatilityImprove automation and production efficiencyElectrical componentsCost (economic)Engineering

The invention relates to a flexible tray for automated mounting of bulk components, and belongs to the field of automated assembling, solving the problem that in the prior art, bulk materials and short strips are not applicable to the material filling mode and the automatic feeding mode of an SMT (Surface Mount Technology) feeder and bulk materials rely on manual mounting. The provided flexible tray for automated mounting of bulk components includes a substrate and a plurality of material filling assemblies, wherein a plurality of positioning grooves are formed in the substrate; the material filling assemblies are arranged in the positioning grooves; and bulk components are filled into the material filling grooves of the material filling assemblies, and the tray is arranged on a chip mounter through the substrate, and the chip mounter is set and controlled through programs, and the bulk components in the material filling grooves are automatically positioned and picked up, and then automated mounting is completed. The flexible tray for automated mounting of bulk components realize SMT automatic mounting and multi-model sharing of multi-variety and small-volume of printed board assembly products, saves economic costs and time costs, and can effectively improve production efficiency and production quality.

Owner:BEIJING MECHANICAL EQUIP INST

Shell ice maker evaporator

InactiveCN102062508AUniform dimensionsQuality improvementLighting and heating apparatusIce productionThermal insulationRefrigerant

The invention relates to the category of the manufacture, processing, storage or classification of ice through immersing a chilling chamber or a chilling plate in water, on F25C1 / 08 of international patent classification (IPC), and particularly belongs to a shell ice maker evaporator. In a technical scheme adopted by the invention, the shell ice maker evaporator comprises an ice making barrel (1) internally provided with a water scattering box (8), a water inlet (9), an ice outlet (10), an ice making pipe (5), a refrigerant inlet (6) and a refrigerant outlet (7), and the shell ice maker evaporator is characterized in that the ice making pipe (5) is externally provided with a plurality of layers of ice making layers (3) and thermal insulation pads (2) are arranged among the ice making layers (3). The shell ice maker evaporator provided by the invention has the advantages that because the ice making layer is segmented into a plurality of segments which are mutually isolated by the thermal insulation pads, the overall dimension of the produced shell ice is neat and uniform without the cutting of ice swords. By using the shell ice maker evaporator, work efficiency can be improved and the quality of the produced shell ice can also be increased.

