Shell ice maker evaporator

An evaporator and tube ice technology, which is applied in the field of tube ice machine evaporators, can solve the problems of different lengths of tube ice, easy to break, irregular end faces, etc., and achieve the effects of uniform shape and size, improving quality and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

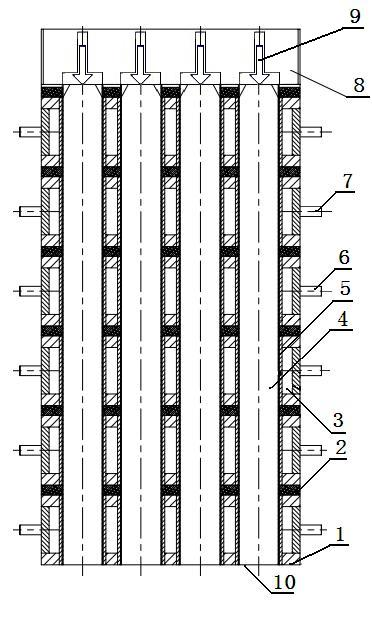

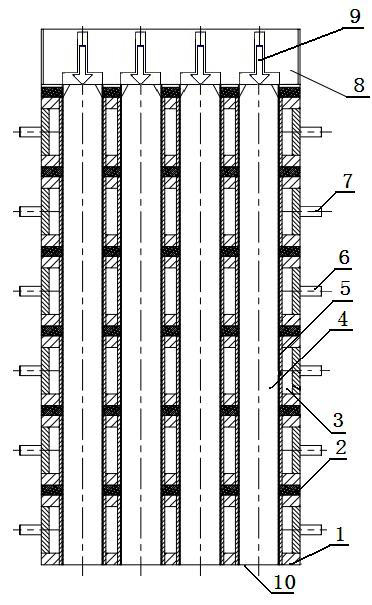

[0011] Such as figure 1 The principle diagram of the present invention is shown, and the present invention includes a diffuser tank (8), a water inlet (9), an ice outlet (10), an ice making pipe (5) and a refrigerant inlet in the ice bucket (1) (6) Refrigerant outlet (7), characterized in that several ice-making layers (3) are formed on the outside of the ice-making tube (5), and heat insulation is formed between the ice-making layers (3) Pad (2).

[0012] Because the present invention is in the cylindrical ice-making bucket 1, the insulation pad 2 and the ice-making layer 3 are stacked on each other in the interlayer. When the refrigerant enters the ice-making layer 3 and evaporates, it absorbs the ice-making chamber 4 The heat of the water freezes, and the water in the ice-making cavity 4 in the thermal insulation pad 2 will not freeze. Therefore, when the ice falls fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com