Flexible tray for automated mounting of bulk components

A component and flexible technology, applied in the field of automatic placement, can solve the problems of low utilization rate, increase economic cost and time cost, increase process flow, etc., to improve production efficiency and degree of automation, good versatility and adaptation performance, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

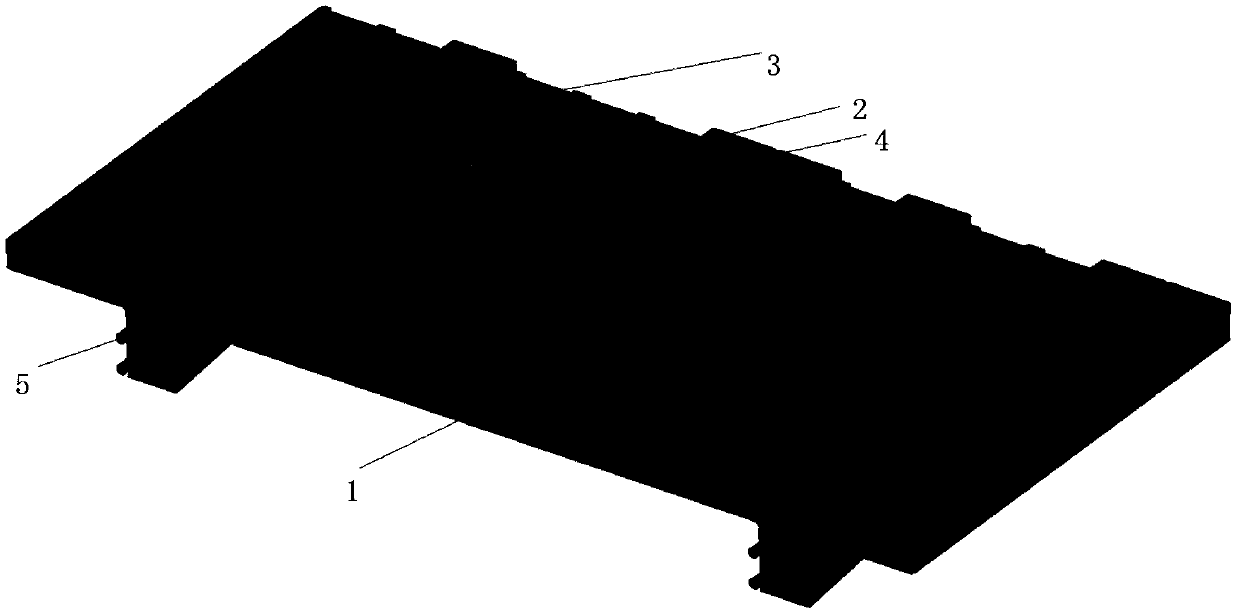

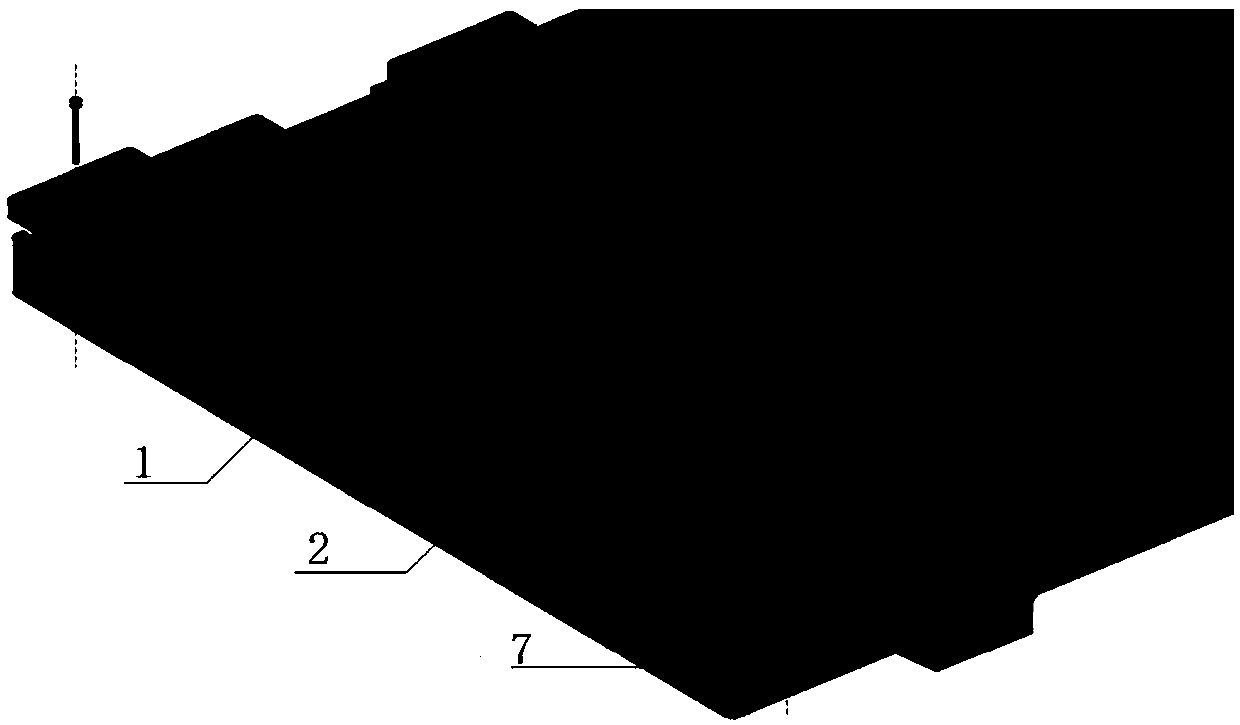

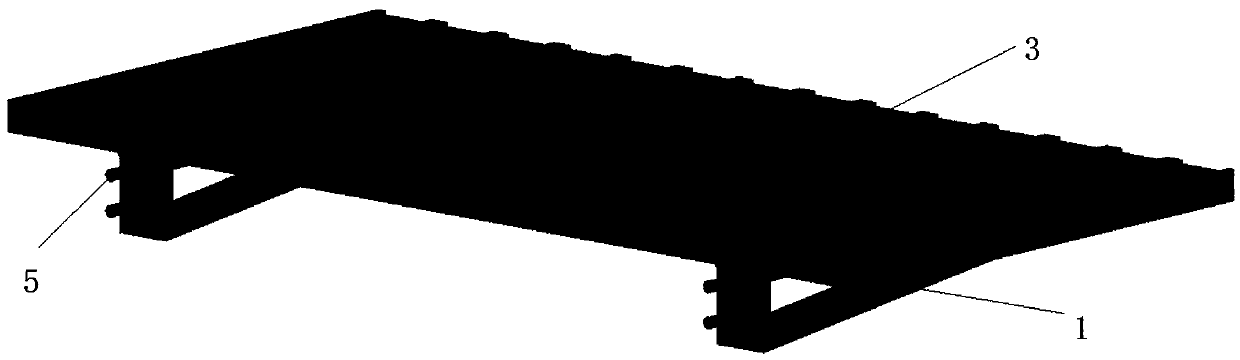

[0039] On the one hand, a specific embodiment of the present invention discloses a flexible tray for automatic placement of bulk components. The flexible tray is used in conjunction with a placement machine. For the structure of the flexible tray, see figure 1 , consisting of a substrate 1 and a plurality of filler components 2 . A plurality of positioning grooves 3 are set on the substrate 1, and the packing assembly 2 is installed in the positioning groove 3, and a plurality of packing grooves 4 are arranged on the packing assembly 2, and bulk components are filled in the packing grooves 4; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com