Owner:FUJIAN SNOWMAN

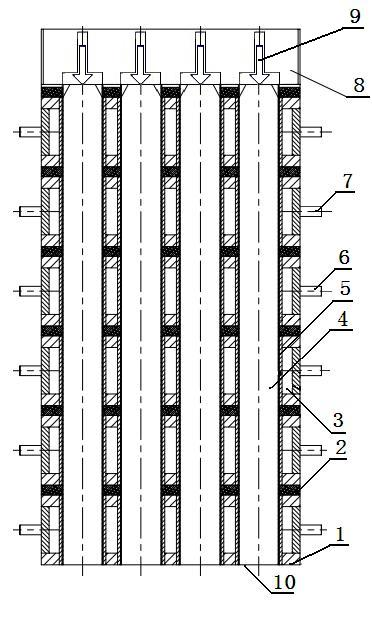

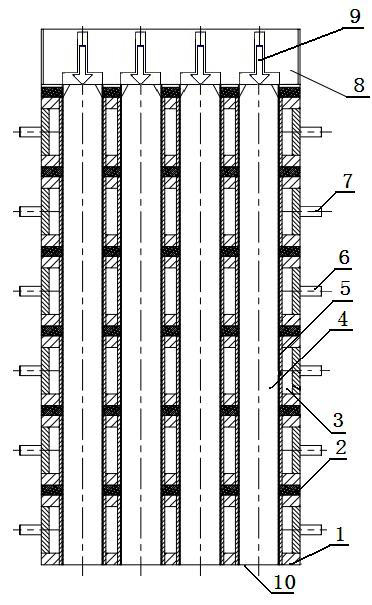

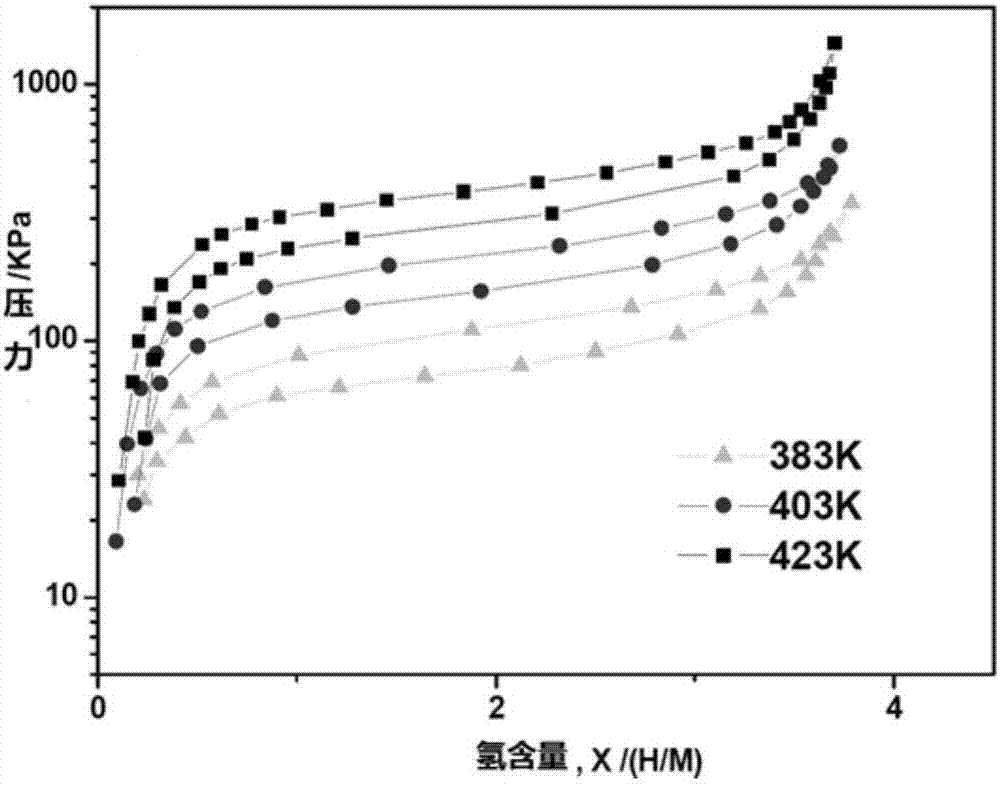

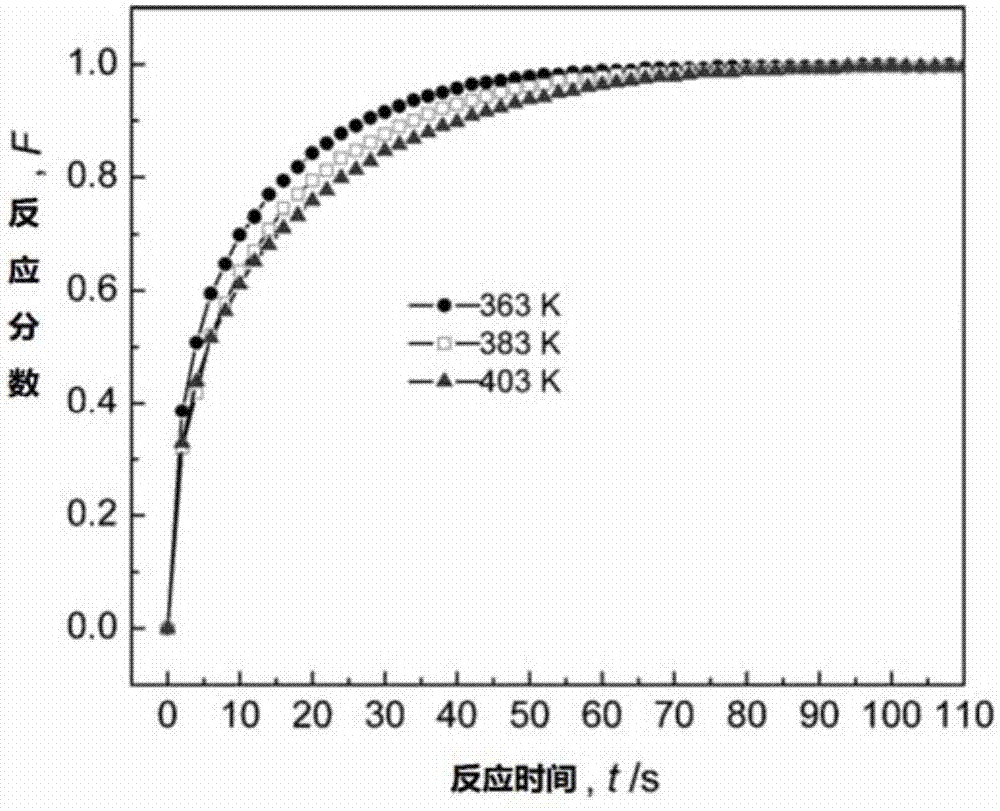

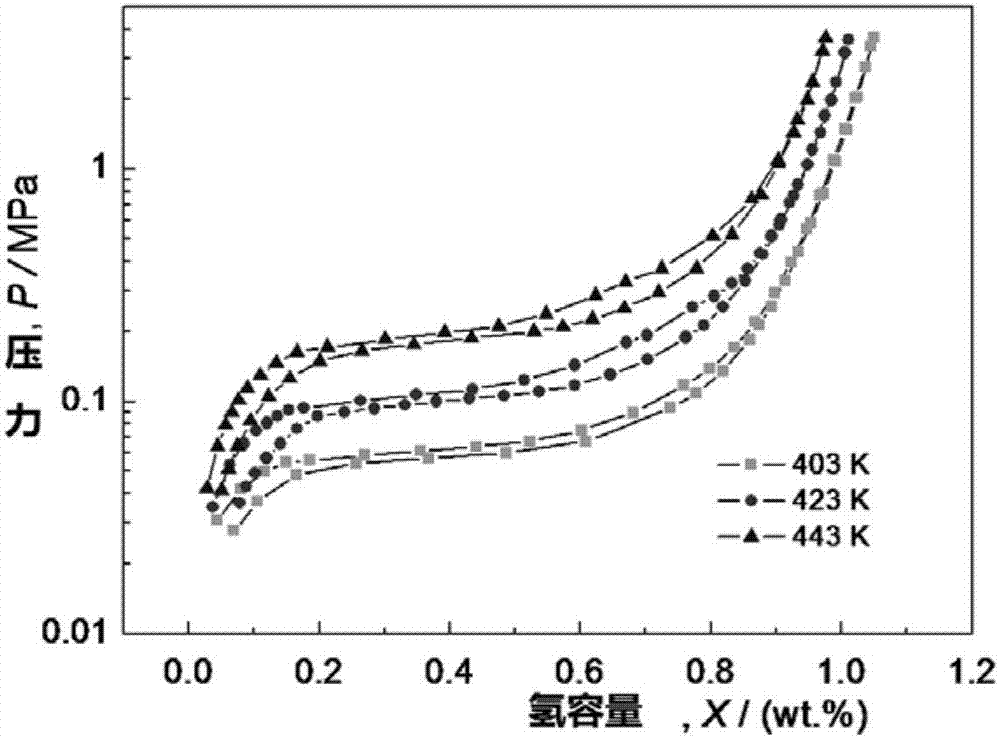

Spherical core-shell type LaNiAl-SiO2 compound hydrogen storage material and preparation method thereof

The invention relates to a spherical core-shell type LaNiAl-SiO2 compound hydrogen storage material applicable to hydrogen separation and a preparation method thereof, and belongs to the field of hydrogen storage materials. LaNiAl alloy has a composition general formula of LaNi5-xAlx, wherein x is more than or equal to zero and less than or equal to 2; the spherical material has an outer diameter of 4-6mm, an intermediate main ingredient of LaNiAl alloy, a porous SiO2 appearance and a thickness of 1-2mm. The preparation process of a material comprises the steps of melting and powdering alloy; stirring, mixing and granulating the alloy powder with silica sol; coating with gaseous SiO2; and performing aging and hydrothermal removing treatment. The preparation method of the compound hydrogen storage material has high automatic degree, uniform appearance and size and small airflow resistance, has maximal filling capacity in a reactor, cannot be ground or further pulverized, and cannot block a filter or cause self-compaction, so that toxicity of CO, O2, NH3, H2S and other impure gases for LaNiAl alloy can be greatly reduced, and the service life is greatly prolonged. The spherical core-shell type LaNiAl-SiO2 compound hydrogen storage material can be used in a hydrogen separating process.

Owner:YANGZHOU UNIV

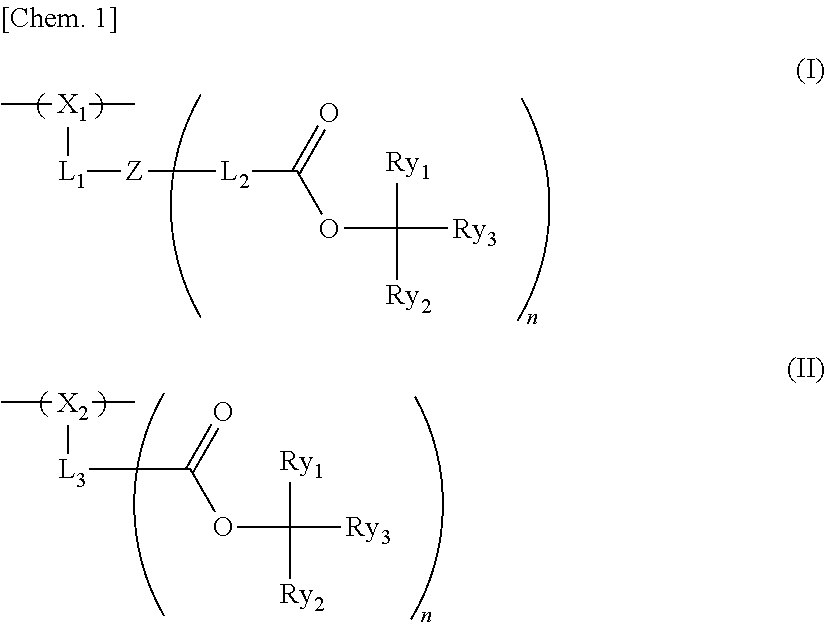

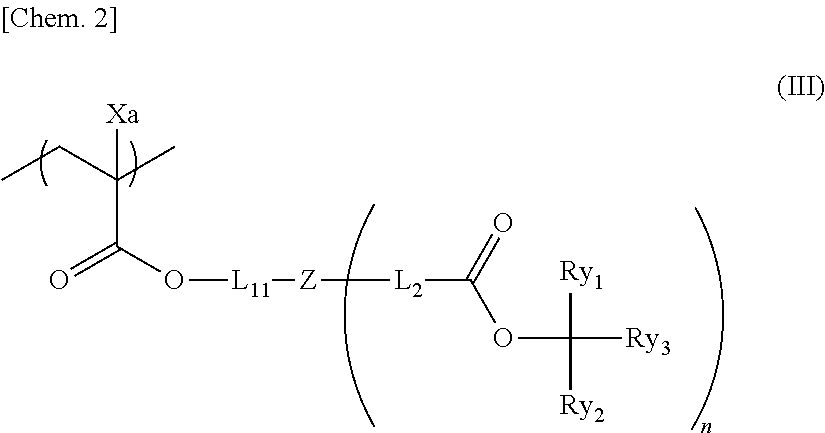

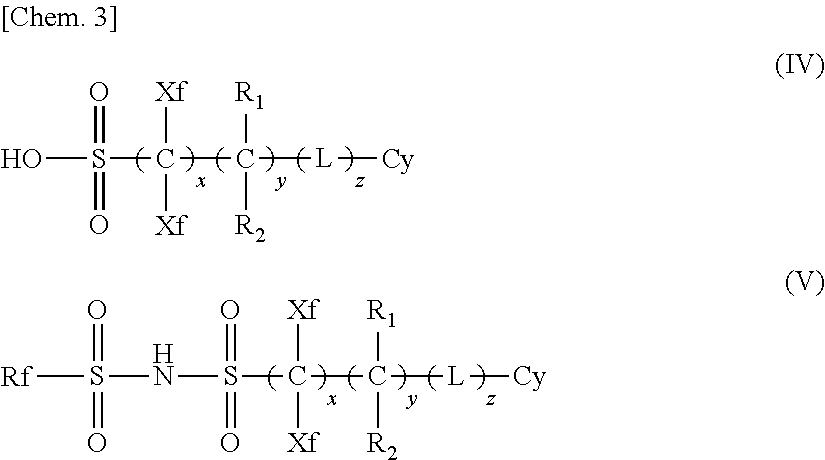

Pattern forming method, actinic ray-sensitive or radiation-sensitive resin composition, actinic ray-sensitive or radiation-sensitive film, manufacturing method of electronic device, and electronic device

