Paint spraying system based on cloud server function and working method thereof

A cloud server and automatic paint spraying machine technology, applied in the field of automation, can solve the problems of uneven paint surface, leakage of paint, affecting the quality of product paint, and achieve the effect of ensuring the pass rate, improving the degree of automation and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

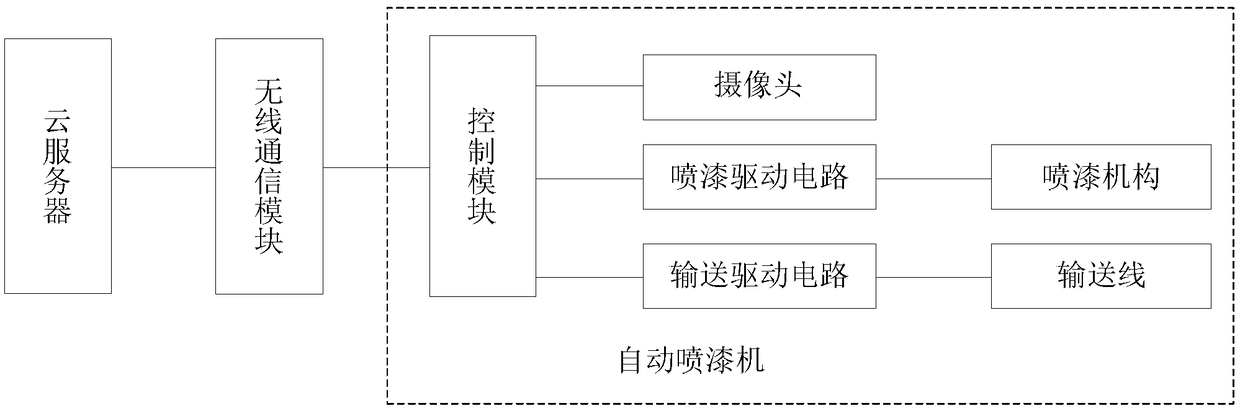

[0025] figure 1 It is the functional block diagram of the painting system of the present invention.

[0026] Such as figure 1 As shown, the present embodiment 1 provides a painting system, including: a cloud server, an automatic painting machine, a wireless communication module for information transmission between the two; the automatic painting machine is suitable for the workpiece on the conveying line The surface is painted and photographed; and the cloud server is adapted to obtain a photo of the paint surface of the workpiece through the wireless communication module to determine whether the paint surface of the workpiece is qualified, and the total number of workpieces and the number of unqualified counts can also be counted by the statistics module. To count the pass rate of painting of the workpiece.

[0027] The painting system of Embodiment 1 judges whether the painted surface of the workpiece is qualified through the cloud server, realizes the automatic painting a...

Embodiment 2

[0051] On the basis of Embodiment 1, this Embodiment 2 provides a working method of a painting system, including: a cloud server and an automatic paint spraying machine for spraying paint on the surface of a workpiece and taking pictures; wherein the cloud server is suitable for wireless communication The module obtains the photo of the paint surface of the workpiece after painting to determine whether the paint surface of the workpiece is qualified.

[0052] For the specific structure and implementation process of the painting system, please refer to the relevant discussion of Embodiment 1, and details will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com