Intelligent vertical-type multi-station expansion tank forming machine

A multi-station, forming machine technology, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of low work efficiency and automation, short service life, environmental pollution, etc., and achieve high automation and production efficiency. , the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

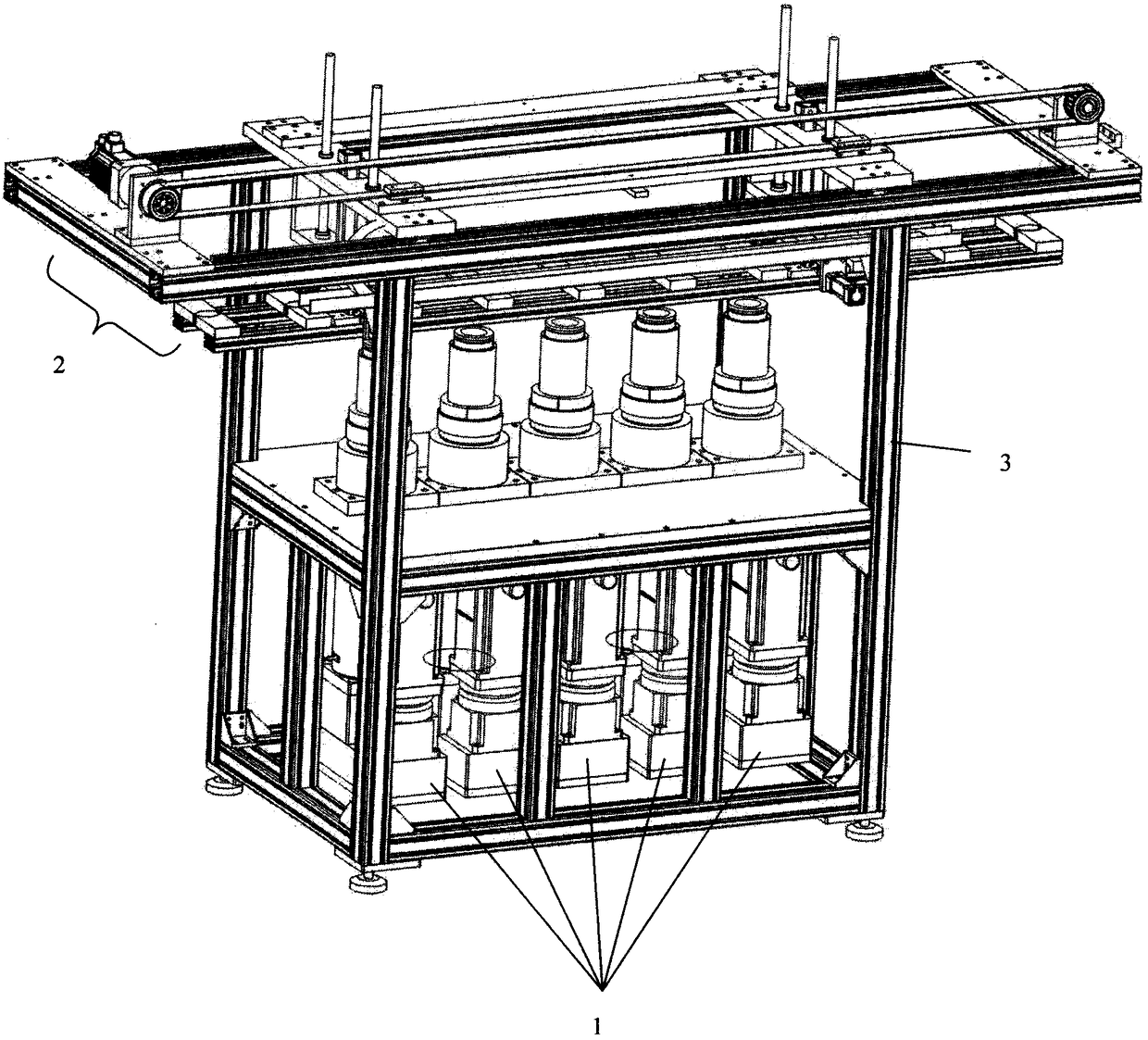

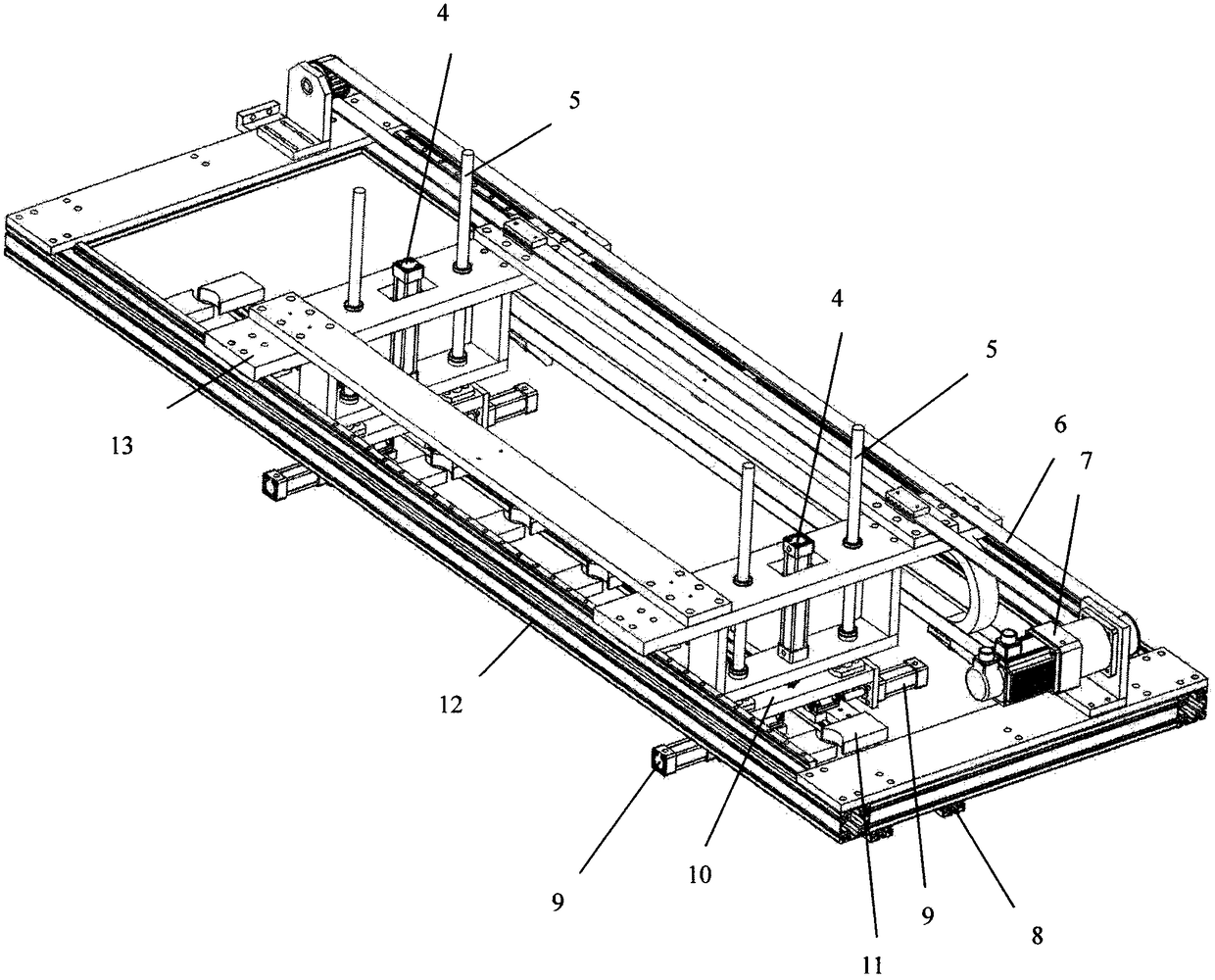

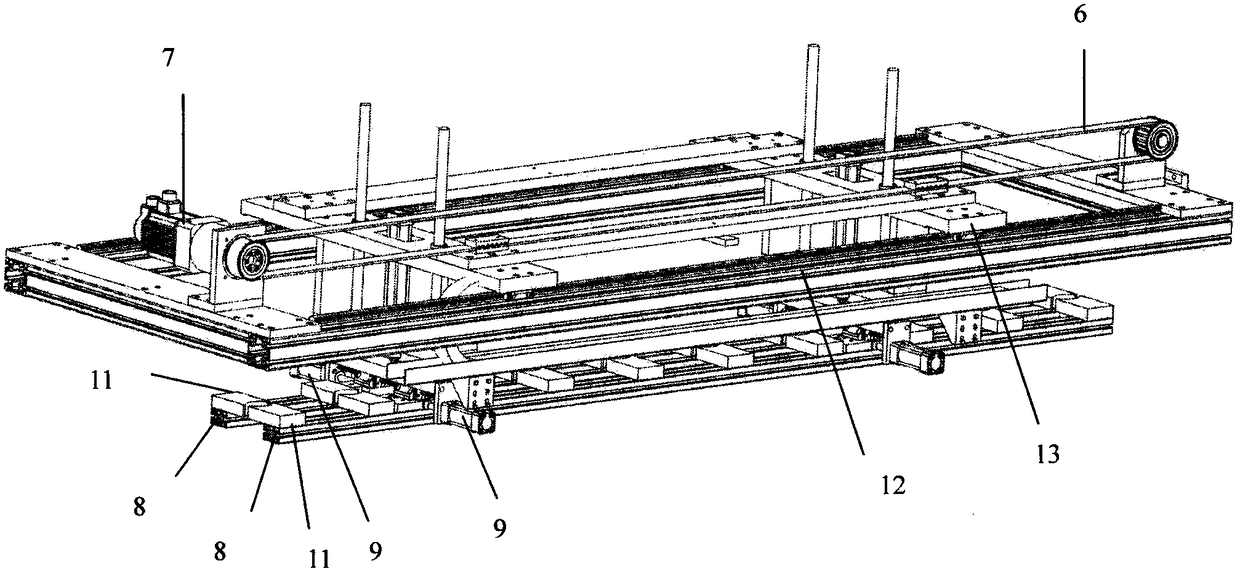

[0023] As a specific example, such as Figure 1 to Figure 4 As shown, the intelligent vertical multi-station expanding can forming machine of the present invention includes a main frame 3, five electric forming units 1 are arranged in a row under the main frame 3 in parallel, and the clamping and shifting device 2 is arranged on the electric forming unit Above the body 1; the clamping displacement device 2 includes 20 parallel clamping blocks 11 that can move laterally and vertically, the clamping blocks 11 are arranged in pairs, and the ends of the clamping blocks 11 are provided with arcs Shaped clamping surface, the two clamping blocks 11 arranged symmetrically can realize clamping and releasing actions by changing the distance between the clamping blocks 11, and the arc-shaped clamping surface can be stably clamped on the tube to be formed. On the outer cylindrical wall; the electric forming unit 1 includes an electric forming cylinder 16, a forming die 14 installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com