InactiveUS20140234762A1Increase roughnessGood dry etching resistancePhotosensitive materialsPhotomechanical apparatusActinic RaysOrganic solvent

A pattern forming method including: a process of forming a film using an actinic ray-sensitive or radiation-sensitive resin composition containing a resin including a Repeating Unit (a1) having a group capable of being decomposed by acid and generating a carboxyl group, and a compound capable of generating acid through irradiation of actinic rays or radiation; a process of exposing the film; and a process of developing the exposed film using a developer including an organic solvent to form a negative tone pattern, wherein the value X obtained by substituting the number of each atom included in the Repeating Unit (a1) after being decomposed by acid and generating a carboxyl group in the following formula is 0<X≦5.X=(total number of atoms configuring repeating unit after being decomposed by acid) / [(number of carbon atoms)−(number of atoms that are neither carbon atoms nor hydrogen atoms)]

Owner:FUJIFILM CORP

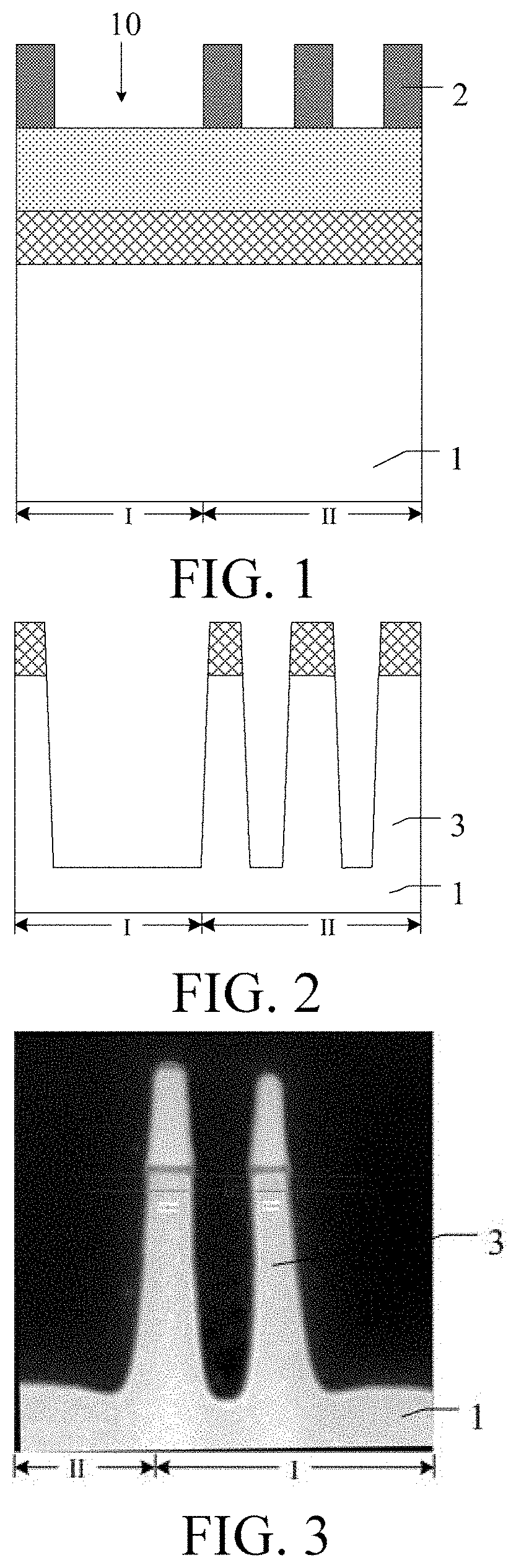

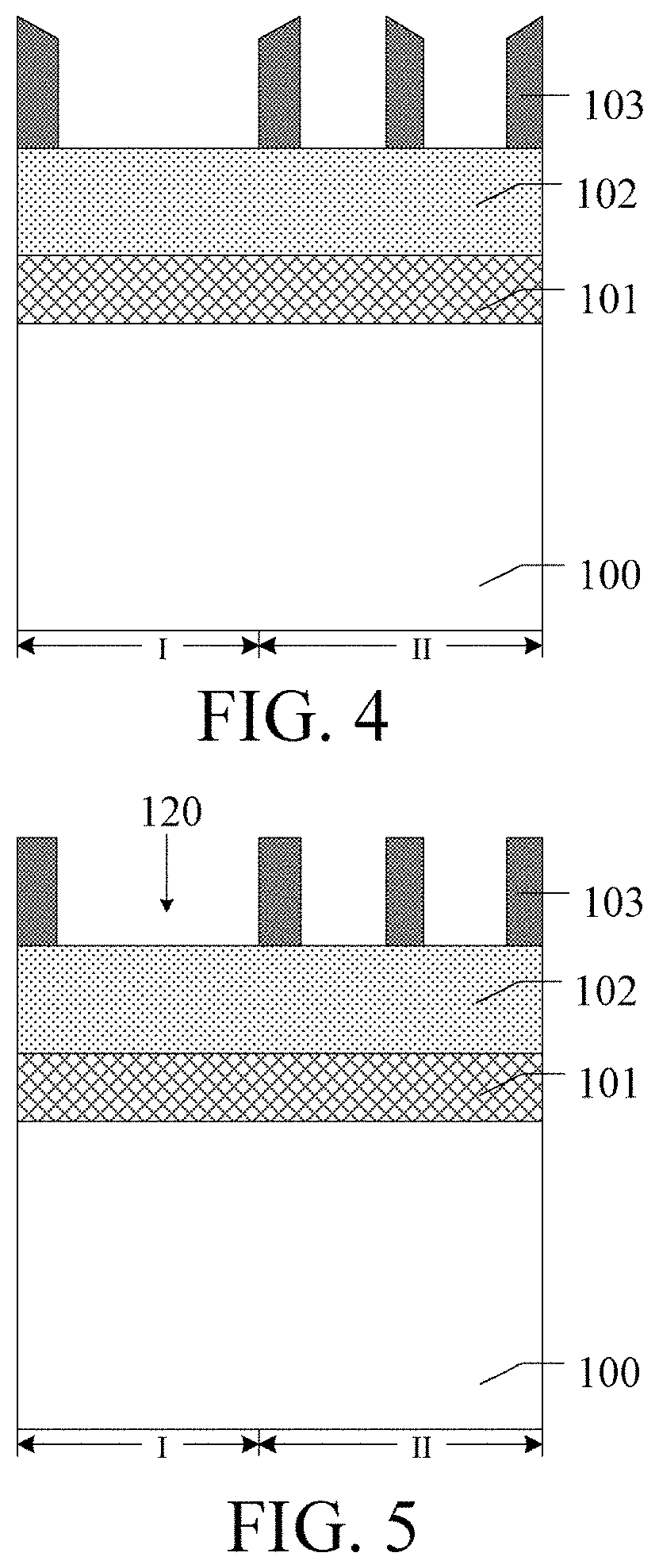

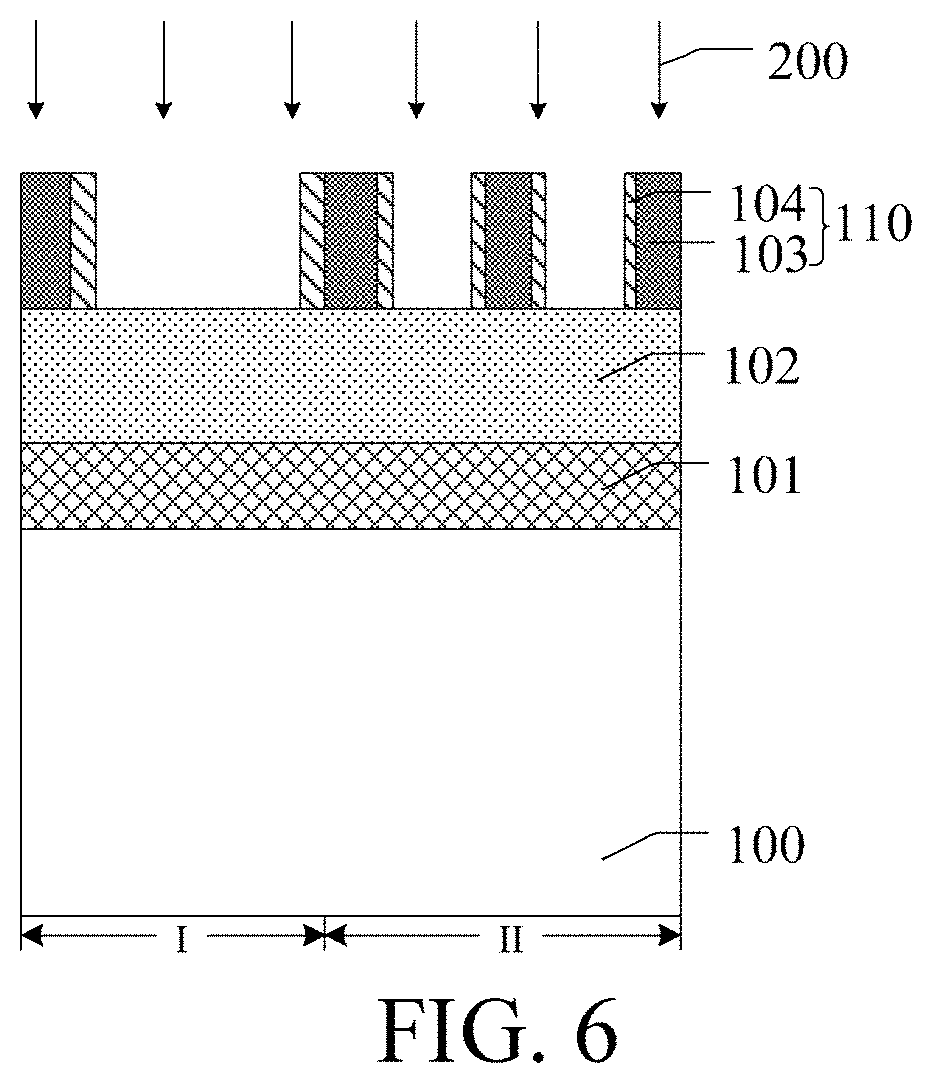

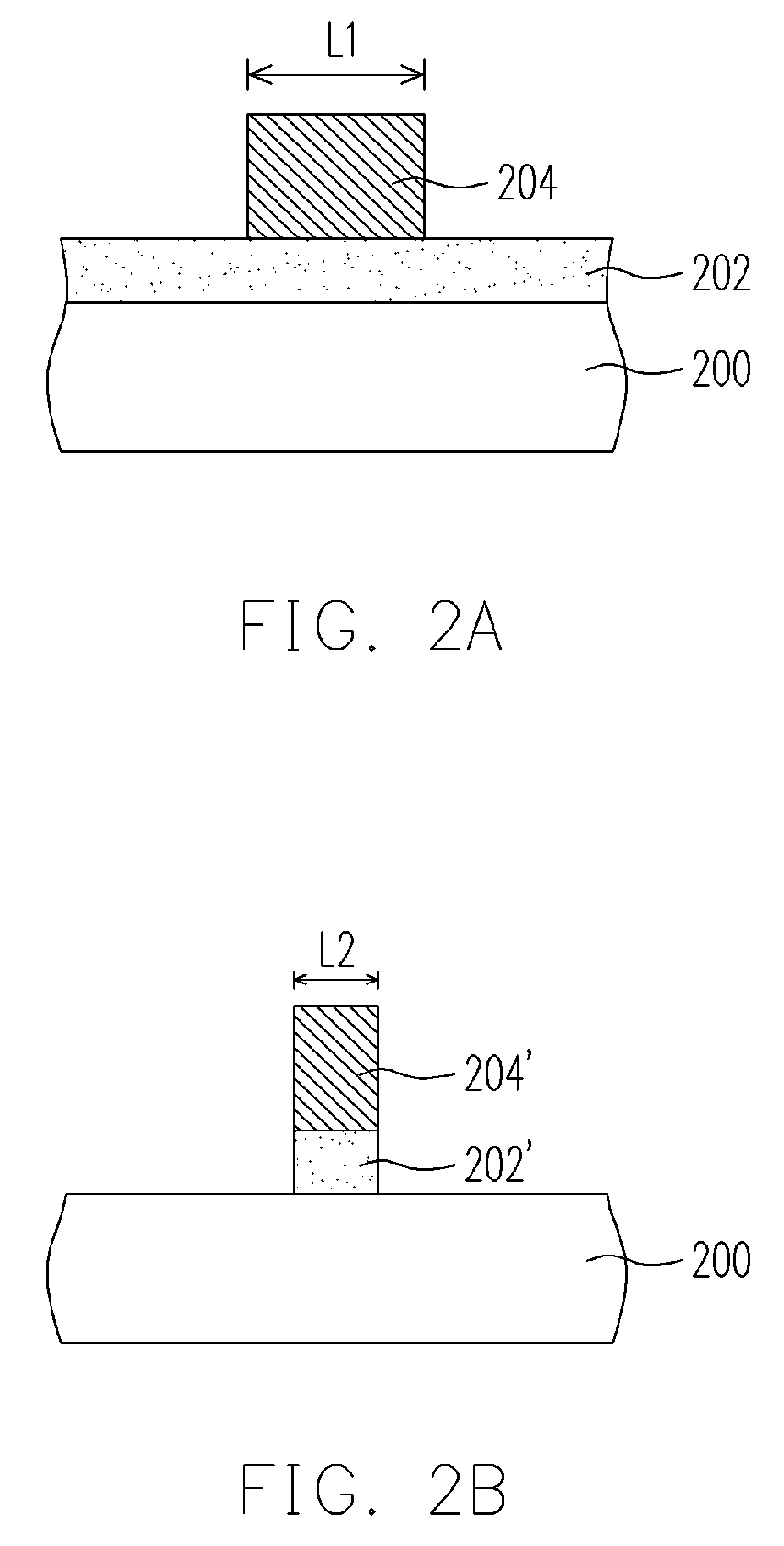

Semiconductor structure and formation method thereof

ActiveUS20200279748A1Reduce width sizeReduce opening widthSemiconductor/solid-state device manufacturingSemiconductor devicesCrystallographySemiconductor structure

A semiconductor structure and a formation method thereof are provided. The formation method includes: providing a base, the base including a pattern dense region and a pattern isolated region; forming a plurality of separate hard mask layers on the base, where adjacent hard mask layers and the base define an opening, and an opening of the pattern isolated region is wider than an opening of the pattern dense region; forming a trimming layer at least on a side wall of the opening of the pattern isolated region, the trimming layer and the hard mask layer constituting a mask structure layer; and etching, using the mask structure layer as a mask, a portion of the thickness of the base exposed by the opening to form a plurality of target pattern layers protruding from the remaining base. Embodiments and implementations of the present disclosure are advantageous for improving a critical dimension uniformity of a target pattern layer in each region.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

On-site combined type rectangular high-low frequency mixed loading connector

ActiveCN101771223BUniform dimensionsSimple structureCoupling device detailsTwo-part coupling devicesComputer moduleEngineering

The invention discloses an on-site combined type rectangular high-low frequency mixed loading connector, which comprises a connector plug and a connector socket, wherein the connector plug comprises a plug outer shell and a plurality of plug modules which can be arranged on the plug outer shell in a plurality of assembling modes to correspondingly form a plurality of types of combined type plugs and comprise a high-frequency plug module and a low-frequency plug module; the connector socket comprises a socket outer shell and a plurality of socket modules which can be arranged on the socket outer shell in a plurality of assembling modes to correspondingly form a plurality of types of combined type sockets and comprise a high-frequency socket module and a low-frequency socket module; and thestructure of the combined type sockets corresponds to that of the combined type plugs. The on-site combined type rectangular high-low frequency mixed loading connector has the advantages of simple structure, convenient processing and manufacturing, standardized batch production, convenient assembly, disassembly and maintenance and stable and reliable working performance, can be used for assembling and replacing a plurality of types of the plugs and sockets randomly on site, and simultaneously realizes integrated transmission of a plurality of types of signals of high and low currents, high and low frequencies and the like.

Owner:SHAANXI SILING ELECTRONICS

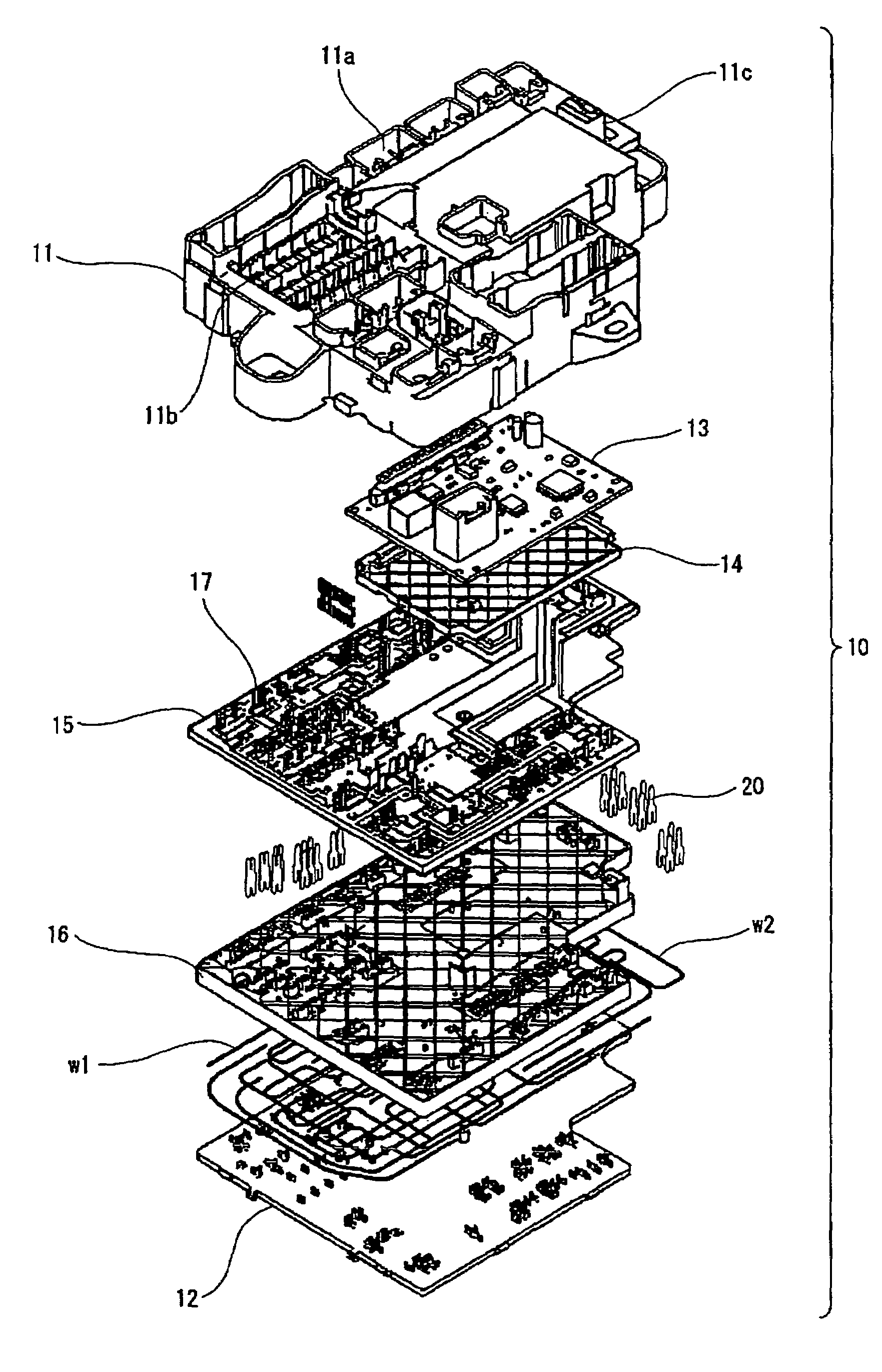

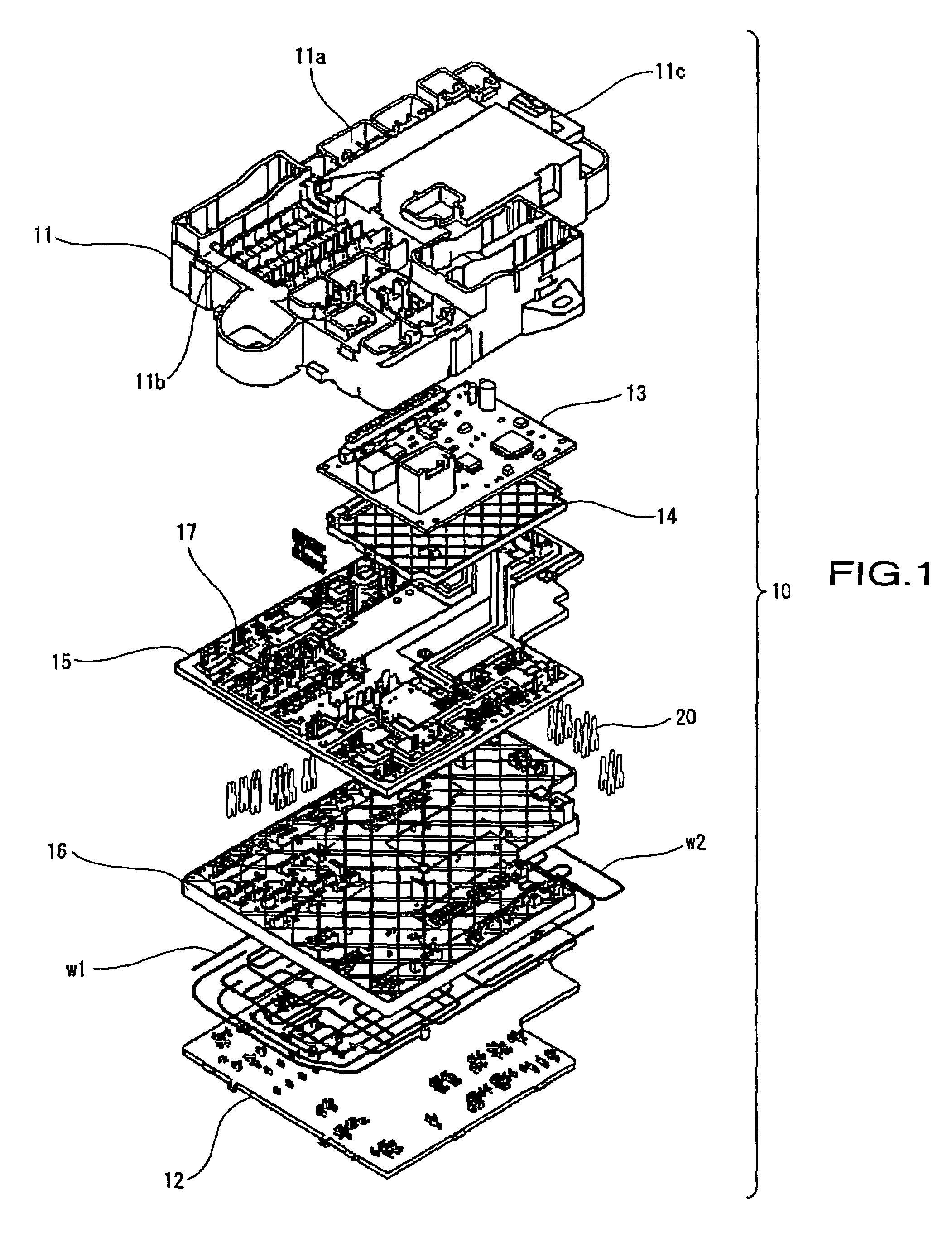

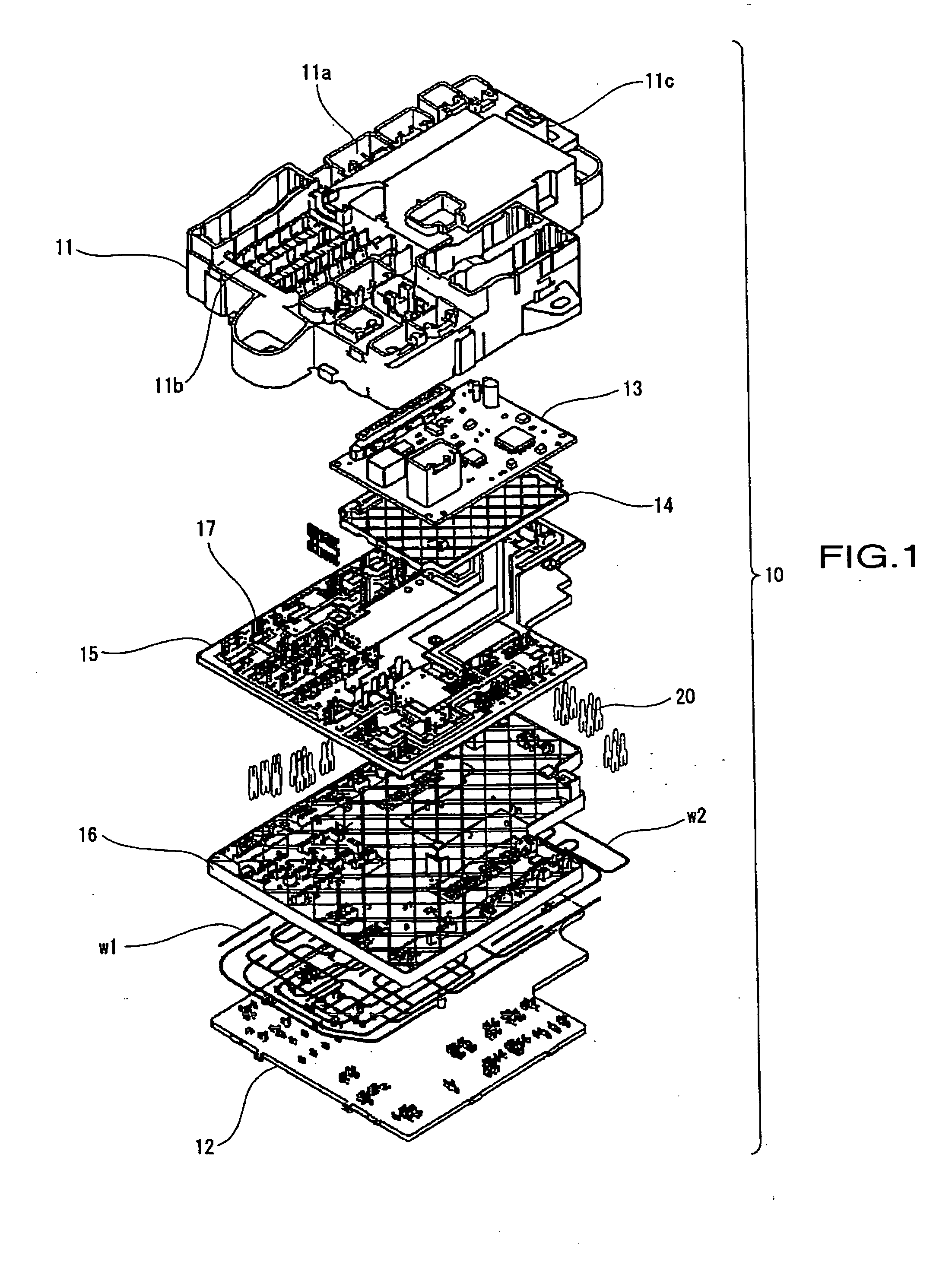

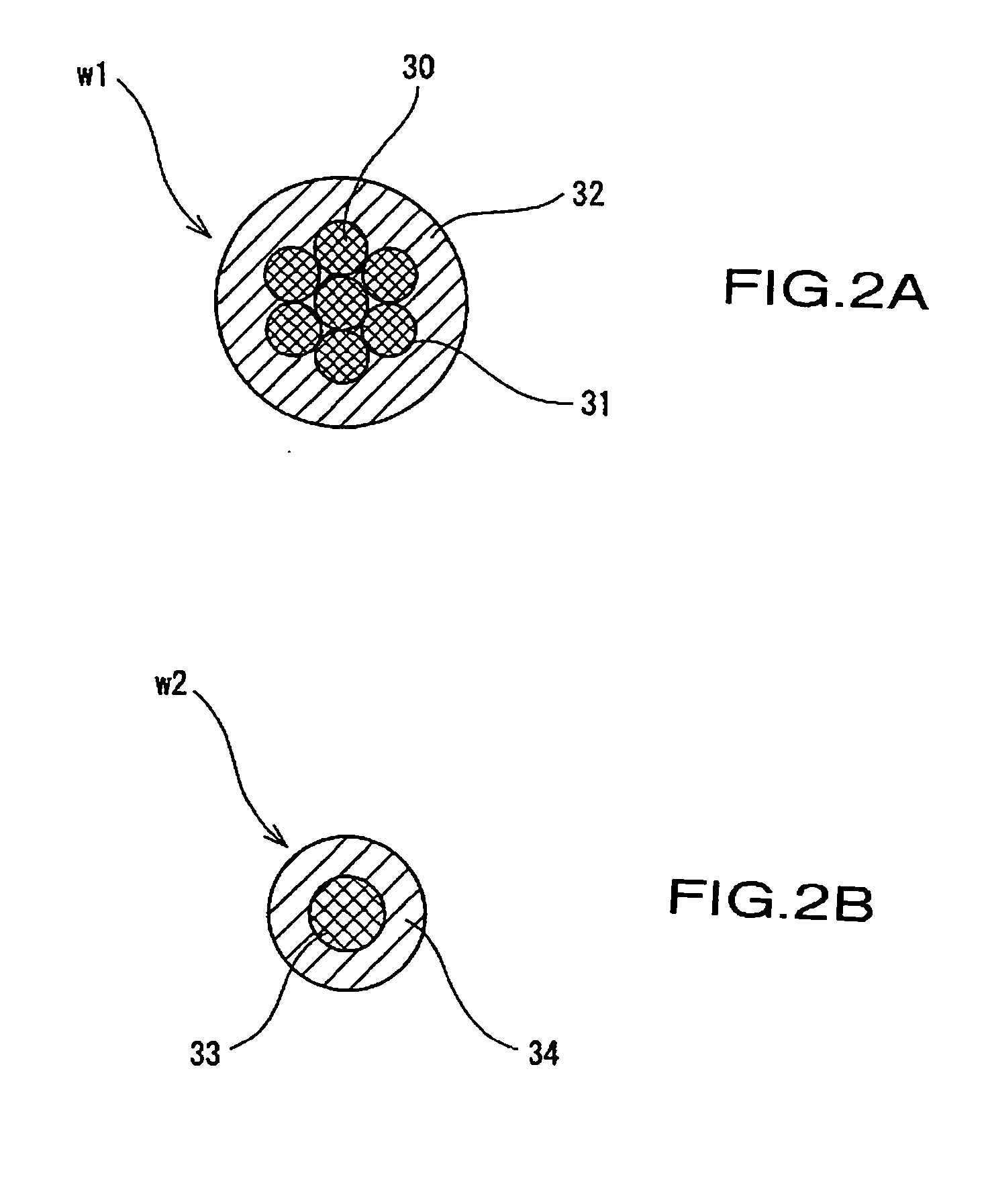

Automotive electrical connector box

InactiveUS7207827B2Reduce in quantityReduce manufacturing costVehicle connectorsCouplings bases/casesEngineeringElectrical connector

An electrical connector box including a pressure contact terminal to connect to electrical wires of various diameters. A container including an upper case and lower case houses electrical wires which are gripped by slots of pressure contact terminals. Either a thick wire, which includes a core wire including multiple twisted strands, or a thin wire, which includes a single core wire, are able to connect to the uniform width slots of the pressure contact terminals.

Owner:SUMITOMO WIRING SYST LTD

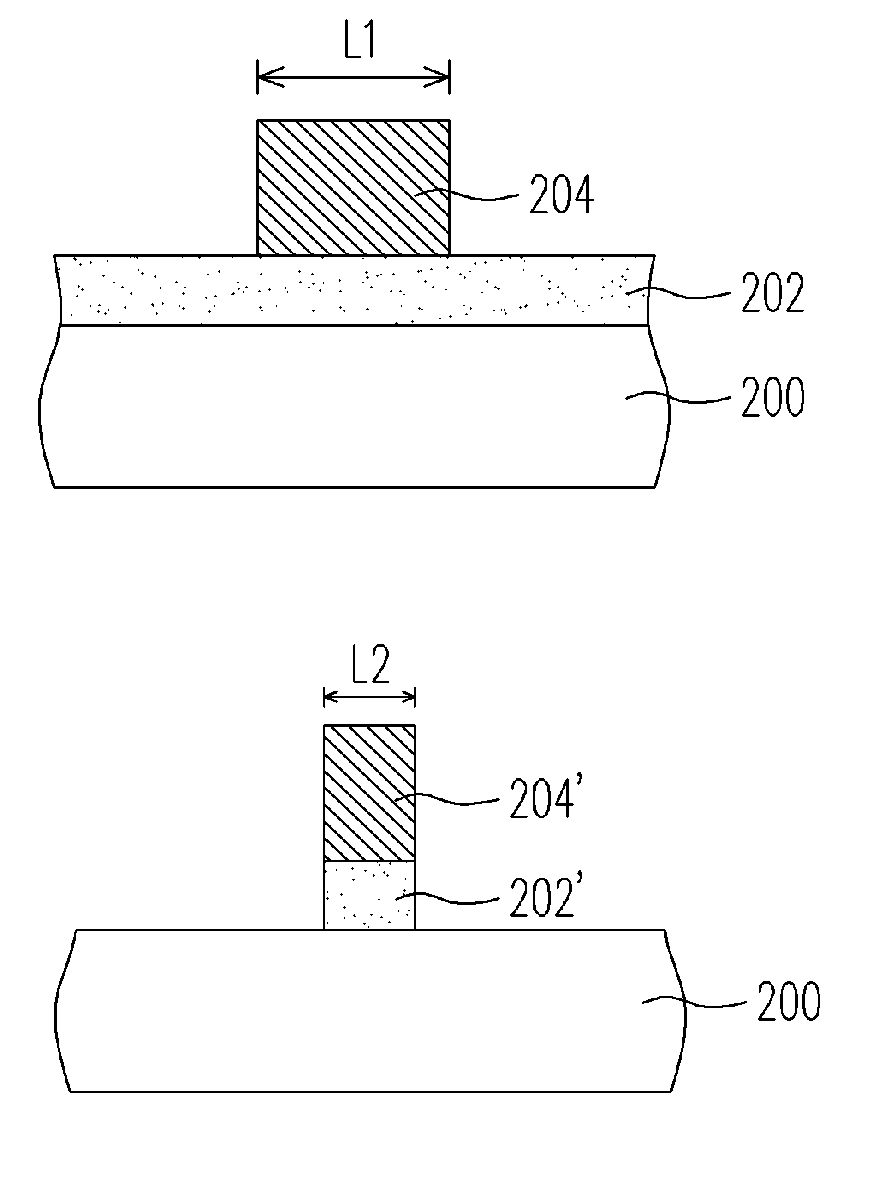

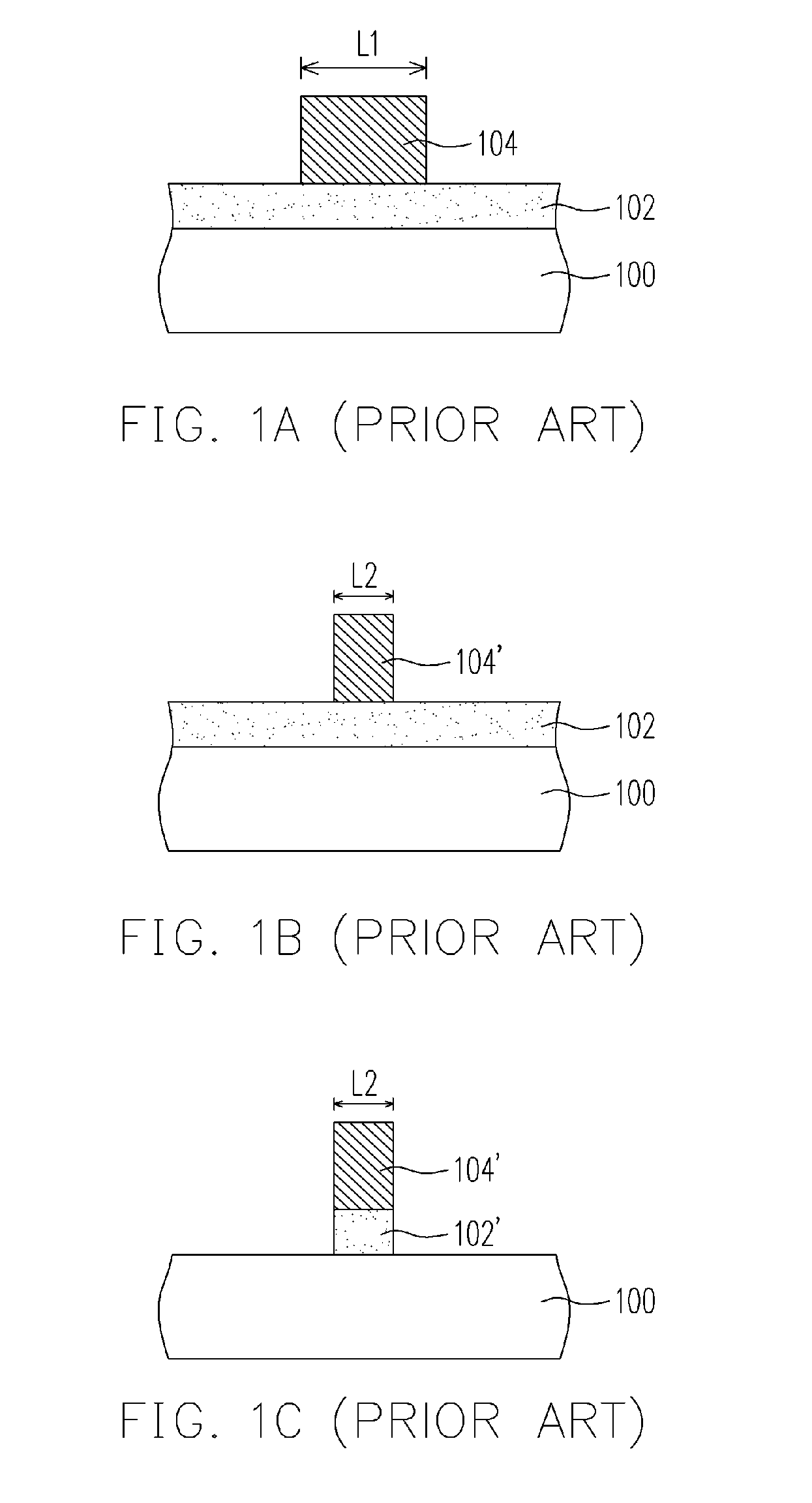

Method for reducing critical dimension and semiconductor etching method

ActiveUS20070051696A1Critical dimension reductionImprove processing stabilityDecorative surface effectsSemiconductor/solid-state device manufacturingResistLine width

A method of reducing critical dimension is provided. A dielectric layer is formed on a substrate. Then, a patterned photoresist is formed on the dielectric layer to expose part of the dielectric layer, wherein the patterned photoresist has a first line width. An etching process is performed to remove the exposed dielectric layer by using the patterned photoresist as an etching mask, wherein the final line width of the dielectric layer is smaller than the first line width. The conditions of the etching process include an etching pressure at 80 torr to 400 torr, an etching gas that includes a fluorocarbon compound and oxygen, wherein the ratio of the fluorocarbon compound to the oxygen is large than 0 and less than 10. Consequently, the etching process can be stabilized to form a smooth sidewall for the gate and to provide a uniform critical dimension.

Owner:UNITED MICROELECTRONICS CORP

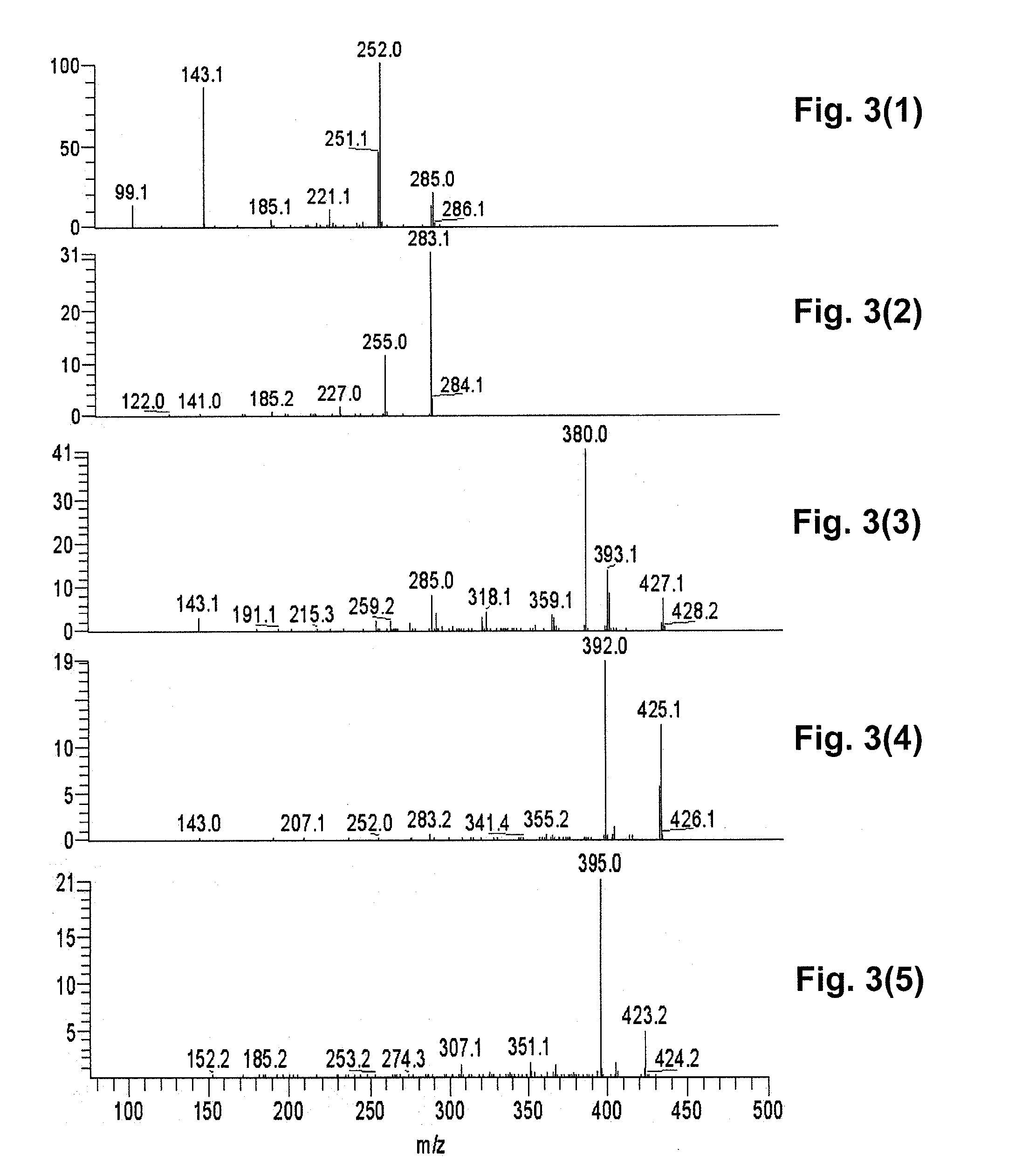

Method for production of solid electrolyte and solid electrolytic capacitor

ActiveUS20110286151A1Uniform shapeUniform dimensionsSolid electrolytic capacitorsCapacitor electrolytes/absorbentsElectrolysisConductive polymer

A method for producing a solid electrolyte is disclosed, which comprises the steps of applying a solution containing a five-membered heterocyclic compound as a polymerizable monomer on a substrate surface, and polymerizing the applied monomer to give a solid electrolyte comprised of an electrically conductive polymer, wherein the monomer-containing solution contains the polymerizable monomer and at least one polymerizable compound selected from a dimer of the monomer and a trimer of the monomer, at a proportion satisfying the equation:A / (B+C)=100-1,000,000where A: concentration of the polymerizable monomer,B: concentration of the dimmer in terms of the concentration of its monomer, andC: concentration of the trimer in terms of the concentration of its monomer. In another aspect, a method is disclosed wherein a solution of a compound having a thiophene skeletal structure, which solution has a light absorbance of 1.5-10 at 300-340 nm, is applied on a substrate surface and polymerized.

Owner:MURATA MFG CO LTD

Automotive electrical connector box

InactiveUS20050118857A1Reduce manufacturing costReduce in quantityVehicle connectorsCouplings bases/casesElectrical connectorSingle-core

An electrical connector box including a pressure contact terminal to connect to electrical wires of various diameters. A container including an upper case and lower case houses electrical wires which are gripped by slots of pressure contact terminals. Either a thick wire, which includes a core wire including multiple twisted strands, or a thin wire, which includes a single core wire, are able to connect to the uniform width slots of the pressure contact terminals.

Owner:SUMITOMO WIRING SYST LTD

Temperature protection device of thermal bimetallic strip

InactiveCN104675674AHigh precisionUniform dimensionsPositive displacement pump componentsPositive-displacement liquid enginesCombustionEngineering

The invention relates to a temperature protection device of a thermal bimetallic strip. The temperature protection device comprises the thermal bimetallic strip, a gas path outlet and a base, wherein the thermal bimetallic strip is fixed on the base through a fixed screw, and the gas path outlet is positioned below the thermal bimetallic strip and penetrates through the base. By virtue of the technical scheme of the temperature protection device, the temperature protection device is installed in the position of a gas inlet of a vacuum pump, and when the internal operating temperature reaches 130 DEG C, the thermal bimetallic strip is automatically deformed from a warping state to a flat state, so that the gas path outlet is fully sealed, and gas cannot pass through; when the internal operating temperature returns to normal temperature, the thermal bimetallic strip is automatically deformed to return to the initial warping state, the gas path outlet is opened, the vacuum pump can be normally used, and accidents such as internal combustion, explosion and the like caused by overtemperature in the vacuum pump can be effectively prevented.

Owner:LUOYANG PRIMEMAN AUTOMATIC CONTROL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com